Neutralization reaction device and automatic control method

A reaction device and neutralization technology, applied in chemical instruments and methods, chemical methods for reacting liquid and gaseous media, feeding devices, etc. It is very good to ensure the acid-base neutralization effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

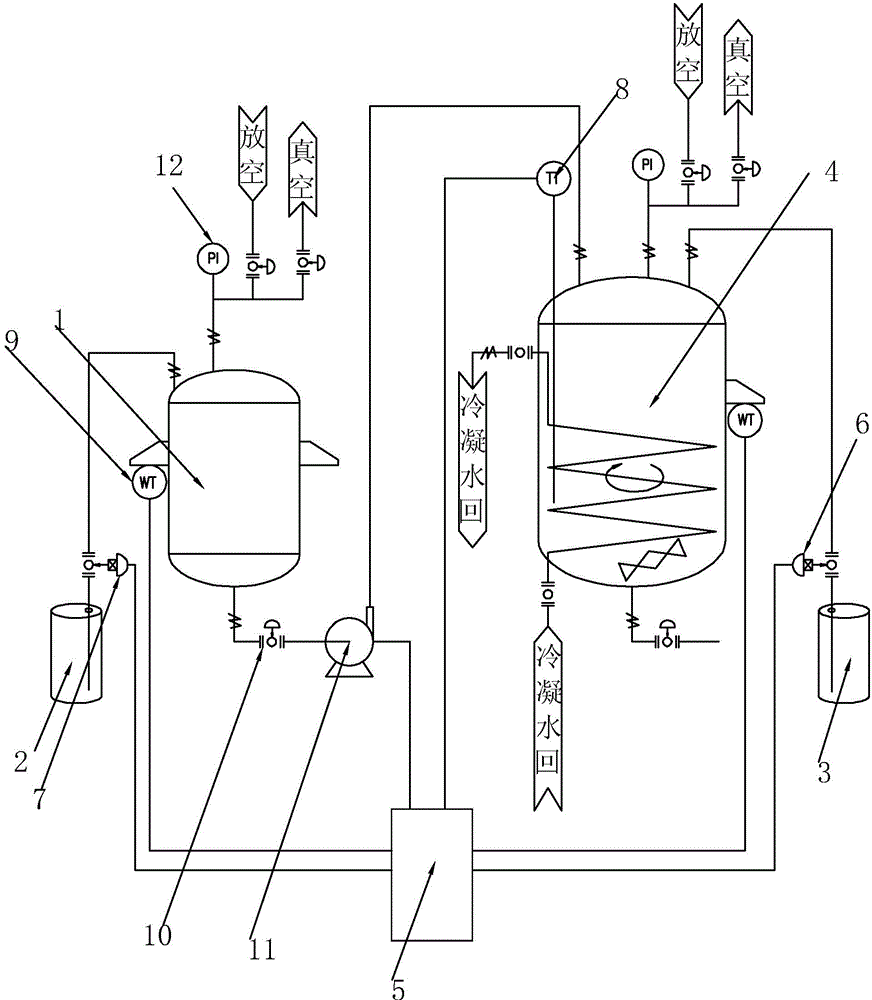

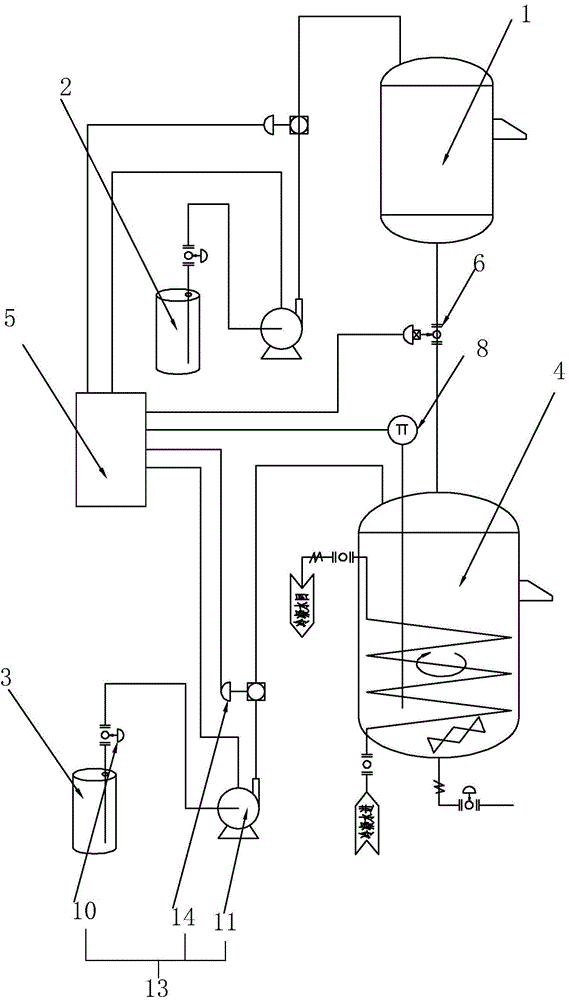

[0027] refer to Figure 1 to Figure 2 The present invention will be further described.

[0028] In the current acid-base neutralization reaction, since there is no precise control of the amount of acid or lye, in actual production, there will be the following problems: first, during the reaction, there will be acid The consumption of lye is more than that of lye, or the consumption of lye is more than that of acid, which increases the excessive consumption of acid or lye, which is not conducive to environmental protection; second, the excess acid or lye after neutralization will It affects the chemical properties (such as PH value) of the product, so that the performance that people expect the product to achieve will not be achieved, thus affecting the production of the subsequent process; third, during the entire neutralization reaction process, it is impossible to neutralize The reaction is precisely controlled in real time, so the effect of acid-base neutralization cannot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com