Patents

Literature

84results about How to "To achieve the purpose of processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

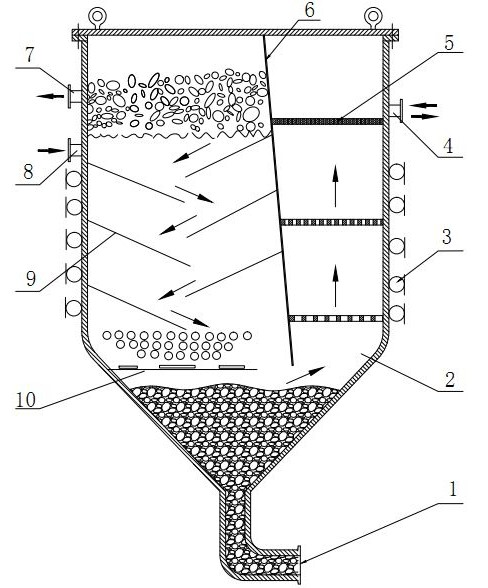

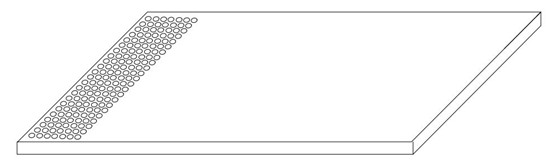

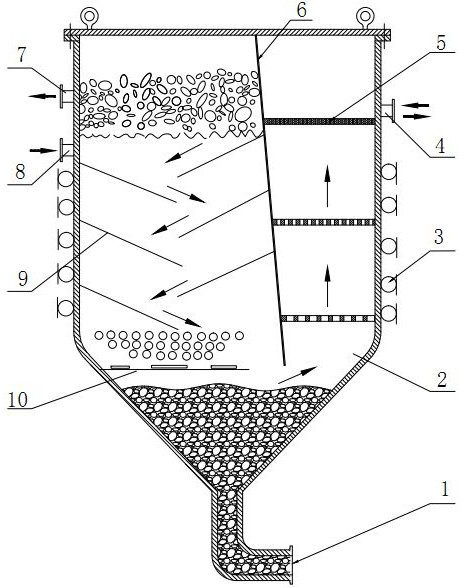

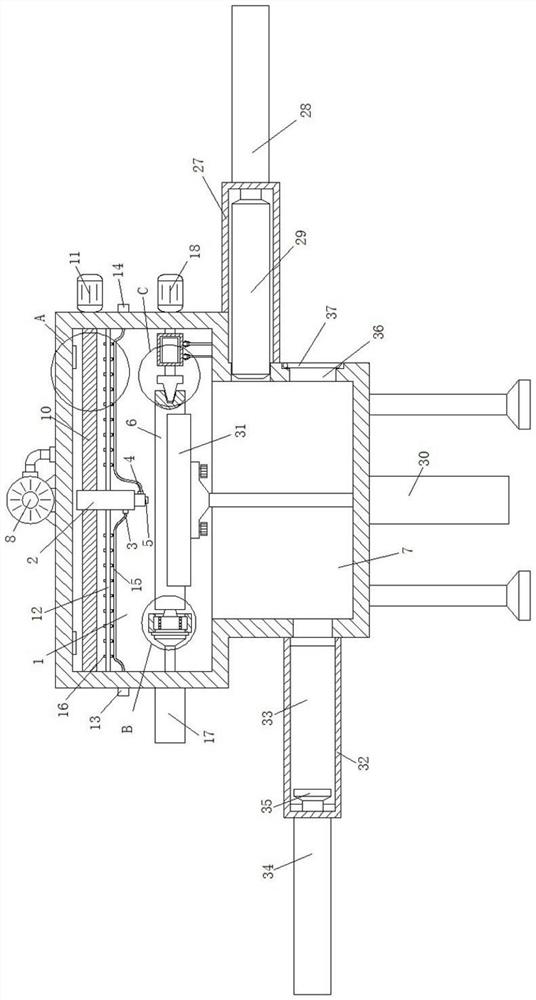

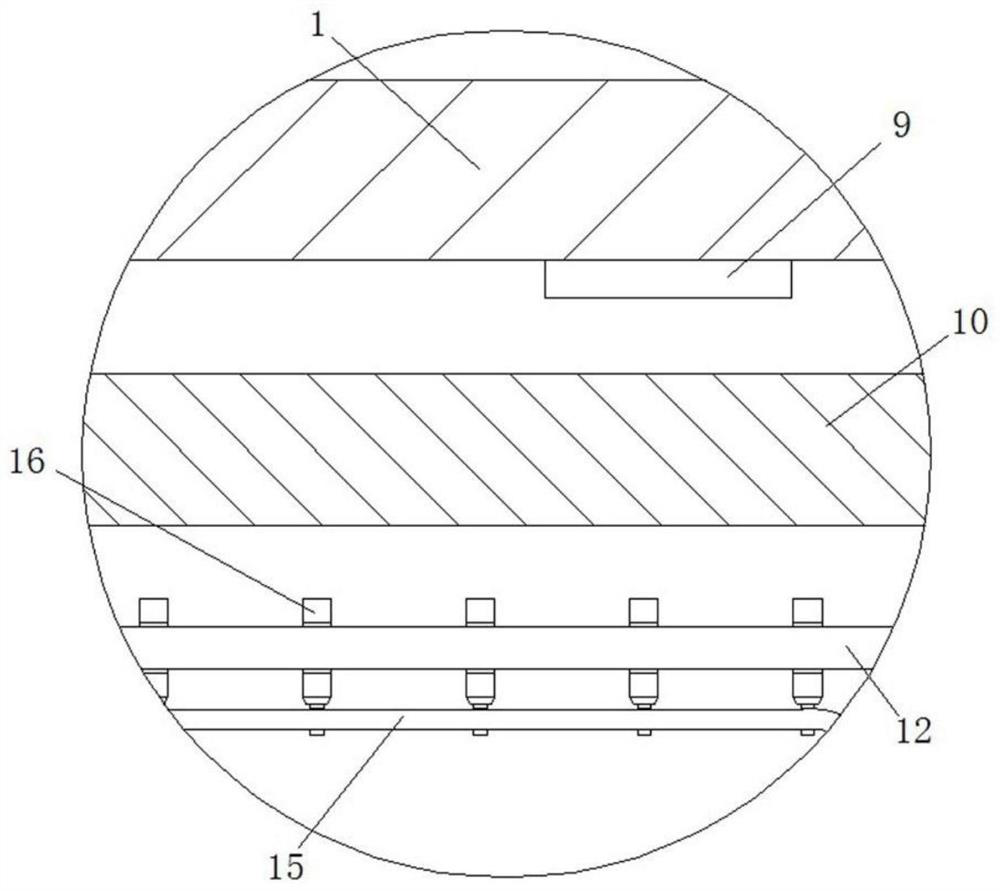

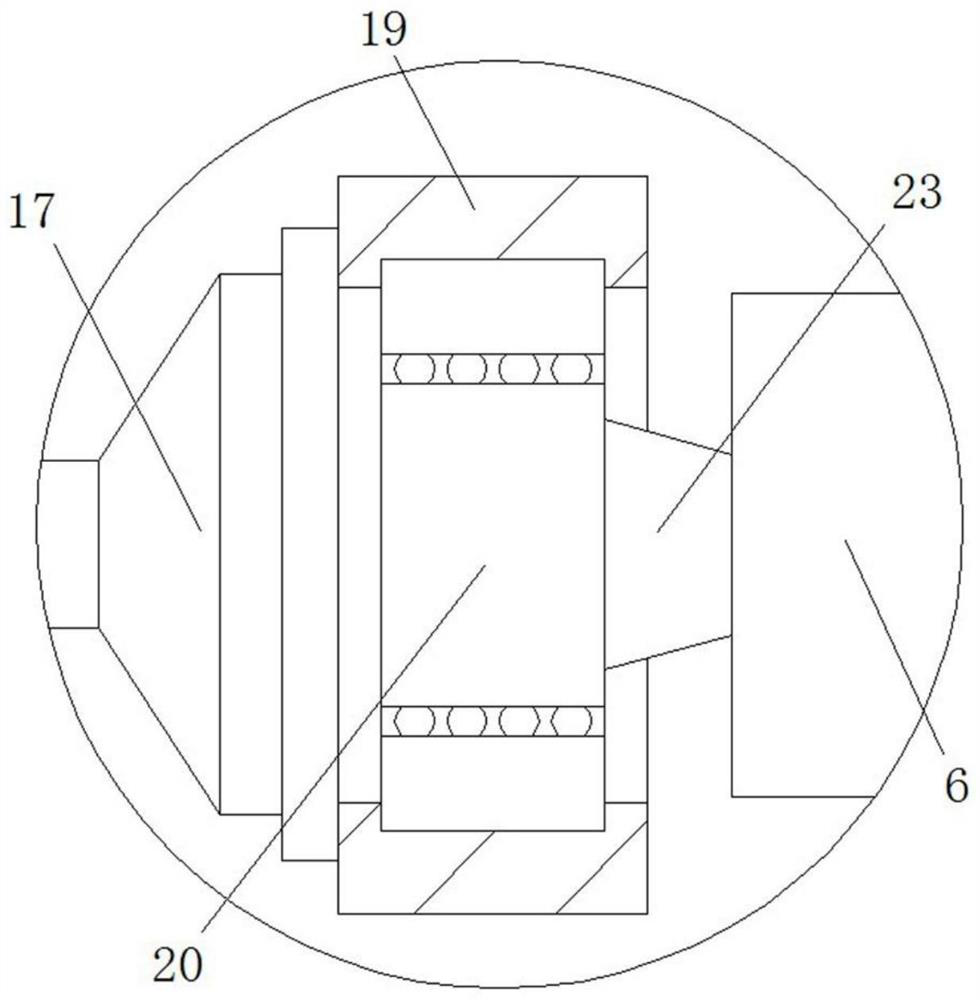

Method and device for continuously separating oil-water slag without dismantling and cleaning

InactiveCN102503008ABeneficial to emergeEasy dischargeWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentStopped workSlag

The invention provides a method and a device for continuously separating oil-water slag with dismantling and cleaning. Due to the adoption of a technology of combining gravity separation, air floatation separation, ultrasonic separation and cleaning and the like, wastewater containing oil and slag is separated and treated. The device is a vertical tank type sealing container which is arranged vertically, wherein the upper part of the container is rectangular; the lower part of the container is of an inverted pyramidal shape; a rectangular casing is externally surrounded by an ultrasonic generator and is internally divided into two inner cavities with the different sizes by a partition board; an oil drain port, a wastewater inlet, rectangular inclined plates arranged in a staggered way andan air floatation coiled pipe are arranged in the bigger inner cavity; a clear water outlet, a rectangular dense hole filtering mesh plate, a rectangular mesoporous filtering mesh plate and a rectangular gross porous filtering mesh plate are respectively arranged in the smaller inner cavity; and a slag discharging opening is connected to the lower end of a groove body at the tank bottom of the inverted pyramidal shape. The device is advanced in separation method, simple in structure and high in treatment efficiency; and particularly, in the production, internal cleaning can be carried out without stopping work and dismantling a casing of the device, and thus the continuous high-efficiency operation of the equipment can be ensured.

Owner:HUBEI UNIV +1

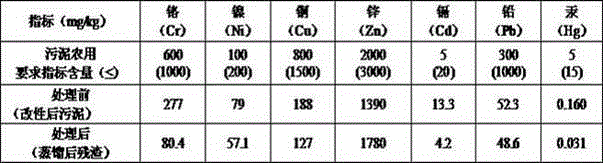

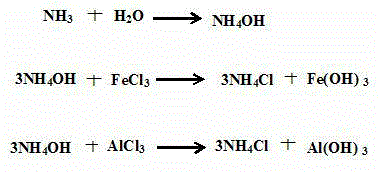

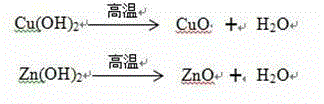

Treatment method of heavy metals in sludge

ActiveCN104649528ATo achieve the purpose of processingSpecific water treatment objectivesBiological sludge treatmentCalcium hydroxideSludge

The invention discloses a treatment method of heavy metals in sludge, relates to the technical field of environmental protection and chemical engineering, and in particular relates to the technical field of treatment of sludge heavy metal through filter pressing of urban domestic sewage. The treatment method of the heavy metals in sludge is characterized by comprising the following steps: hydrolyzing proteins in the sludge through a function of a modifying agent; deaminizing amino acid and fixing amino; performing reaction on ammonium chloride generated by fixation and the added calcium hydroxide and glucose powder step by step to reduce sludge heavy metal ion valence or to be directly reduced into elementary substances; reducing heavy metal ions which are not completely reduced under a reduction function of surplus fixed carbon after the heating of the sludge in a subsequent distillation process. The invention discloses a sludge innocent treatment method; resources contained in the sludge are fully utilized, and a practical and feasible new method is provided for sludge treatment.

Owner:山东一元绿碳环保科技有限责任公司

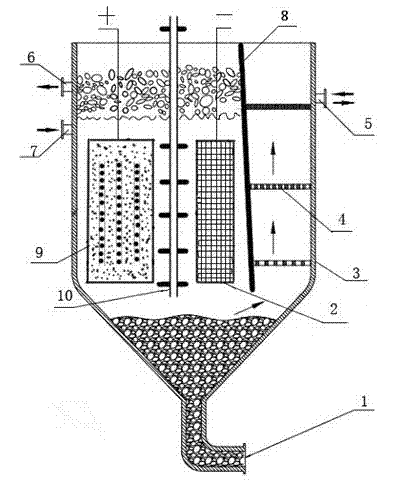

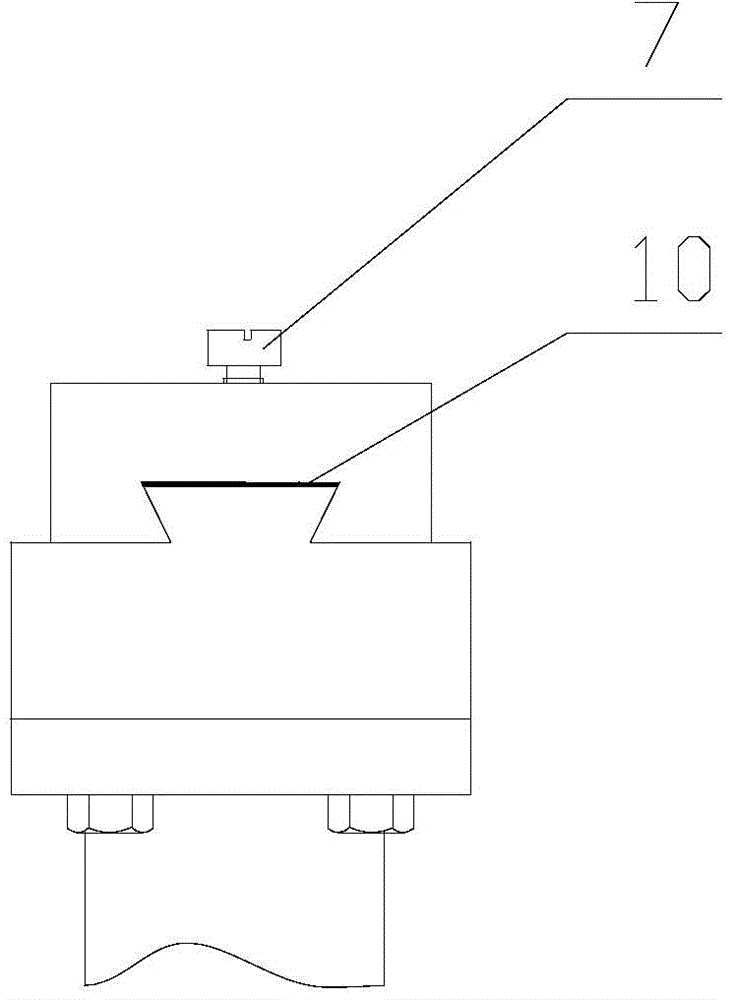

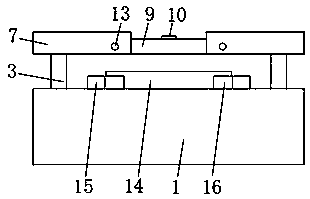

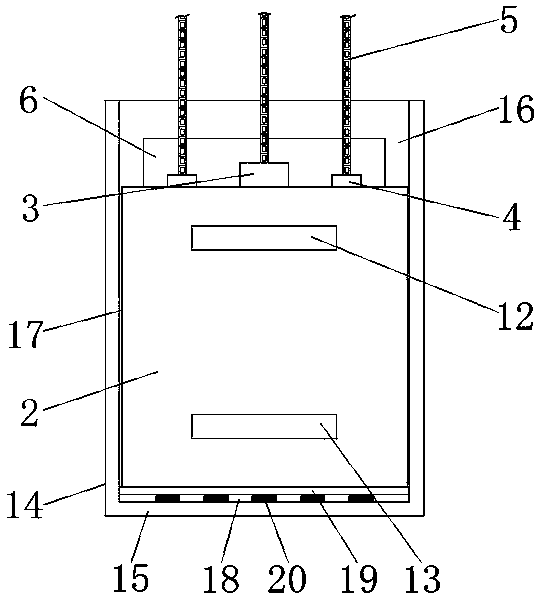

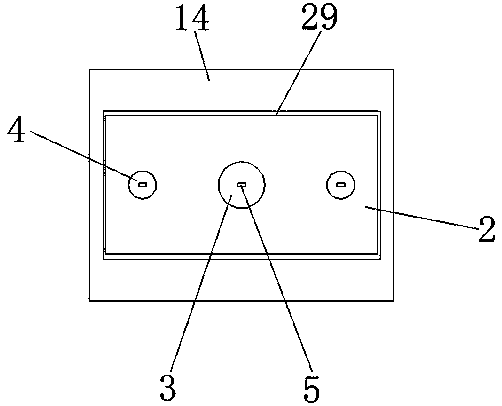

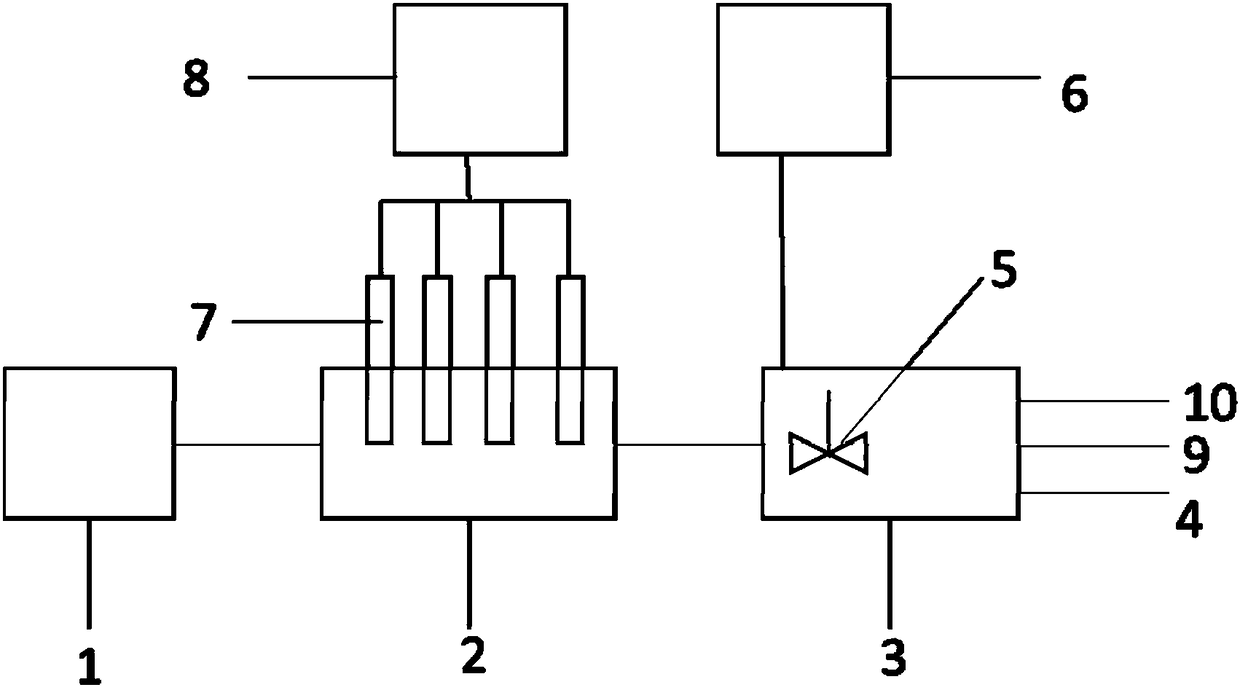

Electrochemical wastewater treatment method and device capable of continuously separating oil, water and residue

ActiveCN103043753ALow water solubilityWith flocculationFatty/oily/floating substances removal devicesLiquid separationHigh concentrationChemical oxygen demand

The invention discloses an electrochemical wastewater treatment method and device capable of continuously separating oil, water and residue. The device adopts proposals such as physical absorption, electrochemical catalytic oxidization, flocculent precipitate, adopting a central partition, bottom sediment, three-layer mesh and the like, so as to realize a technology of combining dynamic water treatment and automatic oil, water and residue separation, reduce COD (Chemical Oxygen Demand), ammonia nitrogen and chrominance in coking wastewater (or other organic wastewater) furthest, and the device has a low power consumption and a good degradation effect, while the device is simple, and has a high treatment efficiency, a low preparation and operation cost and a good separation effect. While a plurality of identical devices can be connected together through pipelines (or grooves) to carry out multi-stage treatment to the wastewater, so that organic wastewater of high concentration or high difficulty can be easily degraded to meet the standard. Compared with biochemical treatment, the treatment method occupies a small area, has less investment and lower cost, and can work continuously and efficiently.

