Contour processing clamp for bending part

A technology for shape processing and parts, applied in the field of fixtures for shape processing of curved parts, can solve the problems of radial deformation of curved parts, difficult to guarantee processing quality, increase processing difficulty, etc., achieve small deformation, ensure processing accuracy, The effect of quick processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

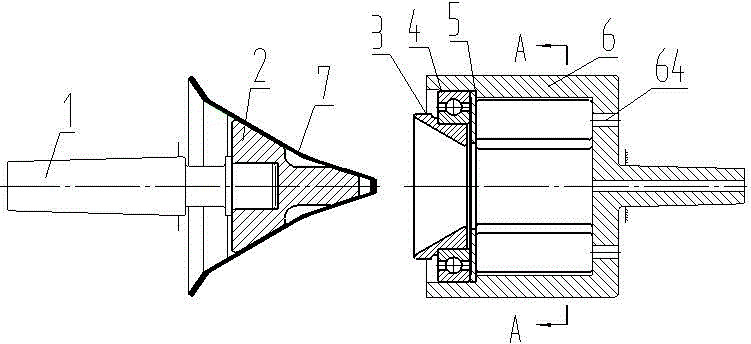

[0024] The present invention will be described in detail below in conjunction with the drawings, and the following embodiments can enable those skilled in the art to better understand the present invention, but do not limit the present invention in any form.

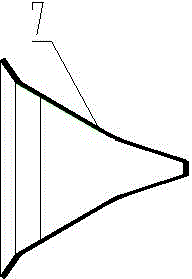

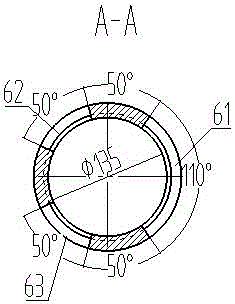

[0025] Such as figure 1 , 2 As shown, a fixture for contour processing of curved parts includes a positioning device and a clamping device. The positioning device includes a mandrel 1 and a top post 2. The top post 2 is fixed on the top of the mandrel 1. The other part of the top post 2 is The mandrel at one end matches the spindle of the lathe. The clamping device includes top bowl 3, bearing 4, gasket 5, and tip body 6. The top bowl 3 is connected to the tip body 6 through the bearing 4, and the gasket 5 is located between the bearing 4 and the tip body. In the middle of the connection surface of 6, the bearing 4 and the top bowl 3 can be easily disassembled through the four process holes 64 on the top body, the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com