Device and method for simultaneously metering and mixing two or more materials

A technology of mixing device and feeding device, which is applied in mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of reducing the accuracy of adding amount, many process steps, and the difference between the quality of the matrix graphite powder and the set quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

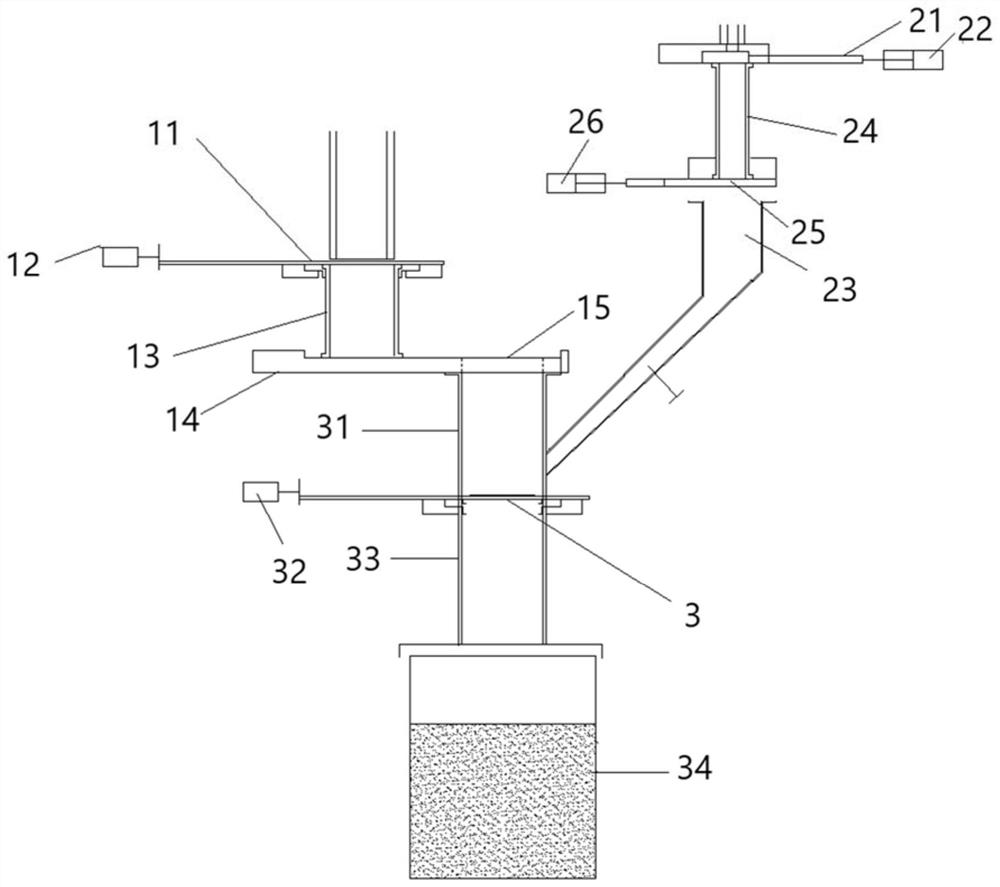

[0100] like figure 1 As shown, a device that realizes simultaneous metering and mixing of two or more materials, including:

[0101] 1) The first material quantitative device, which includes:

[0102] The first material quantitative cup,

[0103] The first material feeding device, the first material feeding device is used to transport the first material into the first material quantitative cup, the first material feeding device is provided with a first material feeding control device, and the first material feeding device is equipped with a first material feeding control device. The first material feeding control device is used to control the feeding time and feeding intermittent time of the first material,

[0104] The first material scraper 11, the first material scraper 11 is arranged above the first material quantitative cup,

[0105] The first material scraper control device 12, the first material scraper control device 12 is used to drive the first material scraper 1...

