Feeding control system and its method

A control system and control method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of SMD circuit board printing errors, increase material loading processing time, increase manufacturing costs, etc. The effect of improving the accuracy of materials, shortening the downtime for refueling, and reducing the rework rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

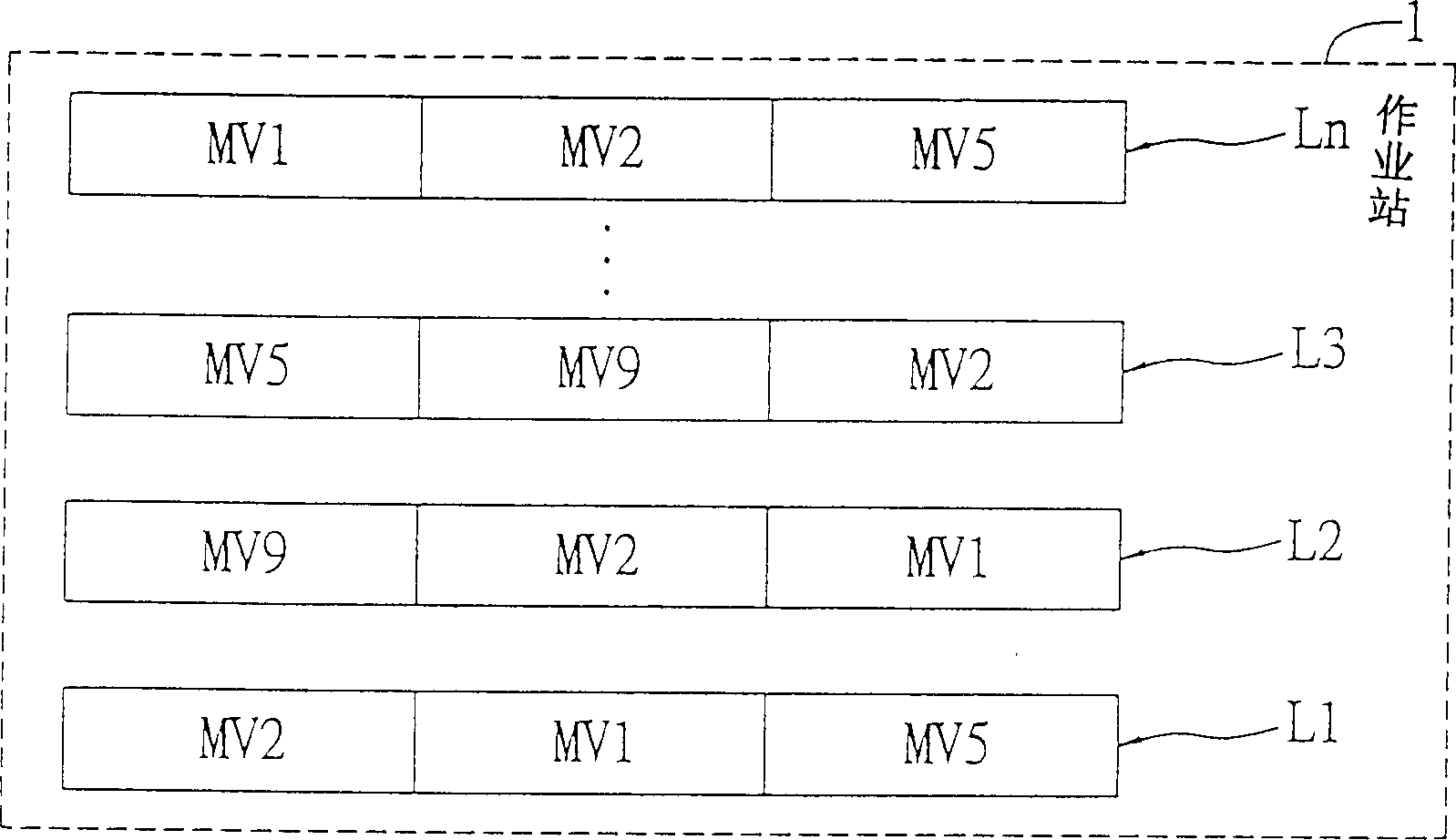

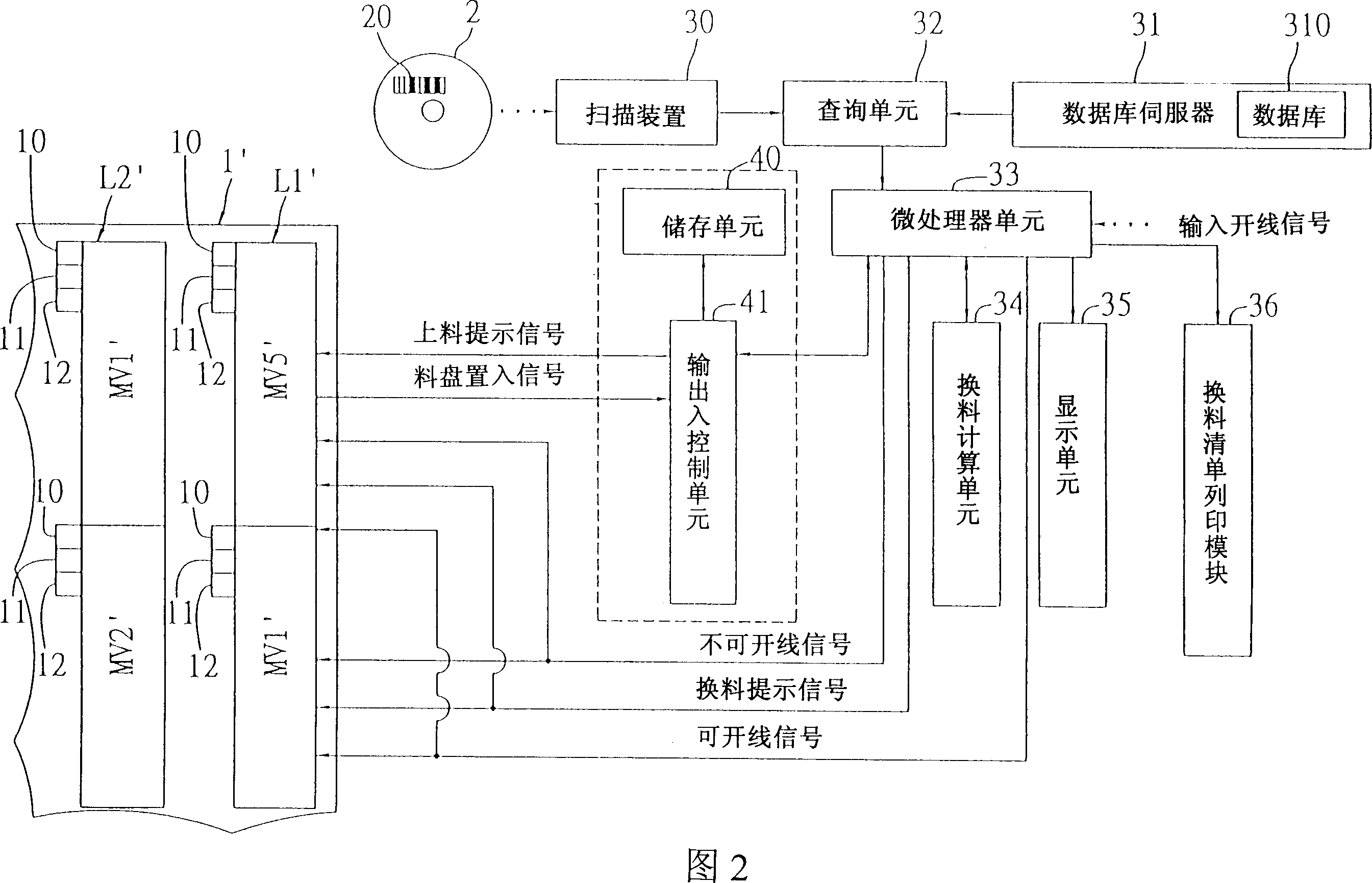

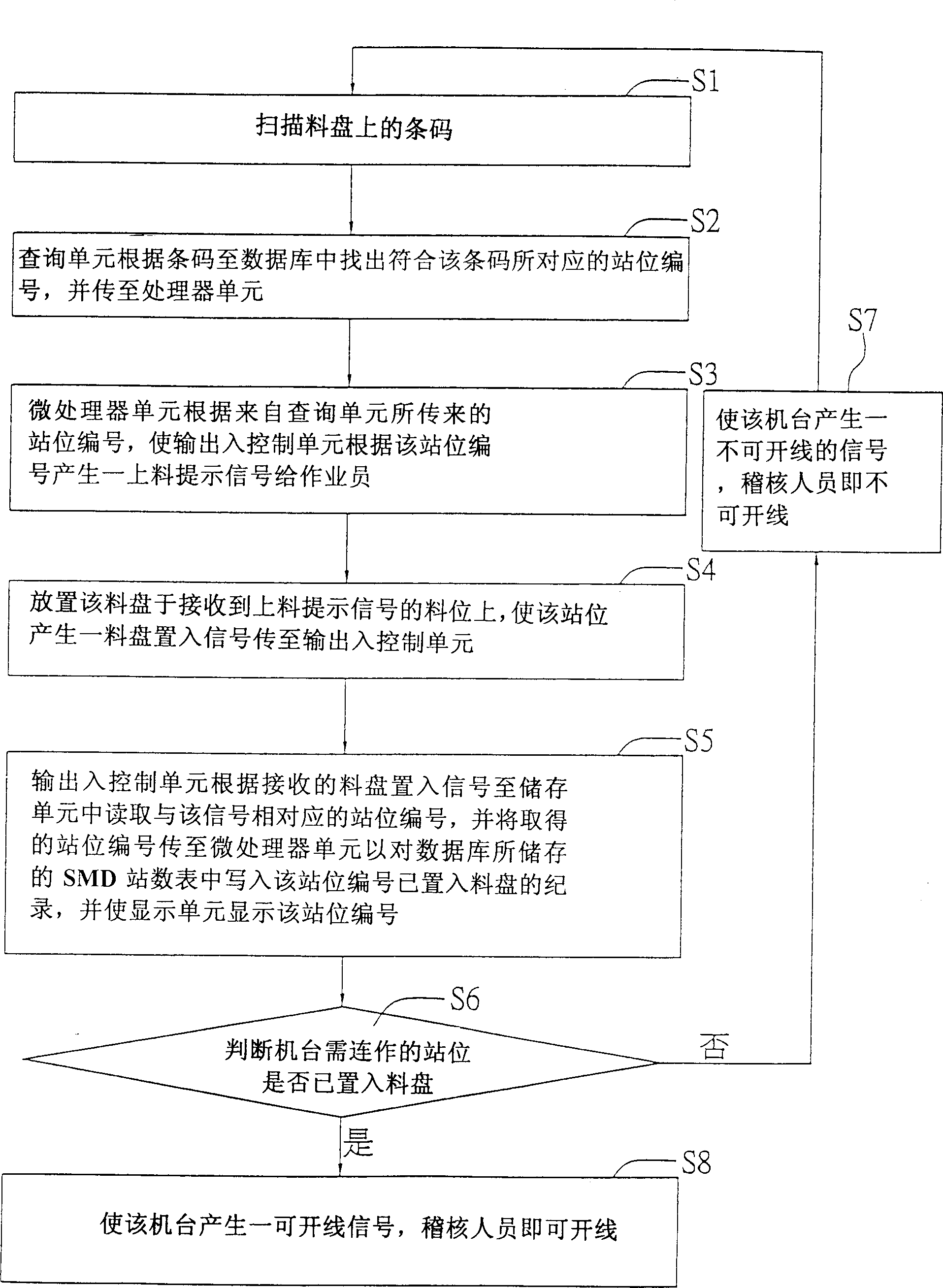

[0045] Please refer to FIG. 2 , which is a block diagram of the system structure of the feeding control system of the present invention. As shown in the figure, the feeding control system of the present invention includes a scanning device 30, a database server 31, a query unit 32, a microprocessor unit 33, a refueling calculation unit 34, a display unit 35, a refueling list printing module 36, and a storage unit 40 and the I / O control unit 41, wherein each line position (L1', L2') of the SMD operation station 1' needs to be connected to the feeding control system respectively, and each machine platform (MV1', MV2', MV5' ) are respectively connected to the storage unit 40 and the I / O control unit 41 (that is, at the dotted line box), wherein, in order to simplify the drawings and descriptions, the system architecture here only shows the SMD operation station 1' part of the machines.

[0046] First, the material number of each tray 2 needs to be coded in advance, and the coded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com