Machining fixture for eccentric part

A technology of fixtures and parts, which is applied in the field of processing fixtures for eccentric parts, can solve the problems of incomplete processing, poor strength, precision and reliability, and impossibility of realization, and achieve the effect of high processing accuracy, good reliability, and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

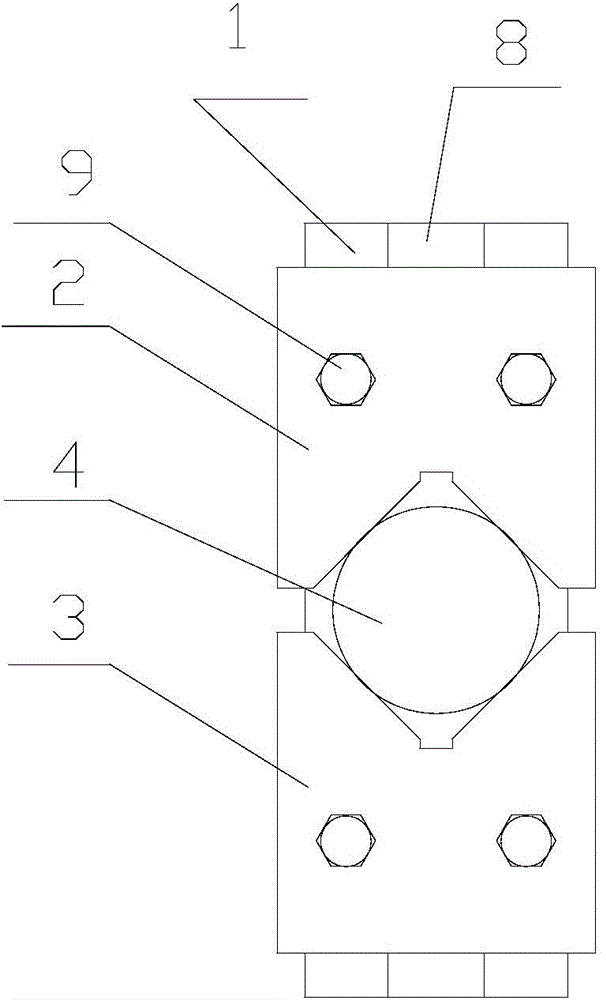

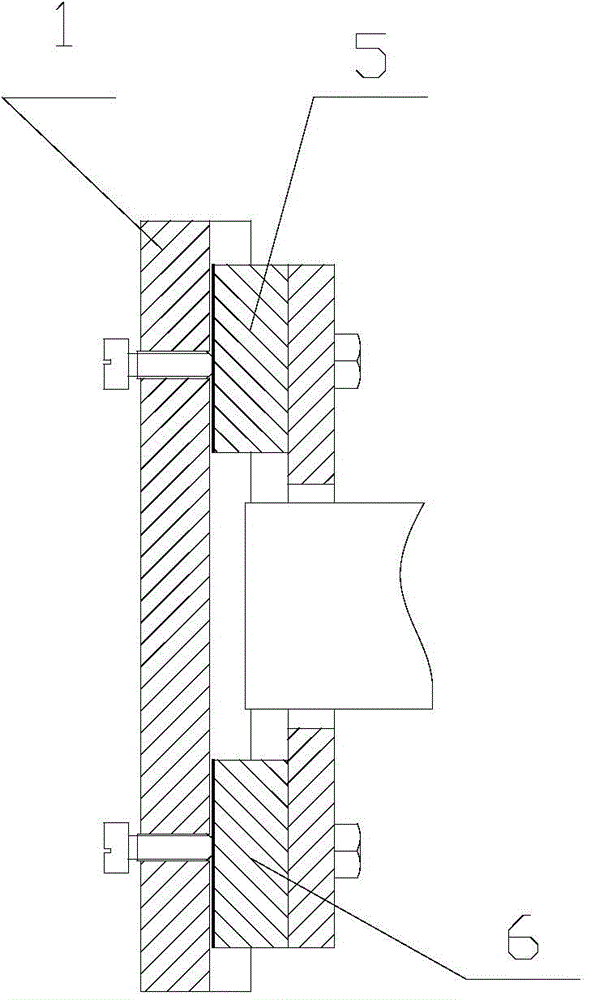

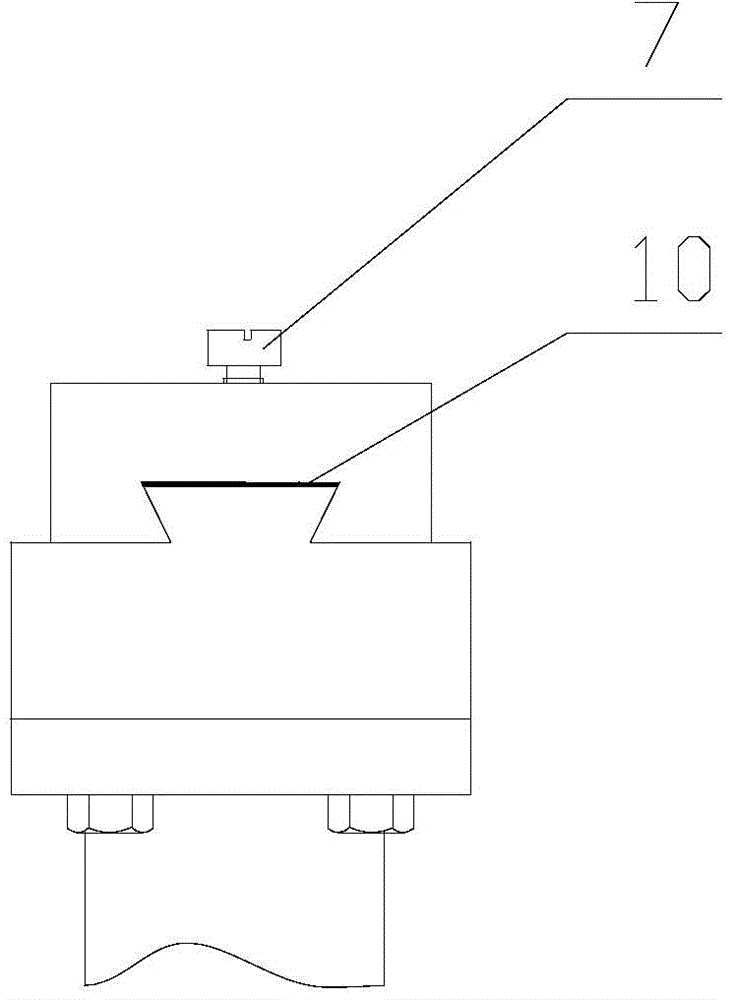

[0009] As shown in the figure, the processing fixture for eccentric parts includes a guide rail 1, an upper slider 5, a lower slider 6, an upper chuck 2, a lower chuck 3, and a set screw 7. The guide rail 1 is provided with a dovetail groove 8 , one side of the upper slider 5 and the lower slider 6 is provided with a dovetail structure, and is installed on the dovetail groove 8 on the guide rail, the upper slider 5 and the lower slider 6 can slide on the guide rail 1; the upper slider The other side of 5 is fixedly installed with upper chuck 2, and the other side of lower slider 6 is fixedly installed with lower chuck 3, and one end of described upper chuck 2 and lower chuck 3 is V-shaped, and the two described The V-shaped end faces are opposite and have the same size. The two V-shaped end faces can clamp the round shaft 4; the guide rail 1 is also provided with two set screws 7, one end of the set screw 7 has a tightening device, and the other end is respectively pushed On u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com