Biomass fuel aluminum melting furnace

A biomass fuel and aluminum melting furnace technology, applied in the field of aluminum melting furnaces, can solve the problems of poor heat preservation performance, high fuel consumption, high cost, etc., to enhance the ability to maintain the temperature in the crucible, delay the loss of room temperature, and reduce consumption costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

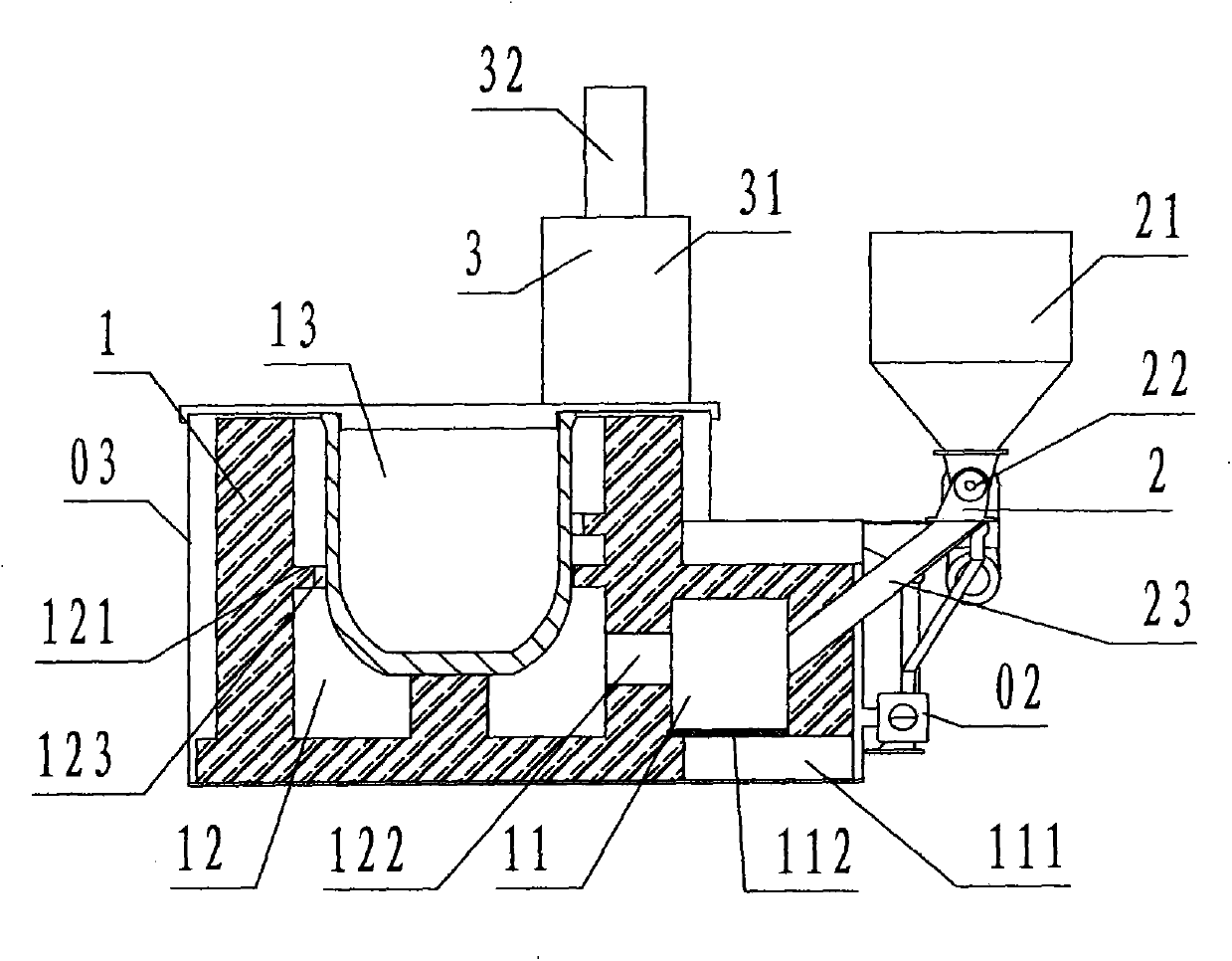

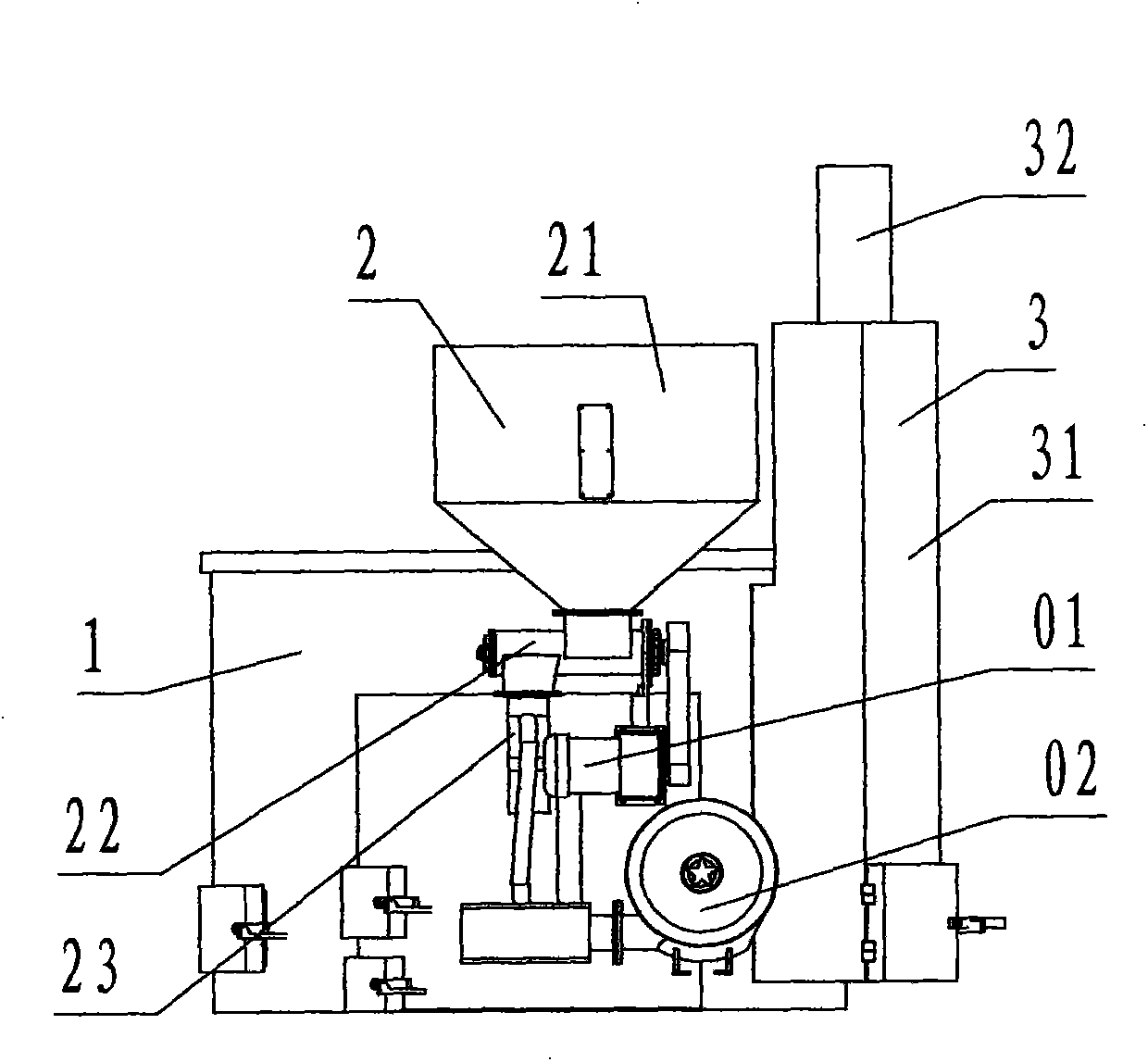

[0018] refer to figure 1 , figure 2 , a biomass fuel aluminum melting furnace of the present invention comprises a furnace body 1, a screw feeder 2, and a chimney 3, and the furnace body 1 is made of a refractory material composed of a combustion chamber 11, a heating chamber 12 and a crucible 13. The device, wherein, the heating chamber 12 is located at the left part of the furnace body 1, the heating chamber 12 is hollow, the upper part is open, the lower part has a bottom, and the cylindrical barrel-shaped structure, the crucible 13 is located in the heating chamber 12, and the heating chamber 12 furnace wall A horizontal ring-shaped partition wall is set between the outer wall of the crucible 13 and is called a fire barrier layer 121, and several rectangular gaps are evenly distributed on the inner circle of the fire barrier layer 121 in contact with the crucible 13, which are called hot gas. Road 123; the upper edge of the crucible 13 is flush with the upper edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com