Digital linear reciprocal paper sheet feeding mechanism of automatic flat pressing cutter

A paper feeding mechanism and linear reciprocating technology, which is applied to flatbed printing machines, printing machines, printing, etc., can solve the problems of high manufacturing cost, large mechanical wear, and short life of the whole machine, so as to reduce maintenance workload and reduce material costs. Effects of cost reduction and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

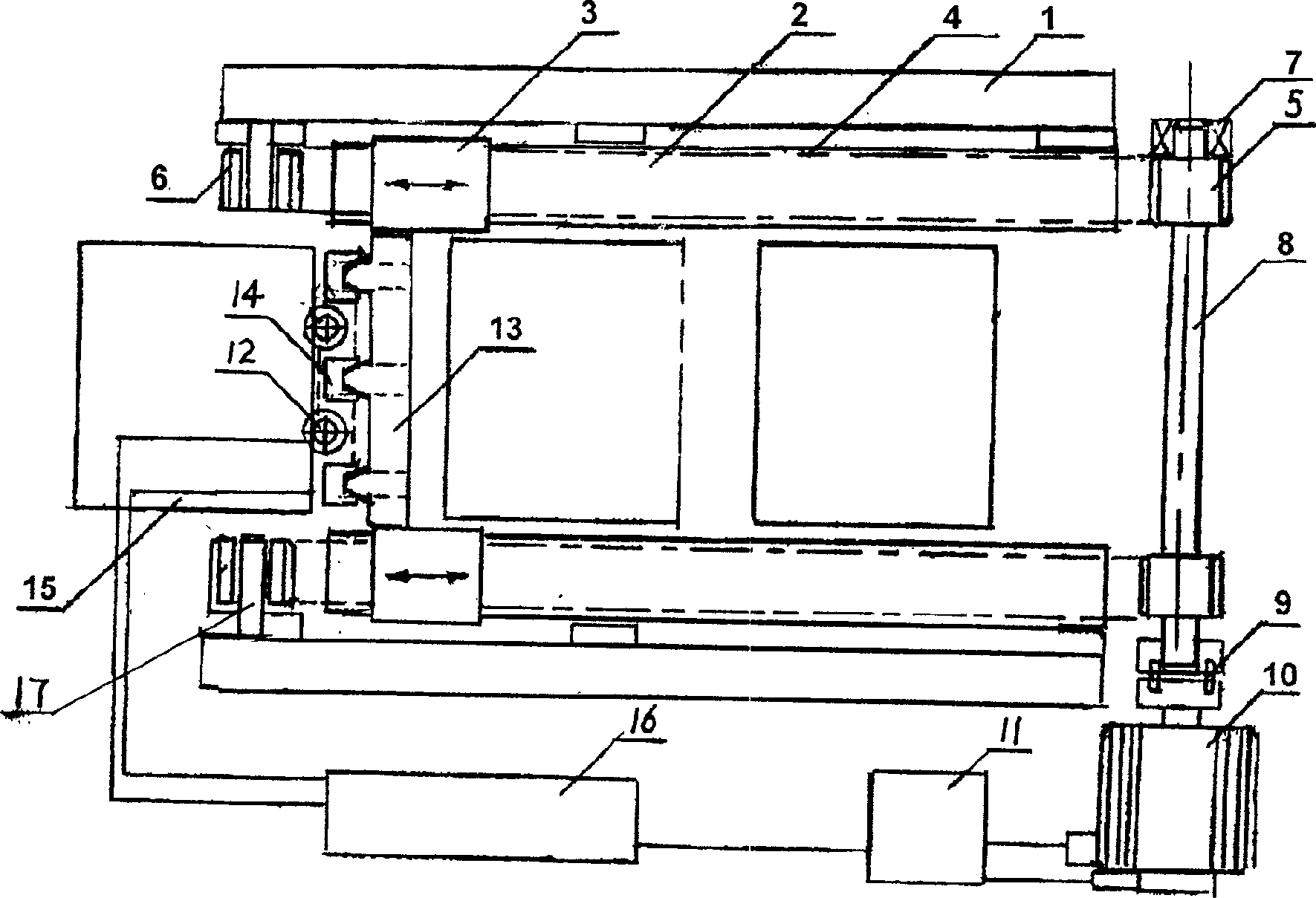

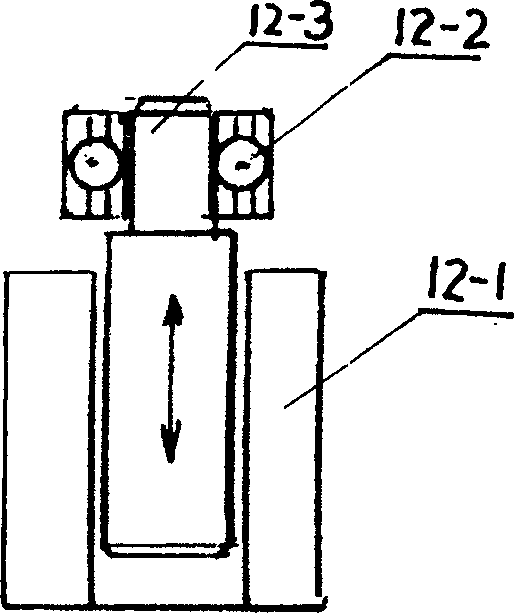

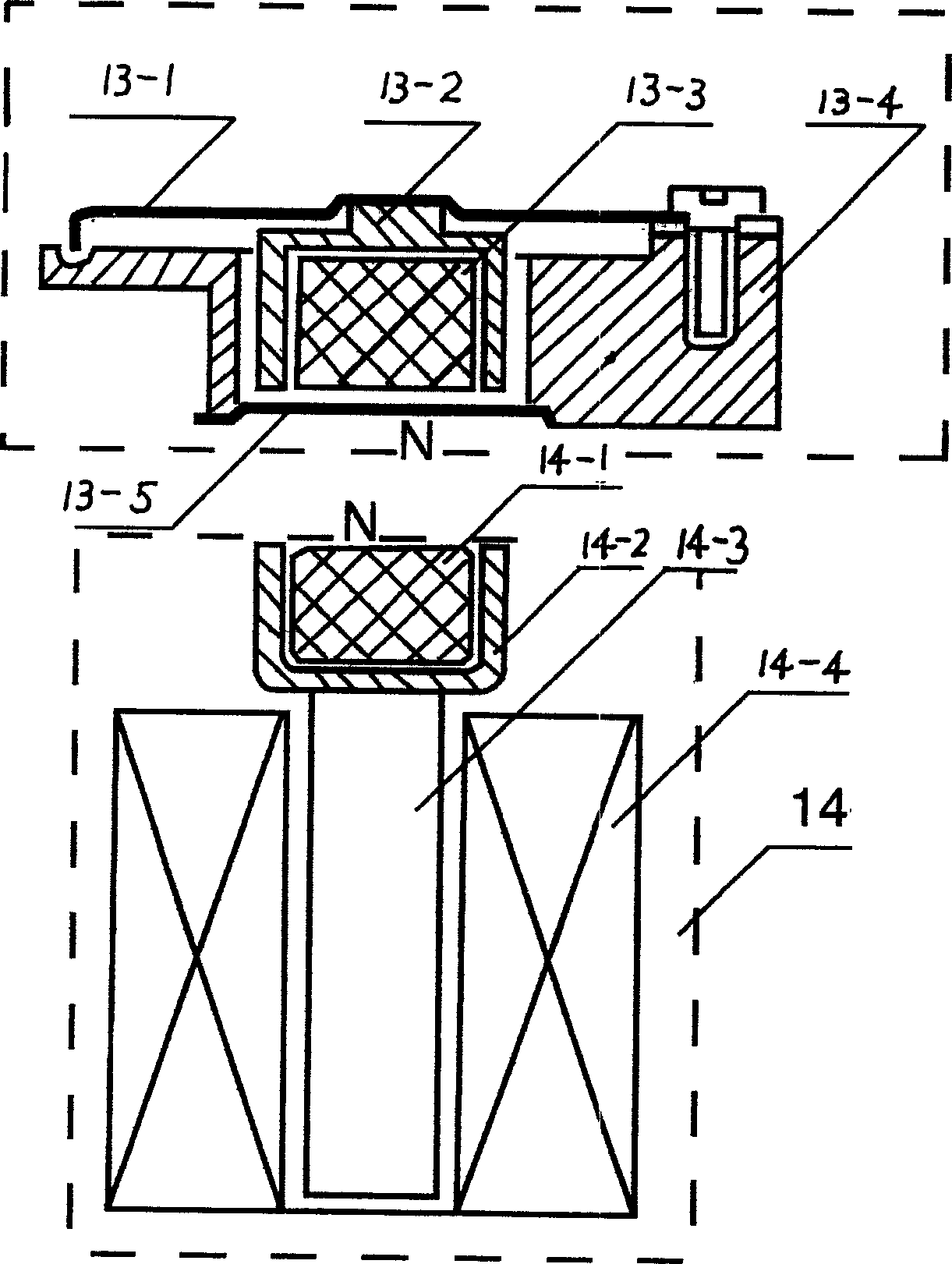

[0010] see figure 1 , the digital linear reciprocating paper feeding mechanism of the flat-press flat automatic die-cutting machine of the present invention is composed of a row of teeth moving assembly, a paper feeding positioning front rail and a driving part, wherein the moving assembly of the row of teeth includes a synchronous toothed belt pulley 5, 6. Synchronous toothed belt 4, linear guide rail body 2, guide rail slider 3, and paper tooth row 13, wherein the synchronous toothed belt 4 meshes with the synchronous toothed belt pulleys 5 and 6, and is located on the two wall panels 1 of the die-cutting machine The inner side of the drive toothed belt pulley 5 is installed on the transmission shaft 8 driven by the servo motor 10, the servo motor 10 and the transmission shaft 8 are connected through the servo coupling 9, and connected to the servo drive 11 by wires; the passive tooth shape Belt pulley 6 is sleeved on the axle 17 that is fixed on die-cutting machine both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com