Owner:王麒钧 +1

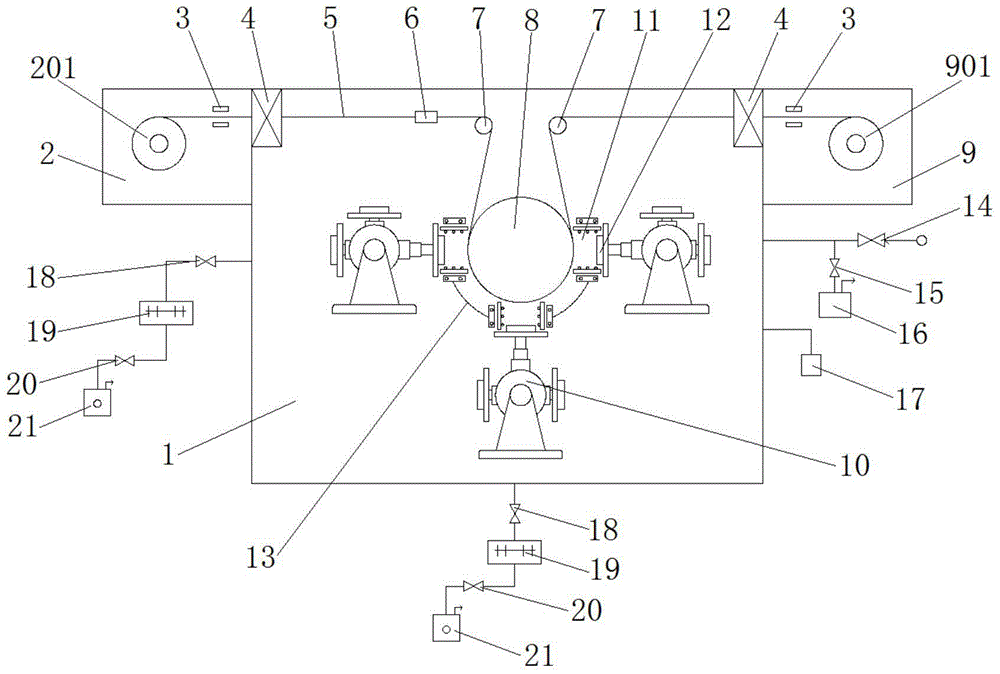

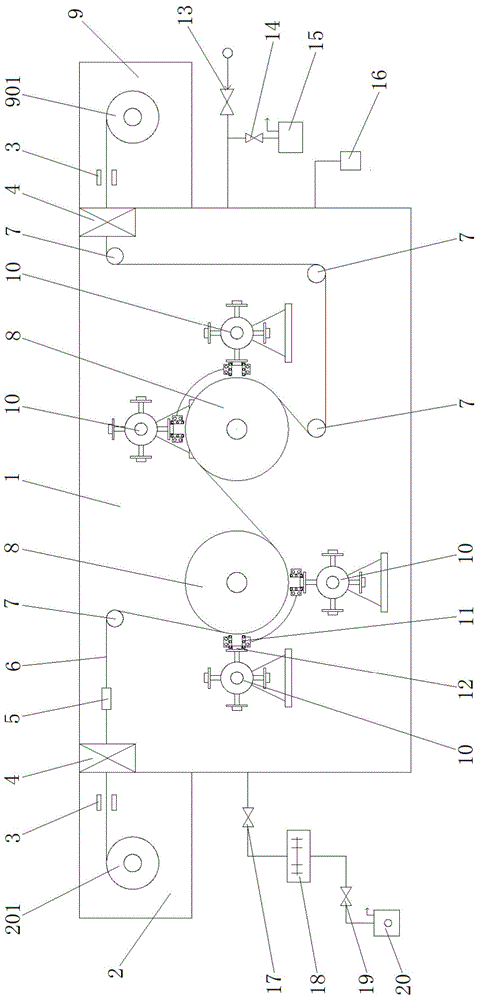

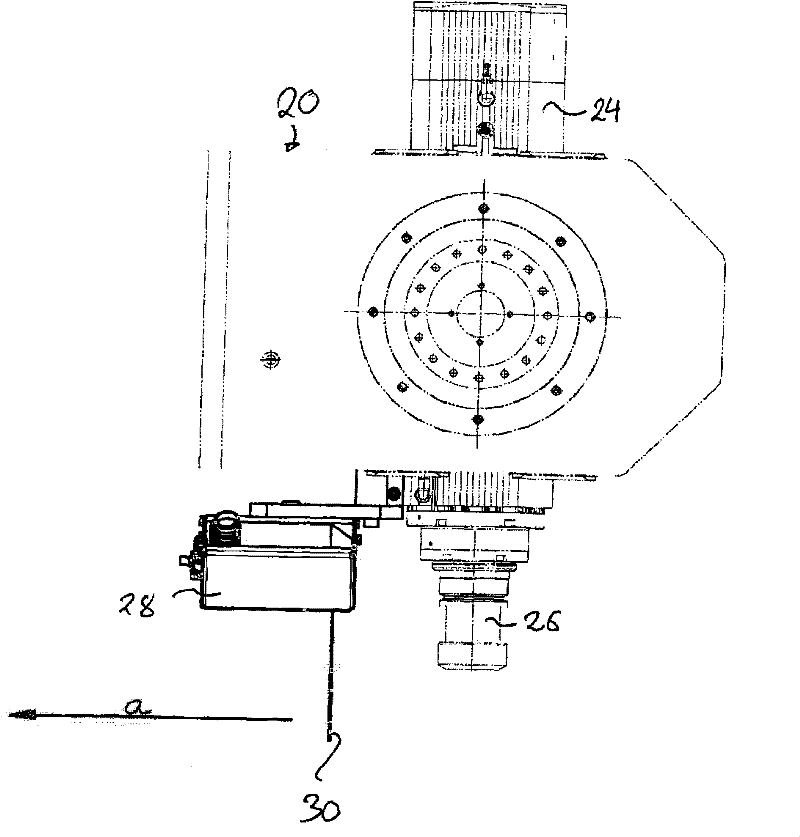

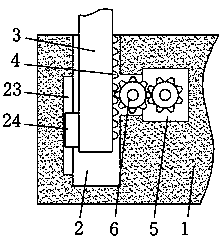

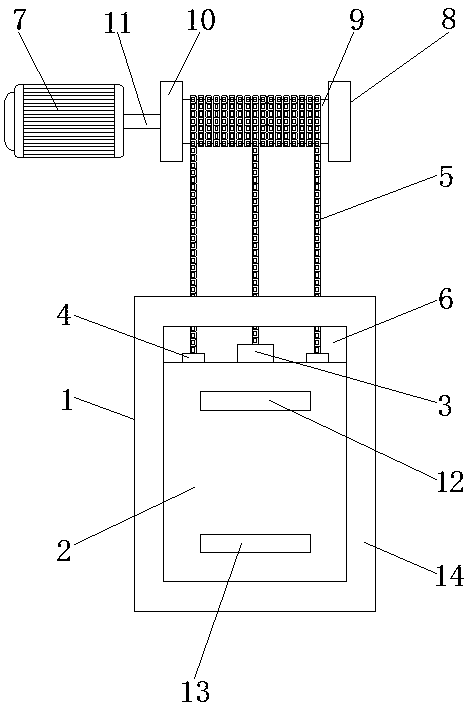

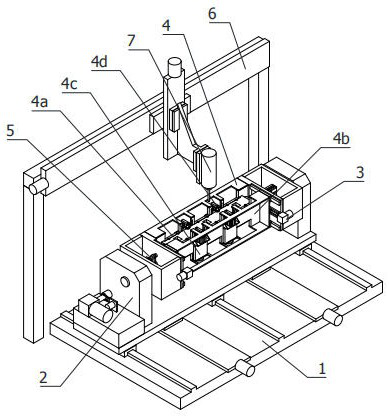

Magnetron-sputtering winding coating machine capable of rapidly changing target and continuously and efficiently coating film in single-surface reciprocating manner

ActiveCN104611681ARealize reciprocating continuous motionNeat winding edgeVacuum evaporation coatingSputtering coatingReciprocating motionEngineering

The invention discloses a magnetron-sputtering winding coating machine capable of rapidly changing target and continuously and efficiently coating a film in a single-surface reciprocating manner, belonging to the field of coating equipment. The magnetron-sputtering winding coating machine comprises a vacuum chamber, an uncoiling mechanism, a coiling mechanism, a cold roll, deviation correcting devices, two or more rotary target changing devices and negative electrode cells, wherein the negative electrode cells are formed corresponding to each rotary target changing device, openings are formed in the two sides of each negative electrode cell; a set of deviation correcting device is arranged at each of the uncoiling mechanism and the coiling mechanism; the negative electrode cells are distributed on the circumference, coated with a base band, of the cold roll, and each set of the deviation correcting device and the corresponding negative electrode cells are arranged on the same axis; the base band is driven to do a reciprocating motion by the uncoiling mechanism and the coiling mechanism. According to the magnetron-sputtering winding coating machine, a negative electrode target can be timely and rapidly replaced when the coating vacuum chamber is not opened, and multiple film layers can be coated by virtue of the reciprocating motion of base materials in a film coating process, so that the film coating efficiency is greatly improved; the magnetron-sputtering winding coating machine is particularly suitable for large-scale high-efficiency production.

