High-speed efficient drill bit

A high-efficiency and high-speed technology, applied in the direction of stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problems of difficult discharge and the inability of the drill to work at high speed and high efficiency, and achieve the effect of high speed and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

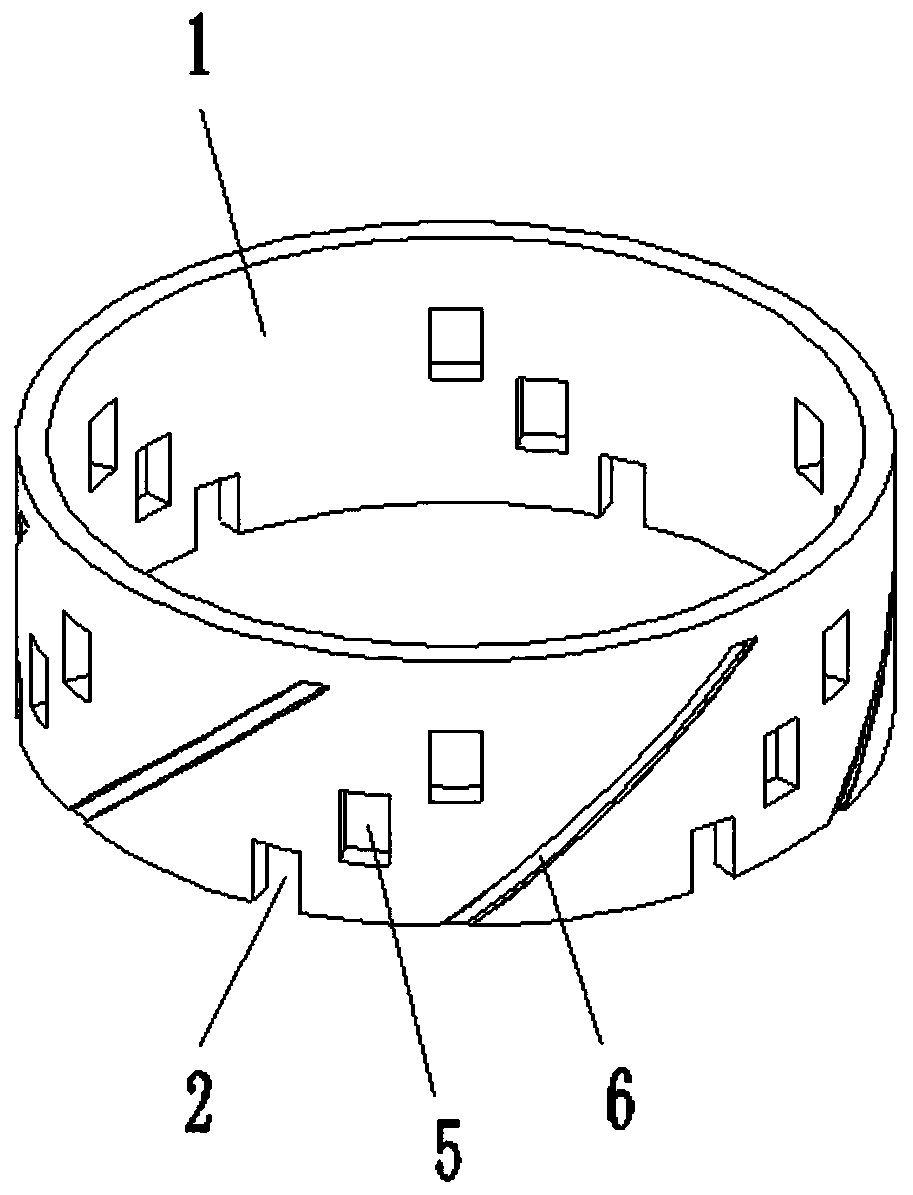

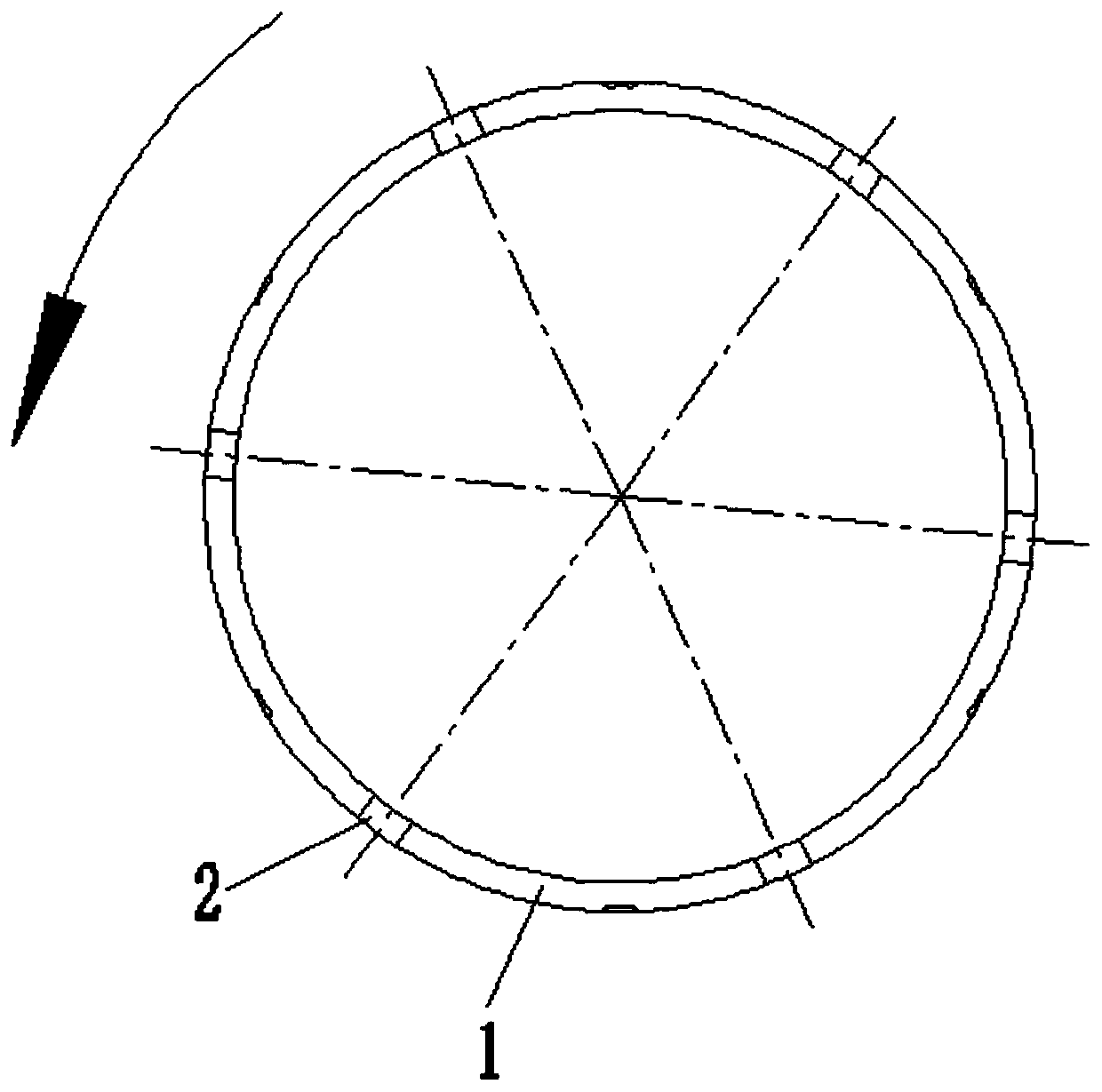

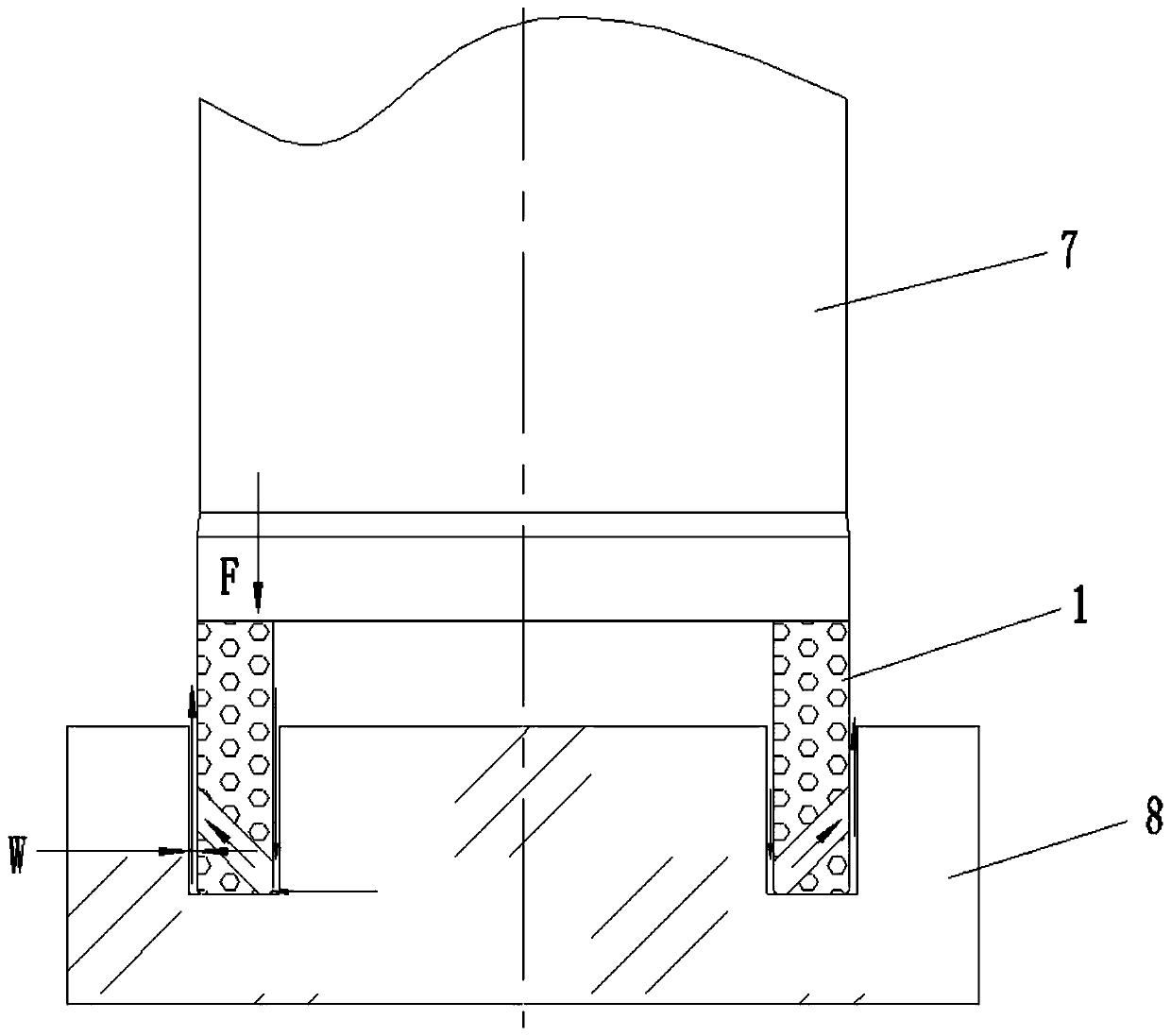

[0048] Such as Figure 4 with 5 As shown, a high-speed and high-efficiency drill bit includes a working ring 1 and a discharge port 2. The working ring 1 has a cylindrical structure, and the discharge ports 2 are arranged in a plurality, which are distributed in a ring shape at the bottom of the side wall of the working ring 1 to discharge scraps when the working ring 1 is rotating and processing. The two sides of the bottom of the discharge port 2 are arranged in parallel, and the center line of symmetry does not pass through the center of the bottom surface of the working ring 1, and the two sides of the bottom of the discharge port 2 are in a spiral shape relative to the center of