Electromechanical solution combination feeding driving control device in high-hardness spherical precision grinding and method thereof

A precision grinding, electromechanical hydraulic technology, applied in the direction of grinding drive device, grinding machine parts, grinding/polishing equipment, etc., can solve the problems that it is difficult to guarantee grinding efficiency and dimensional accuracy, and avoid grinding Burn, best grinding effect, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below. Based on the premise of the technical solution of the present invention, the present embodiment provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

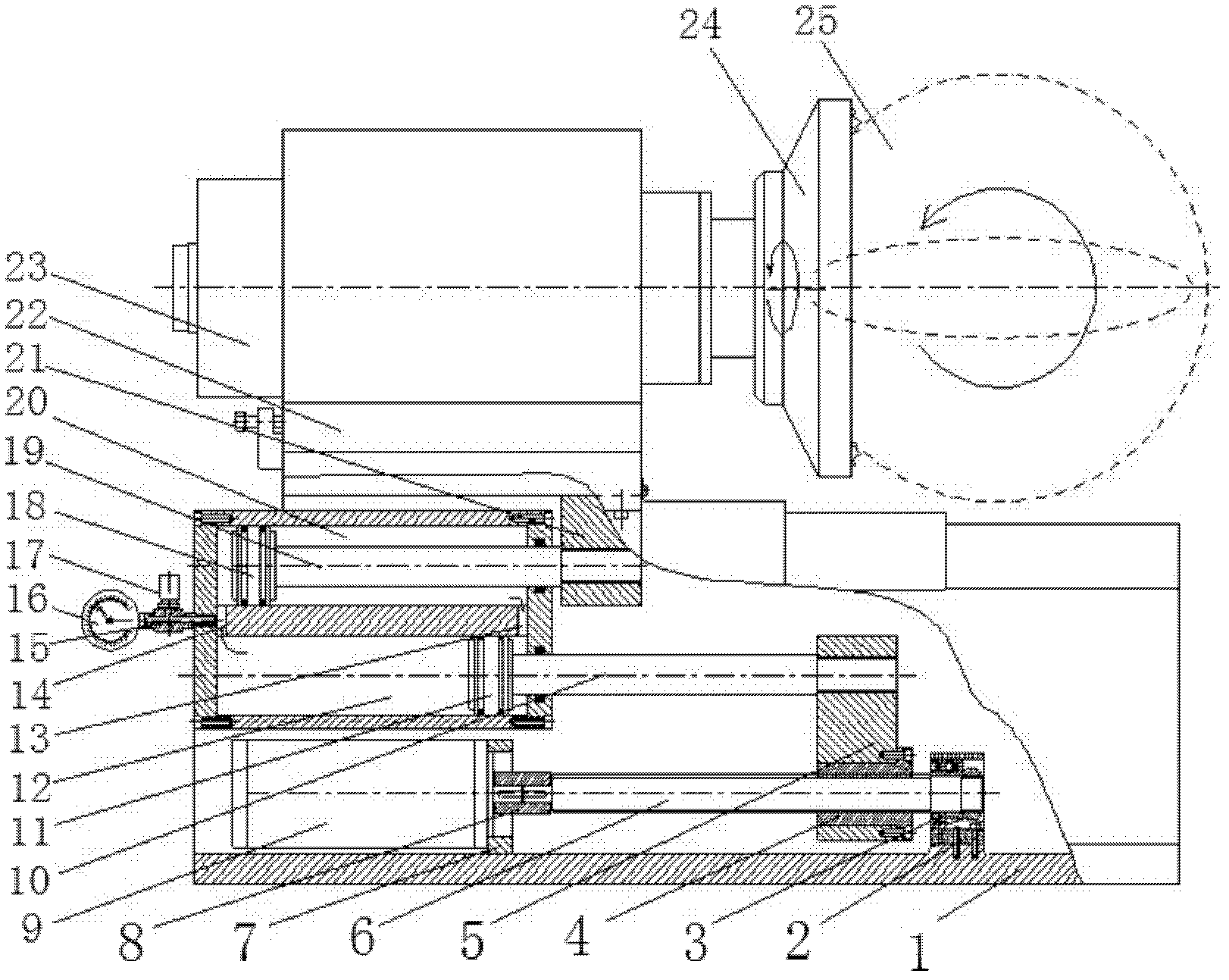

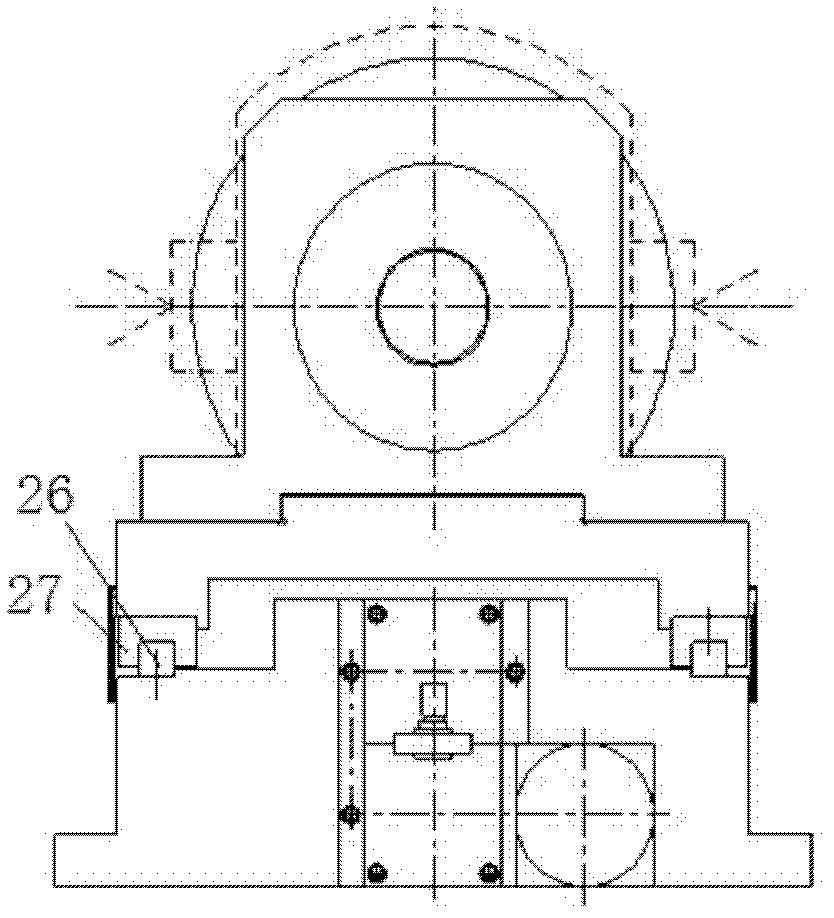

