Nonuniform heating enclosed method in large-sized high-pressure bottle heat sleeve stove

A non-uniform heating and high-pressure vessel technology, applied in pressure vessels, metal processing, metal processing equipment, etc., can solve problems such as rework, difficulty, horizontal displacement and fitting, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

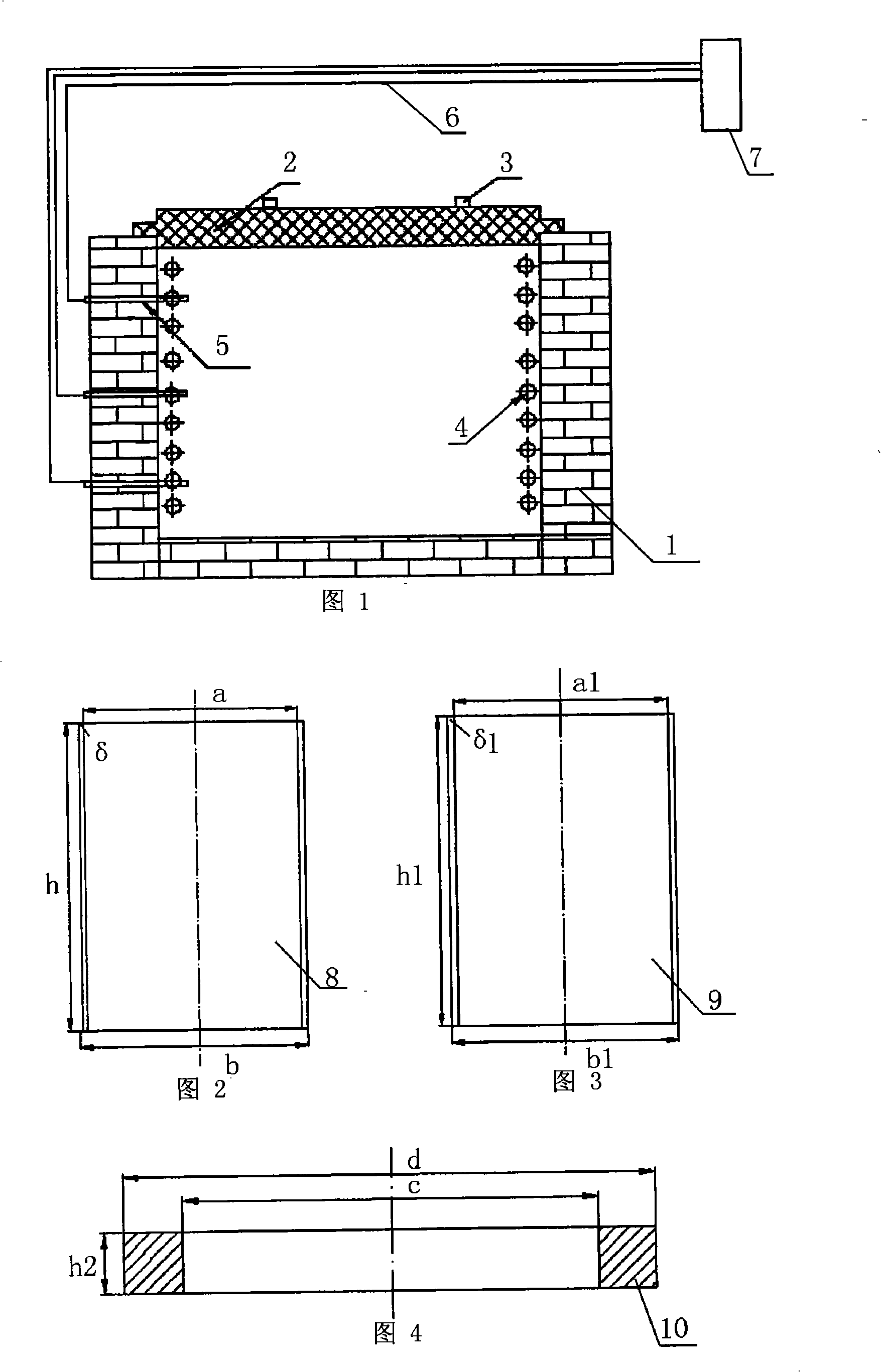

[0018] As shown in Fig. 1, the equipment used in the present invention: 380KW well-type furnace, the furnace body 1 of the well-type furnace is provided with a furnace cover 2, and the lifting lug 3 is installed on the furnace cover 2 to control the opening of the furnace cover 2, and the furnace body 1 Multiple sets of resistance wires 4 for heating are distributed on the inner walls of both sides. The resistance wires 4 are connected to the thermocouple 5, and the thermocouple 5 is connected to the temperature controller 7 through the compensation wire 6. During the production process, the cylinder is heated by the resistance wire 4 , by thermocouple 5 and temperature controller 7 to control different heating temperatures.

[0019] The material used for the outer cylinder 8 and the inner cylinder 9: 13MnNiMoNbR.

[0020] The inner diameter a of the outer cylinder is 1468mm, the outer diameter b is 1548mm, the wall thickness δ is 40mm, and the height h is 2145mm; the inner di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com