Treatment method of heavy metals in sludge

A heavy metal and sewage treatment plant technology, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of immature technology, high cost, and narrow phytoremediation treatment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

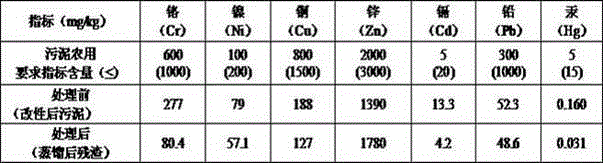

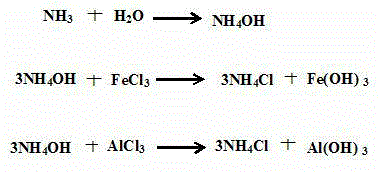

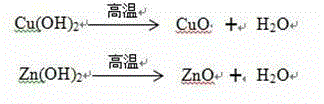

[0011] A method for treating heavy metals in sludge, including the conversion and fixation of N in protein in the sludge of sewage treatment plants and the treatment of heavy metals in the sludge. Specifically, it is achieved through the following steps: the protein in the sludge produced by the sewage treatment plant is hydrolyzed into free amino acids; the amino acids are deaminated under the action of amino acid oxidase to generate ammonia gas; and then through the conversion and fixation of ammonia, ammonia gas and water to generate ammonium hydroxide; ammonia hydroxide reacts with ferric chloride and aluminum chloride present in the sludge to generate ammonium chloride, and completes the modification process; the modified sludge is mixed with 0.001-0.003 % glucose powder and 0.1-0.3% calcium hydroxide are fully mixed and then heated mechanically. When the sludge is heated to a temperature above 100°C, the ammonium chloride in the sludge reacts with calcium hydroxide to gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com