Ratio control method for realizing different processing strategies

A technology of processing strategy and control method, applied in the field of CNC machine tools, can solve problems such as inconvenient operation and accidents, and achieve the effect of overcoming technical defects, convenient and simple operation, and overcoming accidents that are easy to cause.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

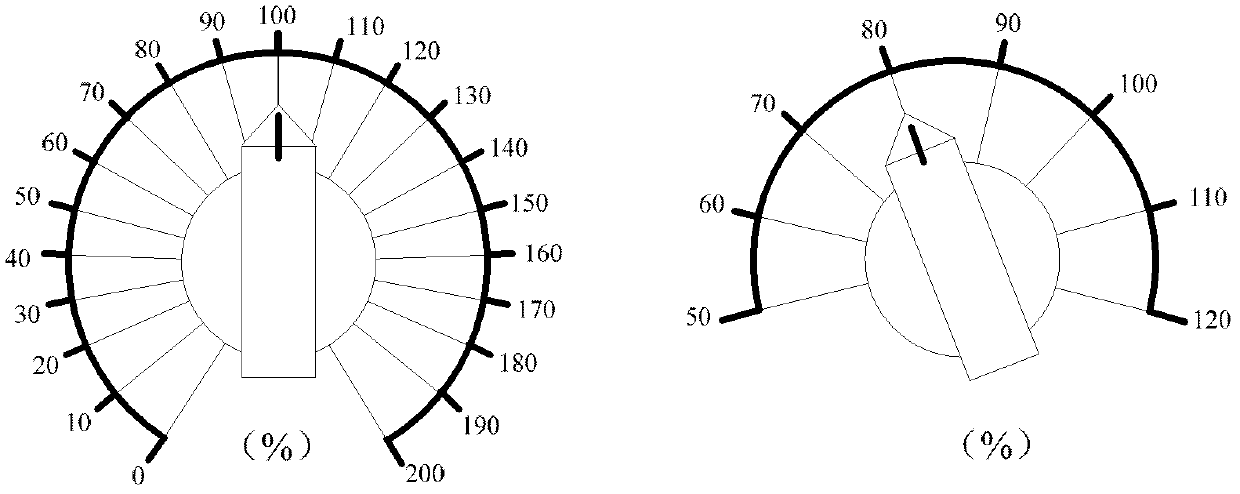

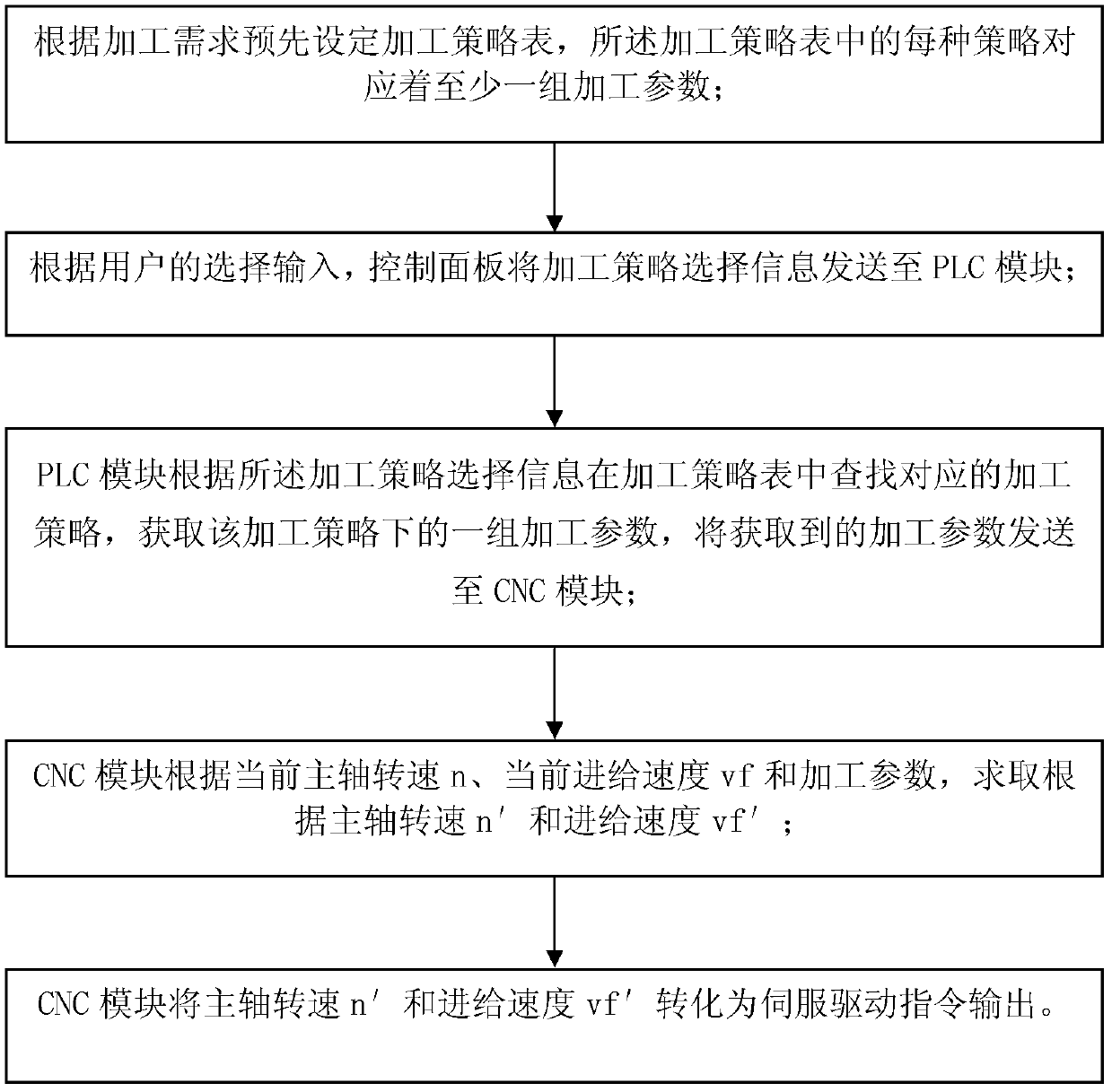

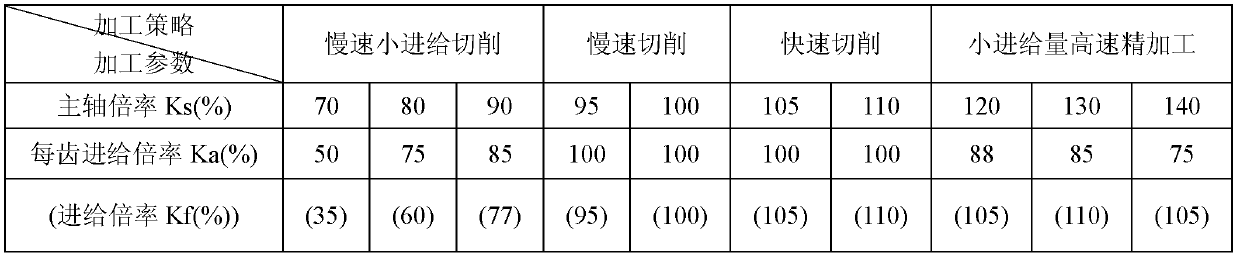

[0027] figure 1 It is a schematic diagram of CNC cutting machining parameter control in the prior art. As shown in the figure, the machining parameters are pre-set, mainly including two types, namely feed override and spindle override. When the switch is used to adjust the feed override and spindle override, the feed override switch and the spindle override switch need to be adjusted separately. The feed override switch and the spindle override switch each have multiple gears to choose from, but the values of the preset multiple gears generally do not change, and the user can only select a certain range within the preset gear range. first gear. The feed override and the spindle override are independent of each other, and only the feed override or the spindle override can be adjusted independently during the machining process. The separate adjustment of feed speed and spindle speed in the existing technology may cause huge fluctuations in the actual tool feed per tooth. Too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com