Owner:常州常工院技术转移有限公司

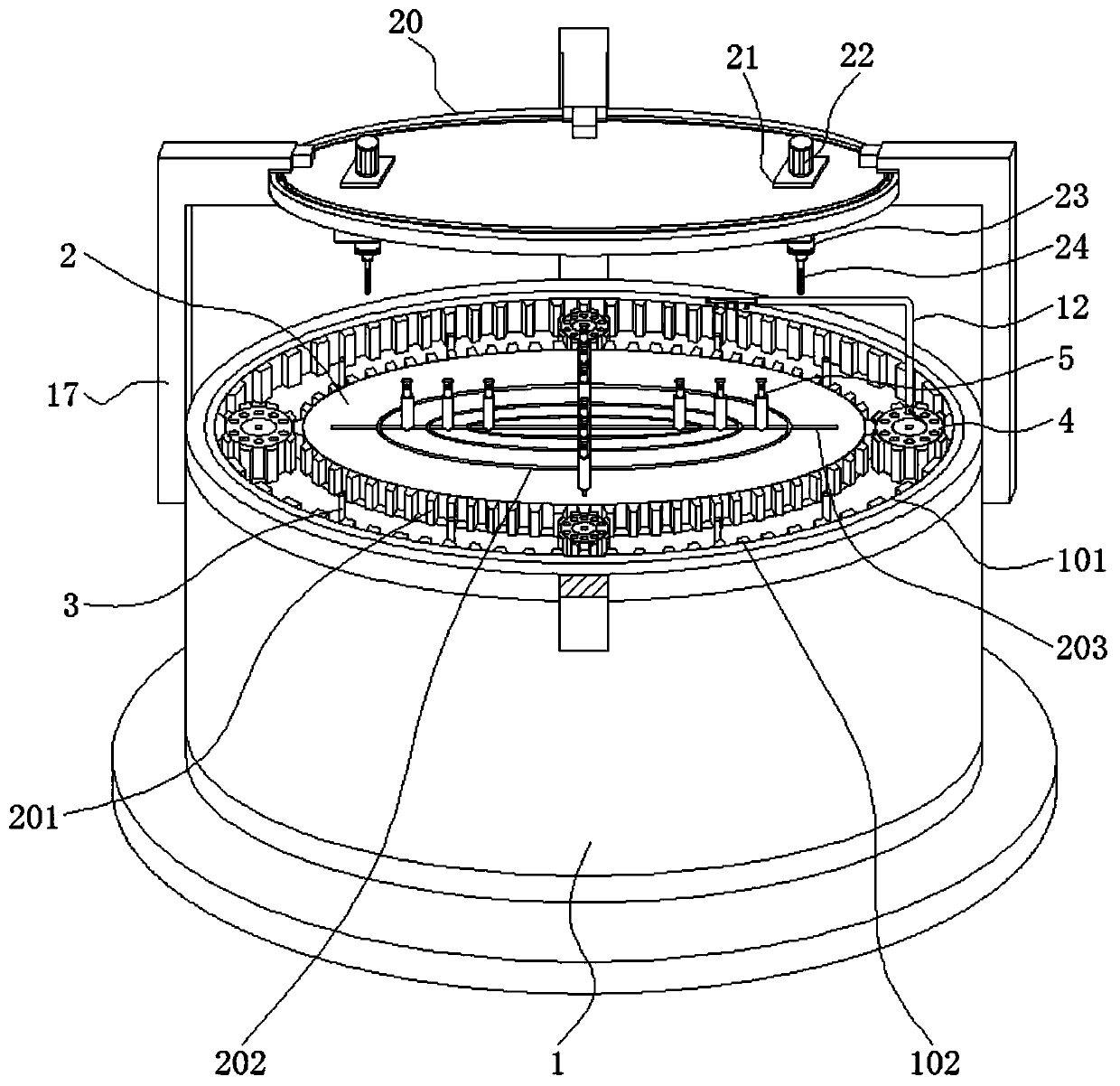

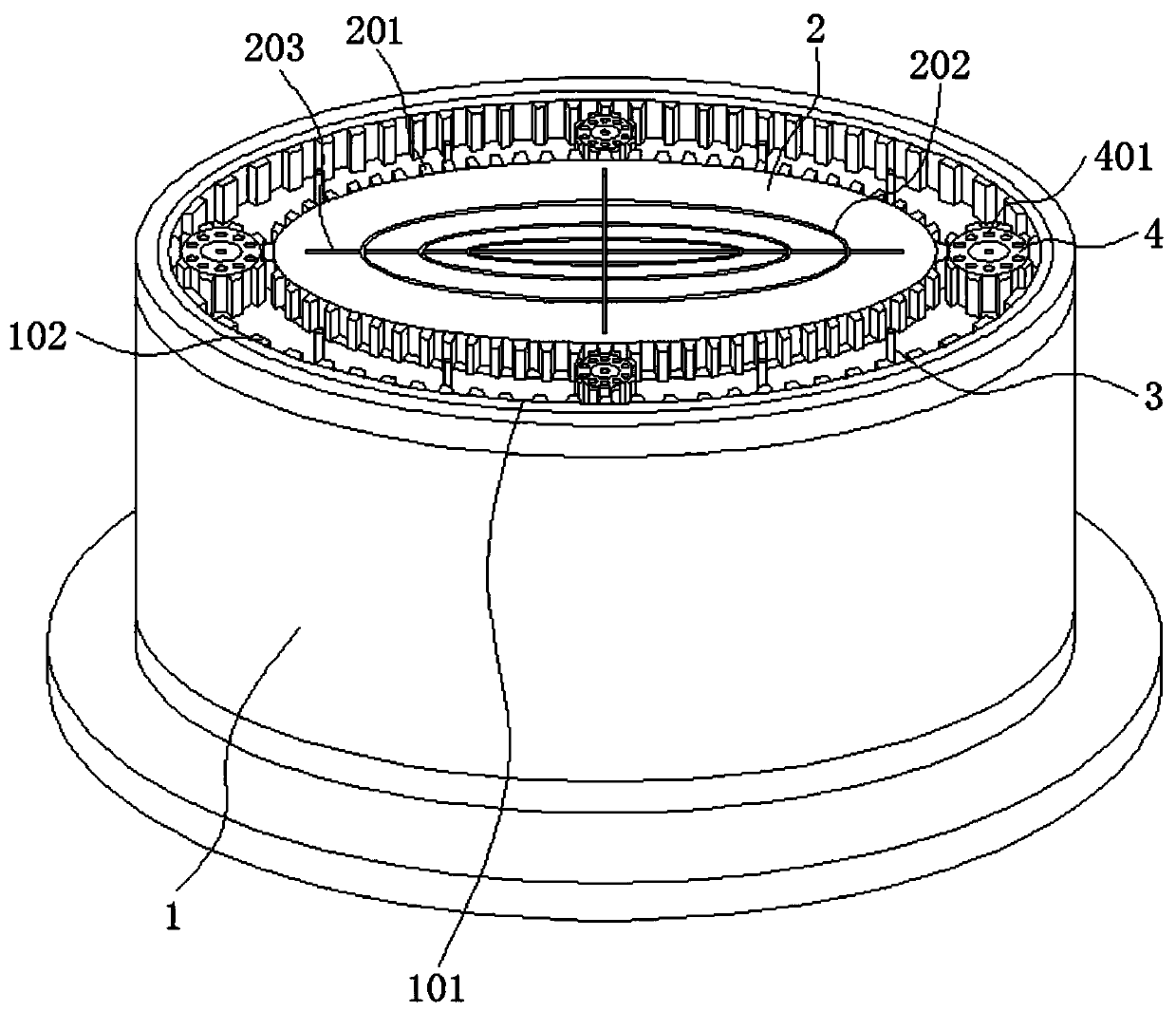

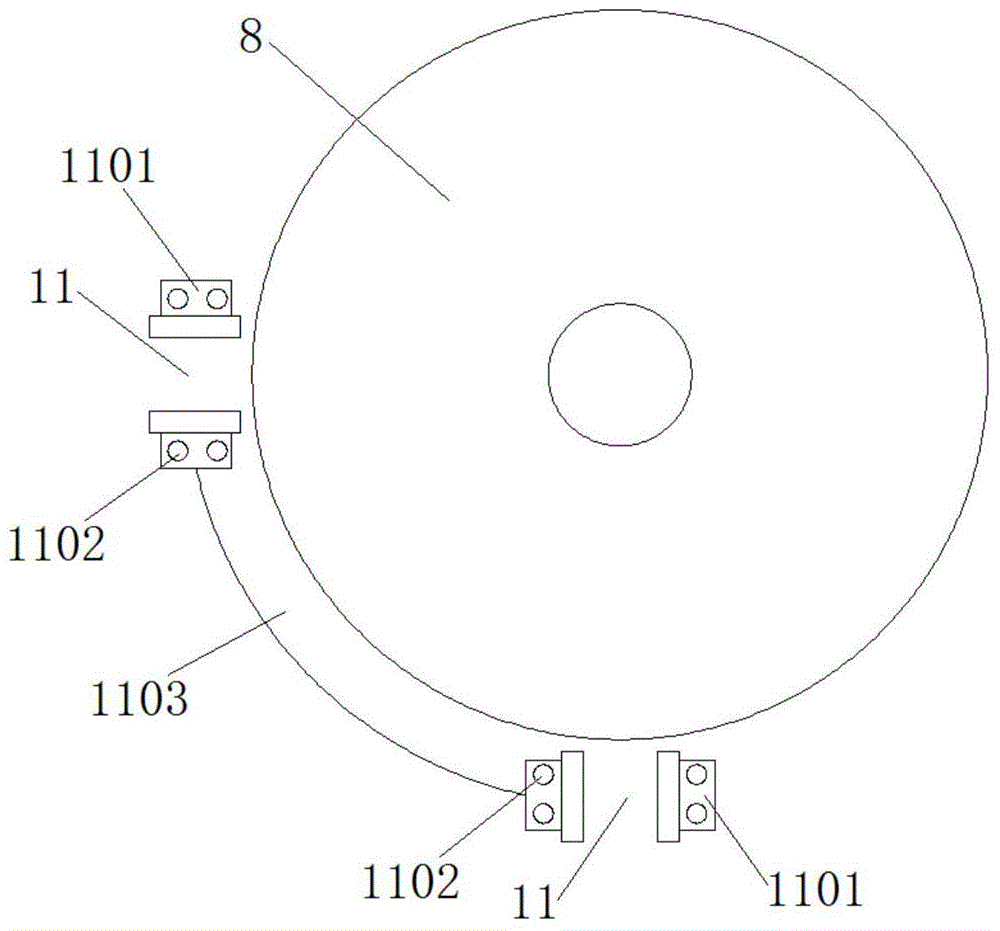

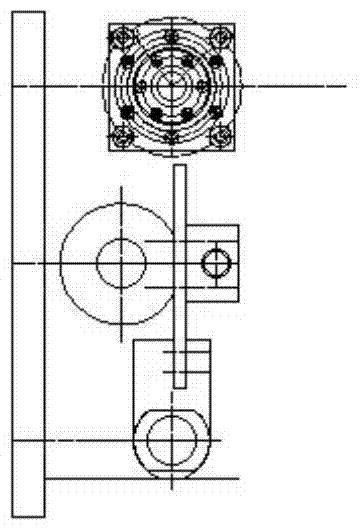

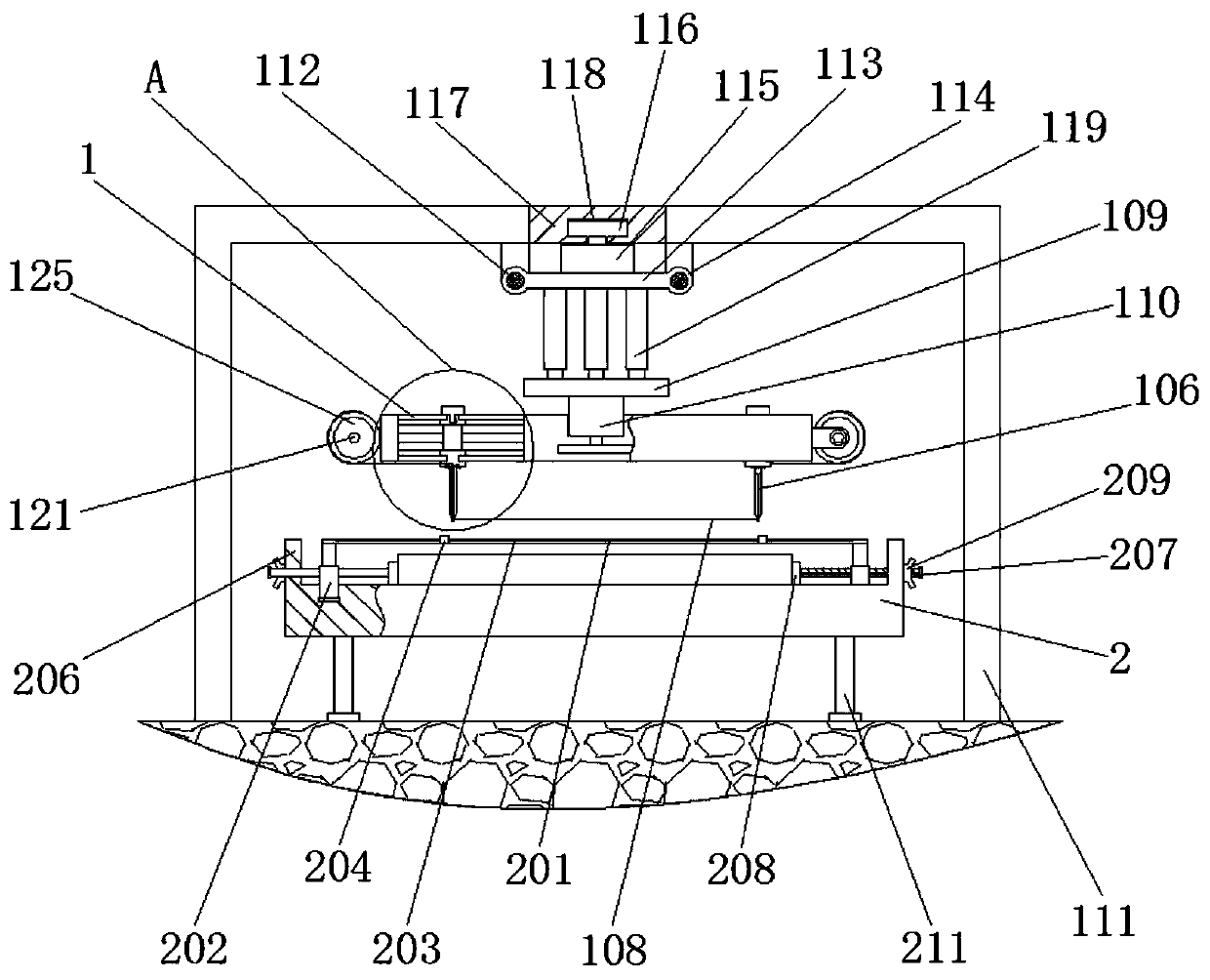

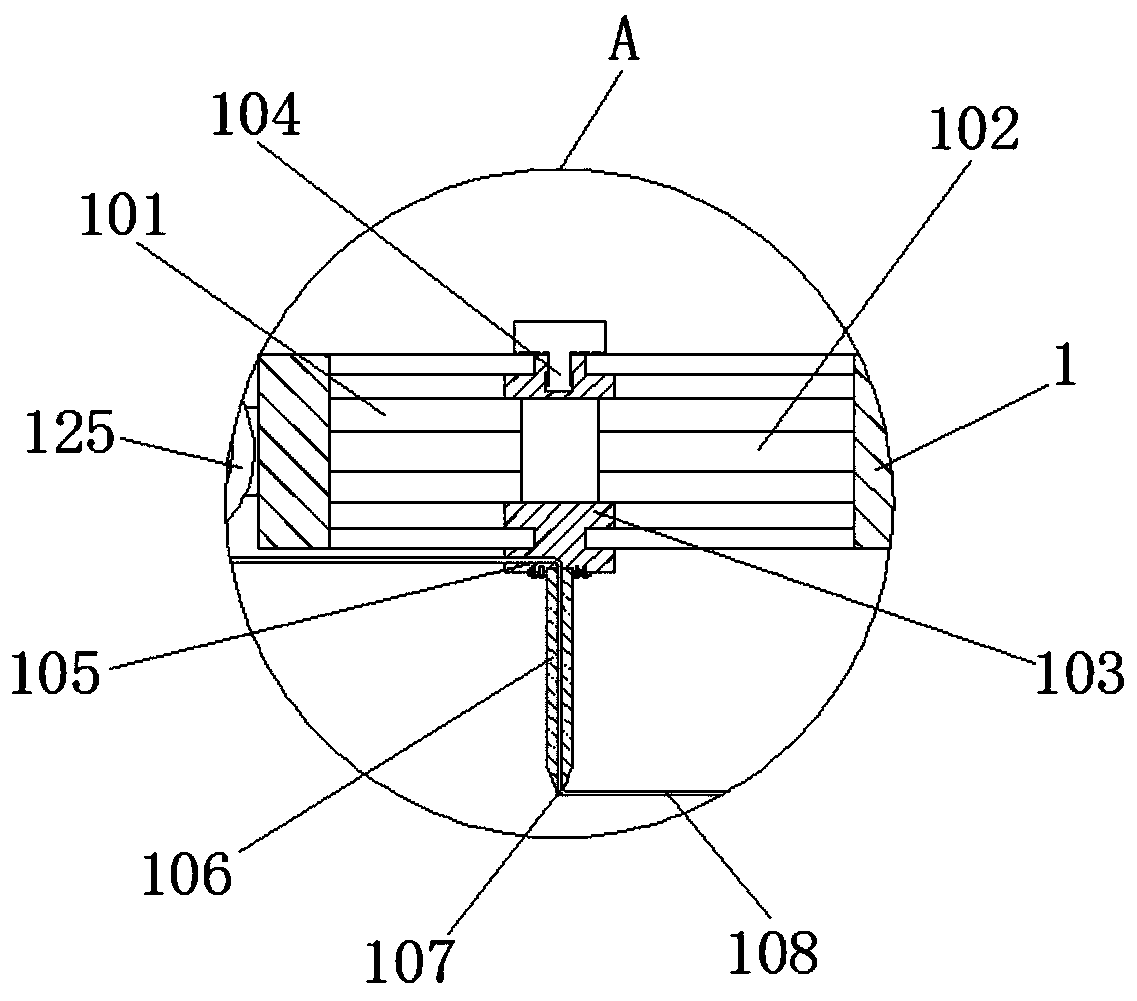

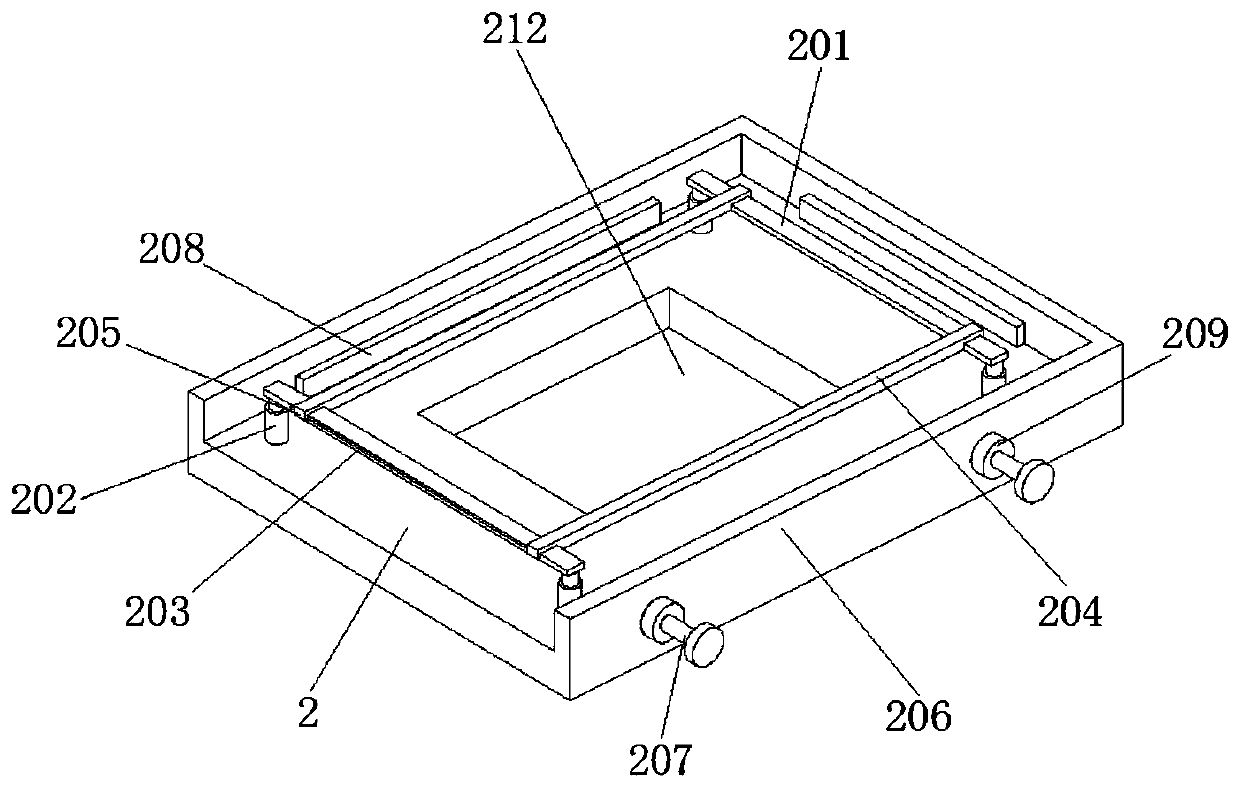

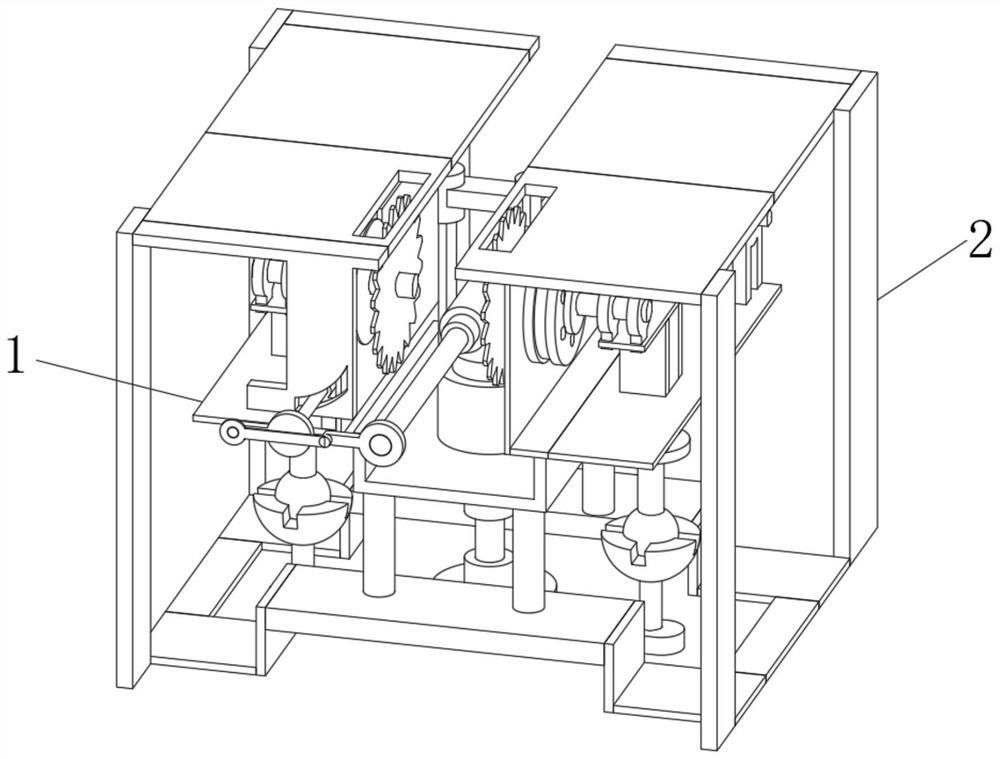

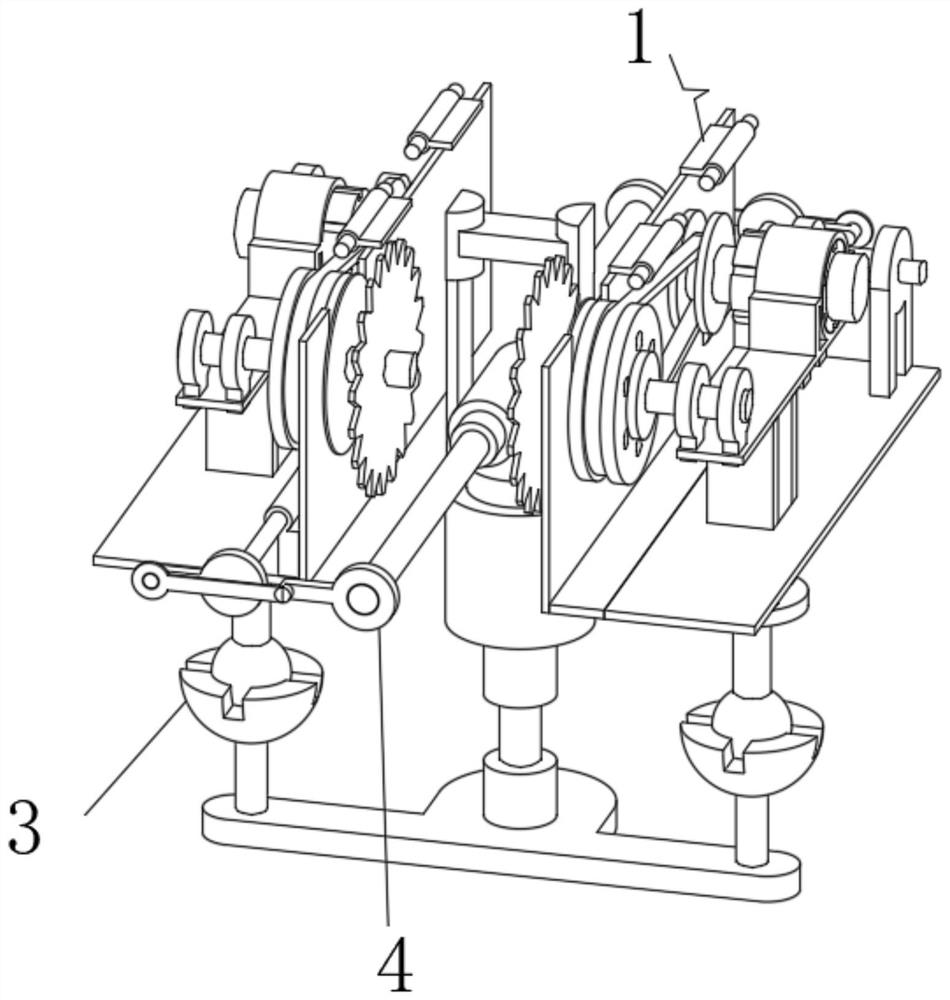

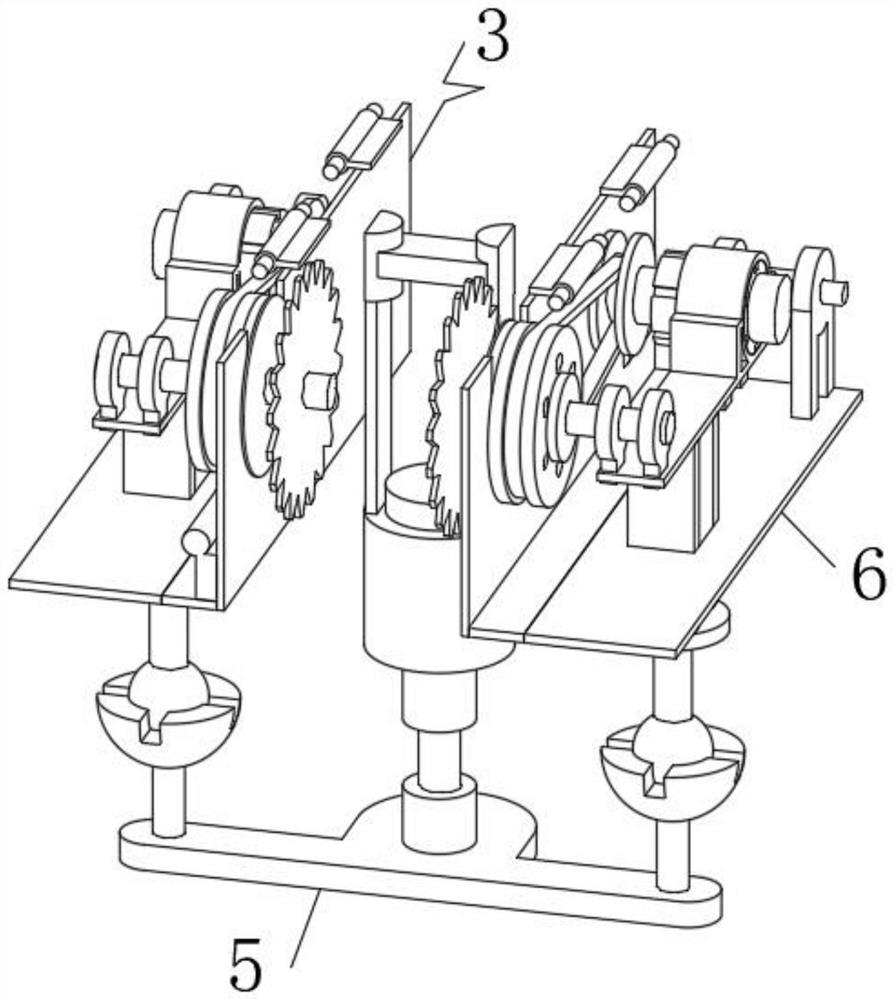

Bearing gear ring gear stripe profiling cutting equipment and machining technology

PendingCN111390297ARealize circular movementAvoid interferenceFeeding apparatusCleaning using gasesStructural engineeringMachining process

The invention discloses bearing gear ring gear stripe profiling cutting equipment and a machining technology, and relates to the technical field of bearing gear ring gear stripe machining. Specifically, a base, a rotation disc, a fixing mechanism, a scrap blowing mechanism, supports and a tool rotation disc are included. The edge of the upper surface of the base is provided with a ring groove. Therotation disc is rotationally matched to the center position of the upper surface of the base. The fixing mechanism is arranged above the base through an arc groove and a linear groove. The scrap blowing mechanism is inserted and connected in an inserting hole. The supports are welded to the position above the outer side wall of the base at equal intervals. The tool rotation disc is clamped and placed in a clamp groove. According to the bearing gear ring gear stripe profiling cutting equipment and the machining technology, a tool and a workpiece can move and are opposite in moving direction,during tooth-shaped structure machining is conducted on the workpiece, the problem of interference in the tool moving process can be effectively prevented, the workpiece tooth-shaped structure machining process is stably and reliably conducted, and the machining quality is effectively guaranteed.

Owner:WUXI YITONG PRECISION MACHINERY

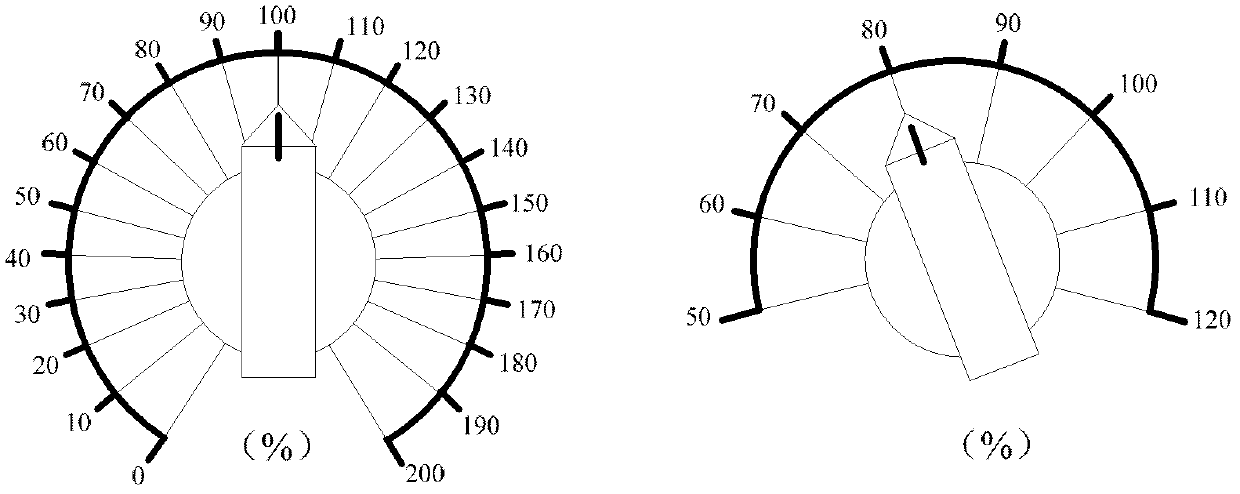

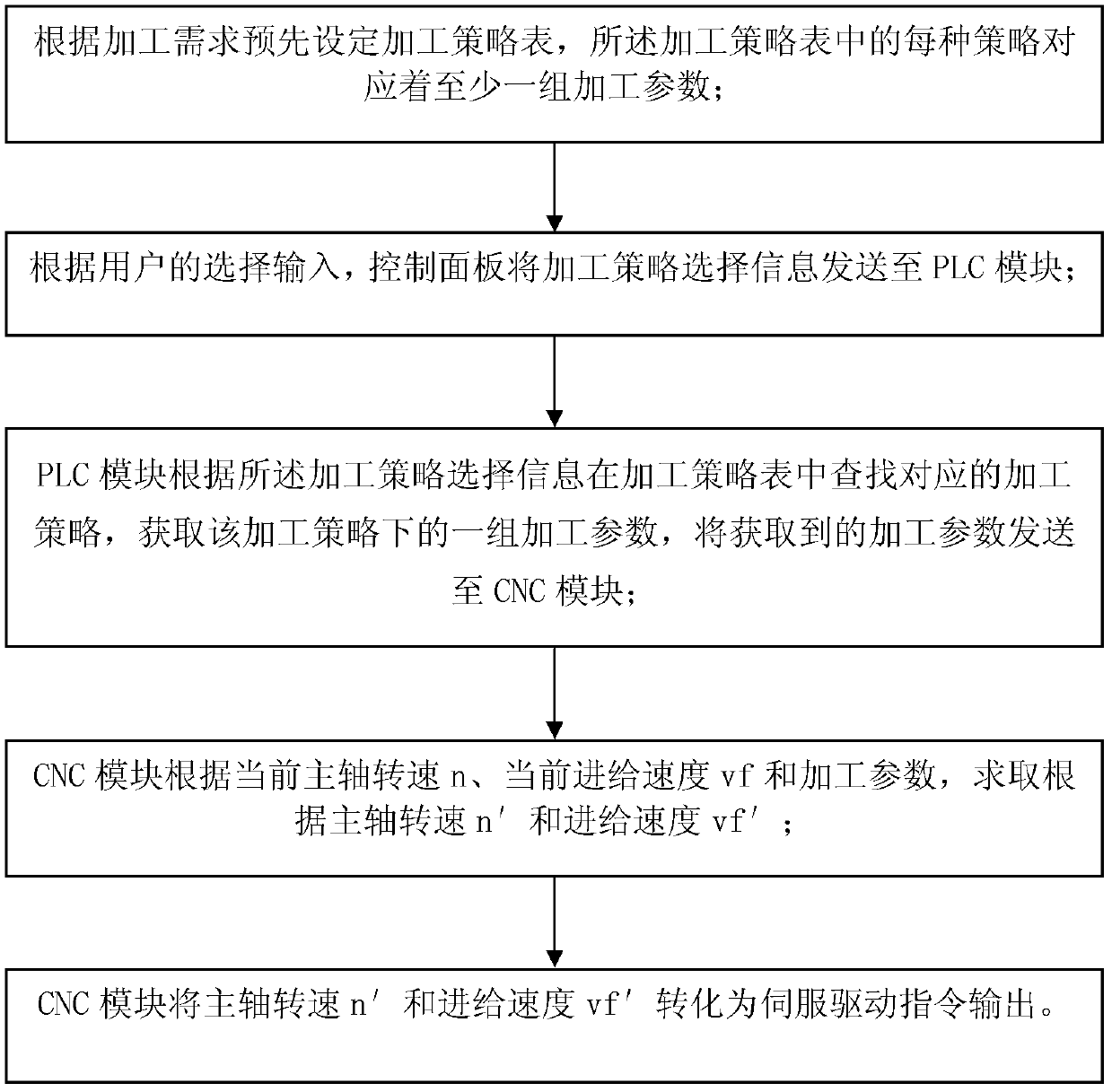

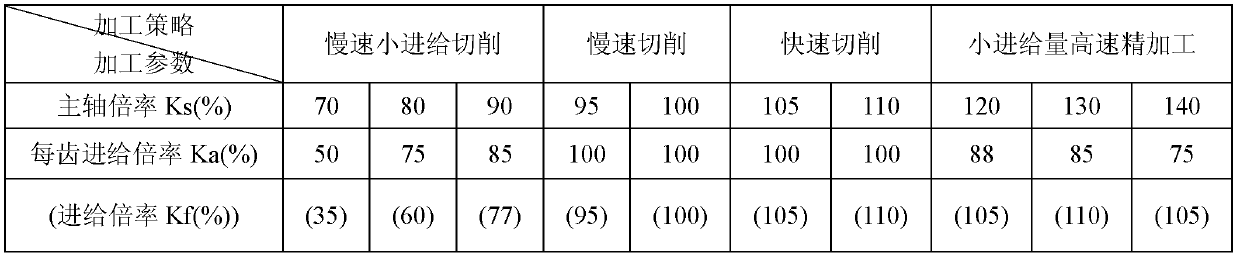

Ratio control method for realizing different processing strategies

ActiveCN103372788ATo achieve the purpose of processingEasy to operateAutomatic control devicesFeeding apparatusNumerical controlProgrammable logic controller

The invention provides a ratio control method for realizing different processing strategies. The ratio control method includes that a processing strategy table is preset according to processing needs, each strategy on the processing strategy table corresponds to at least one group of processing parameters; a control panel transmits selection information of the processing strategy to a PLC (programmable logic controller) module according to selection input of a user; the PLC module acquires the group of processing parameters under the processing strategy and transmits the acquired processing parameters to a CNC (computer numerical control) module; the CNC module calculates spindle speed n' and feed speed vf'; the CNC module converts the spindle speed n' and the feed speed vf' into servo drive instructions to be outputted. Due to the fact that one processing strategy is needed to be selected to adjust various processing parameters to achieve the processing purpose, the ratio control method is convenient and simple to operate, and the technical defect that the various parameters adjusted separately are easy to cause accidents can be overcome.

