Centrifugation filter-belt dewaterer

A dehydrator and filter belt technology, applied in the direction of moving filter element filters, filtration separation, separation methods, etc., can solve the problems of large power consumption, many operators and high equipment cost, and achieve low equipment cost, simple operation, and dehydration. And the effect of high discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

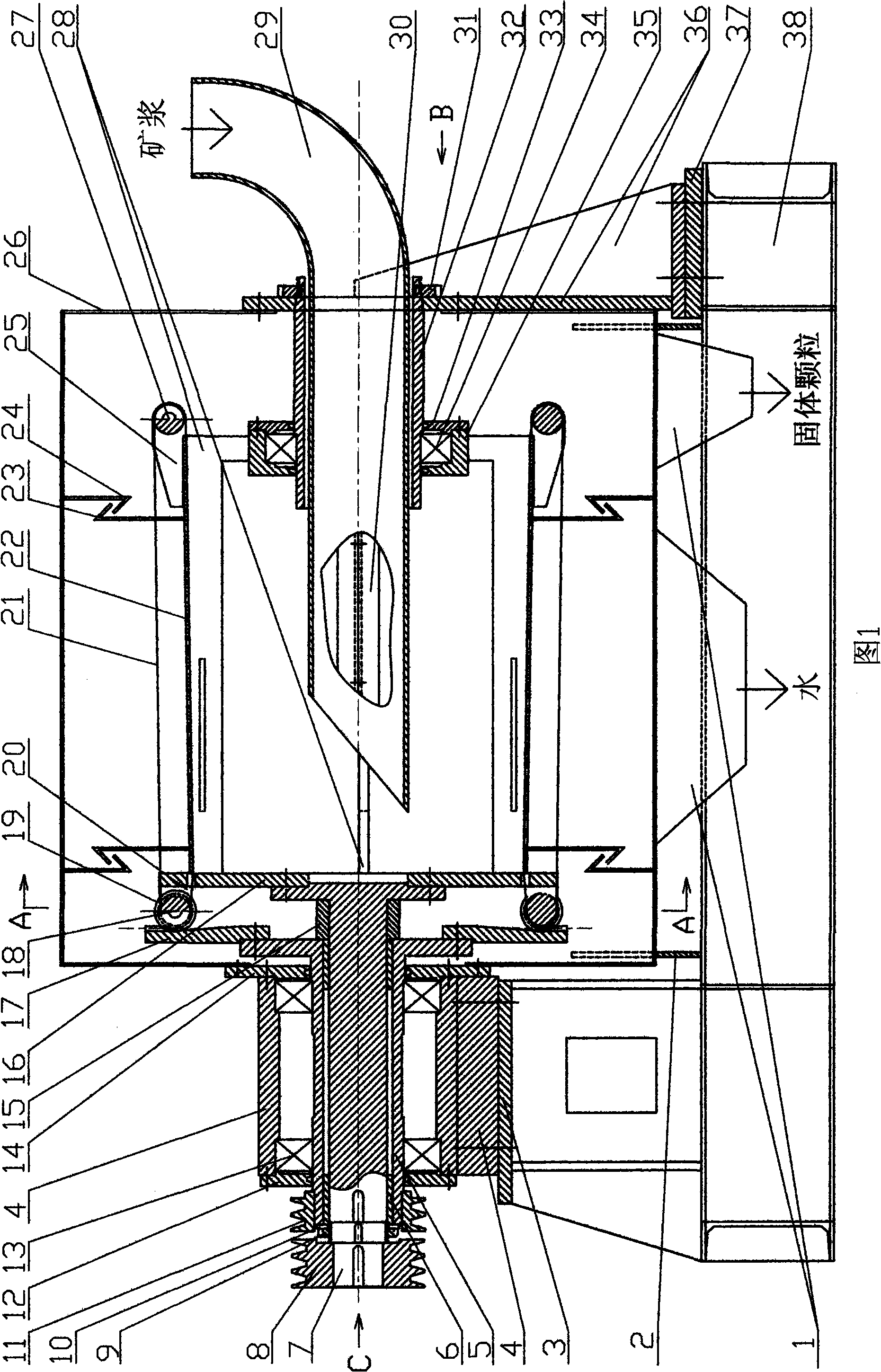

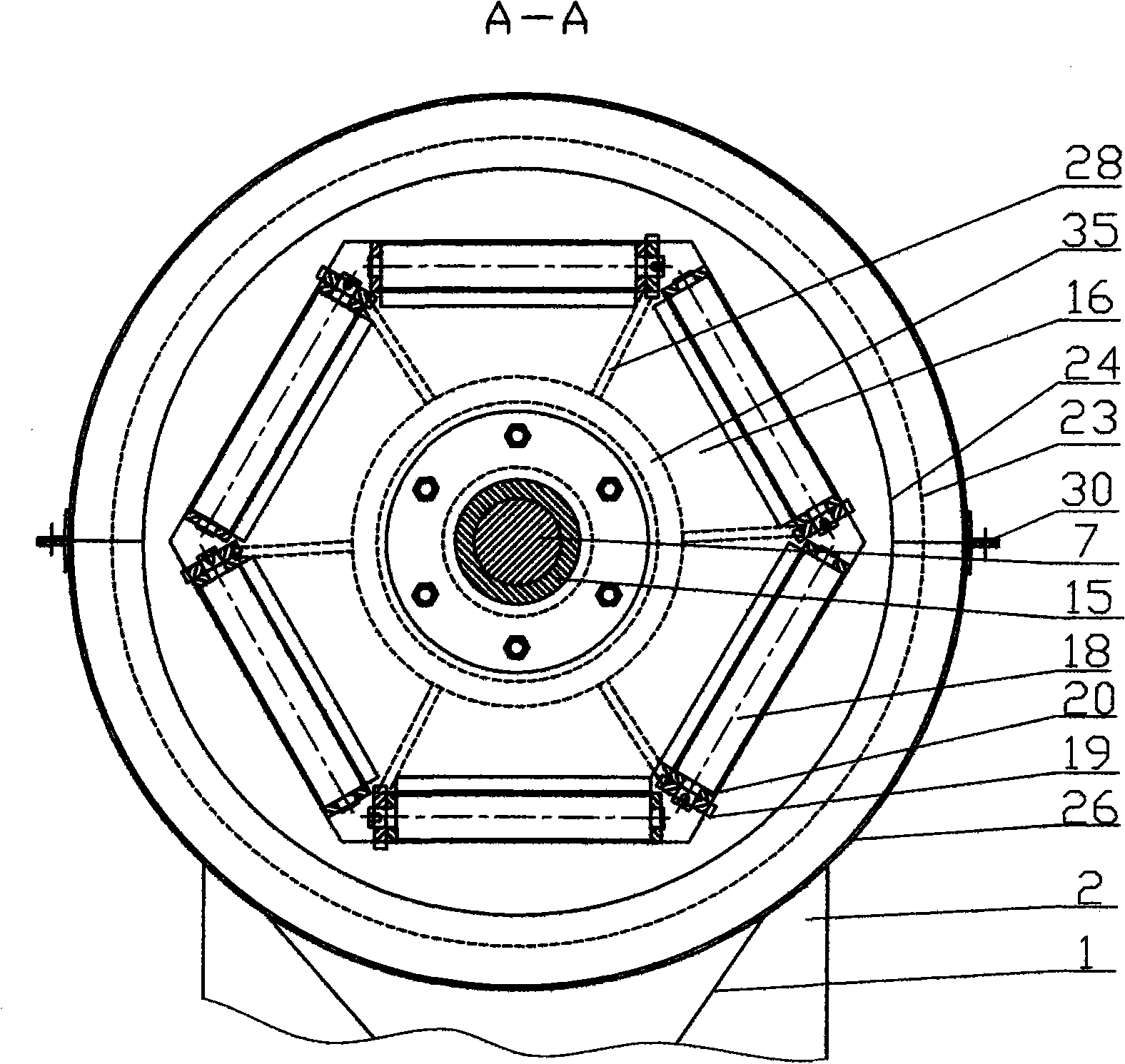

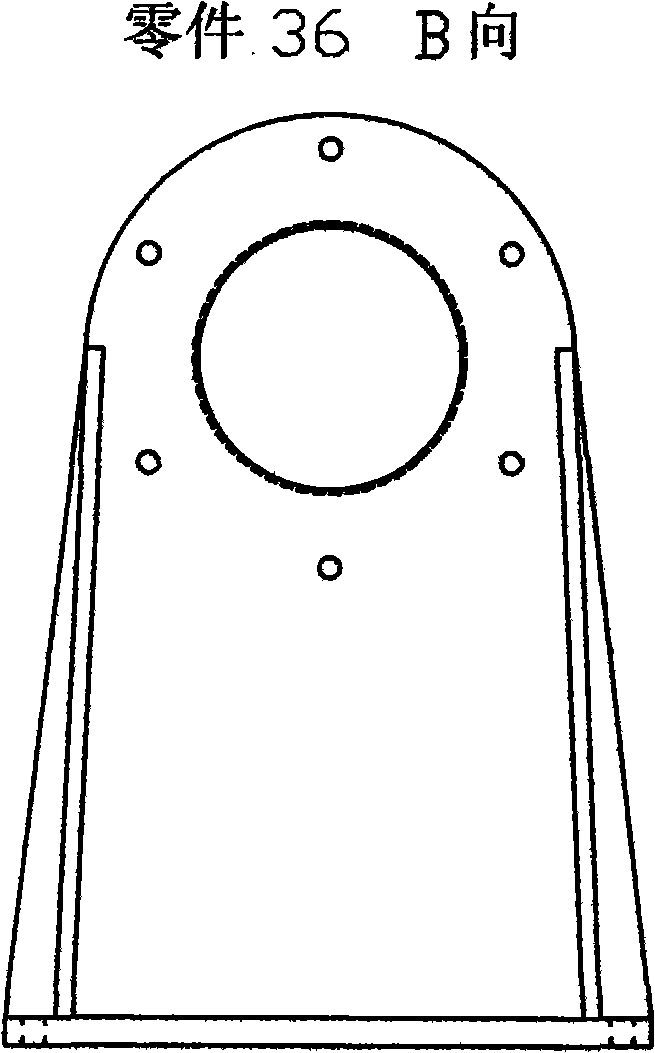

[0012] As shown in the figure, the centrifugal dynamic filter belt dehydrator includes a shaft (7), a hollow shaft (5), a transmission tooth plate (17), a main bearing seat (4), a drum main board (16), and a drum wall ( 22), support seat (36), outer cover (26); it is characterized in that: the two ends of the inner diameter of the hollow shaft (5) are fixedly connected to the shaft sleeve (6), and the two ends of the outer diameter are equipped with inner pulleys (11), transmission gears Disk (17), shaft sleeve (6) is equipped with shaft (7), one end of shaft (7) is equipped with outer pulley (8), shaft nut (9), gasket (10), and the other end is equipped with spacer (15) and drum main board (16), the hollow shaft (5) is contained on the bearing I (13) in the main bearing seat (4), and the outer gland (12) and the main bearing seat (4) two ends are equipped with The inner gland (14), the inner gland (14) is fixedly connected with one end of the outer cover (26), the other end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com