Pretreating agent for ultrafine tailings as well as preparation method and application thereof

A pretreatment agent and mine-used technology, applied in the field of polymers, can solve problems such as poor flocculation effect and inability to flocculate ultrafine tailings solid matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

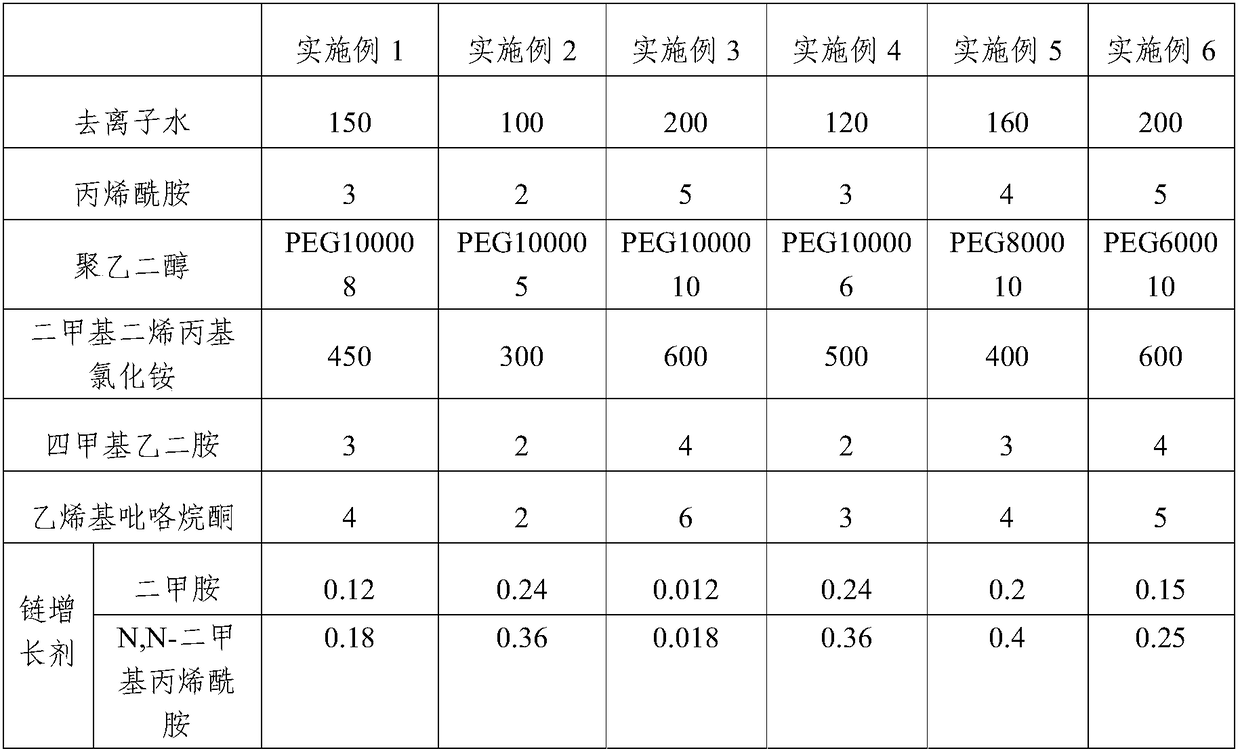

[0028] The invention provides a method for preparing a pretreatment agent for ultrafine tailings. The preparation raw materials used include the following components: 2-5 parts by weight of acrylamide, 5-10 parts by weight of polyethylene glycol, dimethyl di 300-600 parts by weight of allyl ammonium chloride, 2-4 parts by weight of tetramethylethylenediamine, 2-6 parts by weight of vinylpyrrolidone, 100-200 parts by weight of solvent, 0.03-0.06 parts by weight of chain extender and initiator Agent 0.18 ~ 0.62 parts by weight and a certain amount of fumed silica. Described preparation method comprises the steps:

[0029] (1) Premix: Mix acrylamide, polyethylene glycol, dimethyldiallyl ammonium chloride, tetramethylethylenediamine, vinylpyrrolidone and a solvent to prepare a mixed solution. In this step, polyethylene glycol is selected from any one of PEG2000, PEG4000, PEG6000, PEG8000, and PEG10000, preferably PEG10000. The solvent used can be deionized water, ultrapure water...