Owner:KEDE NUMERICAL CONTROL CO LTD

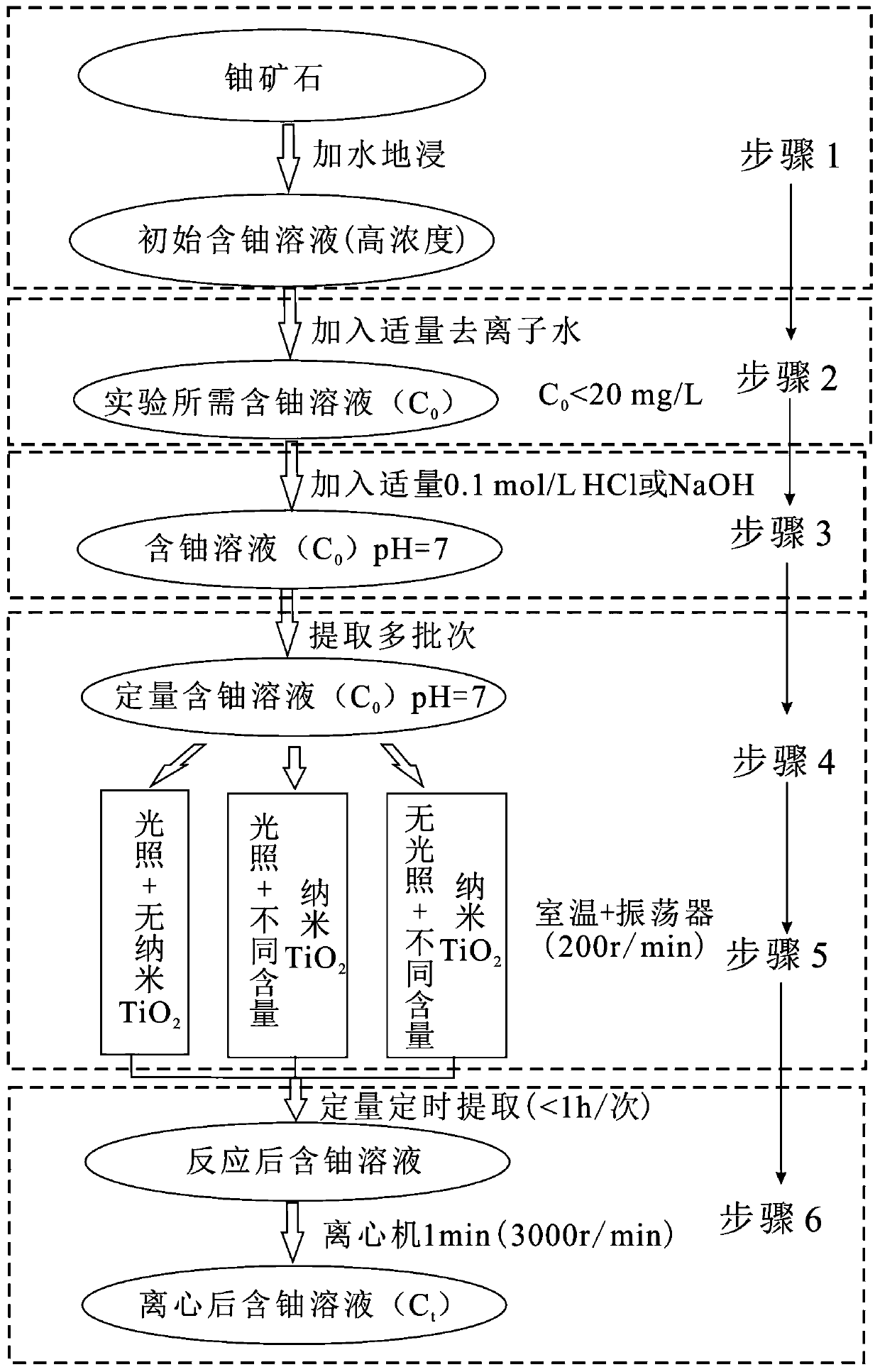

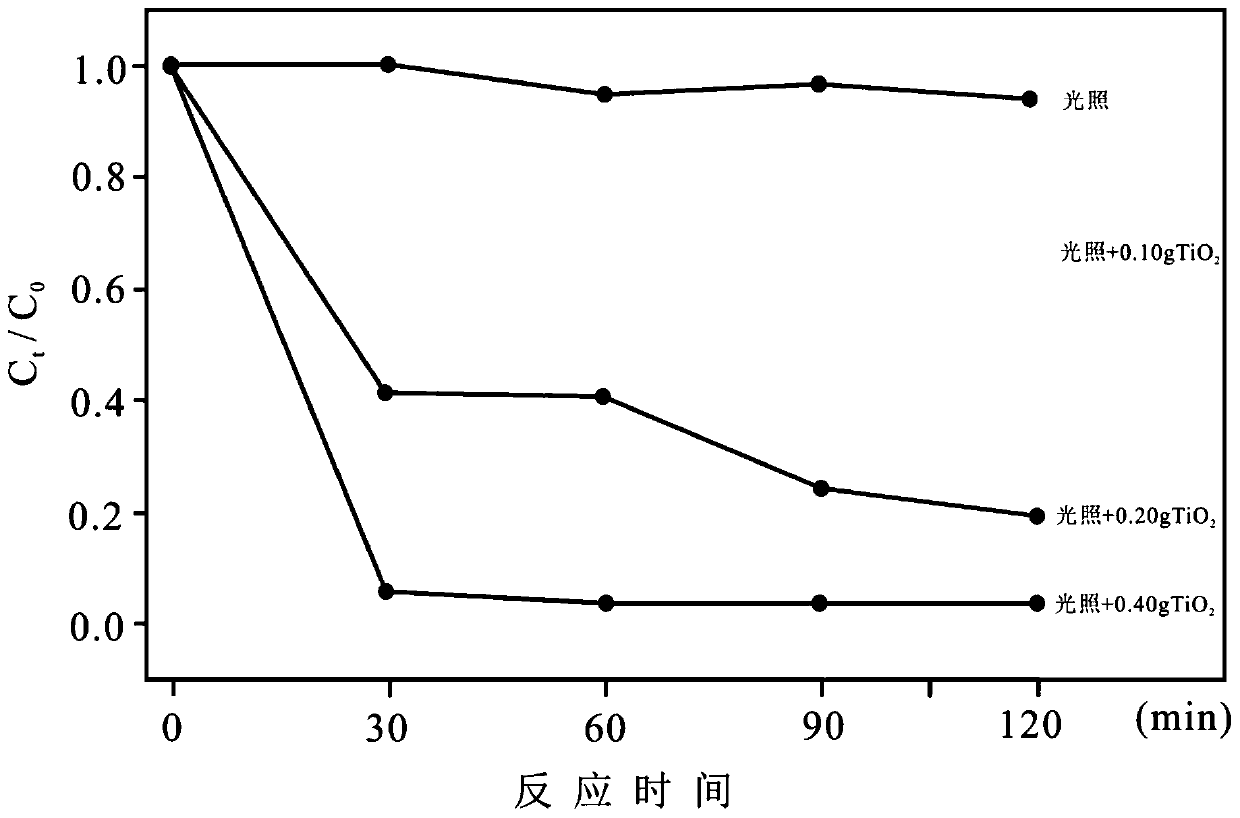

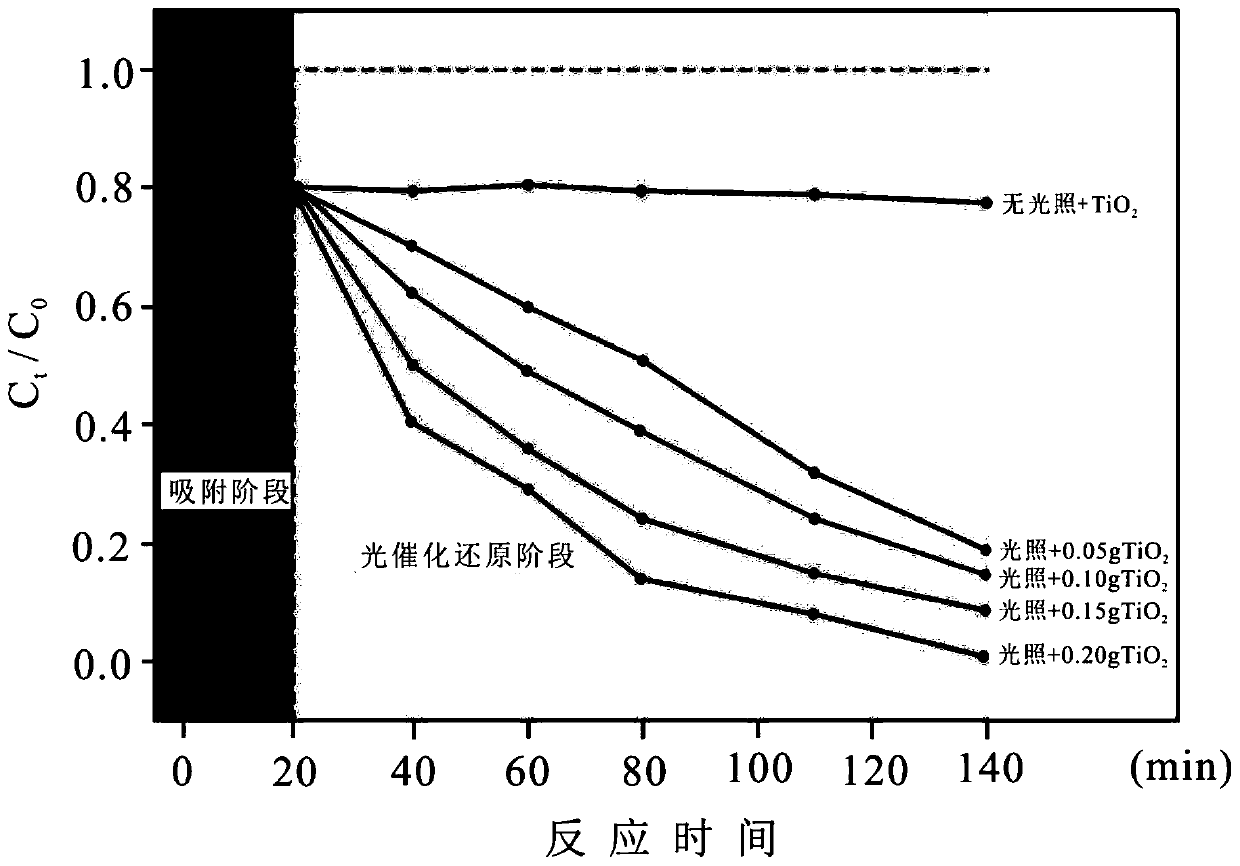

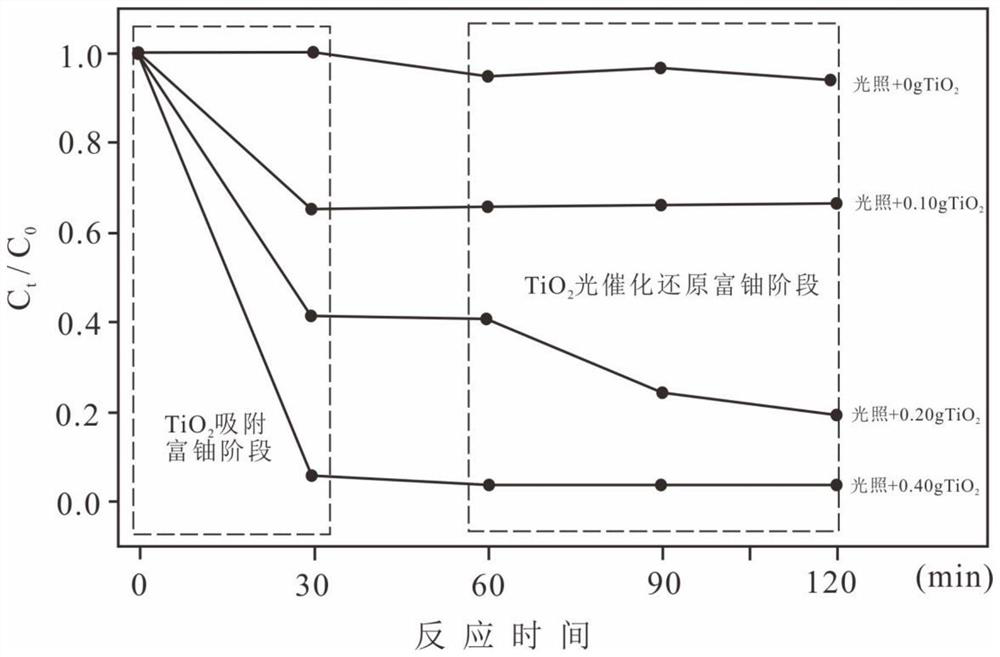

Method for treating uranium-containing wastewater by TiO2 adsorption-photocatalytic reduction

InactiveCN110655243ATo achieve the purpose of processingReduce energy consumptionWater/sewage treatment by centrifugal separationWater/sewage treatment by irradiationUranium minePhoto catalysis

The invention belongs to the field of uranium mine environment treatment, in particular, relates to a method for treating uranium-containing wastewater by TiO2 adsorption-photocatalytic reduction, andaims to provide a novel material for radioactive uranium-containing wastewater treatment. The method is characterized in that a TiO2 photocatalytic reduction technology is introduced into a uranium-containing wastewater treatment process; nano TiO2 is added into the uranium-containing wastewater, the feasibility that the TiO2 treats U (VI) in the uranium-containing wastewater through the adsorption-photocatalytic reduction effect is demonstrated, 99.0% of uranium in the uranium-containing wastewater can be fixed to the maximum extent, and the nano TiO2 can be used as a novel material for treating the uranium-containing wastewater. The method has the advantages of low energy consumption, no toxicity, good selectivity, rapidness, high efficiency, capability of being carried out at normal temperature and normal pressure and the like; the novel material TiO2 is different from other adsorption and reduction materials for treating the radioactive uranium-containing wastewater, has adsorption-autocatalytic reduction dual properties, and can achieve the purposes of uranium-containing wastewater treatment and uranium recovery more efficiently.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

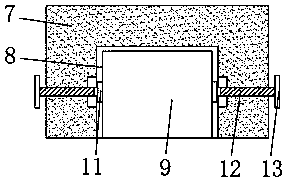

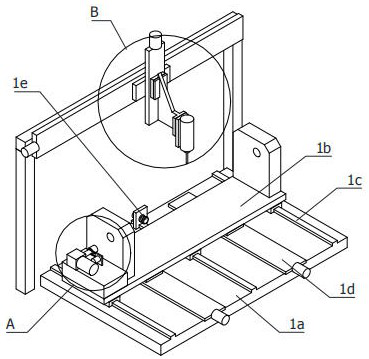

High-efficiency magnetron sputtering winding coating machine capable of continuously coating in double-sided reciprocated way

ActiveCN104674176ANeat winding edgeImprove efficiencyVacuum evaporation coatingSputtering coatingReciprocating motionMaterials science

The invention discloses a high-efficiency magnetron sputtering winding coating machine capable of continuously coating in a double-sided reciprocated way, belonging to the field of vacuum coating equipment. The high-efficiency magnetron sputtering winding coating machine comprises a vacuum chamber, an unrolling mechanism, a rolling mechanism, cooling rollers, error correcting devices and rotary target replacing devices, wherein a base band arranged between the unrolling mechanism and the rolling mechanism is wound on the two groups of cooling rollers in an S shape after being reversed by using reversing rollers arranged in the vacuum chamber, and the unrolling mechanism and the rolling mechanism are respectively provided with a group of error correcting device; the base band coated peripheral surface of each group of cooling roller is correspondingly provided with the two groups of rotary target replacing devices at least, and a group of small cathode chamber provided with openings in two sides is arranged between each group of rotary target replacing device and the cooling roller corresponding to the rotary target replacing device; and the unrolling mechanism and the rolling mechanism drive the base band to reciprocate. By using the high-efficiency magnetron sputtering winding coating machine, targets can be replaced in time under the condition that the vacuum chamber is not opened, and a plurality of double-sided film layers are continuously coated by virtue of reciprocation design of the double cooling rollers and a base material, so that double-sided coating efficiency of the coating machine is greatly increased; and the high-efficiency magnetron sputtering winding coating machine is compact in structure and small in occupied space.

Owner:广东雄华新材料科技有限公司

Method for machining composite components

InactiveCN102331742ARealize processing operationsTo achieve the purpose of processingProgramme-controlled manipulatorNumerical controlEngineeringMachine tool

The present disclosure relates to a method for machining composite components in a CNC controlled machining station. In accordance with the present disclosure, a machining tool is guided along a preset tool edge by means of a measuring system, wherein it simultaneously carries out the machining operation, while the CNC control program to control the machining tool is generated in accordance with the measured result. The present disclosure furthermore relates to an apparatus for the carrying out of the method.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

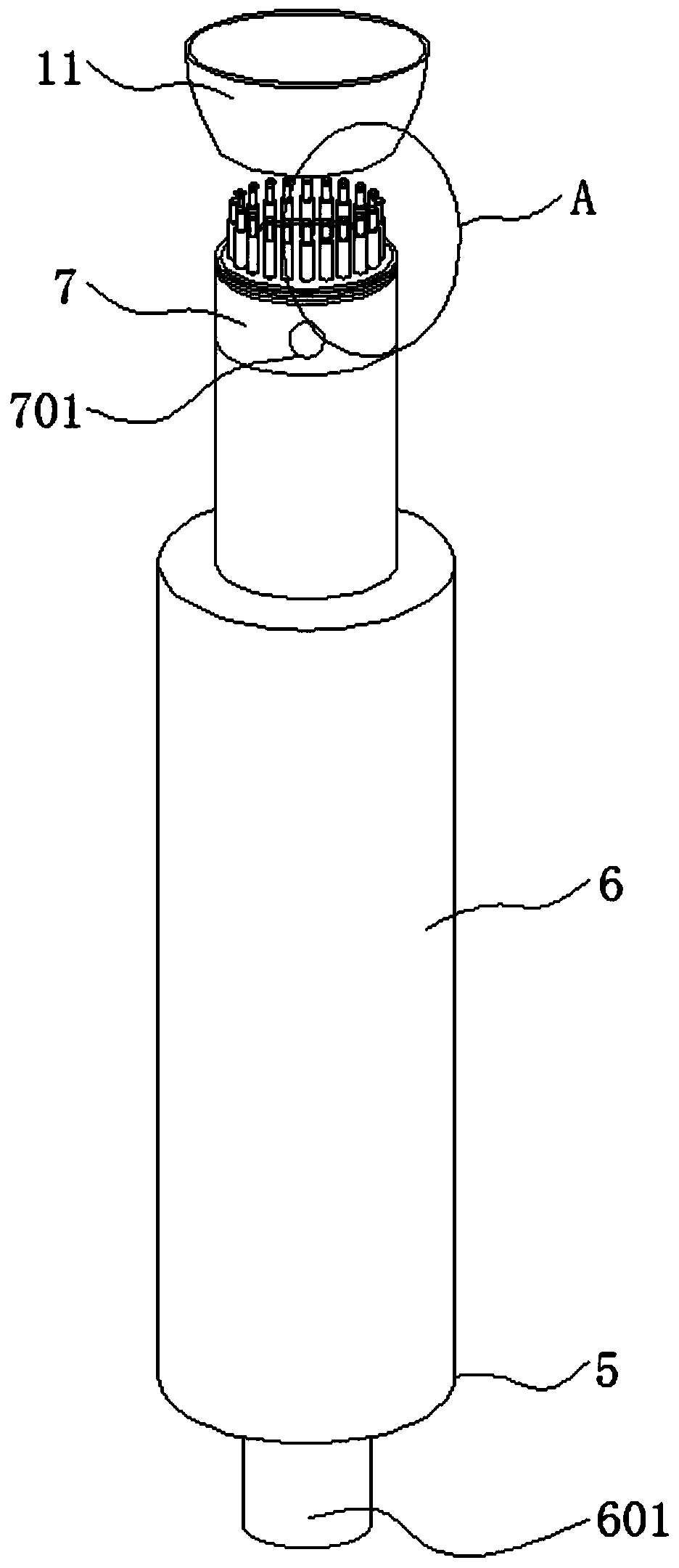

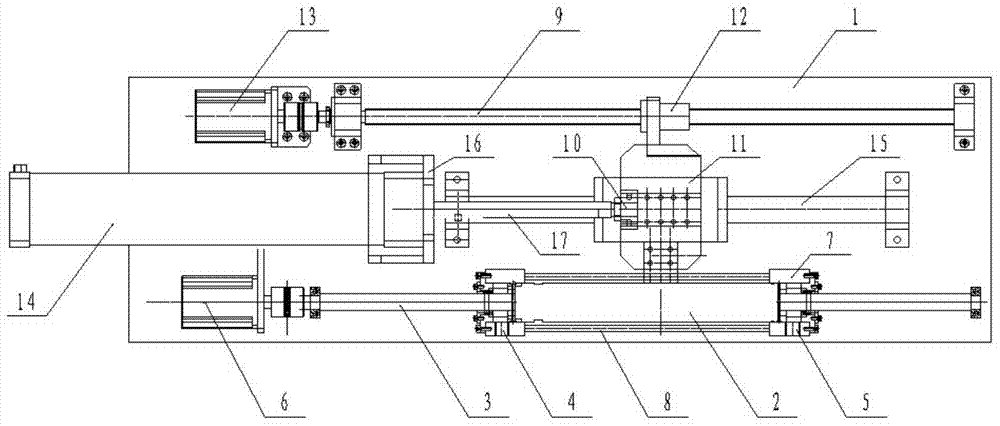

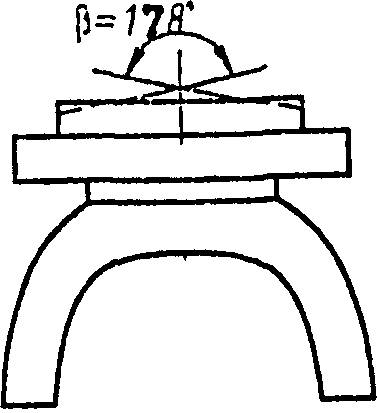

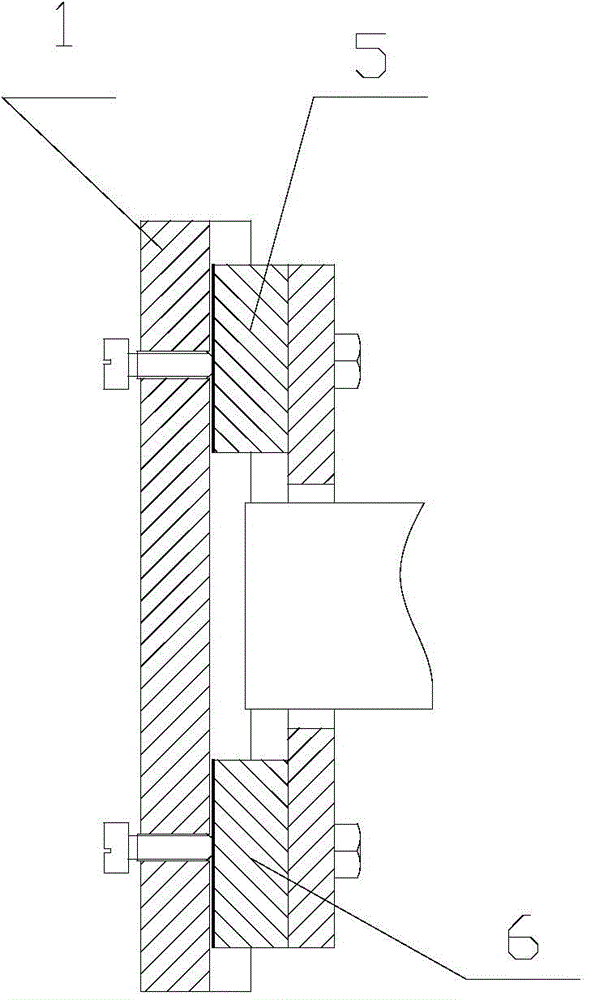

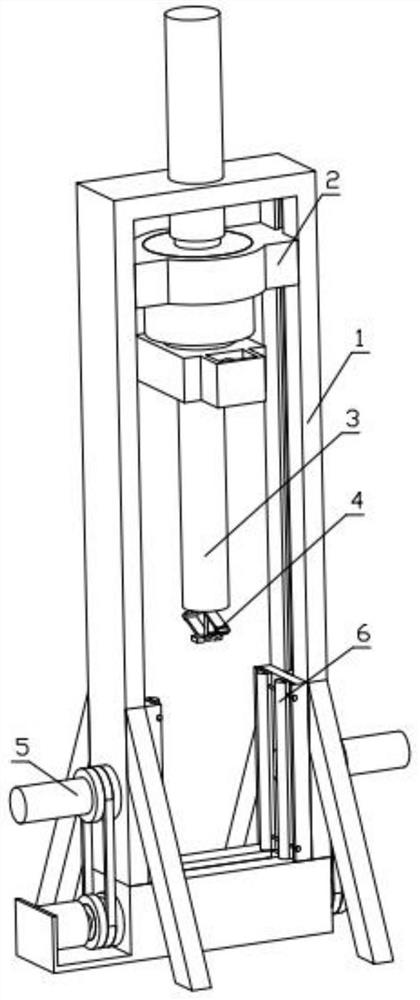

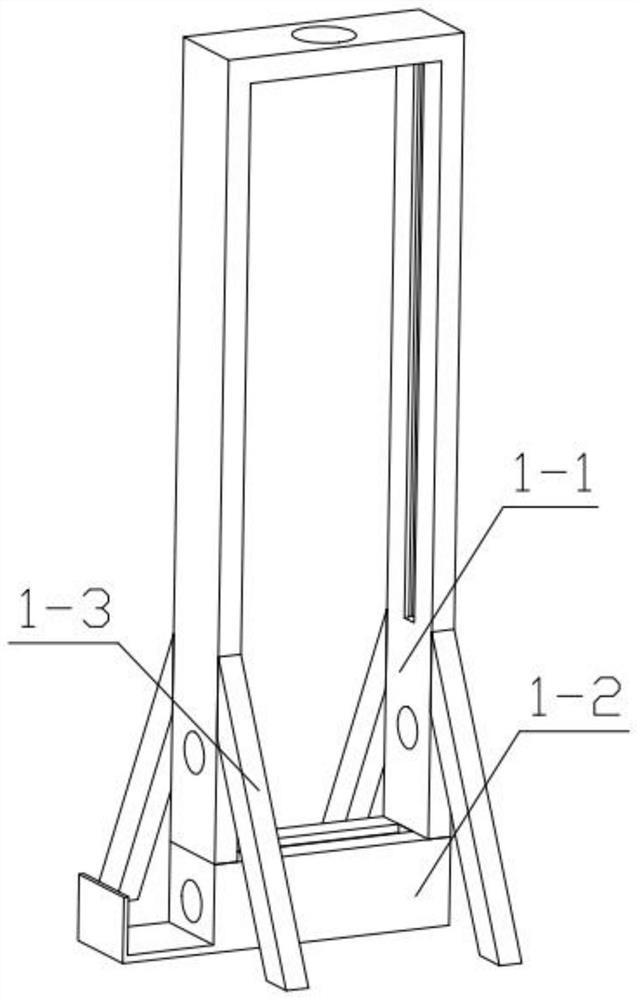

Spiral constrained abrasive flow processing device

ActiveCN104325411AImprove flow performanceThe processing effect is completely controllableAbrasive machine appurtenancesAbrasive blasting machinesEngineeringMechanical engineering

The invention discloses a spiral constrained abrasive flow processing device. The spiral constrained abrasive flow processing device is used for grinding and processing the inner wall of a workpiece to be processed, and comprises a fixed plate, a spiral constrained processing device, a workpiece clamping device, a workpiece feeding device and a damping device, wherein the spiral constrained processing device, the workpiece clamping device, the workpiece feeding device and the damping device are fixedly mounted on the fixed plate; the workpiece clamping device is used for clamping the workpiece to be processed, the spiral constrained processing device comprises a grinding guide rod and a short spiral groove, the short spiral groove is fixed on the grinding guide rod, the workpiece to be processed is sheathed on the grinding guide rod, and the spiral constrained processing device and the workpiece to be processed form a constrained flow passage in the workpiece to be processed; a fluid inlet and a fluid outlet of the constrained flow passage are formed in the workpiece clamping device; and the workpiece feeding device is used for axial feeding of the workpiece clamping device and the workpiece to be processed. The spiral constrained abrasive flow processing device disclosed by the invention has high polishing efficiency and good polishing effect, and is very suitable for ultra-precise processing of the inner wall.

Owner:ZHEJIANG UNIV OF TECH

Low-k material laser processing device and method

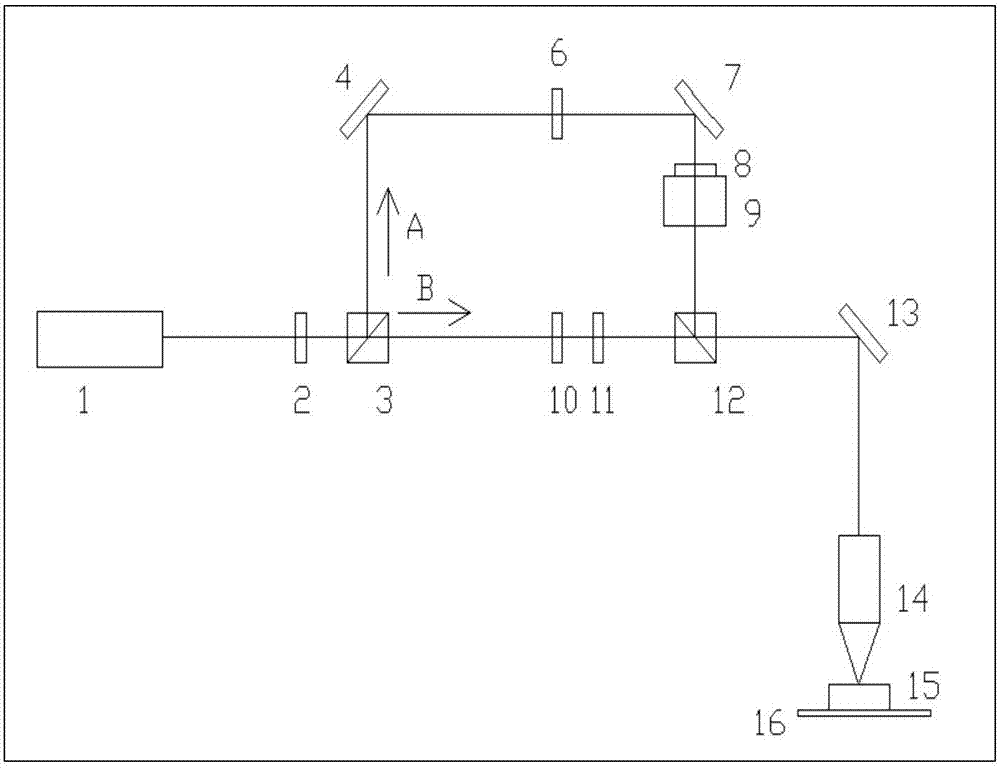

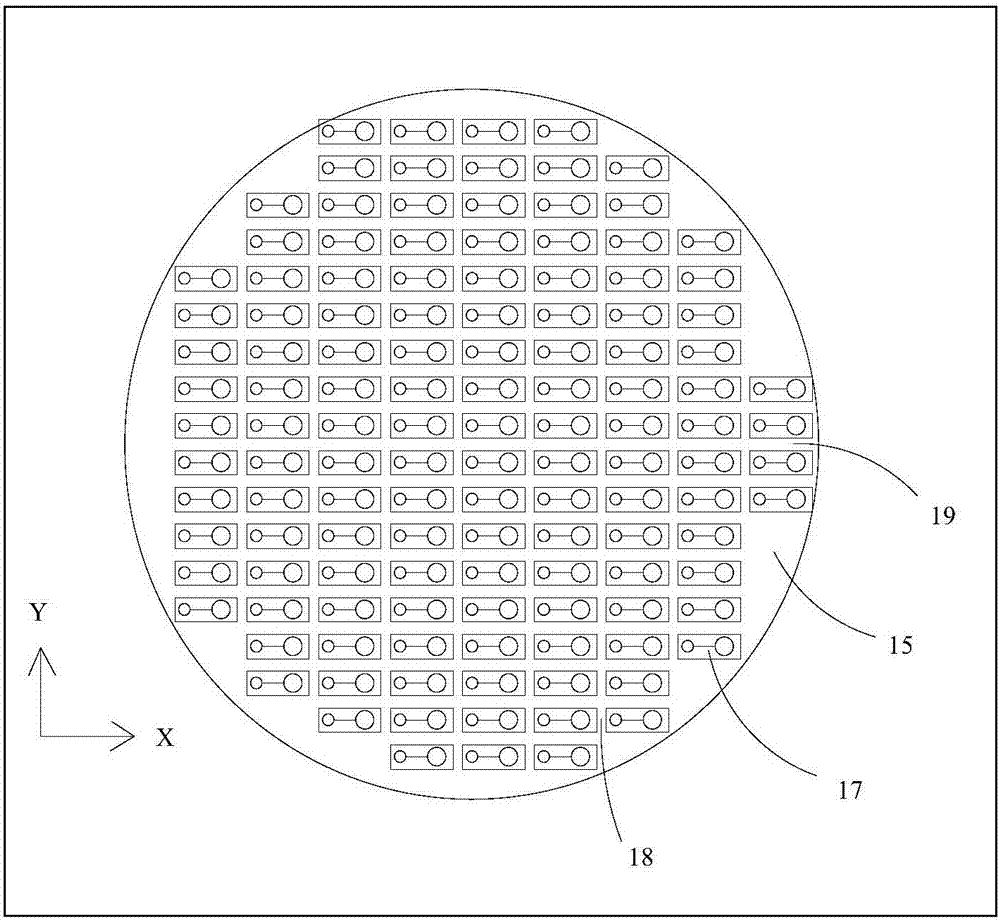

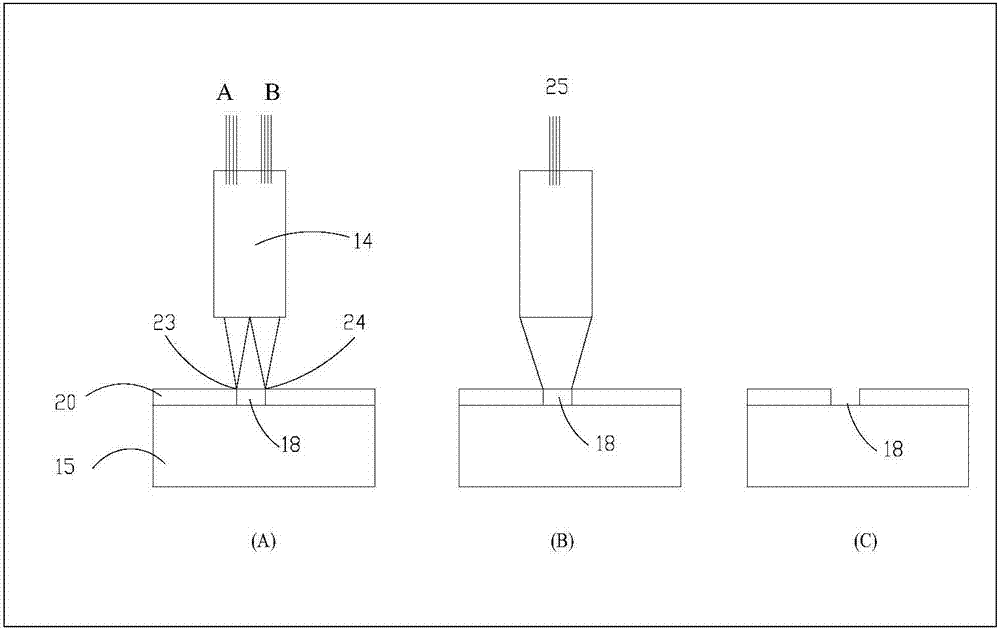

ActiveCN107378259ASimple structureReliable functionLaser beam welding apparatusLaser processingLight beam

