Inclined wedge type grinding head feeding device

A technology of grinding head feed and wedge, which is applied in the direction of grinding drive device, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of affecting processing accuracy, limited feeding accuracy, and high labor intensity. Achieve the effect of realizing automatic control, reducing feed speed, and automatically realizing feed and exit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

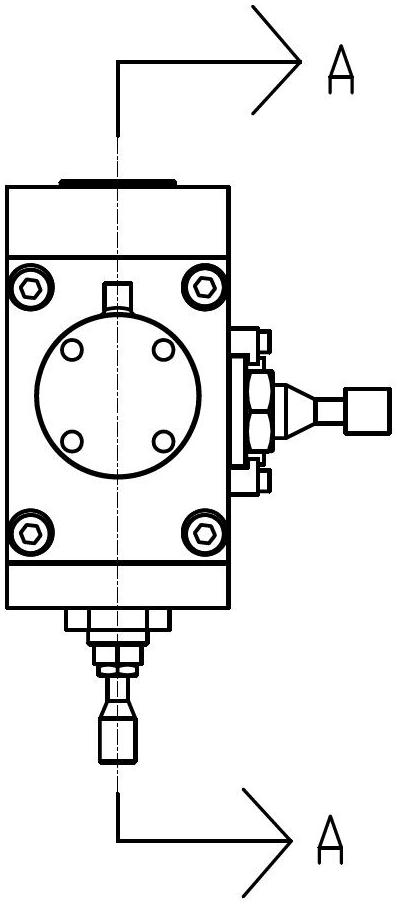

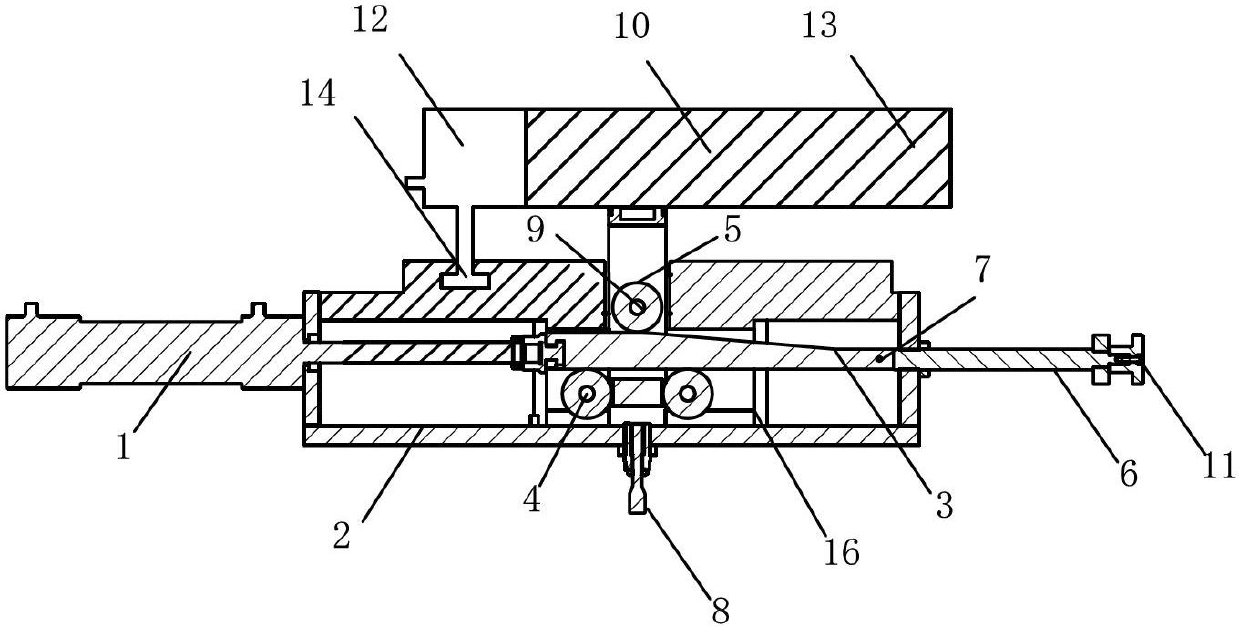

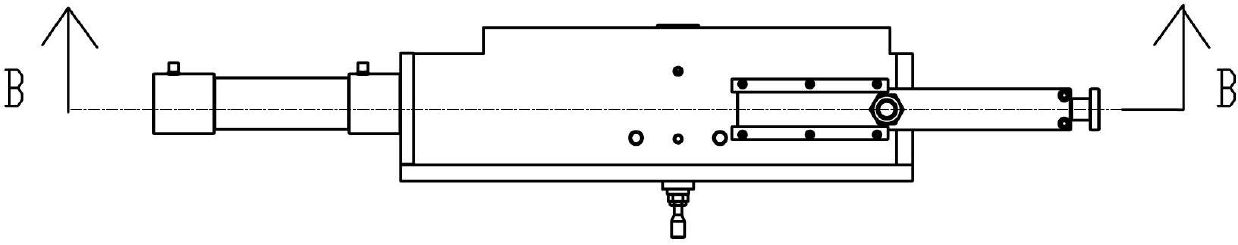

[0039] Such as Figure 1~4 Shown, a kind of wedge type grinding head feeding device of the present invention comprises:

[0040] Base 13;

[0041] The guide column 10 fixedly connected with the machine base 13;

[0042] A casing 2 for installing a grinding head that is slidably matched with the guide column 10;

[0043] A second oil cylinder 12 fixedly connected to the base 13 for pulling the casing 2 toward the base 13;

[0044] Roller 5 installed on the guide column 10;

[0045] Slide the feed ramp rod 3 installed in the shell 2, the slope of the feed ramp rod is close to the outer circumference of the roller 5;

[0046] A first oil cylinder 1 arranged on the casing 2 for pulling the feed ramp rod 3;

[0047] The sensing element used to sense the limit position of the feed ramp rod 3, the control signal of the first oil cylinder comes from the sensing element.

[0048] The piston rod 14 of the second oil cylinder 12 is parallel to the guide column 10 .

[0049] The gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com