Air cooled dedusting device for producing fine rubber powder by utilizing waste tires

A technology of dust removal device and waste tires, which is applied in recycling technology, plastic recycling, etc., can solve the problems of incomplete cooling, affecting the health of employees in the environment, and affecting the tensile strength of downstream reclaimed rubber products, so as to slow down the feeding speed, The effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

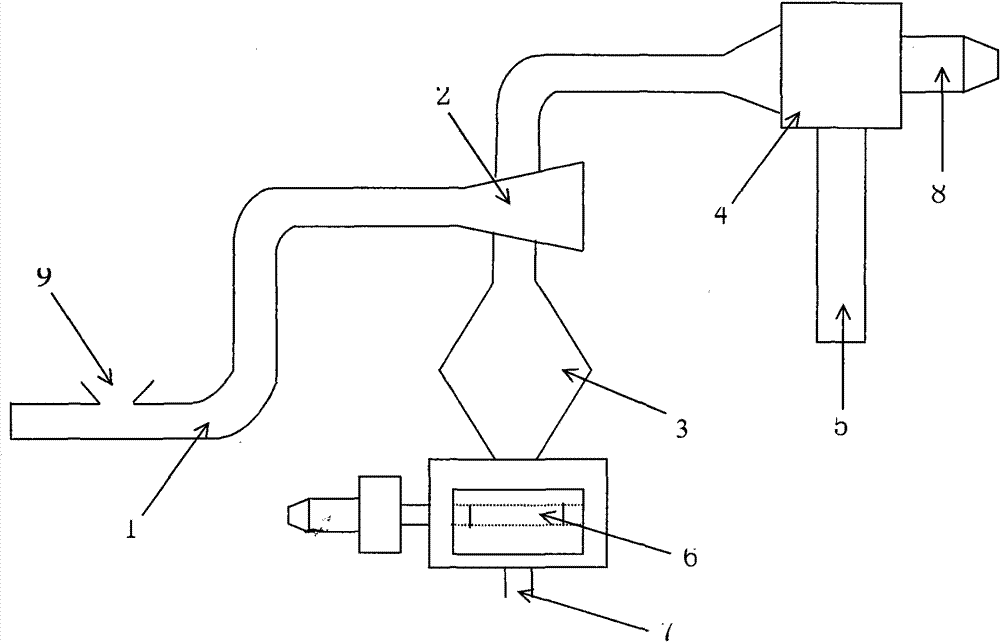

[0011] Such as figure 1 As shown, the air-cooled dedusting device consists of a feeding pipe 1, a cooling chamber 2, a storage chamber 3, a blower 4, a dust storage and lowering chamber 5, and a feeder 6. One end of the feeding pipe 1 is provided with a feeding port 9, The other end of the feeding pipe 1 forms a cooling chamber 2, the feeding pipe 1 is "S" shaped, the cooling chamber 2 communicates with the storage chamber 3 arranged at the bottom, and the lower part of the storage chamber 3 is provided with a feeder 6, which The bottom of the feeder 6 is provided with a discharge port 7, the top of the cooling chamber 2 communicates with the blower 4, the bottom of the blower 4 is provided with a dust storage and cooling chamber 5, and the blower 4 is provided with a blower motor 8.

[0012] When working, the ground fine rubber powder is sent to the feed port 9 on the feeding pipe 1 through the pipeline, the blower motor 8 is started, and the suction of the blower 4 sucks the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com