The invention relates to the technical field of laser processing, and discloses a low-k material laser processing device and method. A laser beam emitted by a laser device sequentially passes through a half-wavelength plate and a first polarizing film and then is split into a laser beam A and a laser beam B; after sequentially passing through a first 45-degree reflector, a first optical shutter and a second 45-degree reflector, the laser beam A passes through a second optical shutter and selectively enters a laser beam shaper, then the laser beam A sequentially enters a second polarizing film and a third 45-degree reflector, and finally the laser beam A enters a focusing mirror and is focused on a processed material; and the laser beam B sequentially passes through a third optical shutter, a prism, the second polarizing film and a fourth 45-degree reflector, and finally enters the focusing mirror to be focused on the processed material. A low-k layer is cut along a cutting path by using a laser, a groove is formed in the cutting path, a silicon substrate is prevented from being affected by the laser while the low-k material is removed, the processing effect is good, and the processed groove is uniform and free o obvious collapse, wavy grains and the like.

Owner:深圳市大族半导体装备科技有限公司

Material and method for treating uranium-containing wastewater

PendingCN112349443ATo achieve the purpose of processingHas dual properties of adsorption-autocatalytic reductionPhysical/chemical process catalystsRadioactive decontaminationUranium minePhoto catalysis

The invention belongs to the field of uranium mine environment treatment, and discloses a material and method for treating uranium-containing wastewater. According to the method, based on the adsorbability of TiO2, a TiO2 photocatalysis technology is introduced into the field of uranium-containing wastewater; a series of comparative experimental studies prove that TiO2 can treat U (VI) in the uranium-containing wastewater through adsorption-photocatalytic reduction, 99.0% of uranium in the uranium-containing wastewater can be fixed to the maximum extent, so that the TiO2 can be filled into a permeable reactive barrier (PRB) to be used for treating the uranium-containing wastewater and can be used as a novel uranium-containing wastewater treatment material; according to the material, the nano TiO2 is added into auranium-containing wastewater solution. Compared with other methods, the method for treating the uranium-containing wastewater by the TiO2 adsorption and photocatalytic reduction has the advantages of low energy consumption, no toxicity, good selectivity, quickness, high efficiency, capability of being carried out at normal temperature and normal pressure and the like.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

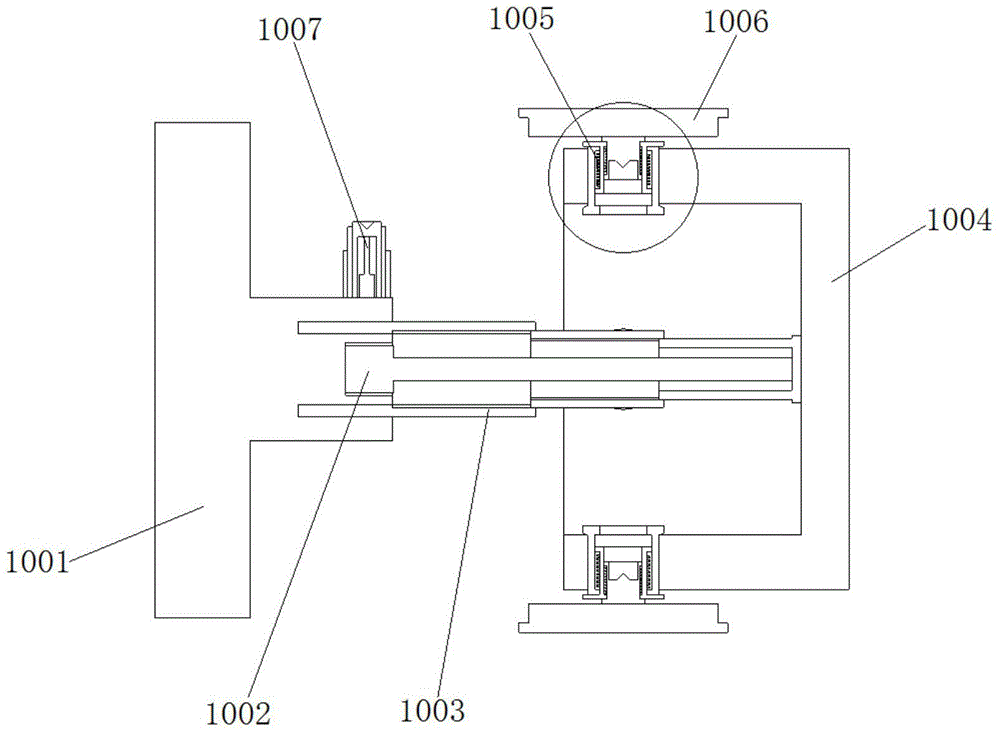

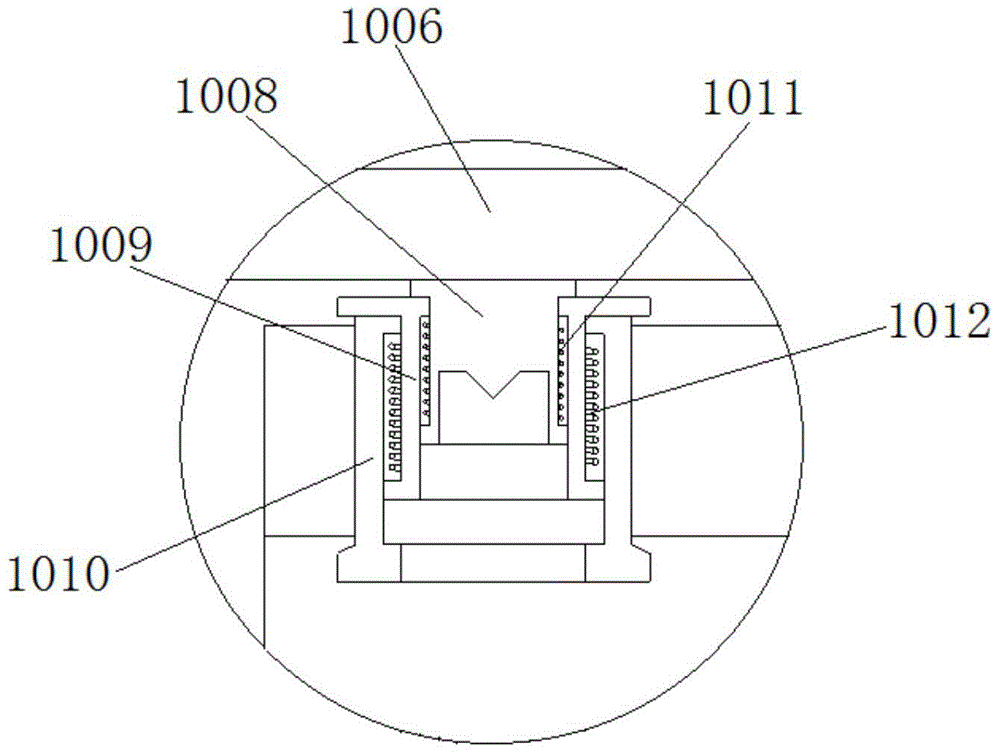

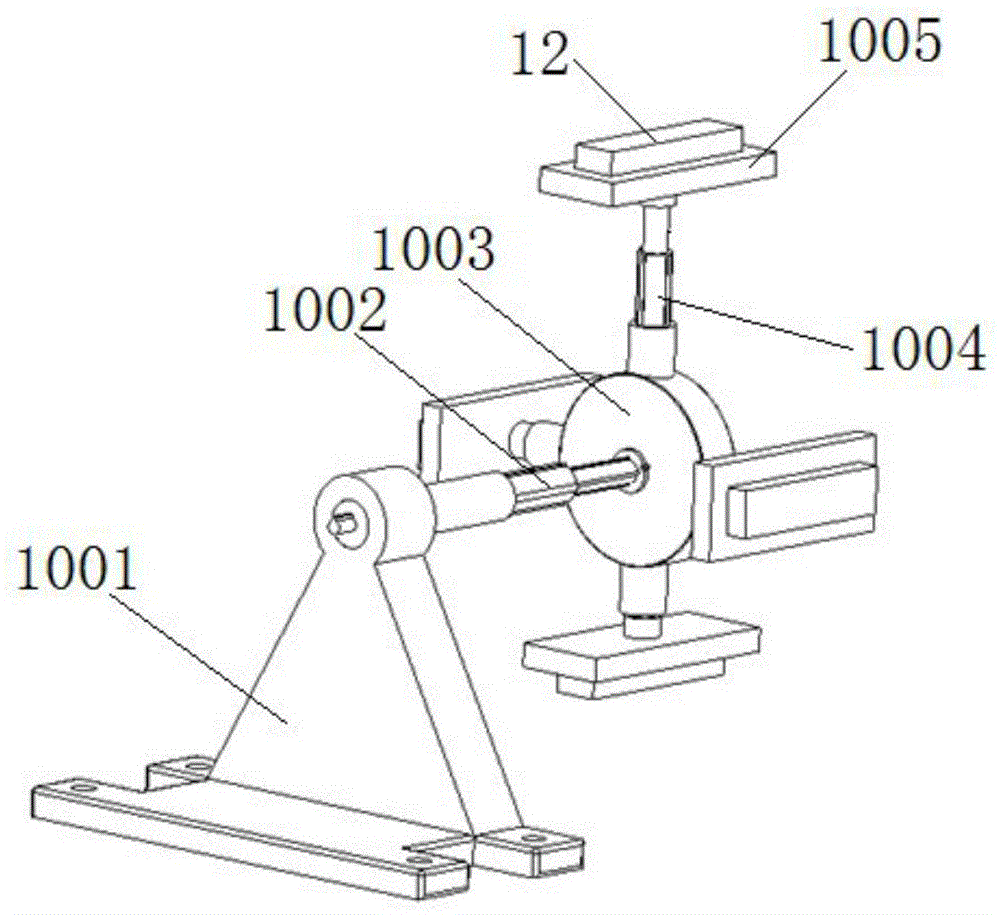

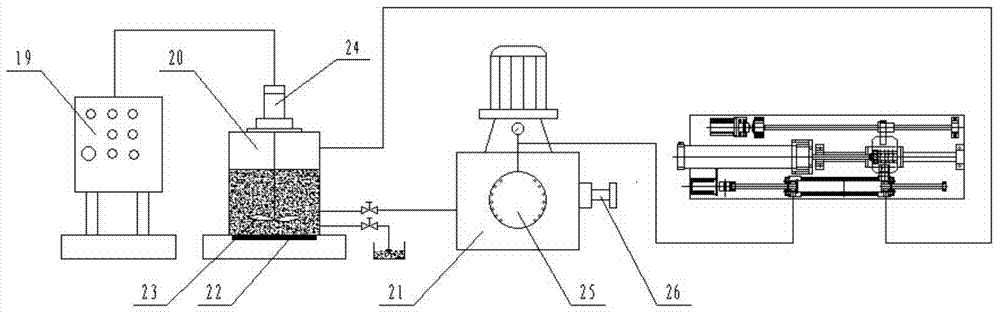

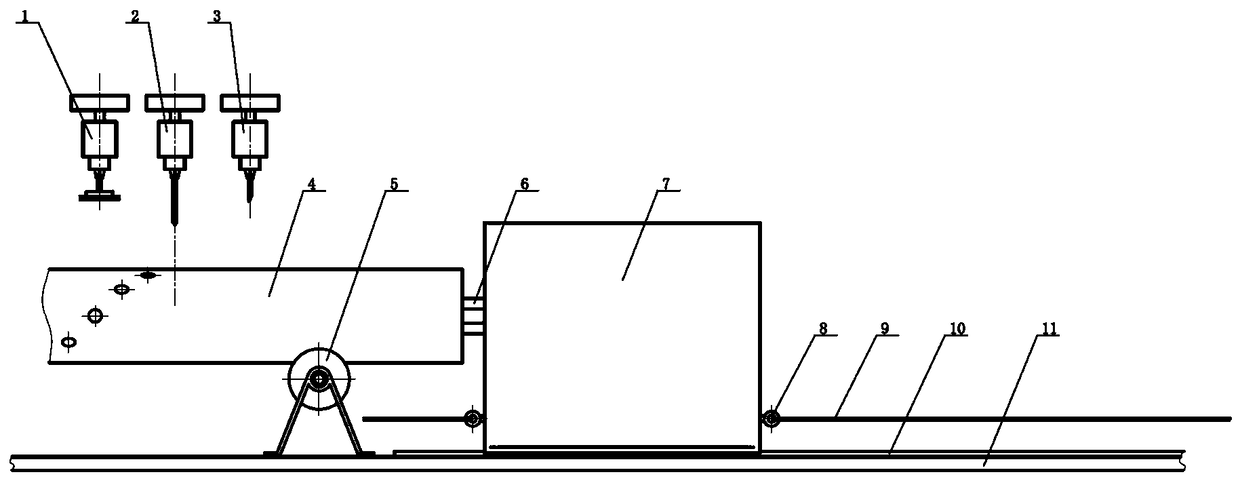

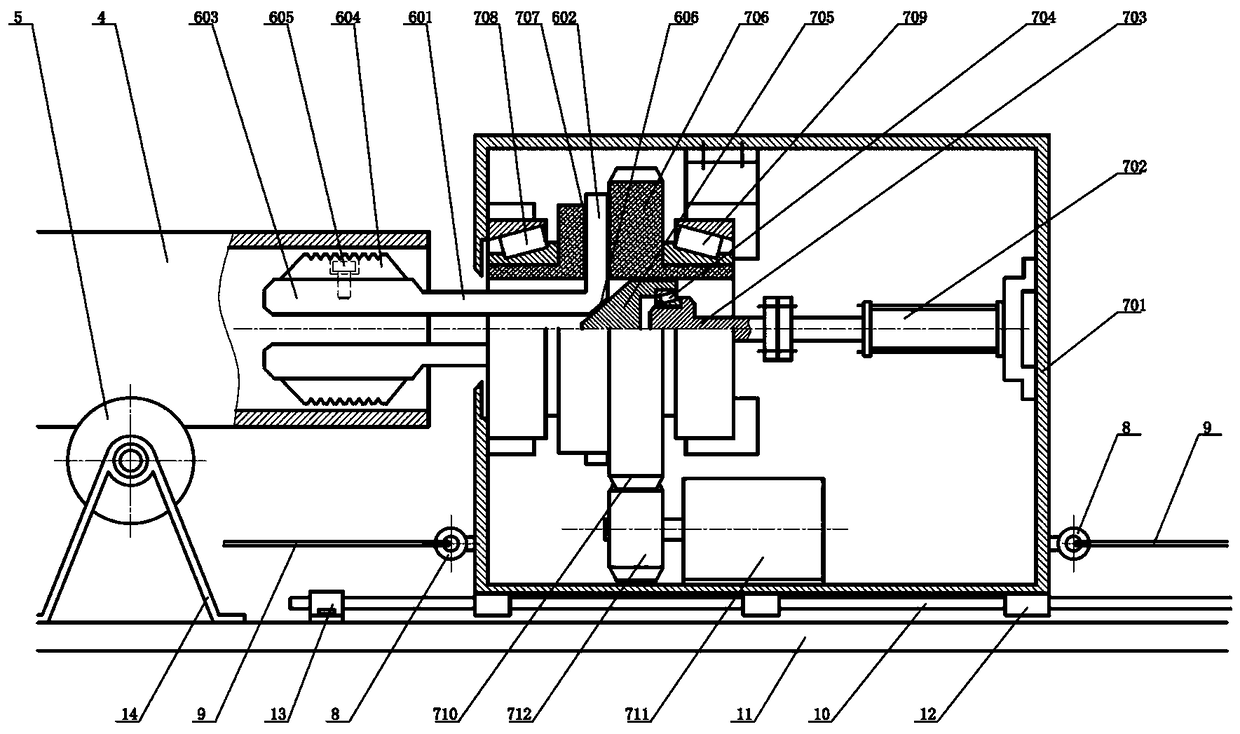

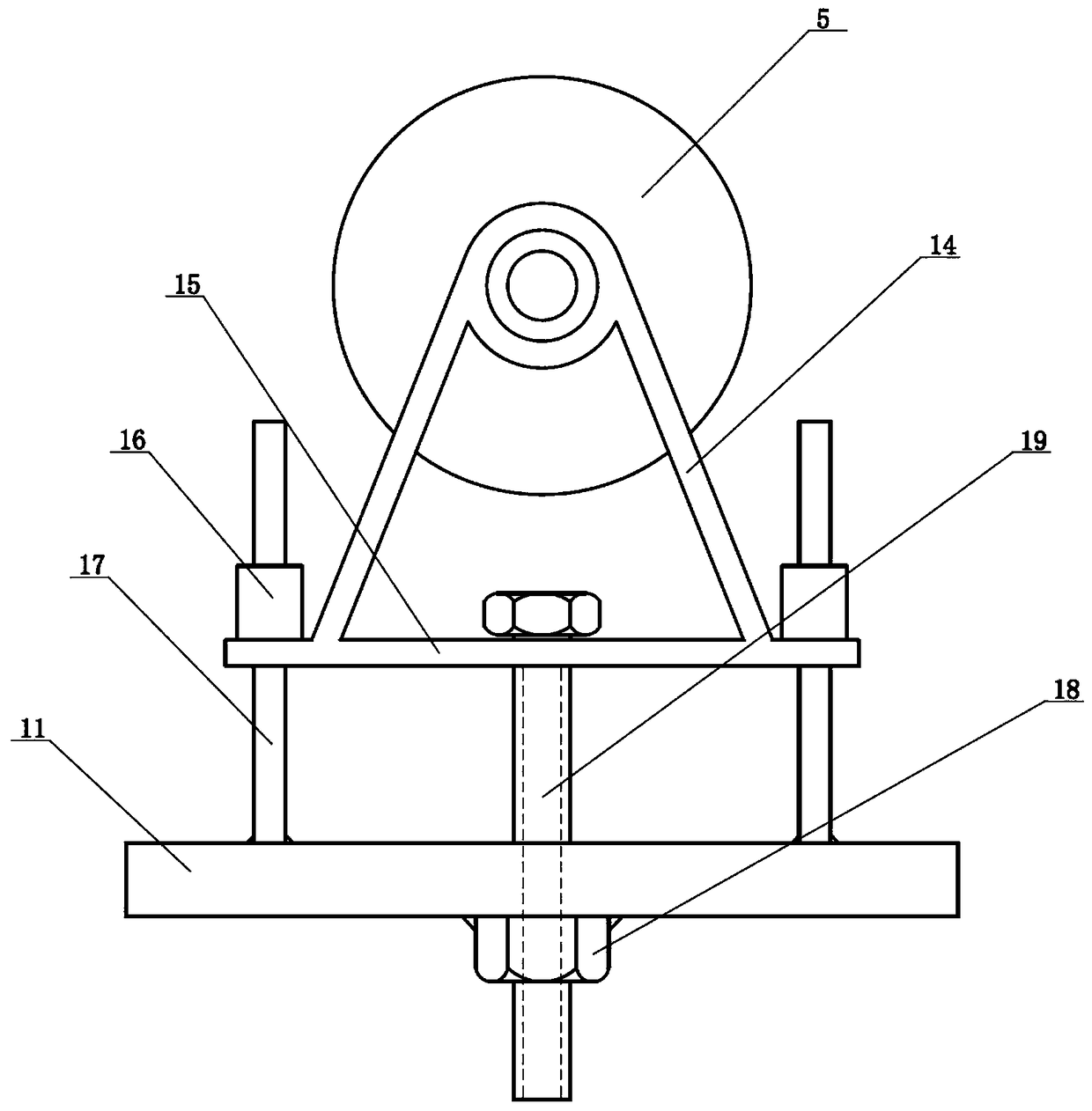

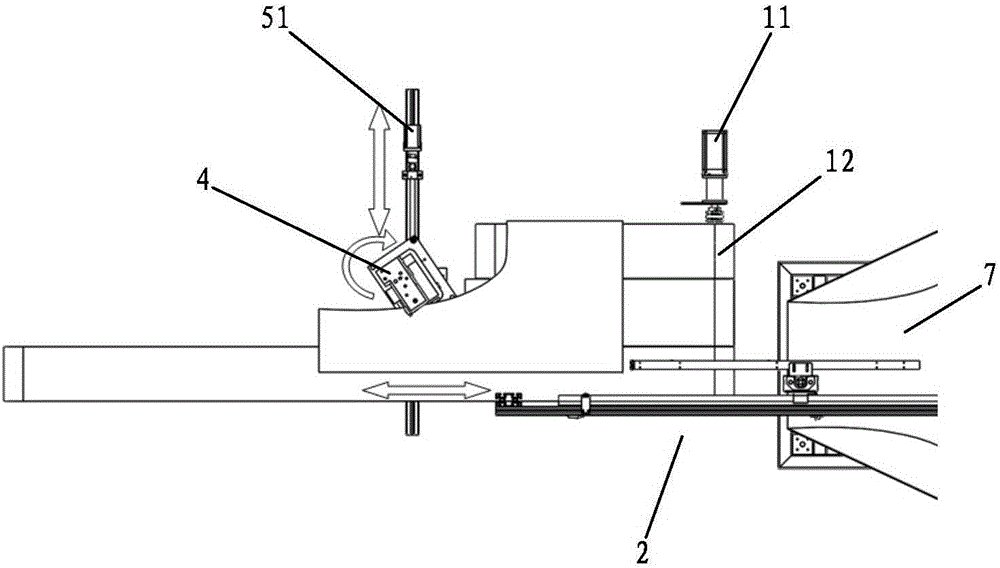

Pipe fitting traction rotation precision machining device

ActiveCN108544234ATo achieve the purpose of processingImprove machining accuracyOther manufacturing equipments/toolsExpansion mandrelsPipe fittingMachining

The invention discloses a pipe fitting traction rotation precision machining device. The pipe fitting traction rotation precision machining device comprises a pipe fitting supporting traveling mechanism, a pipe fitting machining mechanism and a pipe fitting fixation traction mechanism. The pipe fitting fixation traction mechanism comprises a clamping rotating mechanism, an inner clamping device and a draw-off mechanism, a horizontal movement guiding mechanism is disposed between the clamping rotating mechanism and a bracket, and the draw-off mechanism is fixed to the bracket and connected withthe clamping rotating mechanism. The end portion of a pipe fitting can be clamped and fixed through the inner clamping device, the pipe fitting can be moved to any position at will in the radial direction by means of the draw-off mechanism, and the pipe fitting can rotated at any angle as needed, so that the purpose of machining the cylindrical surface of the pipe fitting at any position can be achieved. Moreover, the machining precision and efficiency of the pipe fitting are greatly improved through clamping and the control over precise horizontal movement and precise rotation.

