Assembly-line sewing system

An assembly line and sewing technology, used in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of high production cost, low work efficiency, and a lot of labor, and achieve high production efficiency, assembly line processing, and strong versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

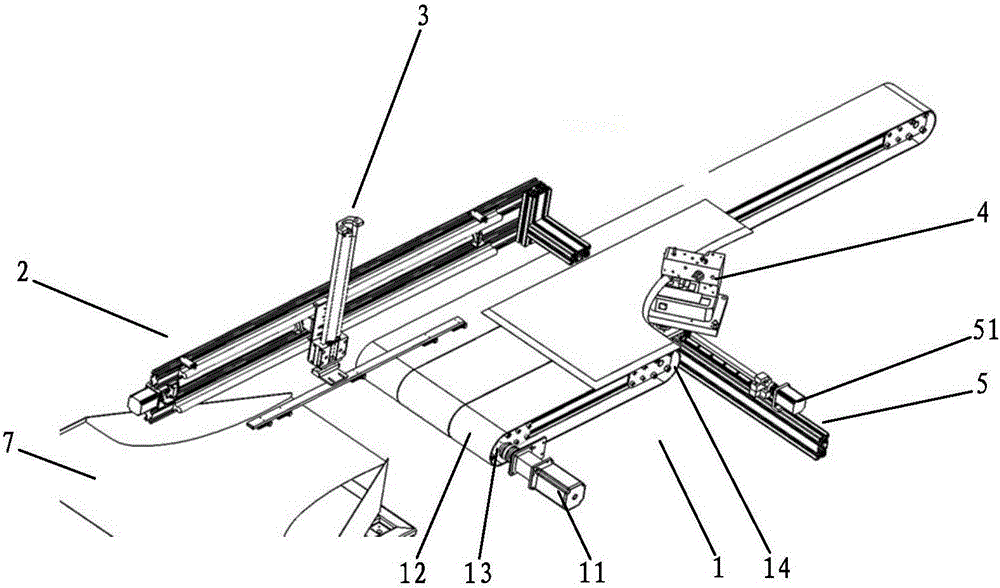

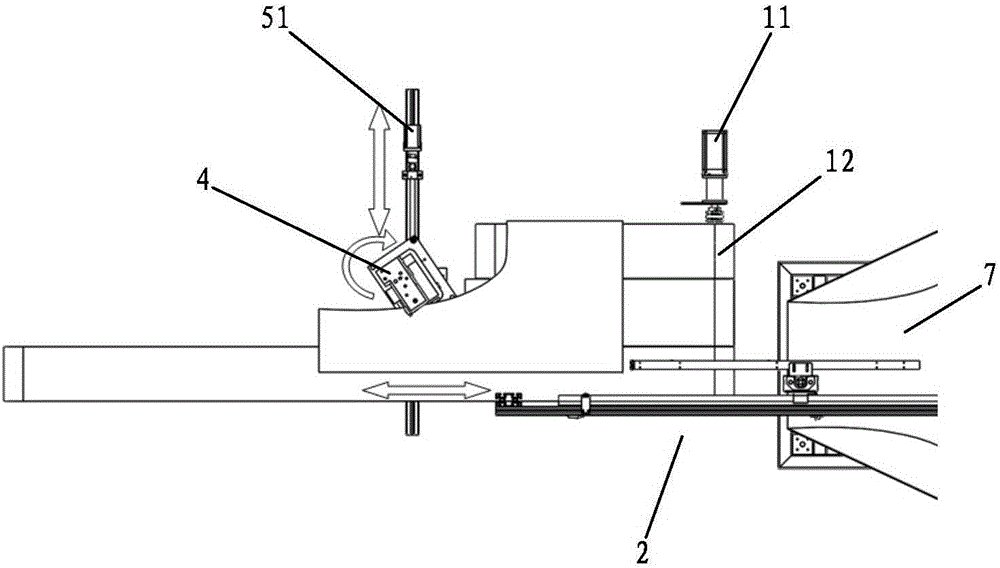

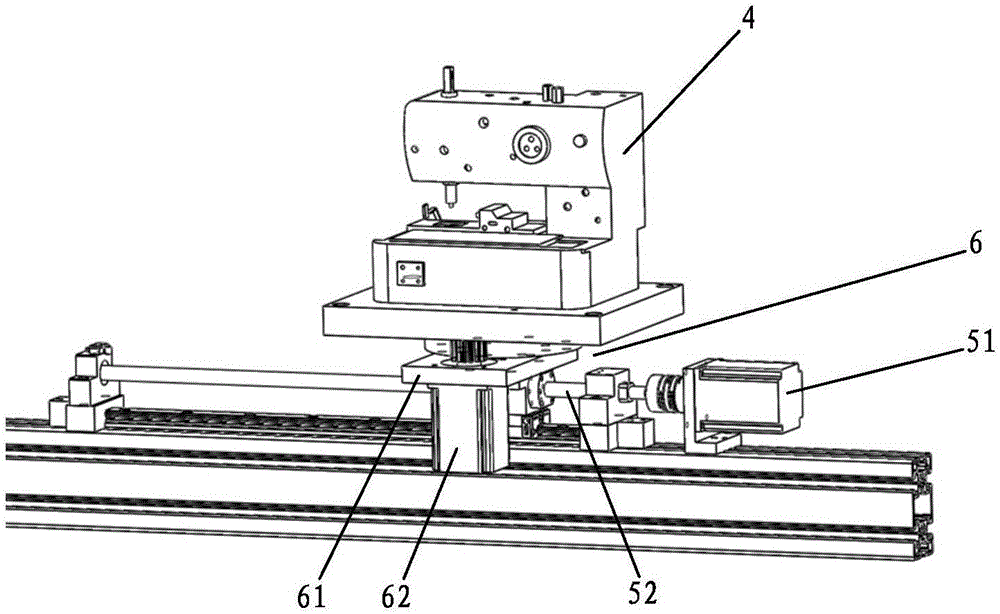

[0031] refer to Figure 1 to Figure 3 , this embodiment relates to an assembly line sewing system, including a frame and a conveyor belt device 1, an X-axis conveying device 2, a Z-axis conveying device 3, a sewing machine 4, a Y-axis conveying device 5 and a rotating conveying device 6 mounted on the frame , the X-axis conveying device 2 and the Z-axis conveying device 3 are located above the conveyor belt device 1, the Z-axis conveying device 3 is installed on the X-axis conveying device 2, and the X-axis conveying device 2 drives the Z-axis The conveying device 3 slides back and forth along the entrance of the conveyor belt device 1; the sewing machine 4 is fixedly mounted on the rotating conveying device 6, and the rotating conveying device 6 is slidably mounted on the Y-axis conveying device 5; the sewing machine 4 is located above the conveyor belt device 1 to sew the fabric 7 on the conveyor belt device.

[0032] The fabric 7 of this structure is transported to the ent...

Embodiment 2

[0050] This embodiment is based on Embodiment 1. As an improvement to the first clamping block 32 and the second clamping block 33, the bottom surfaces of the first clamping block 32 and the second clamping block 33 are provided with of noodle bites. By processing the textured