Embodiment 2

[0152] like figure 1 As shown, a method to achieve simultaneous metering and mixing of two or more materials, including:

[0153] First material quantification: set the feeding time and feeding interval time of the first material feeding device through the first material feeding control device, and transport the first material to the first material quantitative cup through the first material feeding device ; The first material scraper 11 is driven by the first material scraper control device 12 to move to scrape off the overflowing first material on the upper surface of the quantitative cup of the first material, so as to realize equal-volume measurement of the first material;

[0154] Quantitative second material: set the feeding time and intermittent time of the second material feeding device through the second material feeding control device, and transport the second material to the second material quantitative cup through the second material feeding device ; The second m...

Embodiment 3

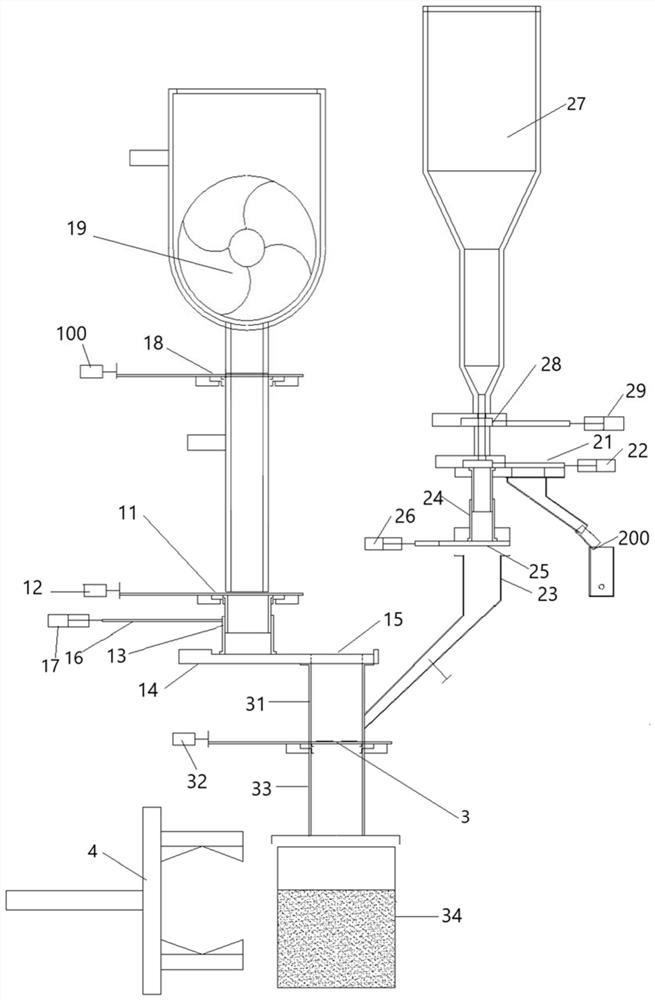

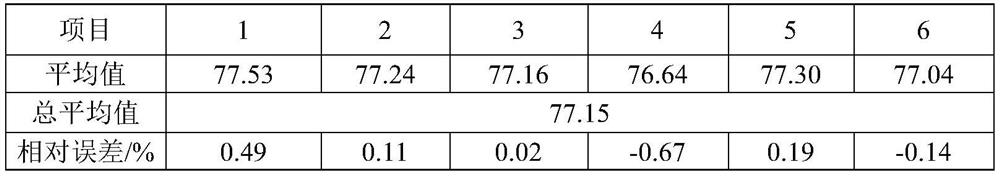

[0167] like figure 2 Shown, a kind of method that realizes matrix graphite powder and dressing particle to finish metering and mixing simultaneously, comprises:

[0168] (1) The first material is matrix graphite powder, and the quantification of the first material includes the following steps: the powder is stored in the powder silo 19; Above the powder quantitative cup; according to the volume of the powder quantitative cup, the feeding time of the powder silo is set to 13s and the interval time is 7s through the first material feeding control device;

[0169] When the powder silo is fed to the powder quantitative cup, the feed screen 18 located below the powder silo 19 is driven by the feed screen control device 100 to move the powder sieve onto the dispersion screen 11; the dispersion screen control device 12 drives the movement of the dispersing screen 11 to drop the powder sieve into the first material quantitative cup;

[0170] Wherein, the diameter of feed screen 18 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com