Owner:福建中童家居有限公司

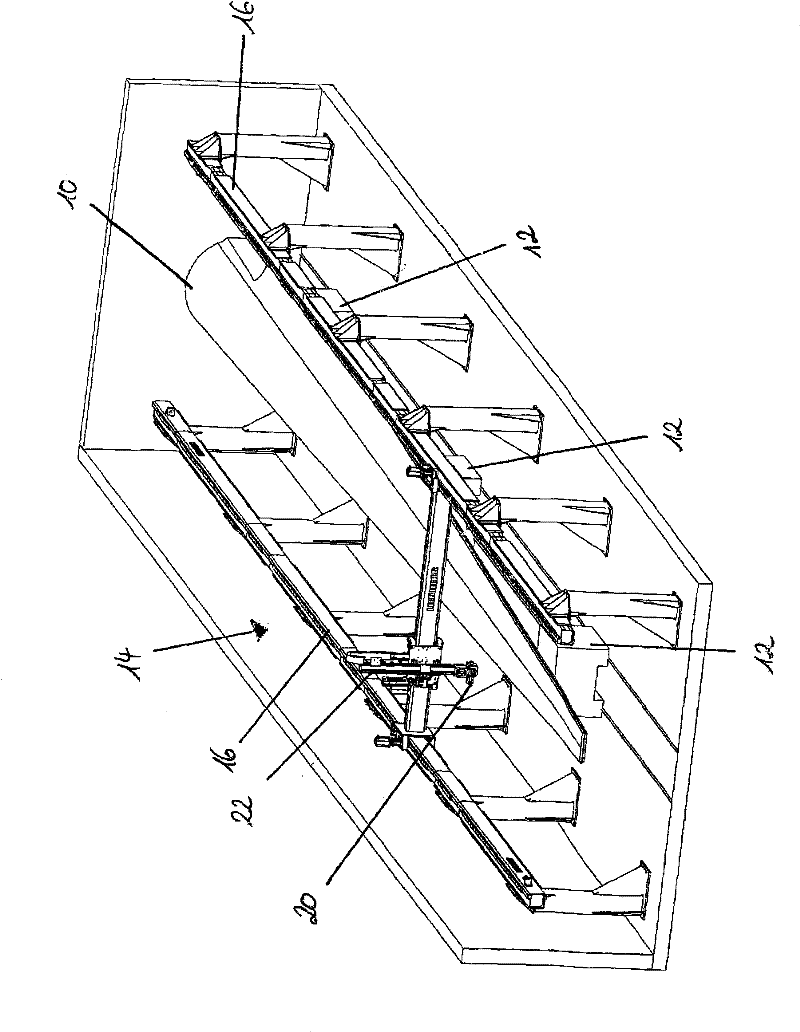

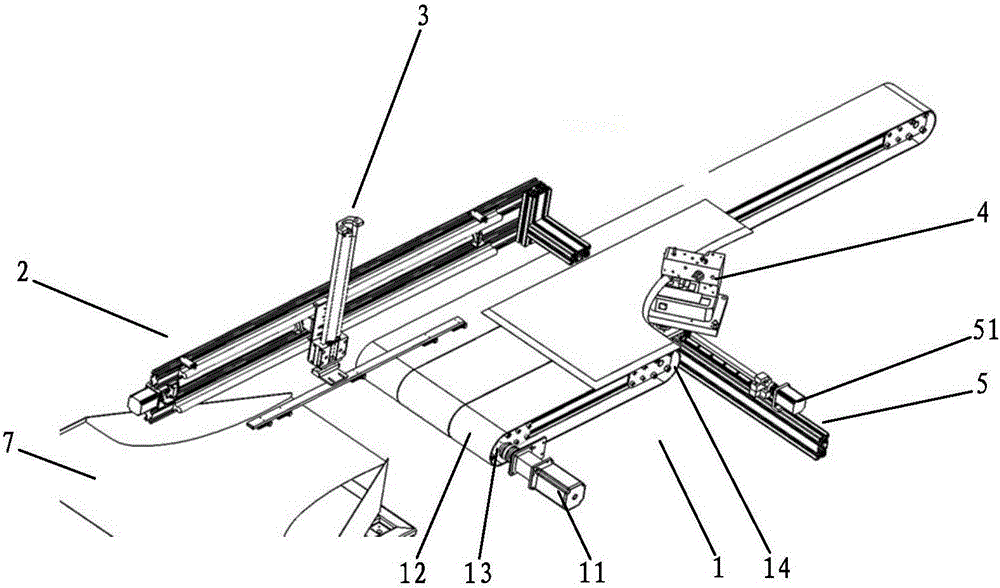

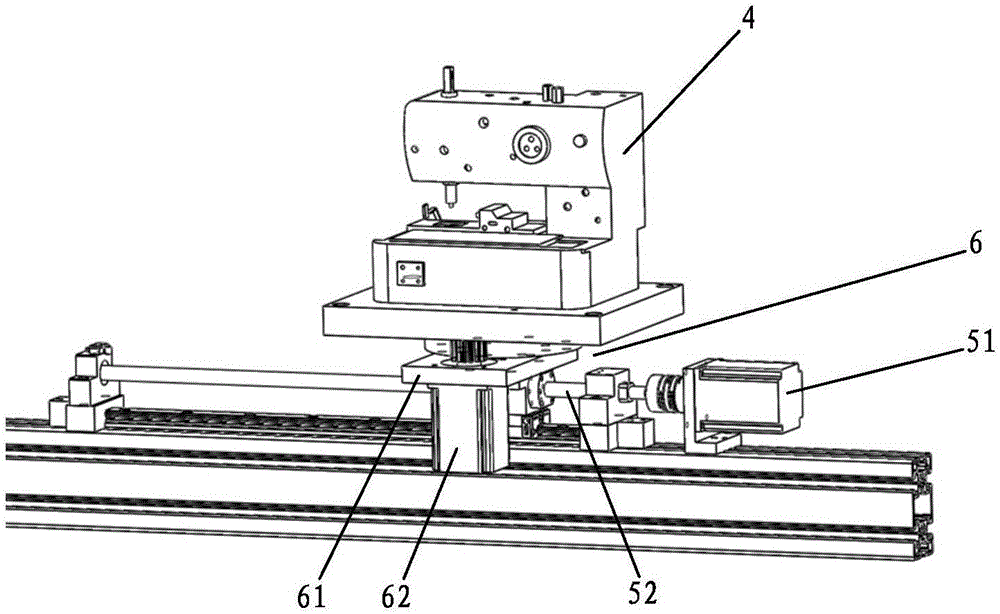

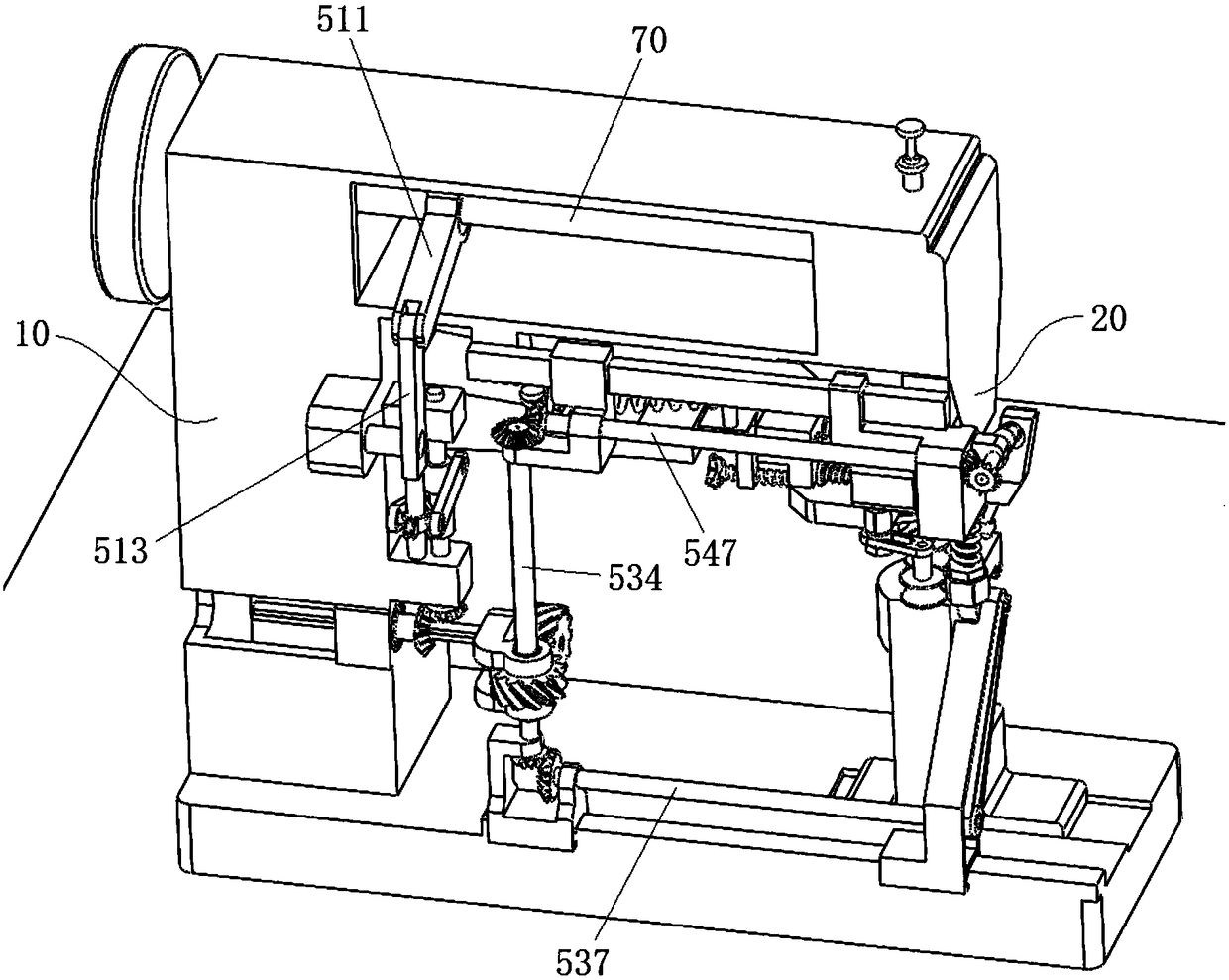

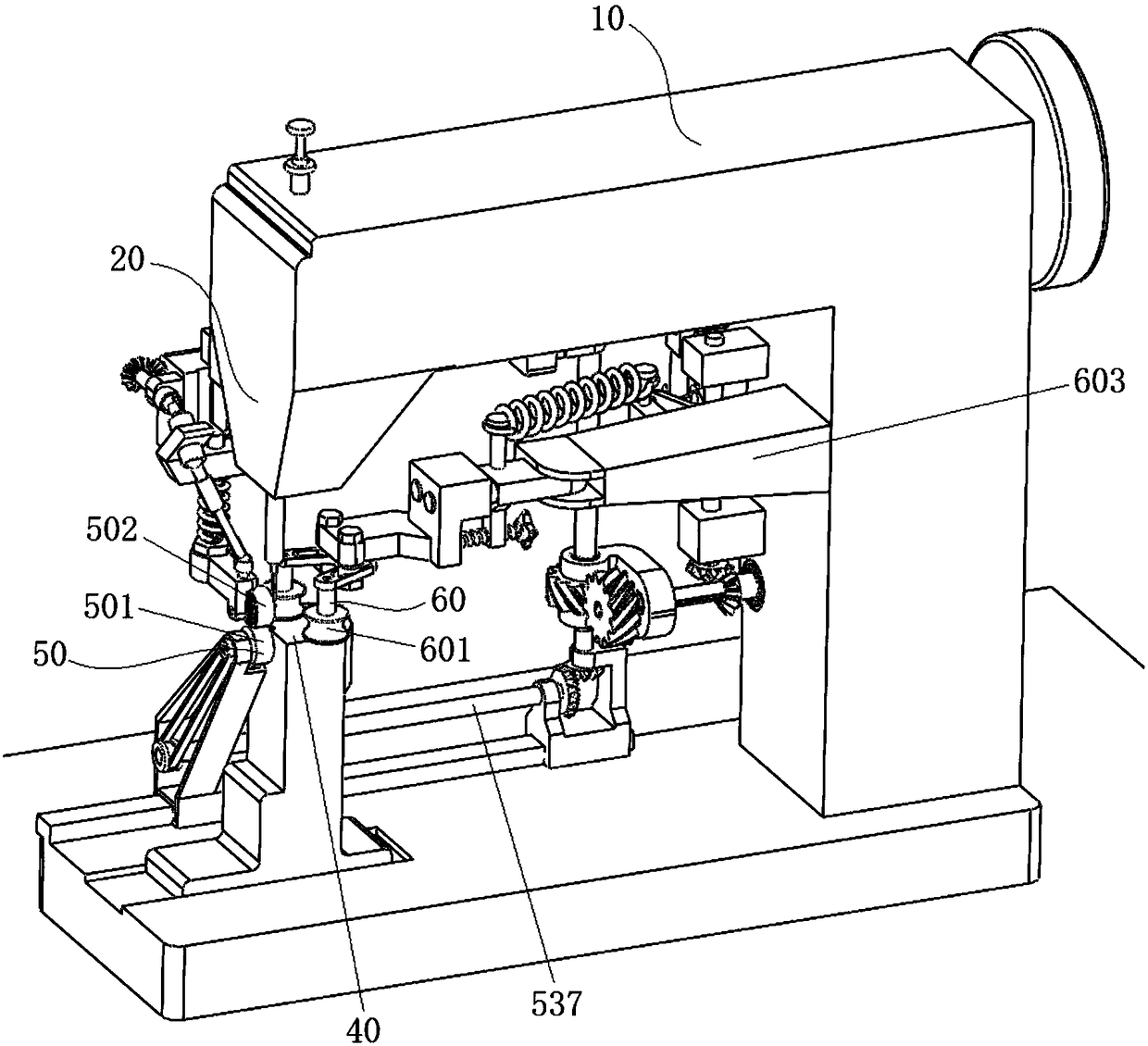

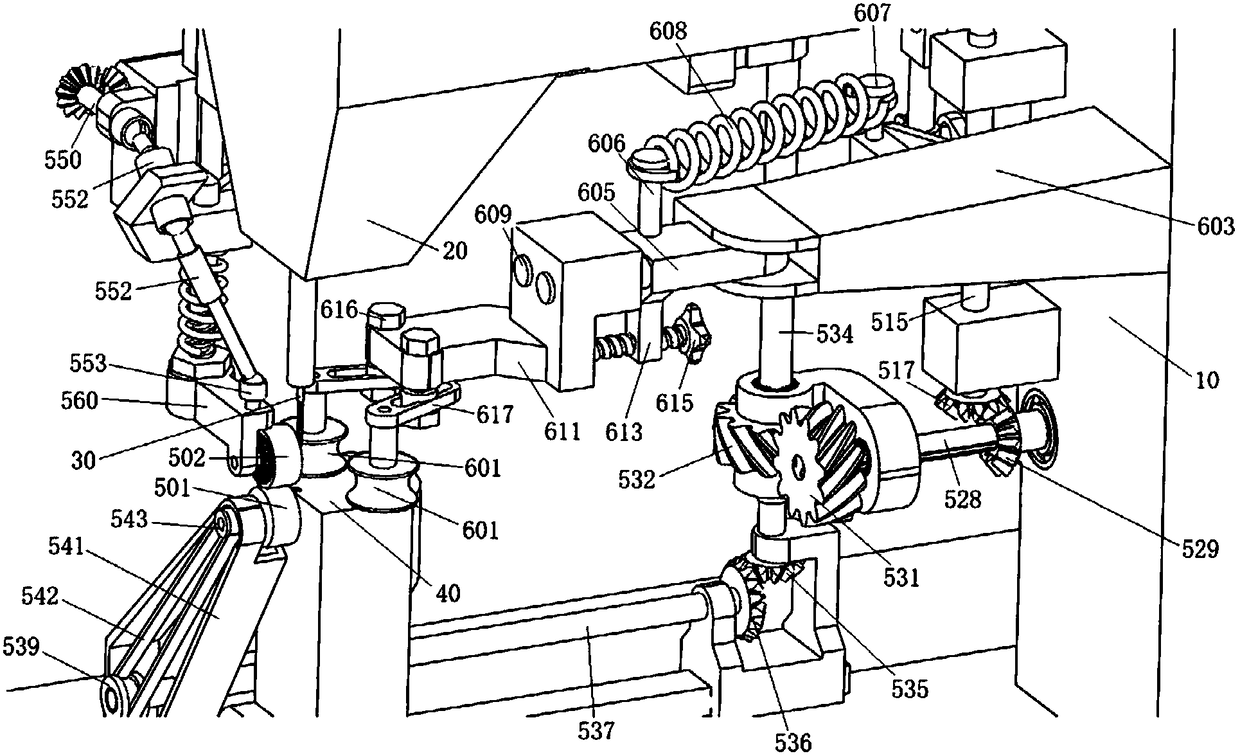

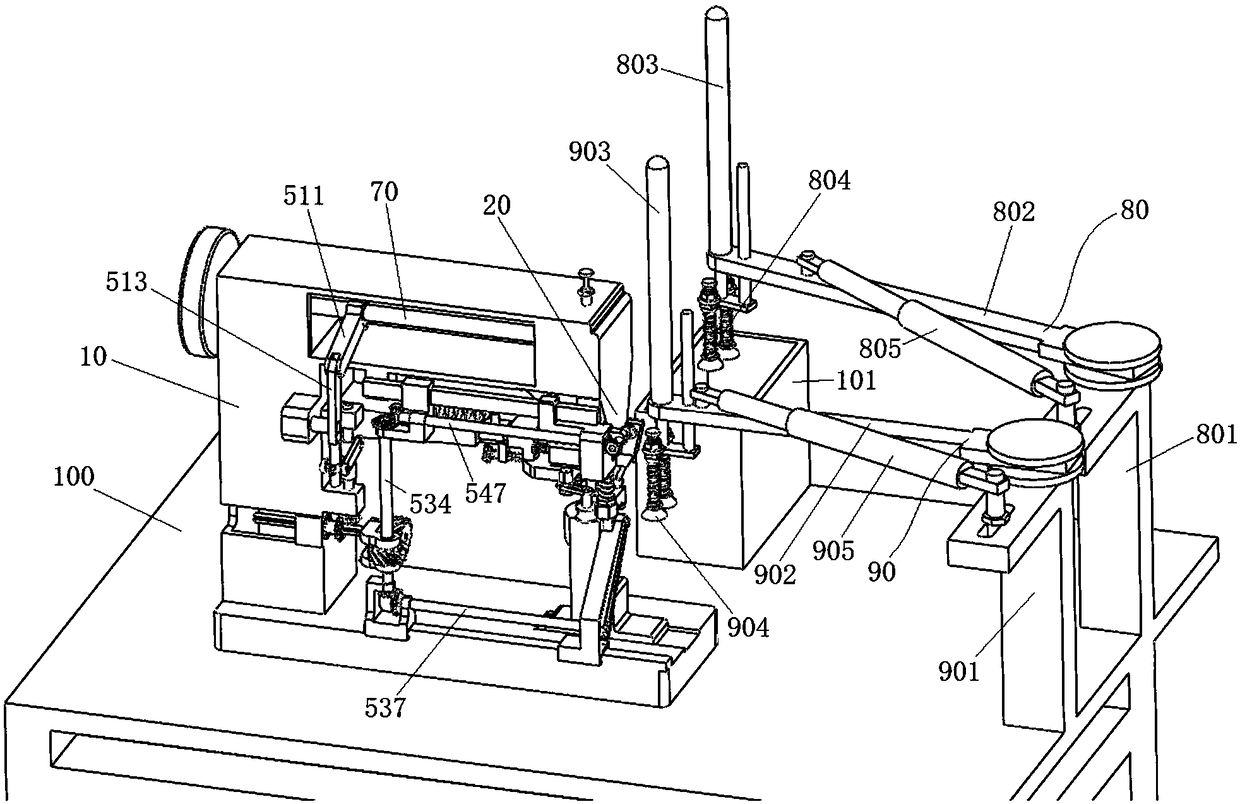

Assembly-line sewing system

ActiveCN106835512ATo achieve the purpose of processingRealize the purpose of processing, with automatic processingWork-feeding meansTransmission beltAssembly line

The invention discloses an assembly-line sewing system. The system includes a rack, a transmission-belt device, an X-axis transportation device, a Z-axis transportation device, a sewing machine, a Y-axis transportation device and a rotation transportation device, the X-axis transportation device and the Z-axis transportation device are arranged above the transmission-belt device, the Z-axis transportation device is installed on the X-axis transportation device, and the X-axis transportation device drives the Z-axis transportation device to slide in a reciprocating mode along the inlet of the transmission-belt device; the sewing machine is fixed on the rotation transportation device, and the rotation transportation device is slidably installed on the Y-axis transportation device; a needle of the sewing machine is located above the transmission-belt device. The sewing machine conducts rectilinear motion and rotational motion under the driving action of the rotation transportation device and the Y-axis transportation device, the needle of the sewing machine can meet various requirements of arc-shaped tracks, and the assembly-line sewing system has the advantages of automation assembly-line processing, and being high in universality and production efficiency.