surface on the bottom surface of the first clamping block 32 and the second clamping block 33, the frictional force between the bottom surface of the first clamping block 32 and the second clamping block 33 and the upper surface of the fabric 7 is improved to prevent the friction between the first clamping block 32 and the second clamping block 33 bottom surface and the upper surface of the fabric 7 During the relative movement of the block 32 and the second clamping block 33 , there is a sliding situation between the clamping block and the material 7 , thereby ensuring that the material 7 produces a bulge 321 and can be clamped by the first clamping block 32 and the second clamping block 33 .

Embodiment 3

[0052] This embodiment is on the basis of Embodiment 1, as an improvement to the first clamping block 32 and the second clamping block 33, the bottom surfaces of the first clamping block 32 and the second clamping block 33 are sprayed with a coating for increasing the coefficient of friction of grit. Surface treatment is carried out on the bottom surface of the first clamping block 32 and the second clamping block 33 through the processing technology of sand blasting, so as to improve the frictional force between the bottom surface of the first clamping block 32 and the second clamping block 33 and the upper surface of the fabric 7 , to prevent sliding between the first clamping block 32 and the second clamping block 33 during the relative movement of the clamping block and the material 7, thereby ensuring that the material 7 produces a bulge 321 that can be captured by the first clamping block 32 and the second clamping block 32. Clamp block 33 clamps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com