Corn threshing device for agricultural product processing

A technology for agricultural product processing and corn threshing, applied in threshing equipment, application, agriculture, etc., can solve problems affecting work efficiency, blockage, etc., and achieve the effect of improving discharge efficiency and maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

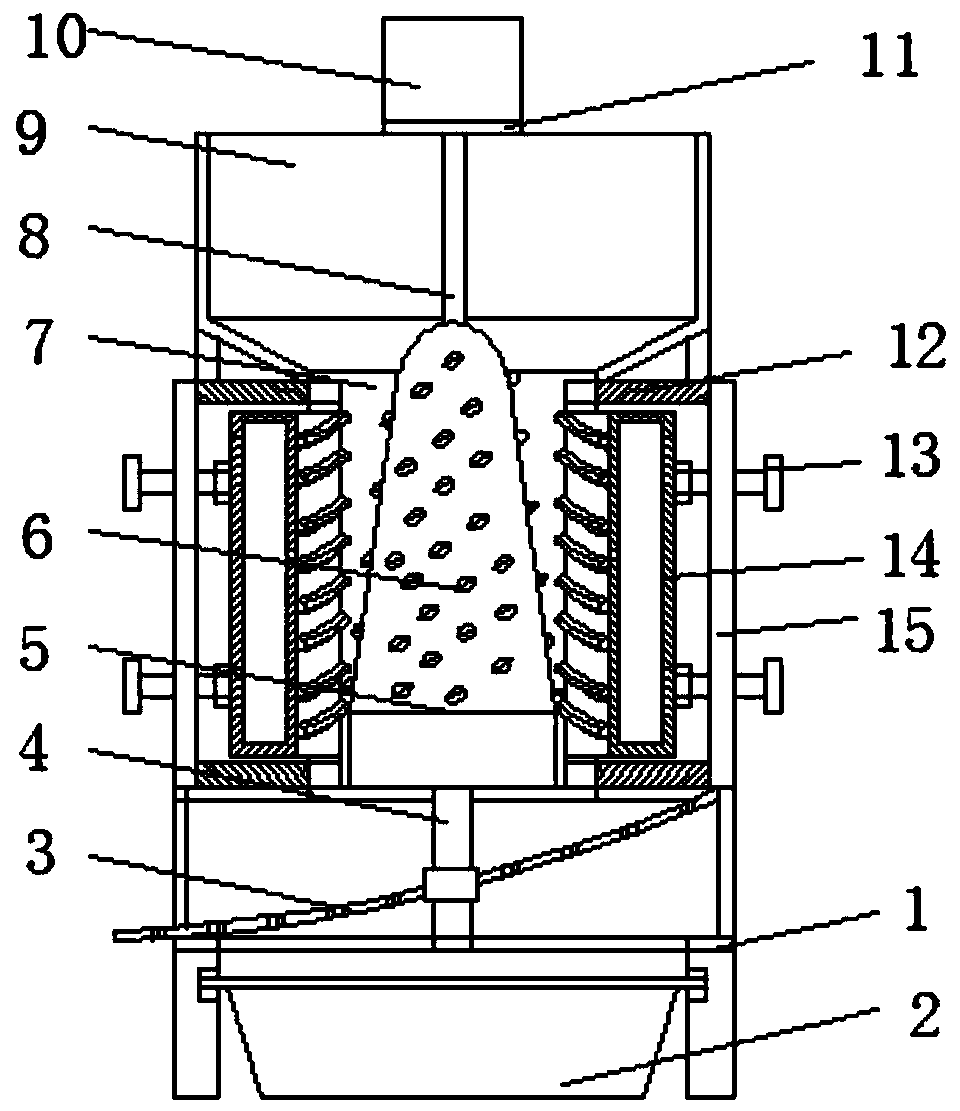

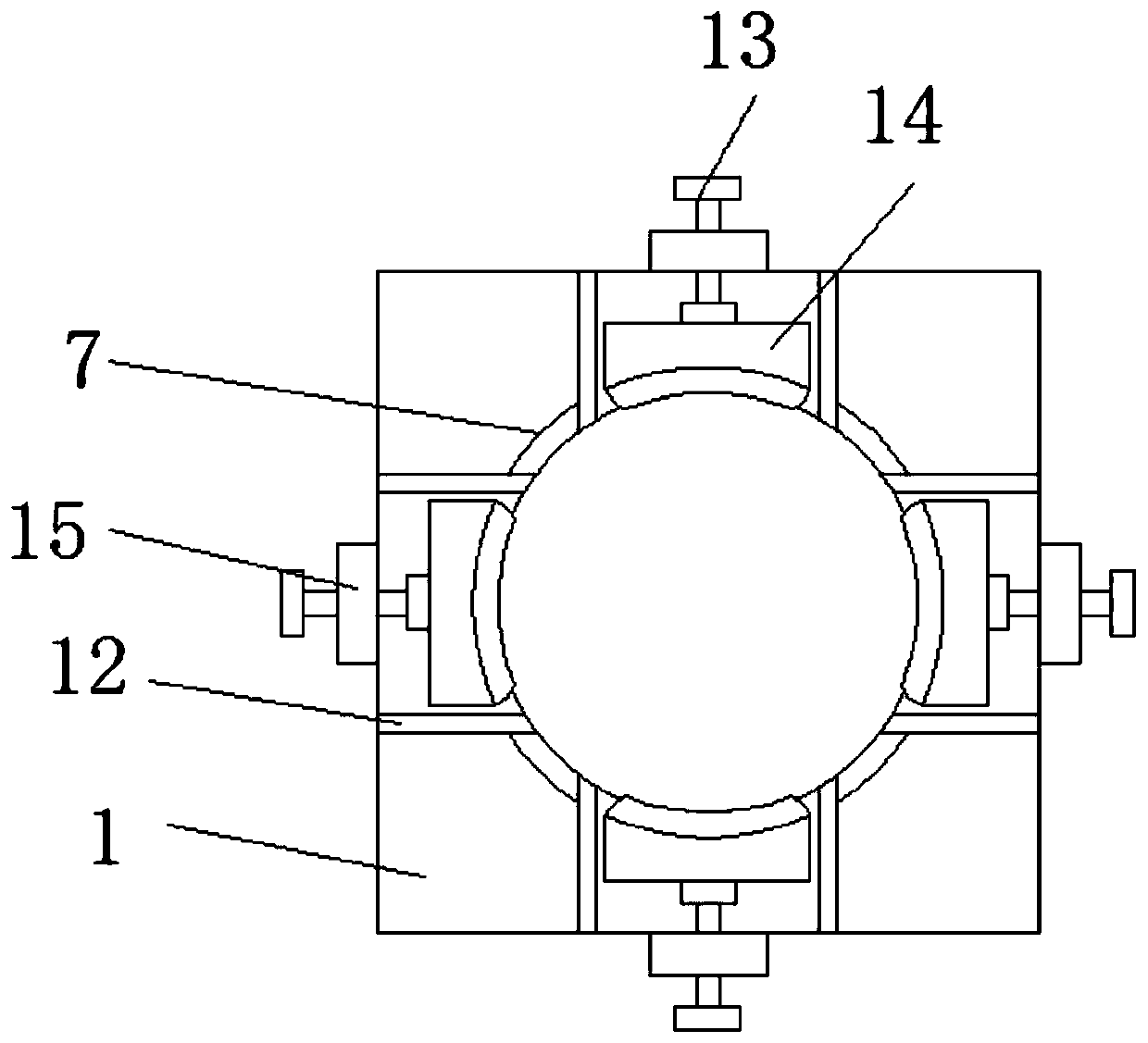

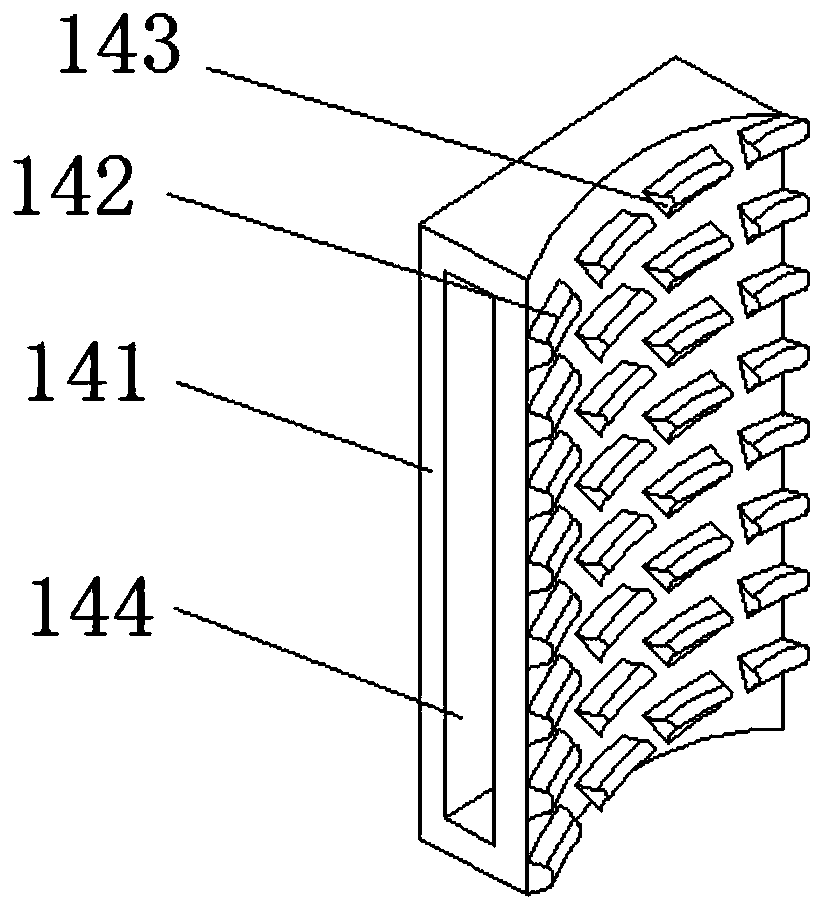

[0025] refer to Figure 1-3 , a corn threshing device for agricultural product processing, comprising a base 1, a box structure is arranged above the base 1, and a cylinder 7 is fixedly installed on the top of the base 1, and a feeding hopper 9 is fixedly installed on the top of the cylinder 7, and The top of the hopper 9 is fixed with a horizontal