Automatic arranging machine for capacitors

A discharger and capacitor technology, applied in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of unfavorable automatic production of capacitors, high labor costs, affecting capacitor performance, etc., to improve automatic production efficiency, reduce production costs, and improve discharge. The effect of material efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

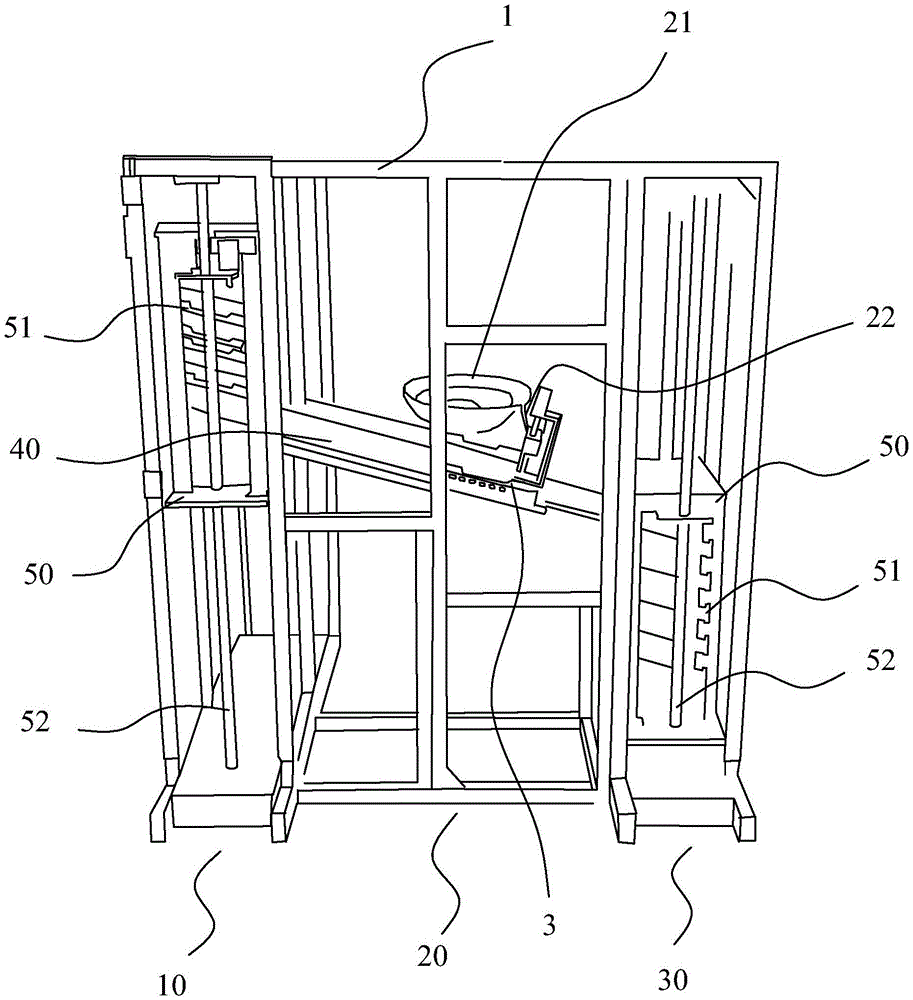

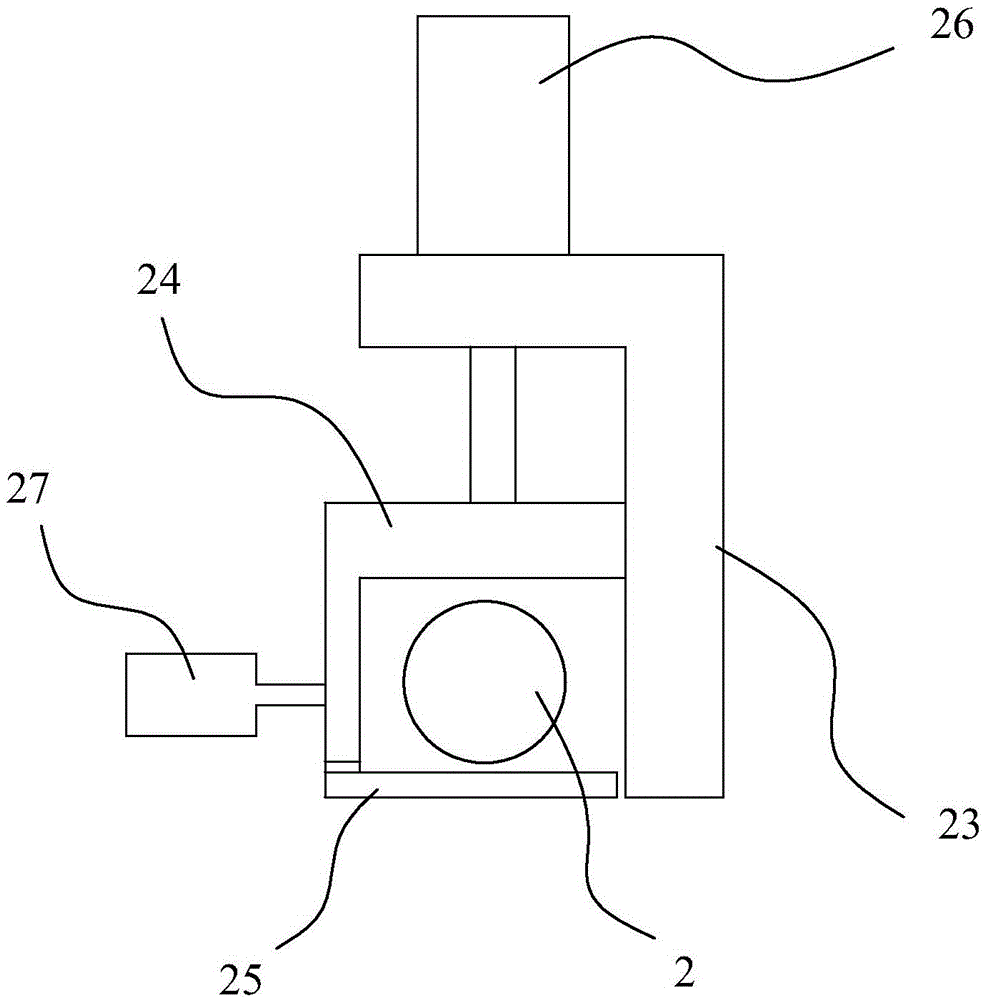

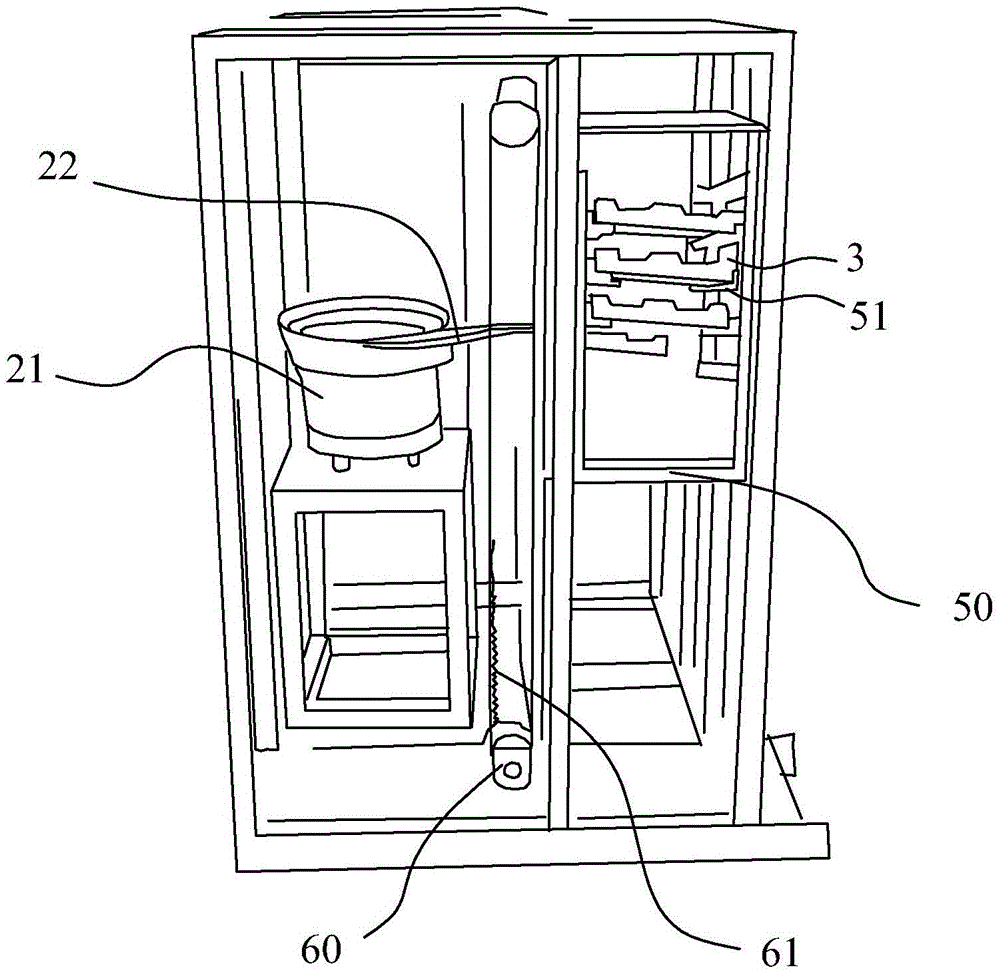

[0023] First, please refer to figure 1 and figure 2 As shown, a capacitor automatic discharge machine includes a frame 1, and a tray supply mechanism 10 located on the frame 1, a capacitor discharge mechanism 20, a tray unloading mechanism 30, and a moving motor controlled by a stepping motor. Transmission track 40, the transmission direction of the transmission track 40 is obliquely downward, the tray supply mechanism 10 and the tray blanking mechanism 30 are respectively arranged at the upper and lower ends of the delivery track 40, and the capacitor discharge mechanism 20 is set At the middle position of the conveying track 40, the tray 3 on the tray supply mechanism 10 is transferred to the capacitor discharge mechanism 20 through the transfer rail 40, and the tray 3 after the material has been discharged on the capacitor discharge mechanism 20 is passed through the conveyor. The track 40 is transferred to the tray unloading mechanism 30 . By making the transmission dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com