the bottom surface of the working ring 1. Arranged, and the helical direction is consistent with the rotation direction of the working ring 1. In this embodiment, the chips can be discharged outward along the discharge port 1 under the action of the centrifugal force of the rotation of the worki...

Embodiment 2

[0051] This embodiment mainly changes the structure of the discharge port 2, and the rest is consistent with the first embodiment.

[0052] Such as Image 6 with 7 As shown, the two sides of the bottom of the discharge opening 2 are respectively the first side 3 and the second side 4 in the direction of rotation of the working ring 1, and the first side 3 and the second side The center line of the angle formed by the sides 4 does not pass through the center of the bottom surface of the working ring 1 . Such as Figure 17 As shown, one end of the first side 3 is at the corresponding position on the inner wall of the working ring 1, and the other end of the first side 3 deflects toward the outside of the working ring 1 and in the direction opposite to the rotation direction of the working ring 1. angle α. One end of the second side 4 is at the corresponding position on the inner wall of the working ring 1, and the other end of the second side 4 faces the outside of the worki...

Embodiment 3

[0055] This embodiment mainly changes the structure of the discharge port 2, and the rest is consistent with the first embodiment.

[0056] Such as Figure 10-13 As shown, the two sides of the discharge port 2 are arranged in parallel, and the symmetrical center line of the two sides of the bottom does not pass through the center of the bottom surface of the working ring 1 . The two sides of the discharge port 2 are arranged obliquely relative to the bottom surface of the working ring 1 in the direction of rotation of the working ring 1, and one end of the two sides of the discharge port 2 is at the corresponding position on the inner wall of the working ring 1, The other end is deflected by a preset angle toward the outside of the working ring 1 and in the direction of rotation of the working ring 1 . The top of the discharge port 2 is rounded, and the bottom and top of the spare discharge port 5 are rounded. The rounded corner structure prevents stress concentration and fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com