plate 11, and the top of the horizontal plate 11 is fixed with a drive motor 10, the bottom end of the output shaft of the drive motor 10 is fixed with a rotating shaft 8, and the inside of the base 1 is equipped with a support rod 4 through a bearing. , and the top of the support rod 4 is fixedly equipped with a threshing drum 5 with a vertebral structure, the top of the threshing drum 5 is firmly connected with the rotating shaft 8, and the outer side of the threshing drum 5 is provided with spirally distributed threshing teeth 6, and the surroundings of the cylinder 7 are uniform An installation groove is opened, and a frame body...

Embodiment 2

[0032] refer to Figure 2-4 , a corn threshing device for agricultural product processing. Compared with Embodiment 1, this embodiment also includes: a strip-shaped groove set at one end of the base 1, and a blower 16 is fixedly installed inside the strip-shaped groove, and the other end of the base 1 Two connecting rods 18 of L-shaped structure are fixedly installed, and a rectangular square tube is fixedly installed between the two connecting rods 18, and a collecting net bag 17 is sleeved on the outside of the rectangular square tube.

[0033]In this embodiment: the air blower 16 is turned on during the corn threshing process, and then the surface of the grid mesh plate 3 is blasted, and the bran etc. produced by corn cob threshing are blown to the bottom in the process of screening the corn kernels The outer side of the seat 1 is used to remove impurities and purify the corn kernels, and the outer side of the base 1 is equipped with a rectangular square tube and a collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com