Embodiment 1

[0035] Mix 150 parts by weight of deionized water, 3 parts by weight of acrylamide, 8 parts by weight of PEG10000, 450 parts by weight of dimethyl diallyl ammonium chloride, 3 parts by weight of tetramethylethylenediamine, and 4 parts by weight of vinylpyrrolidone , and then add adipic acid, adjust the pH value to 4.0, and adjust the temperature to 20°C.

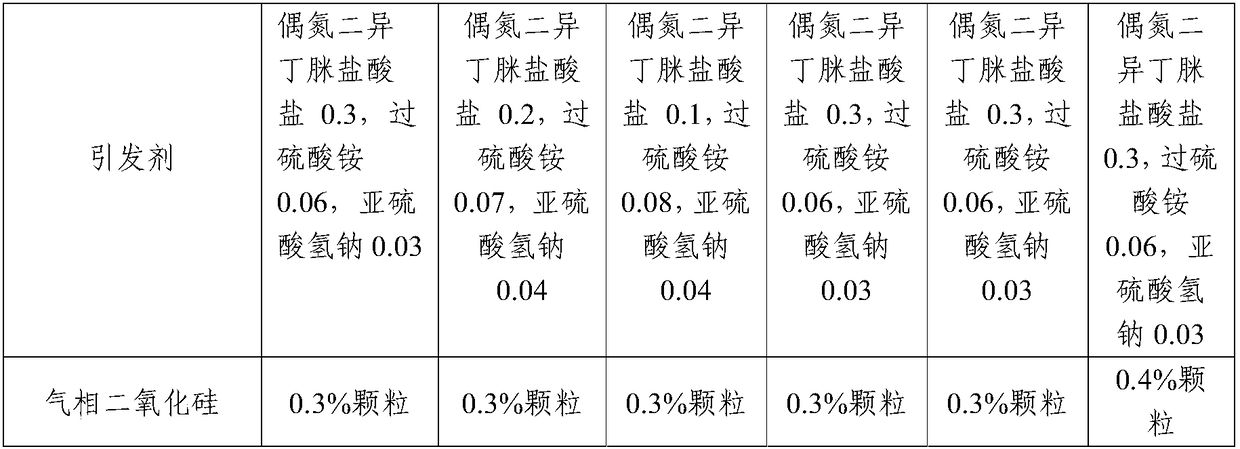

[0036] Nitrogen was passed for 40 minutes to achieve the purpose of oxygen removal, and 0.3 parts by weight of a chain extender (comprising 0.12 parts by weight of dimethylamine and 0.18 parts by weight of N,N-dimethylacrylamide), and 0.3 parts by weight of azobisisobutyramide hydrochloride were added Salt, 0.06 parts by weight of ammonium persulfate and 0.03 parts by weight of sodium bisulfite initiate polymerization, and when the temperature of the system rises to 85° C. and no longer rises, the reaction is considered to be completed.

[0037] The colloidal polymer is chopped and then dried, and crushed to 20-100 mesh to o...

Embodiment 2

[0043] Mix 100 parts by weight of deionized water, 2 parts by weight of acrylamide, 5 parts by weight of PEG10000, 300 parts by weight of dimethyl diallyl ammonium chloride, 2 parts by weight of tetramethylethylenediamine, and 2 parts by weight of vinylpyrrolidone , then add adipic acid, adjust the pH value to 3.5, and adjust the temperature to 18°C.

[0044] Nitrogen was passed for 40 minutes to achieve the purpose of deoxygenation, and 0.6 parts by weight of a chain extender (comprising 0.24 parts by weight of dimethylamine and 0.36 parts by weight of N,N-dimethylacrylamide), 0.2 parts by weight of azobisisobutylamidine hydrochloride were added Salt, 0.07 parts by weight of ammonium persulfate and 0.04 parts by weight of sodium bisulfite initiate polymerization, and when the temperature of the system rises to 78° C. and no longer rises, the reaction is considered to be completed.

[0045] The colloidal polymer is chopped and then dried, and crushed to 20-100 mesh to obtain a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com