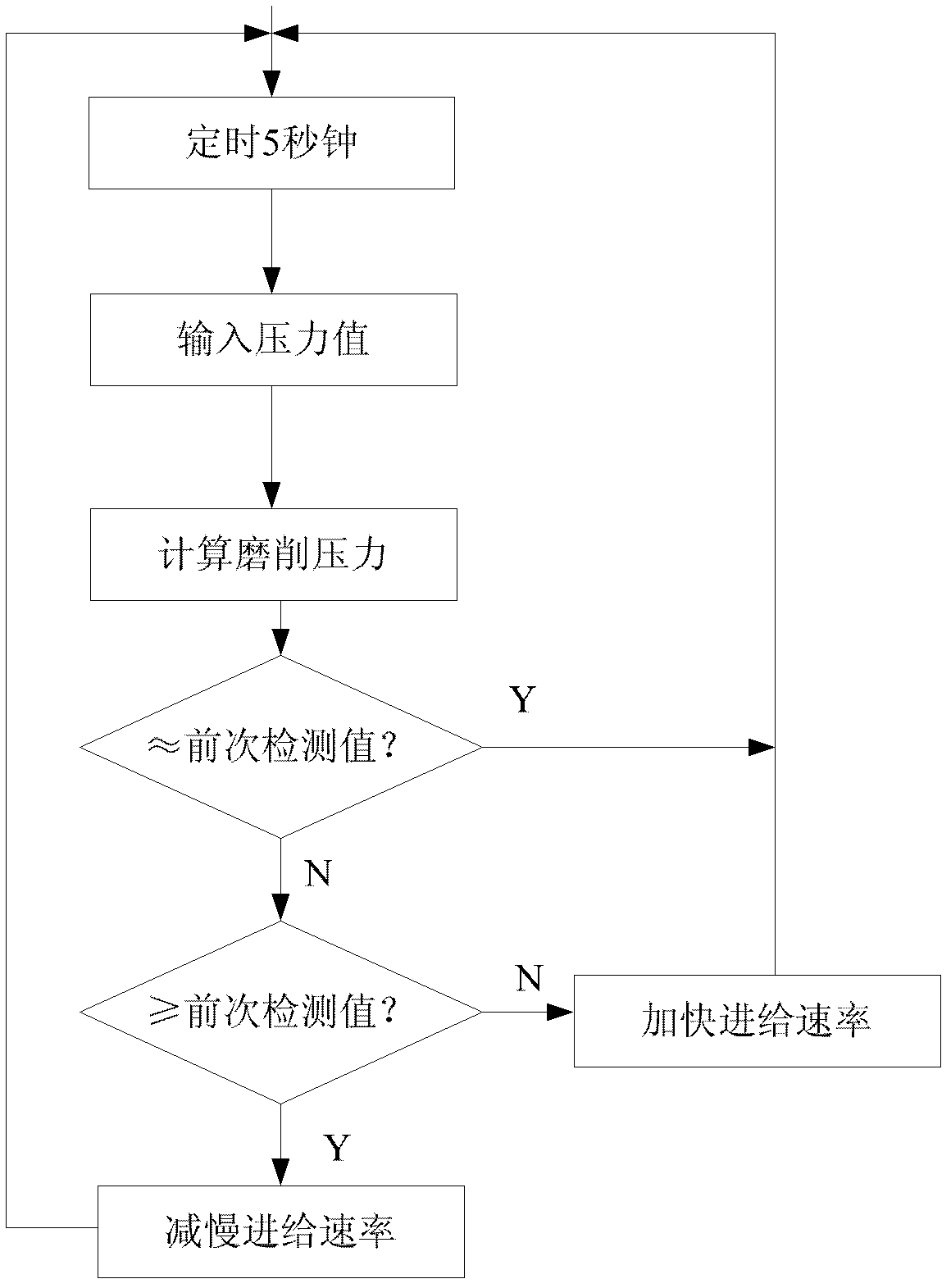

[0019] like figure 1 and figure 2 As shown, this embodiment provides an electromechanical-hydraulic combination feed drive control device for high-hardness spherical precision grinding, including: a grinding wheel frame worktable part 1, a grinding wheel frame sliding seat part 22, wherein: the grinding wheel frame sliding seat part 22 is movable It is arranged on the linear guide rail 26 of the grinding wheel head workbench part 1.

[0020] The wheelhead workbench components include: wheelhead workbench 1, linear guide rail 26, first oil cylinder 12, first piston 11, first piston rod 10, second oil cylinder 20, second piston rod 19, second pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com