Peripheral feeding and separating device of direct current electric arc furnace for titanium slag smelting

A technology of DC electric arc furnace and material distribution device, which is applied to lighting and heating equipment, etc., to achieve the effect of simple structure, small volume and convenient feeding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

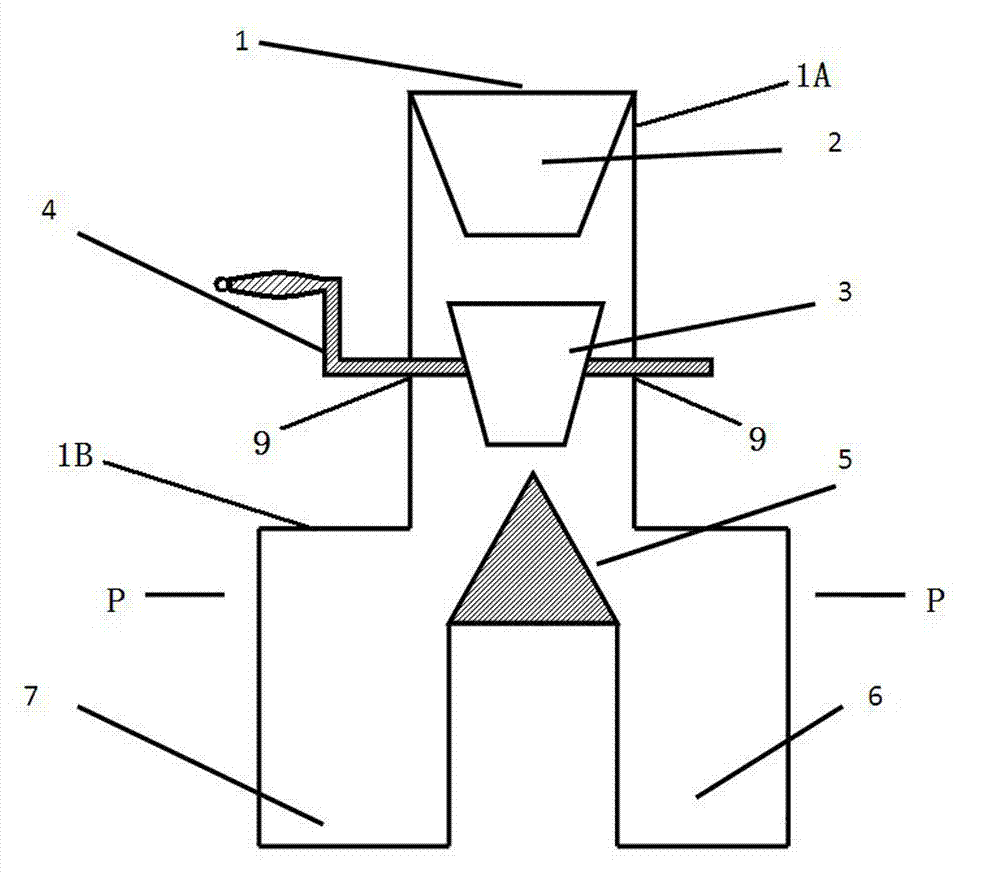

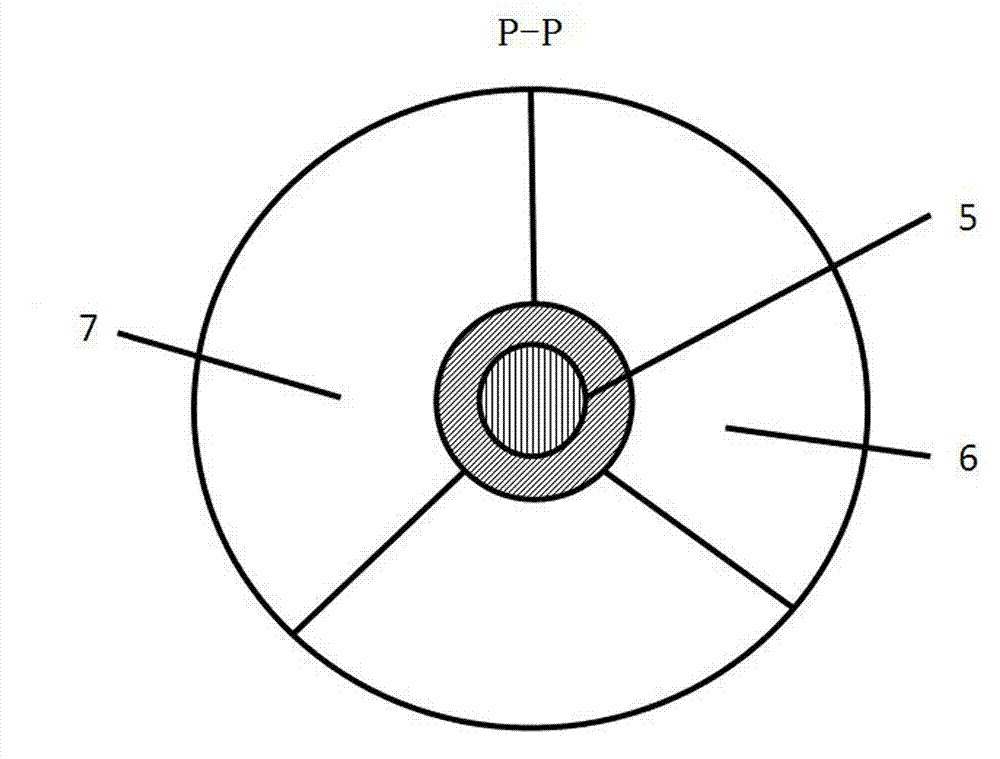

[0017] A peripheral feeding and distributing device of a DC electric arc furnace for titanium slag smelting. The present invention is characterized in that: the material distributing device comprises a shell 1 and a material distributing mechanism arranged on the shell 1, and the material distributing mechanism is sequentially provided with a material collecting device 2, a feeding cup 3 with an adjusting handle 4, a circular material distributing mechanism from top to bottom. The cone 5 and the circular distributing cone 5 are distributed in an annular shape, and there are no less than one feeding openings 6 separated by baffles.

[0018] The casing 1 of the present invention is composed of an upper circular feeding bin 1A and a lower circular feeding bin 1B.

[0019] The adjusting handle 4 of the present invention is fixed on the outside of the feeding cup 3 , and the two ends of the adjusting handle 4 are sleeved on the sleeve holes 8 on both sides of the shell 1 .

[0020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com