CNC lathe fly-cutter disk and assembling method thereof

A technology of flying cutter head and cutter head, applied in the direction of tool holder, etc., can solve the problems of inability to achieve high processing precision and high quality, ordinary cutter head does not have adjustment conditions, reducing the processing efficiency of flying cutter head, etc., to ensure concentricity. and finish, improve processing performance, simple installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention In addition, the terms "first", "second", "above", "bottom" and the like are used for descriptive purposes only, and should not be construed as indicating or implying relative importance.

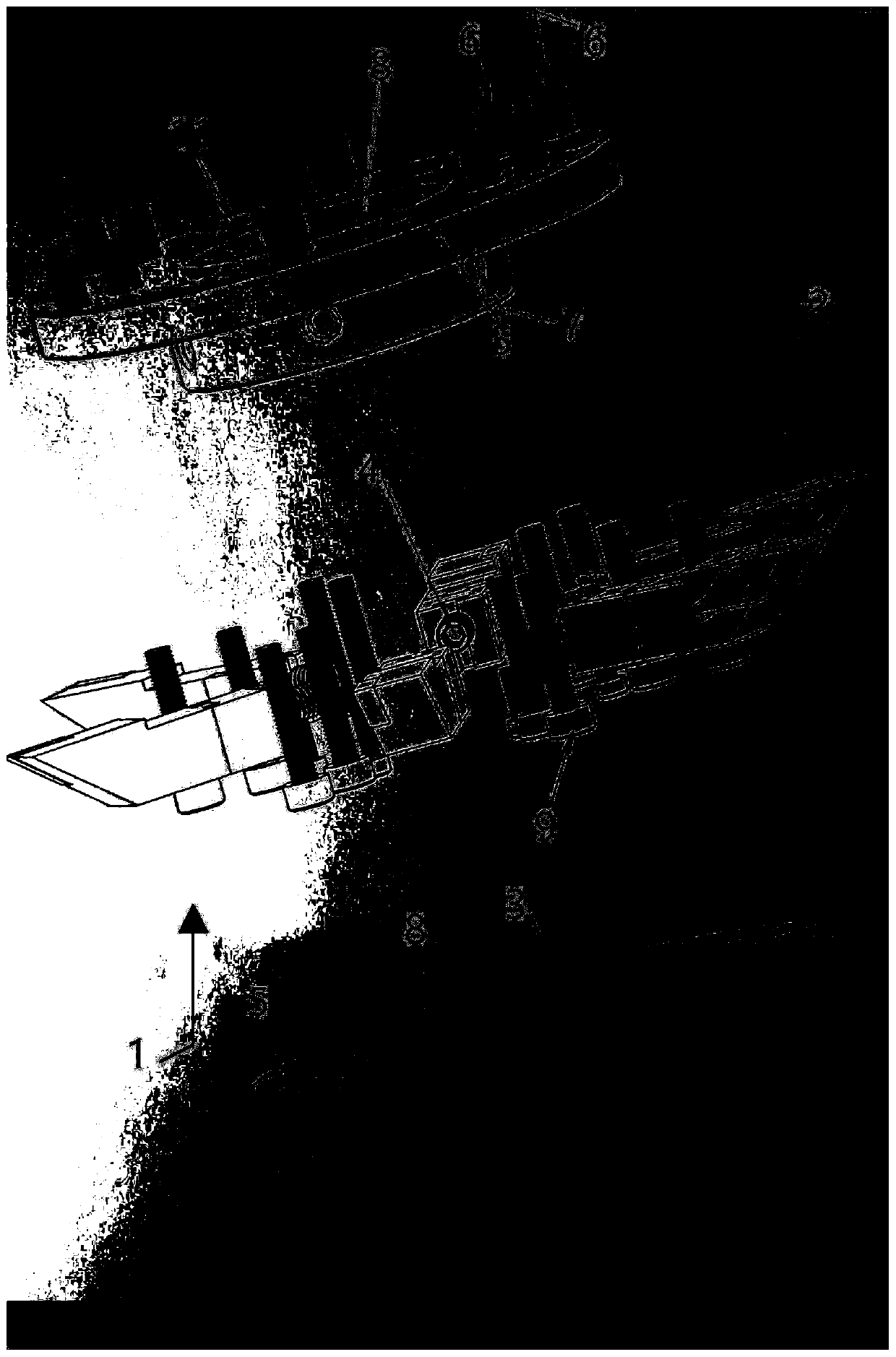

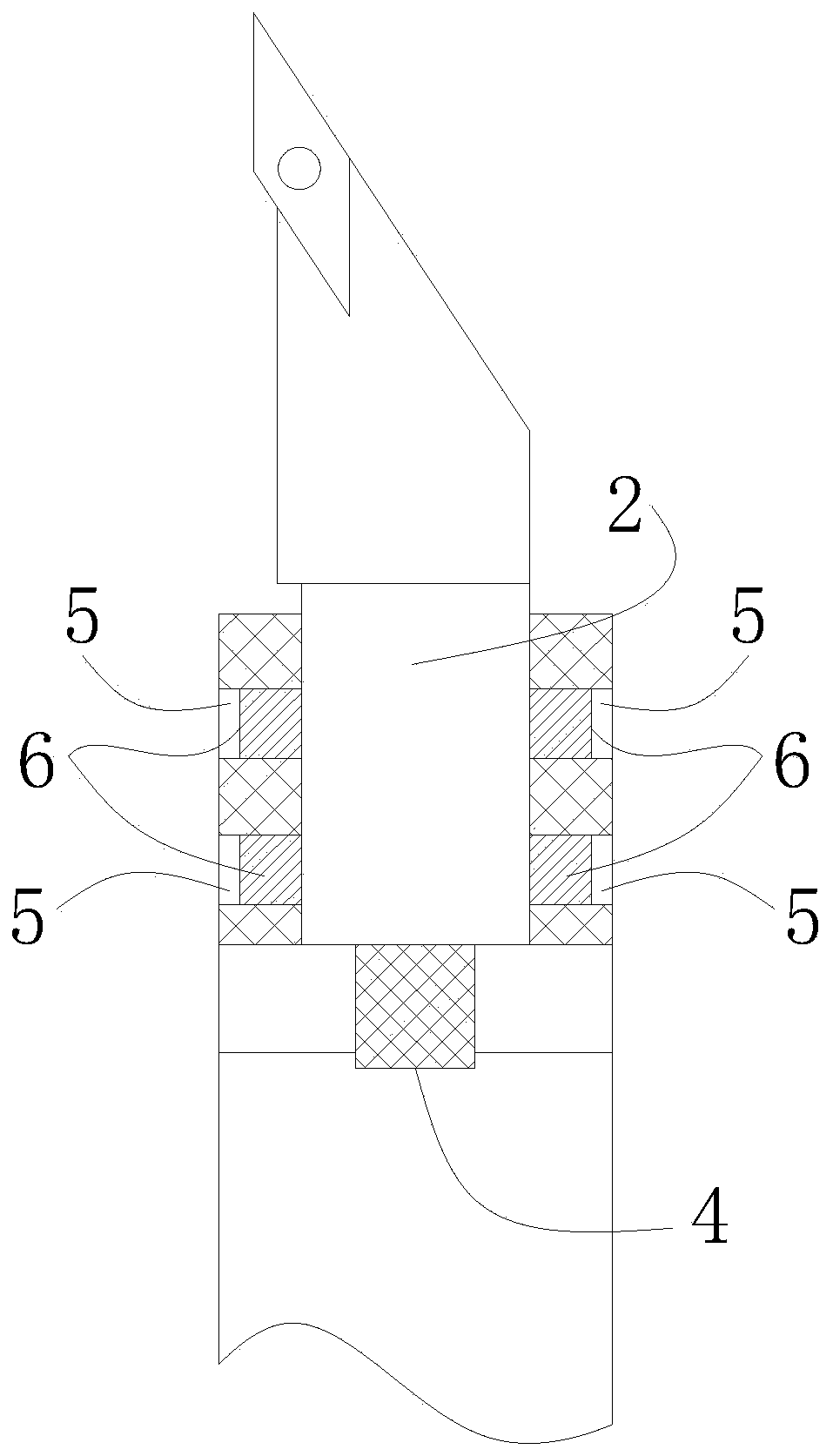

[0032] Please refer to figure 1 and image 3 , the embodiment of the present invention provides a CNC lathe flying cutter head, including a cutter head body 1 and a plurality of cutter bar assemblies 2, since the cutter head body 1 is provided with a plurality of cutter bar assemblies 2, the flying cutter head can be effectively improved. Processing efficiency and processing performance, the cutter head body 1 is provided with a plurality of installation grooves 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com