Owner:张克强

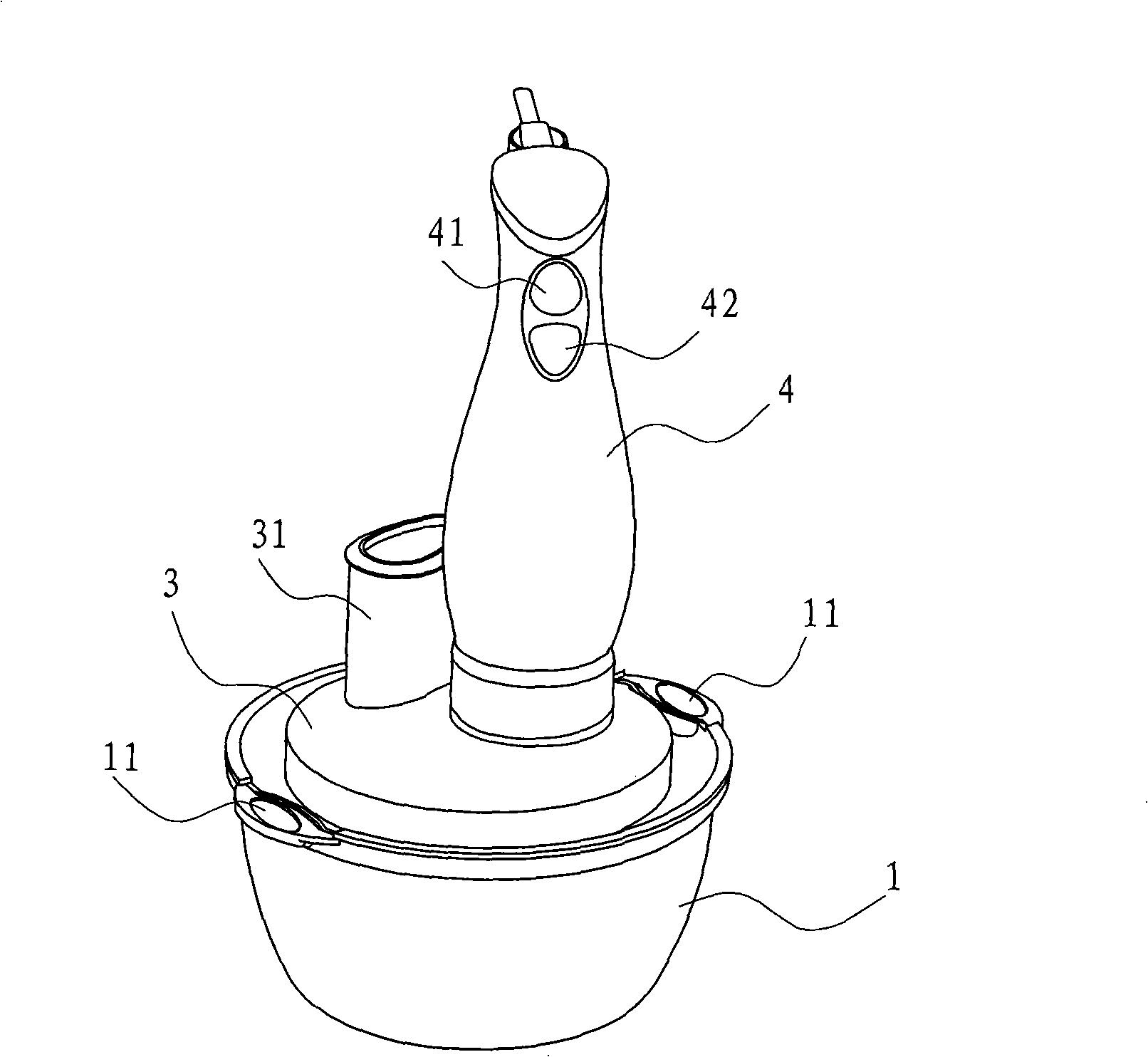

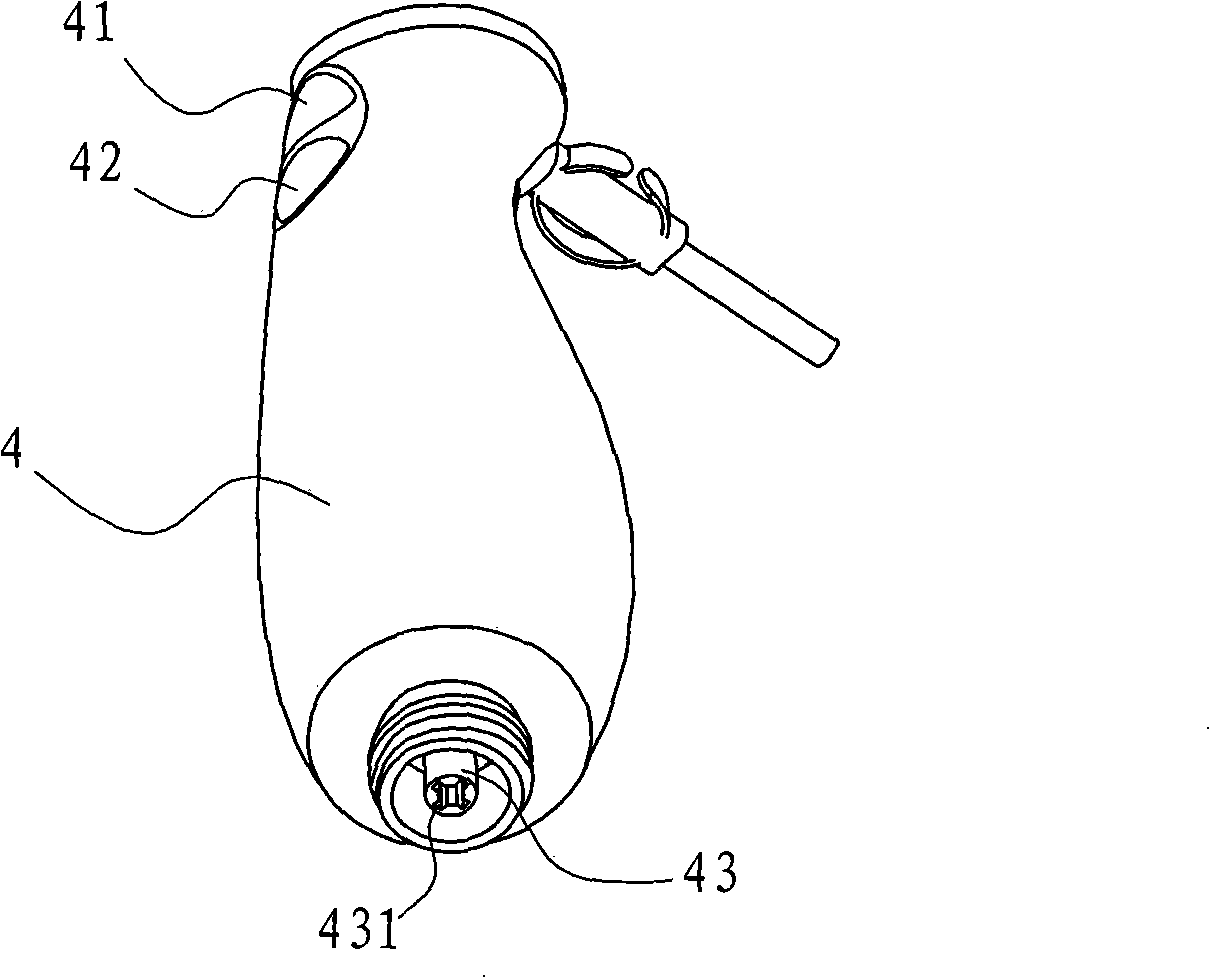

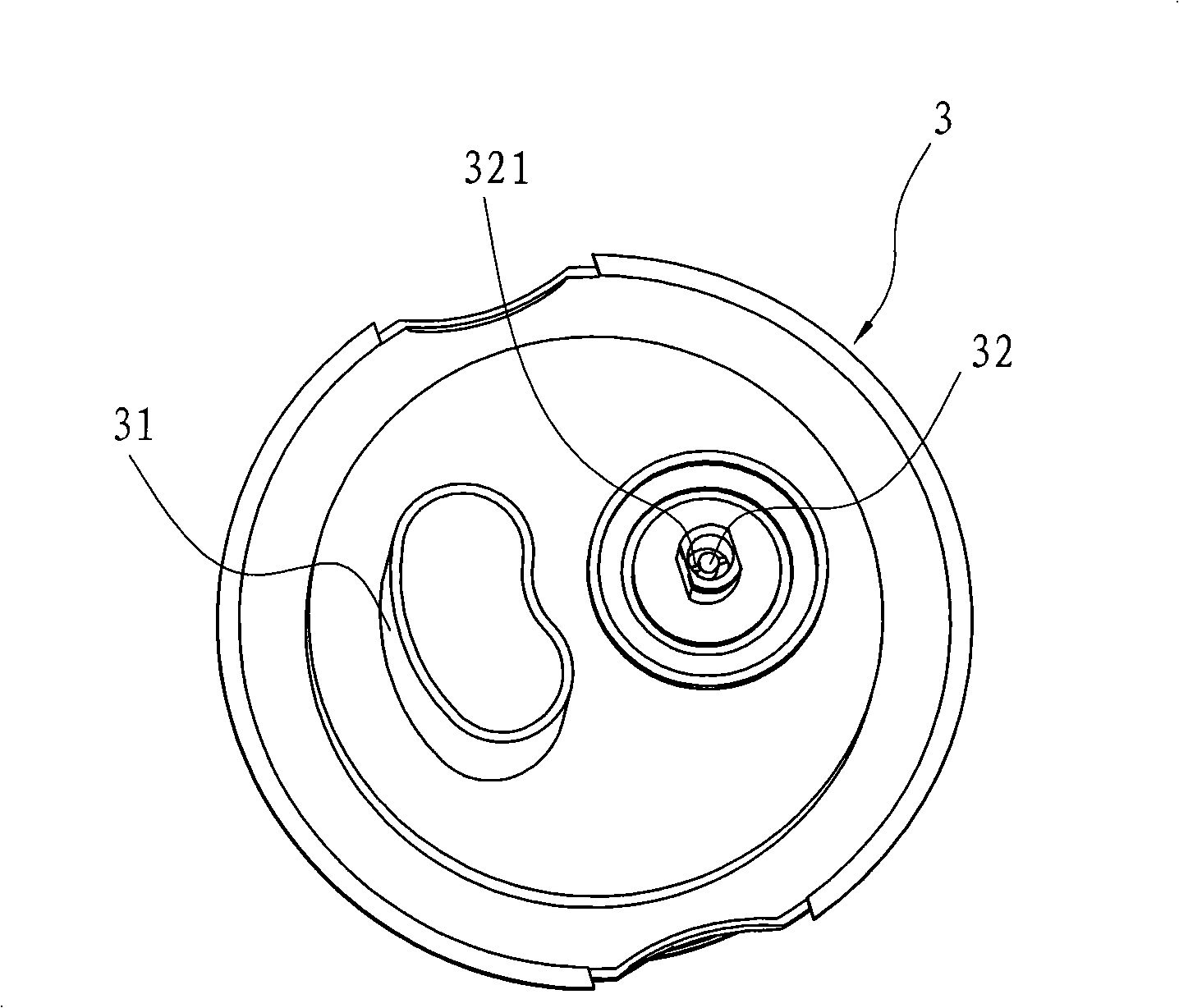

Food processor

InactiveCN101524248ANo increase in volumeIncrease costBeverage vesselsStrainersWhole bodyEngineering

The invention relates to a food processor, comprising an external cup body with an opening at the top and a cup cover covering the mouth of the external cup body in a movable way; wherein, the bottom of the cup cover is provided with an output end which can be driven to rotate by a motor, the cup cover is provided with a food feed inlet, a supporting shaft is fixed at the bottom of the inner wall of the external cup body. The food processor is characterized in that: the food processor further comprises an internal cup, the bottom of the internal cup is provided with a vasiform orifice extending toward the inner axial direction, the supporting shaft is held in the vasiform orifice, an inner tool bit is sheathed on the pipe wall of the vasiform orifice, the upper part of the inner tool bit is connected with the output end in a dismantled and assembled way and can rotate under the drive of the output end, while the food feed inlet is arranged at the position corresponding to the mouth of the internal cup. The food processor has the advantages that: users can change the cup for holding food according to the amount of the processed food, and one cup cover is shared, the internal cup can be put outside the external cup, and the volume of the whole body is not increased, thus facilitating packaging, carrying and transporting.

Owner:潘豪瀚

Plastic foam packaging material machining system and method

ActiveCN110919735ASolve the inconvenience of processingImprove efficiencyMetal working apparatusStructural engineeringMachining system

The invention relates to the production and machining field, in particular to a plastic foam packaging material machining system and method. The plastic foam packaging material machining system comprises a moving platform and a fixing base. First sliding grooves are symmetrically formed in the moving platform. First sliding rods are fixedly connected into the first sliding grooves. The first sliding rods are both sleeved with first sliders. The tops of the first sliders are both provided with fastening bolts. The fastening bolts are connected to the tops of the first sliders in a threaded manner. The bottoms of the first sliders are both provided with first through holes. The bottoms of the first sliders are both fixedly connected with cutting tool bits. Second through holes are both formed in the cutting tool bits. The second through holes communicate with the first through holes. A steel wire is arranged between the two cutting tool bits. The two ends of the steel wire are both inserted into the second through holes and the first through holes. The two ends of the moving platform are both rotationally connected with adjusting wheels. The two ends of the steel wire are both fixedly connected to the adjusting wheels. The plastic foam packaging material machining system has the advantages of being good in machining effect, rapid in machining speed, high in flexibility and the like and is suitable for popularization.

Owner:佛山市新鸣亿包装材料有限公司

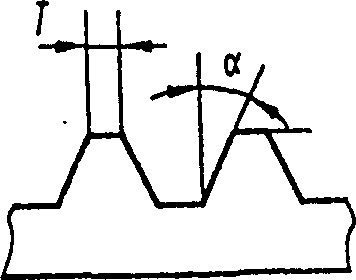

Processing method for cross universal coupling end-face teeth

InactiveCN1907614AIncrease productivityImprove product qualityGear-cutting machinesGear teethMilling cutterCoupling

The invention relates to a method for processing gear, especially a method for processing cross universal coupler end tooth, wherein it comprises: (1) first, fixing milling blade disc at the common milling machine; inserting the middle axle of disc blade setting device into the central hole of disc milling disc; (2) mounting the blade on the milling blade disc, and clamping it on the disc blade setting device to set the blade; when then blade cut is matched with the tooth corner of blade setting device, fixing the blade and taking out the blade setting device; (3) starting the milling machine to rotate the milling blade disc to process; (4) when cutting the A tooth surface, arranging the work-piece vertical to the work bench with 0.75-1 degree; (5) when cutting the B tooth surface, arranging the work-piece vertical to the work bench with 3 degree. The inventive end tooth has high producing efficiency and high quality.

Owner:武汉博能设备制造有限公司

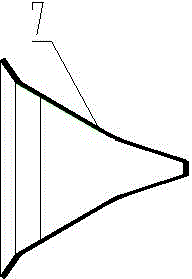

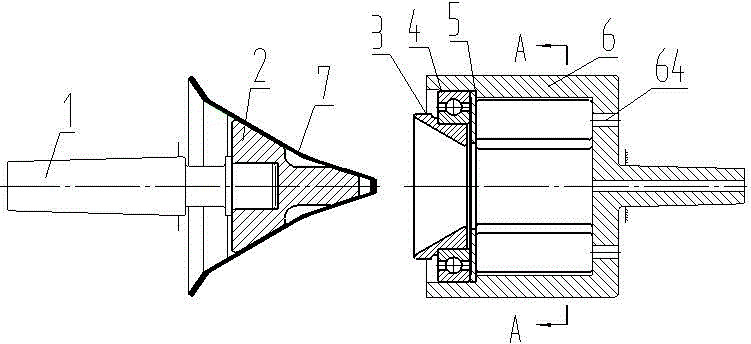

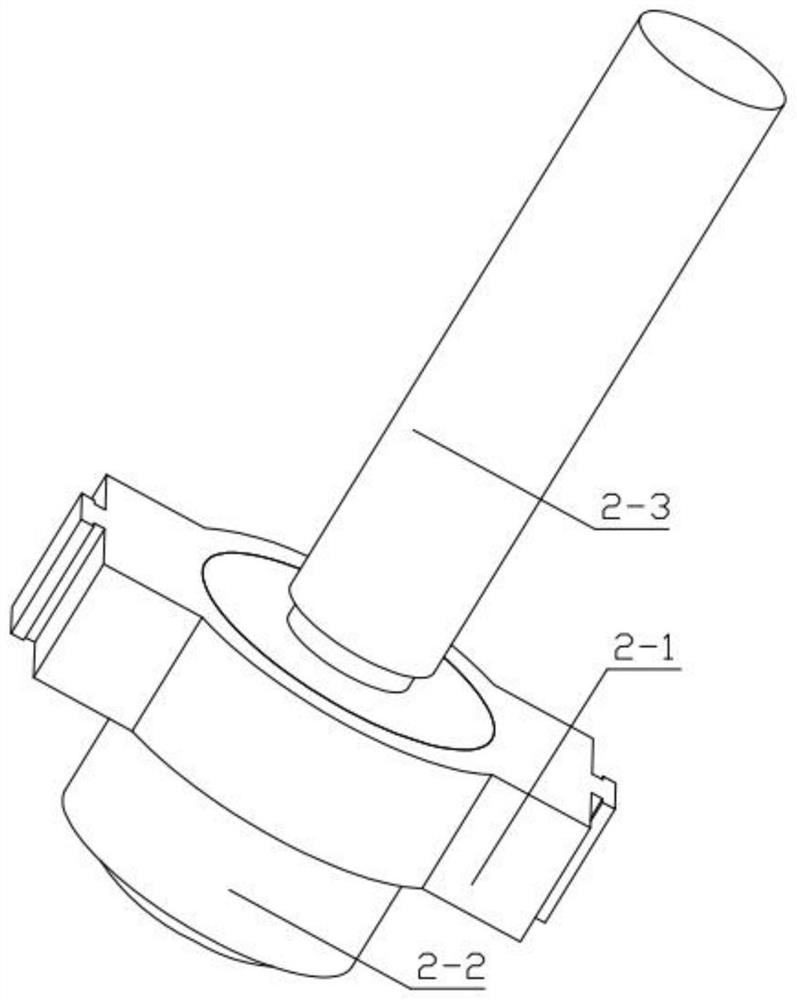

Contour processing clamp for bending part

ActiveCN104476226AEasy loadingGuaranteed machining accuracyPositioning apparatusMetal-working holdersEngineeringLarge deformation

The invention provides a contour processing clamp for a bending part. The contour processing clamp is characterized by comprising a positioning device and a clamping device; the positioning device comprises a mandrel, and a top column which is fixed to the top end of the mandrel; the mandrel at the other end of the top column is in match with a main shaft of a lathe; the clamping device comprises a top bowl, a bearing, a spacer and a tip body; the top bowl is connected with the tip body through the bearing; the spacer is positioned in the middle of the connecting surface between the bearing and the tip body; the bearing and the top bowl can be conveniently dismounted through four process holes in the tip body; a shaft at the tail end of the tip body is in match with a tail seat of a machine tool; an inner hole in the top bowl is matched with the outer surface of a part to be processed in shape; the outer surface of the top column is matched with the inner surface of the part to be processed in shape. With the adoption of the contour processing clamp, the bending part can be conveniently mounted, and the part is avoided large deformation, so that the processing precision of the part can be ensured; the top column, the top bowl or the tip body can be replaced for contour processing of different bending parts, and therefore, the processing purpose can be conveniently and fast achieved.

Owner:FUJIAN ORDNANCE EQUIP

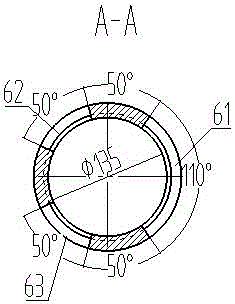

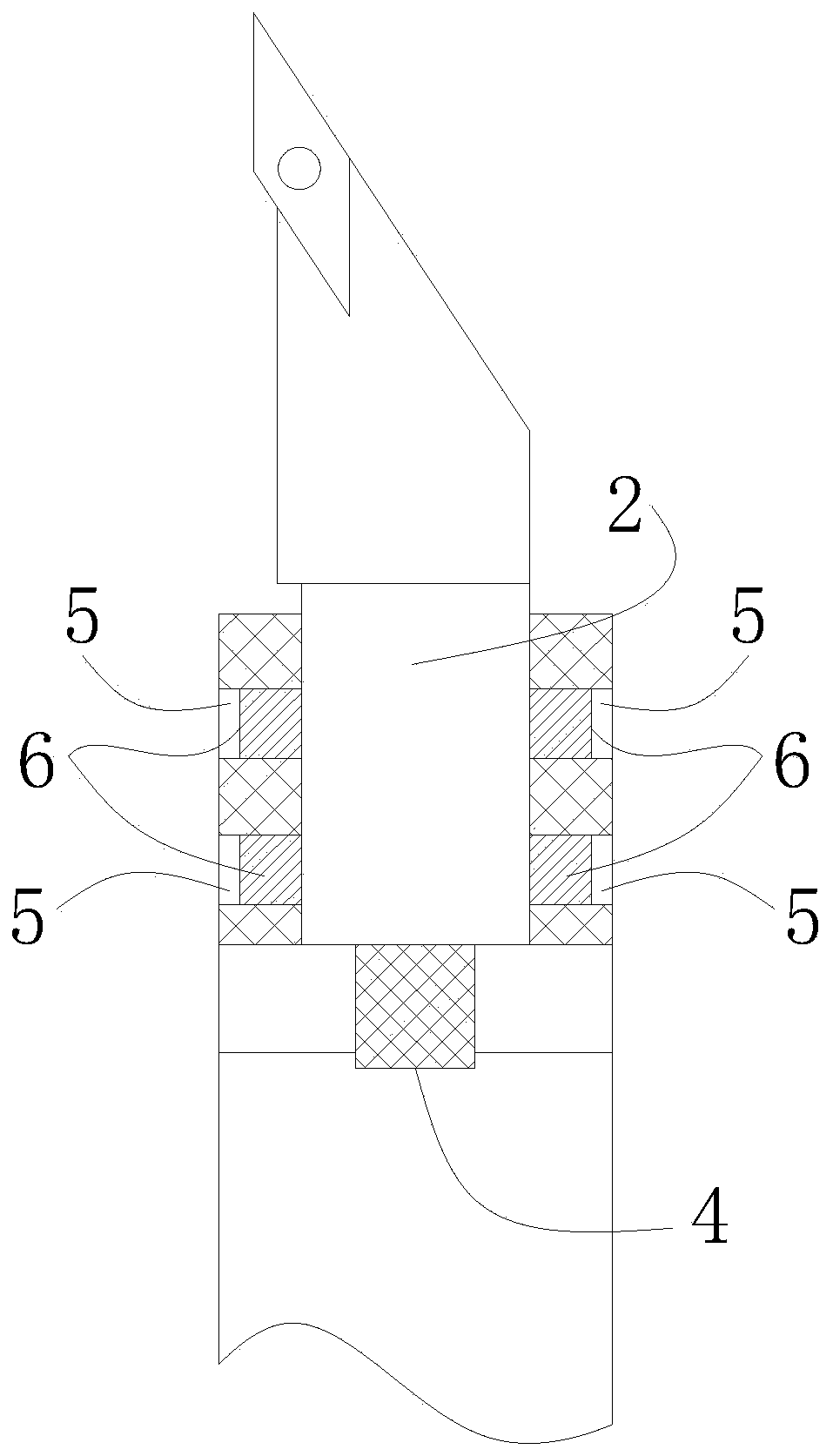

Machining fixture for eccentric part

InactiveCN104057317ATo achieve the purpose of processingGuaranteed reliabilityPositioning apparatusGrinding work supportsSet screwEngineering

The invention relates to a machining fixture for an eccentric part. The machining fixture for the eccentric part comprises a guide rail 1, an upper sliding block 5, a lower sliding block 6, an upper chuck 2, a lower chuck 3 and set screws 7, wherein a dovetail groove 8 is arranged on the guide rail 1, one side of the upper sliding block 5 and one side of the lower sliding block 6 are installed on the dovetail groove 8 on the guide rail, the upper chuck 2 is fixedly installed on the other side of the upper sliding block 5, the lower chuck 3 is fixedly installed on the other side of the lower sliding block 6, one end of the upper chuck 2 and one end of the lower chuck 3 are V-shaped, the two V-shaped end surfaces face to each other, the dimensions of the two V-shaped end surfaces are the same, and two set screws 7 are further arranged on the guide rail 1 and respectively press the upper sliding block 5 and the lower sliding block 6. When the eccentric part is machined, since the machining of the eccentric part is not required to be realized through a center hole of the part, the influences of the center hole and the area of the end surface are avoided, the machining precision is high and the reliability is good.

Owner:HARBIN DONGAN ENGINE GRP

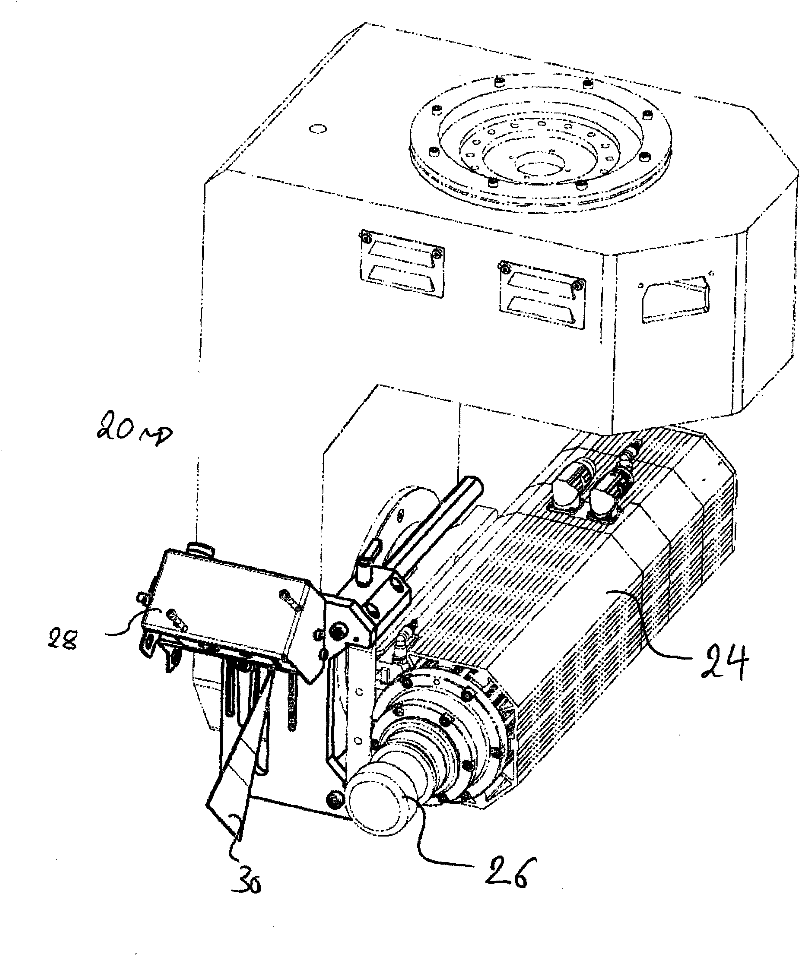

Process and production equipment for manufacturing rotary target material through cold spraying

ActiveCN112746260AImprove compactnessReduce oxygen contentVacuum evaporation coatingSputtering coatingSand blastingMegasonic cleaning

The invention discloses a process and production equipment for manufacturing a rotary target material through cold spraying. The process comprises the following steps of 1) sequentially carrying out ultrasonic cleaning, drying and sand blasting treatment on a base body; (2) vacuumizing the area where the base body is located; (3) introducing ITO powder into a spray gun, and meanwhile, introducing inert gas into the spray gun; and 4) driving and controlling the base body to rotate, and controlling the spray gun to move in the axial direction of the base body, so that the ITO target material is formed. According to the ITO target material prepared through the steps, due to the fact that the ITO target material is always in the helium protection atmosphere during spraying, the oxygen content and mixing of other impurities are reduced, in addition, when the target material is subjected to cold spraying, particles collide with the base body at a high speed and sufficiently deform to form a coating, the coating structure is compact, the relative density of the target material can reach 99.9% or above, the grain structure in the target material is uniform and fine, no defect structure exists, meanwhile, the deposition efficiency is high, and the production cost is reduced.

Owner:HUNAN KOSEN NEW MATERIAL

Portable safe storage rack mold

The invention discloses a portable safe storage rack mold, and relates to the technical field of storage rack production and machining. The portable safe storage rack mold comprises a base, the two ends of the base are respectively both provided with first installation grooves, stretchable plates are arranged in the first installation grooves, the top ends of the stretchable plates penetrate through the first installation grooves and are fixedly connected with an installation frame, a fixing groove is formed in one end of the installation frame, and an upper mold is arranged in the fixing groove; and extrusion blocks are both arranged on the two sides of the fixing groove, one sides of the extrusion blocks are attached and connected with the upper mold, the other sides of the extrusion blocks are fixedly connected with threaded rods, and one ends of the threaded rods penetrate through the installation frame and are fixedly connected with adjusting discs. According to the portable safestorage rack mold, the installation frame, the extrusion block, the threaded rods and the adjusting discs are arranged in a matched mode, on one hand, the effect of firmly fixing the upper mold is achieved, the stability of the device is guaranteed, on the other hand, disassembly and replacement of the upper mold are facilitated, and the upper molds with different types can be conveniently installed.

Owner:江苏筑隆模具有限公司

Novel water gate capable of being unceasingly used in water conservancy dam

InactiveCN107794889AQuality improvementTo achieve the purpose of processingBarrages/weirsWater resourcesWater flow

The invention discloses a new type of sluice that can be used sustainably in a water conservancy dam. The backs of the racks are all provided with water discharge openings, the interior of the sluice gate rack includes a rack body, and the interior of the rack body is provided with a door chamber. The invention makes the gate provide a buffer force to the gate during the descending process, prevents damage to the sluice gantry during the descending process of the gate, improves the protection of the sluice gantry, and prolongs the service life of the sluice body. When a hoisting chain is damaged , does not affect the lifting operation of the gate, it is also convenient to replace the lifting chain, and does not affect the use of the gate in water conservancy, which achieves the advantage of sustainable use, thus effectively solving the problem of the existing water gate being used for a long time. The problem of loss affecting the use of sluices in water conservancy and affecting the control of water flow.

Owner:祝敏

Exhaust pipe deep bolt hole machining equipment

InactiveCN112247200ANot easy to break awayPrecise and stable drillingFeeding apparatusPositioning apparatusStructural engineeringExhaust pipe

The invention relates to the technical field of machining equipment, in particular to exhaust pipe deep bolt hole machining equipment which comprises a heavy horizontal moving table, rotating assemblies, a distance adjusting assembly, clamping assemblies, end abutting assemblies, a gantry lifting translation assembly and a long shaft drilling assembly; the rotating assemblies are arranged at the two sides of the top end of a working part of the heavy horizontal moving table; the distance adjusting assembly is vertically arranged at the output ends of the rotating assemblies; the clamping assemblies comprise fixed clamping plates, movable clamping plates, adjustable abutting devices and corner pressing air cylinders, wherein the clamping plates are horizontally arranged side by side, the two ends of the clamping plates are fixedly connected with a fixed portion and a movable portion of the distance adjusting assembly correspondingly, the adjustable abutting devices and the corner pressing air cylinders are arranged at the opposite sides of the clamping plates at equal intervals, and the working ends of the adjustable abutting devices are opposite to the working ends of the corner pressing air cylinders in the radial directions of the clamping plates; the end abutting assemblies are arranged between the clamping plates; the gantry lifting translation assembly is arranged at the top of one end of the heavy horizontal moving table; and the long shaft drilling assembly is arranged at one side of a lifting part of the gantry lifting translation assembly. The equipment can adaptively clamp and position exhaust pipes of different sizes.

Owner:吴功城

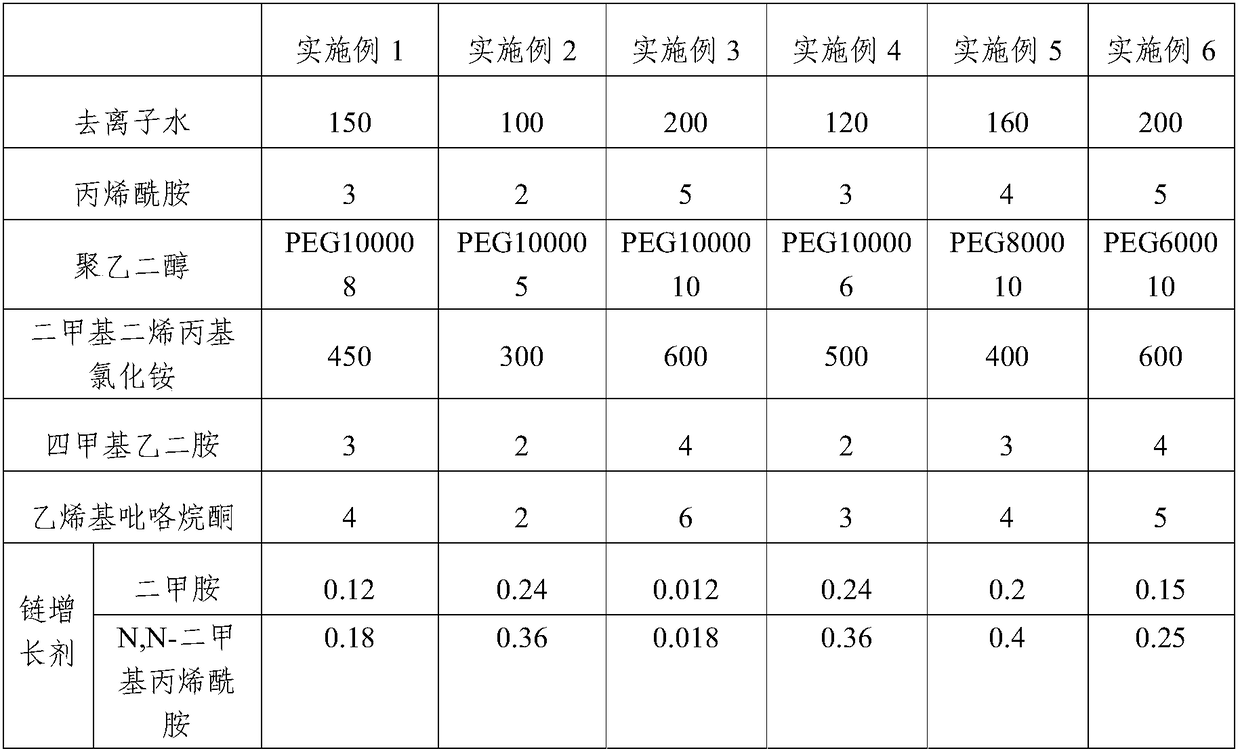

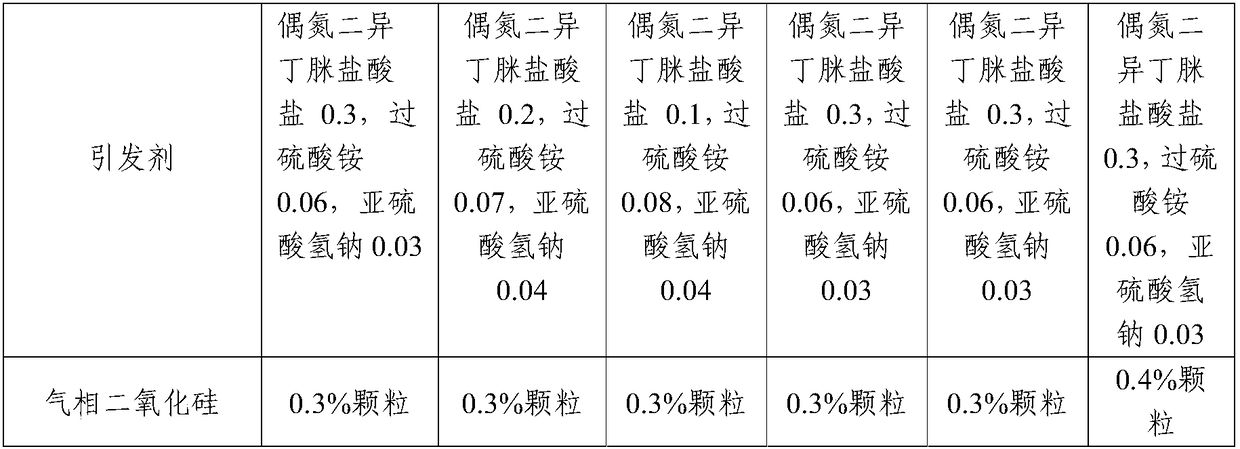

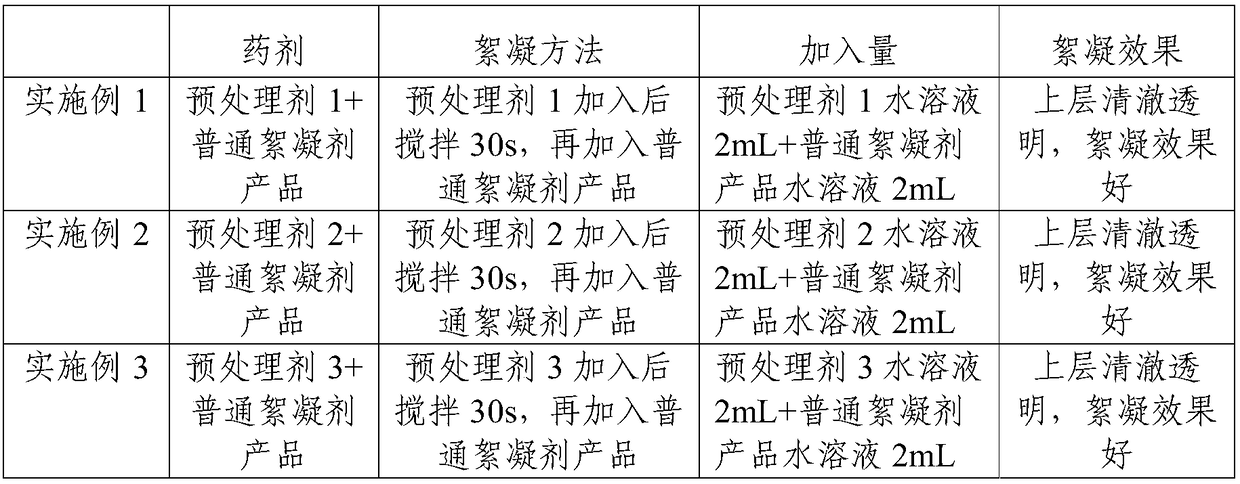

Pretreating agent for ultrafine tailings as well as preparation method and application thereof

ActiveCN108128872ATo achieve the purpose of processingFast dissolutionWater/sewage treatment by flocculation/precipitationGas phasePolyethylene glycol

The invention relates to a pretreating agent for ultrafine tailings as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) pre-mixing materials: mixing acrylic amide, polyethylene glycol, dimethyl diallyl ammonium chloride, tetramethylethylenediamine, vinyl pyrrolidone and a solvent to prepare a mixed liquid; (2) adjusting the mixed liquid: adjusting the temperature and the pH value of the mixed liquid and performing nitrogen-introducing and oxygen-removing treatment on the mixed liquid; (3) performing polymerization: adding a chain extender and an initiator into the mixed liquid treated in the step (2) and performing polymerization reaction on the system under the action of the initiator; and (4) performing aftertreatment: afterthe reaction, preparing particles from the collected reaction products and mixing the particles and fumed silica so as to prepare the pretreating agent. The pretreating agent provided by the inventionis added before the common flocculating agent is used, ultrafine particles of tailing water are polymerized rapidly to form large particles, and then the common flocculating agent is added to form large particles through flocculation, so the effect is remarkable.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Ultrasonic treatment device and ultrasonic treatment method for polymer-containing sludge

InactiveCN108863013ALow viscosityImprove dehydration effectSludge treatment by de-watering/drying/thickeningCavitationSludge

The invention discloses an ultrasonic treatment device and an ultrasonic treatment method for polymer-containing sludge. The device comprises a homogenization tank, an ultrasonic reaction tank and a flocculating and settling tank which are communicated mutually through pipelines. An ultrasonic probe is arranged in the ultrasonic reaction tank, and is connected with an ultrasonic generator. A stirrer is arranged in the flocculating and settling tank. The upper portion of the flocculating and settling tank is communicated with a chemical dosing device. The ultrasonic treatment device and the ultrasonic treatment method have the advantages that through the sponge effect and the cavitation effect of ultrasonic waves on the polymer-containing sludge, the viscosity of the polymer-containing sludge can be reduced without addition of viscosity reducers, and the dewatering capability of the polymer-containing sludge is improved; the polymer-containing sludge is treated, the feeding quantity ofchemicals is reduced, the yield of the sludge is decreased, the treatment efficiency of the polymer-containing sludge is improved, and the foundation is laid for harmless treatment of the polymer-containing sludge.

Owner:CHINA PETROLEUM & CHEM CORP +1

Machining device capable of being adjusted at multiple angles

PendingCN113245619AEasy to process and produceConvenient symmetrical adjustment processingMetal sawing devicesElectric machineryStructural engineering

The invention discloses a machining device capable of being adjusted at multiple angles. The machining device comprises a machining adjusting component, the outer end of the machining adjusting component is movably connected with an installation stabilizing component, the machining adjusting component comprises a lifting adjusting end and an angle adjusting end, the lifting adjusting end is arranged at the bottom of the inner end of the machining adjusting component, and the angle adjusting end is rotationally connected to the upper end of the center of the lifting adjusting end, the lifting adjusting end comprises a pushing structure and a driving structure, the pushing structure is arranged at the bottom of the inner end of the lifting adjusting end, and the driving structure is connected to the upper end of the pushing structure in a sleeving mode; the pushing structure comprises a supporting plate frame, a sleeve frame, a shaft sleeve ring frame, a sleeve shaft rod frame and a lifting motor, the supporting plate frame is arranged at the top of the inner end of the pushing structure, and the lower end of the supporting plate frame is fixedly connected with the sleeve frame. According to the machining device capable of being adjusted at multiple angles, machining device with multiple angle adjustment is achieved, through arranging the machining adjusting component, the purpose of inner end machining adjusting is achieved.

Owner:郝志鹏

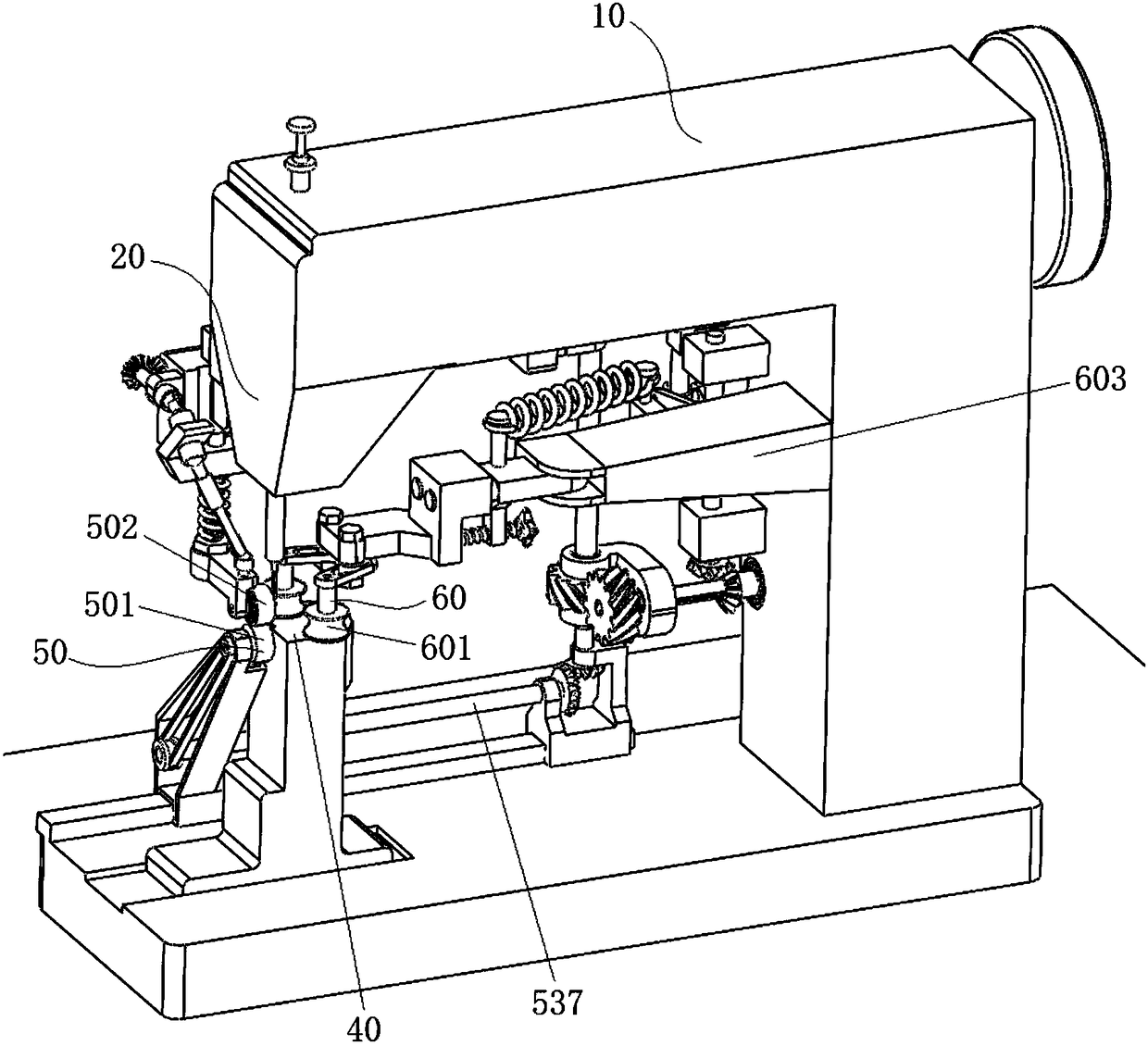

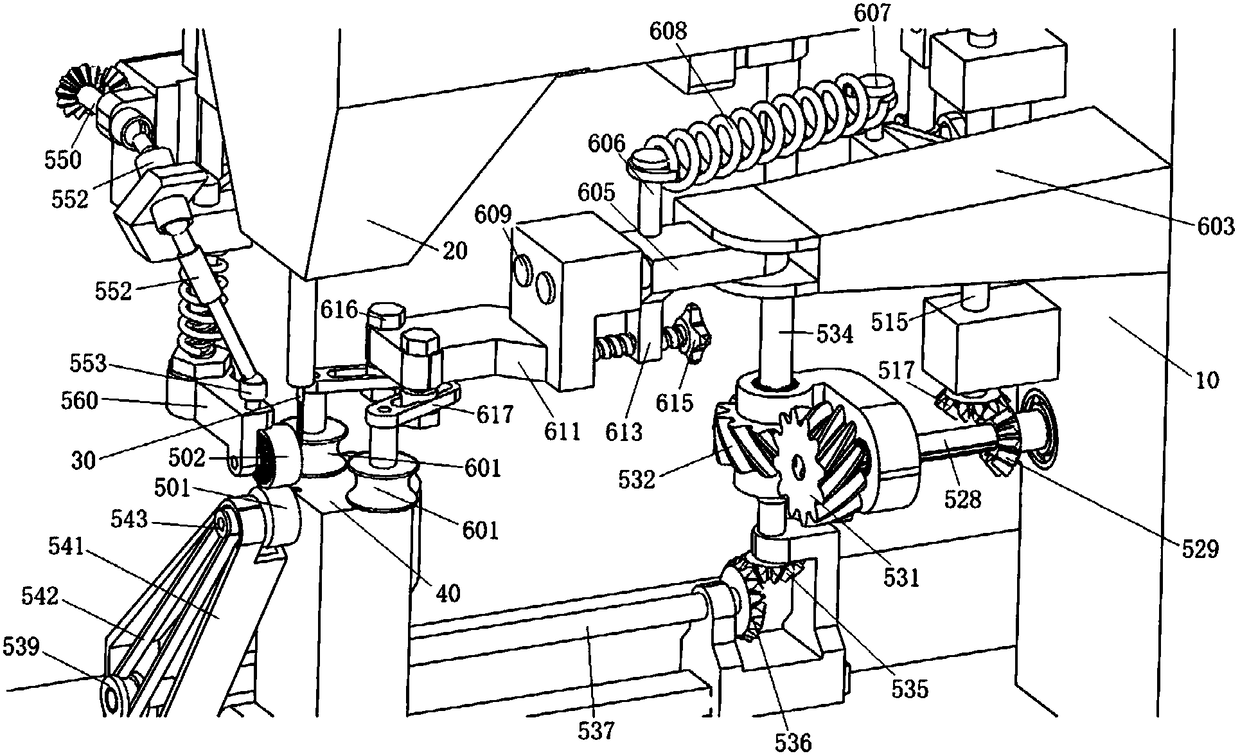

Sewing machine capable of automatic processing sole threads

The invention relates to a sewing machine capable of being used for processing sole threads. The sewing machine comprises a sewing machine body, a sewing machine head, a sewing machine needle and a sewing platform, wherein the sewing machine needle is arranged below the sewing machine head through a needle rod; the sewing machine further comprises a sole movement driving mechanism and a sole steering mechanism; the sole movement driving mechanism comprises a first conveying roller and a second conveying roller that are arranged in front of the sewing machine needle; a clearance for clamping asole is reserved between the first conveying roller and the second conveying roller; the first conveying roller and the second conveying roller are connected with a sewing machine main shaft through atransmission unit; when the sewing machine main shaft rotates, the first conveying roller and the second conveying roller rotate reversely simultaneously to drive a sole to move; the sole steering mechanism comprises two guide wheels arranged above the sewing platform; the two guide wheels are located at the same height; wheel shafts are arranged in a vertical direction; and an included angle between a plane defined by the wheel shafts of the two guide wheels and a roller shaft of each conveying roller is less than 90 DEG C.

Owner:湖南木林帅鞋业有限公司

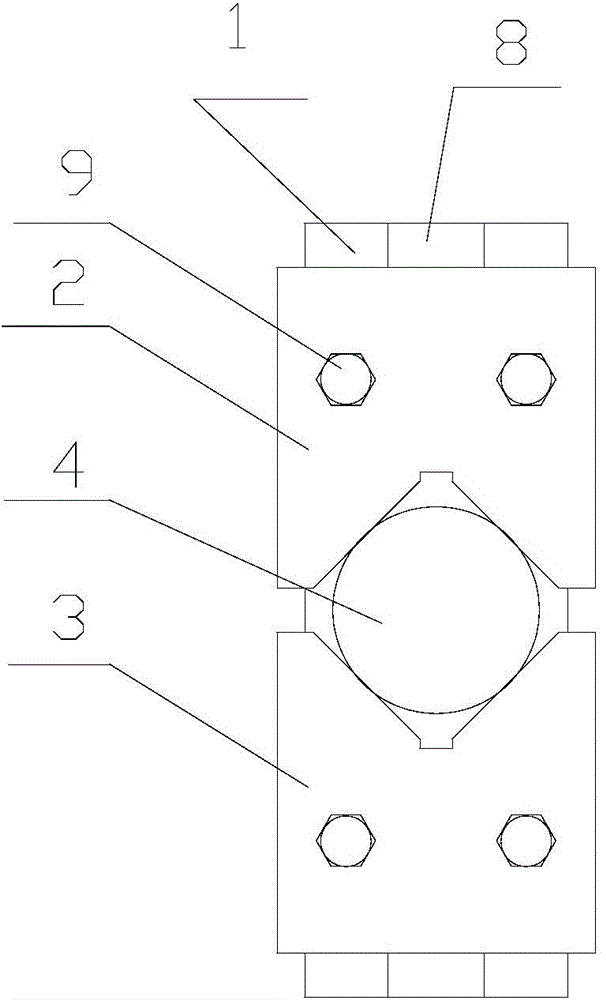

CNC lathe fly-cutter disk and assembling method thereof

InactiveCN110202175AImprove processing efficiencyGuaranteed concentricity and smoothnessTool holdersComputer engineering

The invention relates to a CNC lathe fly-cutter disk. The CNC lathe fly-cutter disk comprises a cutter disk body and a plurality of cutter rod assemblies; a plurality of mounting grooves matched withthe cutter rod assemblies are formed in the cutter disk body; the cutter rod assemblies are positioned in the mounting grooves; the cutter disk body is connected with an adjusting piece for controlling the cutter rod assemblies to draw back and stretch out; a plurality of limiting holes communicating with the mounting grooves are formed at the upper end and the lower end of the cutter disk body; and a limiting block is arranged in single limiting hole and the limiting block can draw back and stretch out from the limiting hole. The CNC lathe fly-cutter disk provided by the embodiment of the invention has extremely high processing efficiency and processing property and can adjust the cutter disk to guarantee high precision and high quality of a processing workpiece.

Owner:邹洪波

Machine part production device

InactiveCN111889822AEnsure stabilityIncrease frictionThread cutting machinesMachine partsEngineering

The invention relates to machining devices, in particular to a machine part production device. The machine part production device comprises a rail frame, an output mechanism, a caliber adjusting mechanism, a depth adjusting mechanism, a sleeve clamping mechanism and a caliber adaption mechanism. The output mechanism is slidably mounted in grooves formed in the rail frame. The caliber adjusting mechanism is fixedly mounted on the output mechanism. The depth adjusting mechanism is fixedly mounted on the caliber adjusting mechanism. The sleeve clamping mechanism is fixedly mounted on the rail frame. The caliber adaption mechanism is slidably mounted in the grooves formed in the rail frame. The sleeve clamping mechanism is rotatably mounted in the grooves formed in the caliber adaption mechanism. The machine part production device has the advantages of being capable of fixing different diameters of connecting sleeves so as to machine the connecting sleeves with different calibers and capable of changing the thread machining depth to meet different requirements for actual machining of the connecting sleeves.

Owner:邵阳县振华机械锻造配件有限责任公司

Sewing machine for automatically processing shoe sole line

ActiveCN108251976ATo achieve the purpose of processingImprove processing efficiencyWork-feeding meansEngineeringWheel and axle

The invention relates to a sewing machine for automatically processing a shoe sole line, which comprises a workbench, a sewing machine main body, a sewing machine nose, a sewing machine needle and a sewing platform; the sewing machine further comprises a shoe sole motion driving mechanism, a shoe sole steering mechanism, a shoe sole input mechanism and a shoe sole output mechanism; the shoe sole motion driving mechanism comprises a first conveying roll wheel and a second conveying roll wheel which are arranged at the front part of the sewing machine needle; a gap for clamping the shoe sole isreserved between the first conveying roll wheel and the second conveying roll wheel, the first conveying roll wheel and the second conveying roll wheel are connected with a sewing machine spindle through a drive unit; when the sewing machine spindle is rotated, the first conveying roll wheel and the second conveying roll wheel are rotated in a reverse direction at the same time, thus the shoe soleis driven to move; the shoe sole steering mechanism comprises two guide wheels arranged at the upper part of the sewing platform; two guide wheels are located at the same height and the wheel axle isarranged in a vertical direction; there is an included angle which is not less than 90 degrees between the plane where the wheel axles of two guide wheels are confirmed and the wheel axle of the conveying roll wheel.

Owner:中山市志捷鞋业技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com