Rapid powder point equipment applied to lining cloth and used for garment production

A technology of powder spot and interlining, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of wasting manpower, high labor intensity, and difficult to control the speed to be completely consistent, so as to maintain the discharge rate. Consistent speed and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

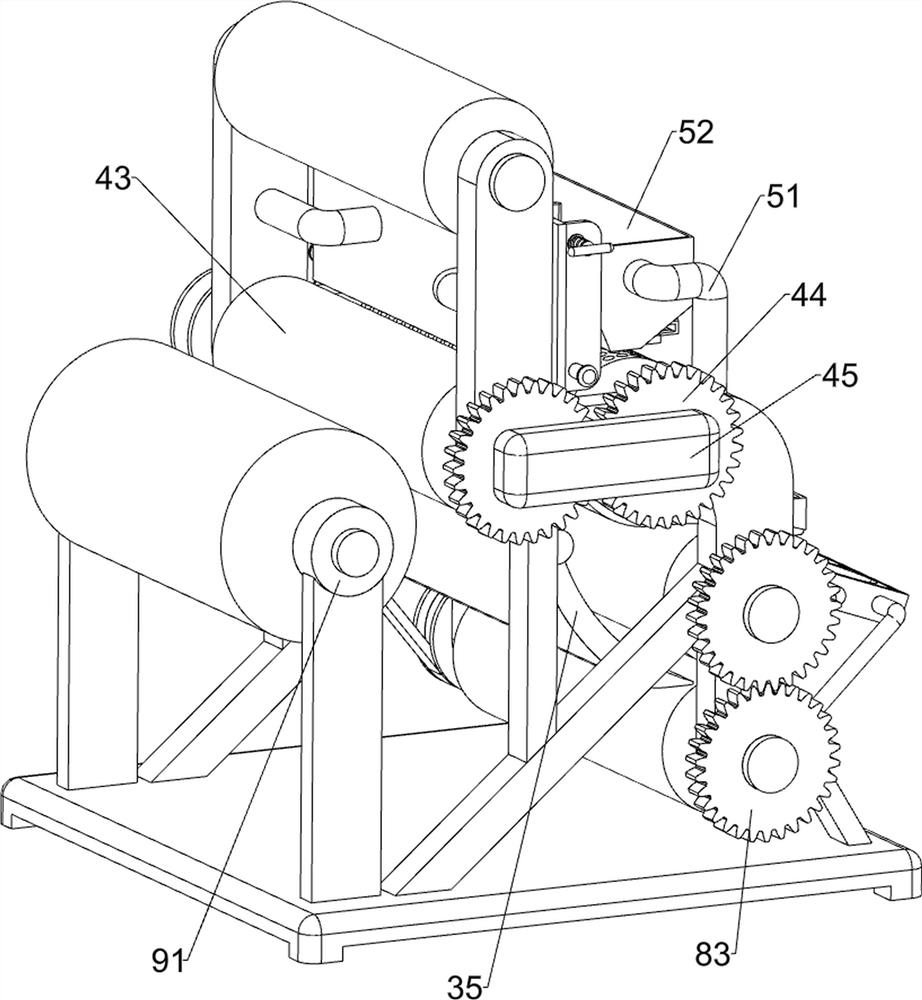

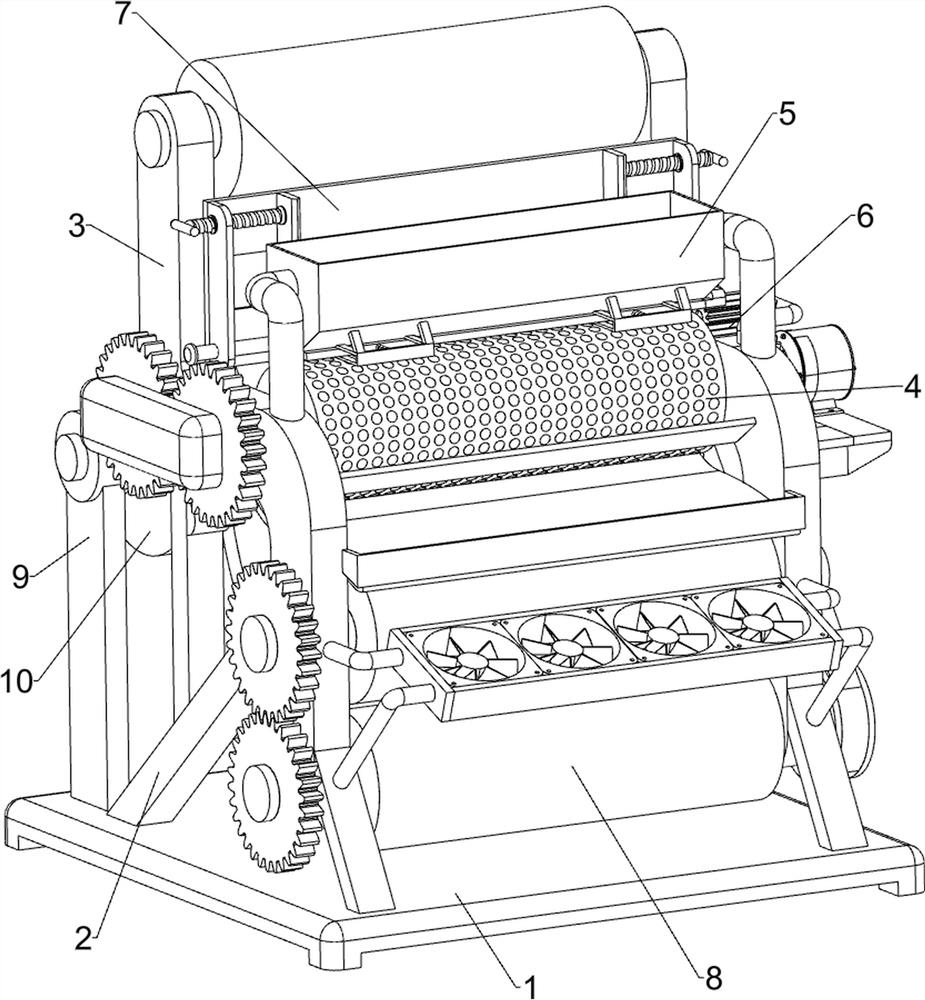

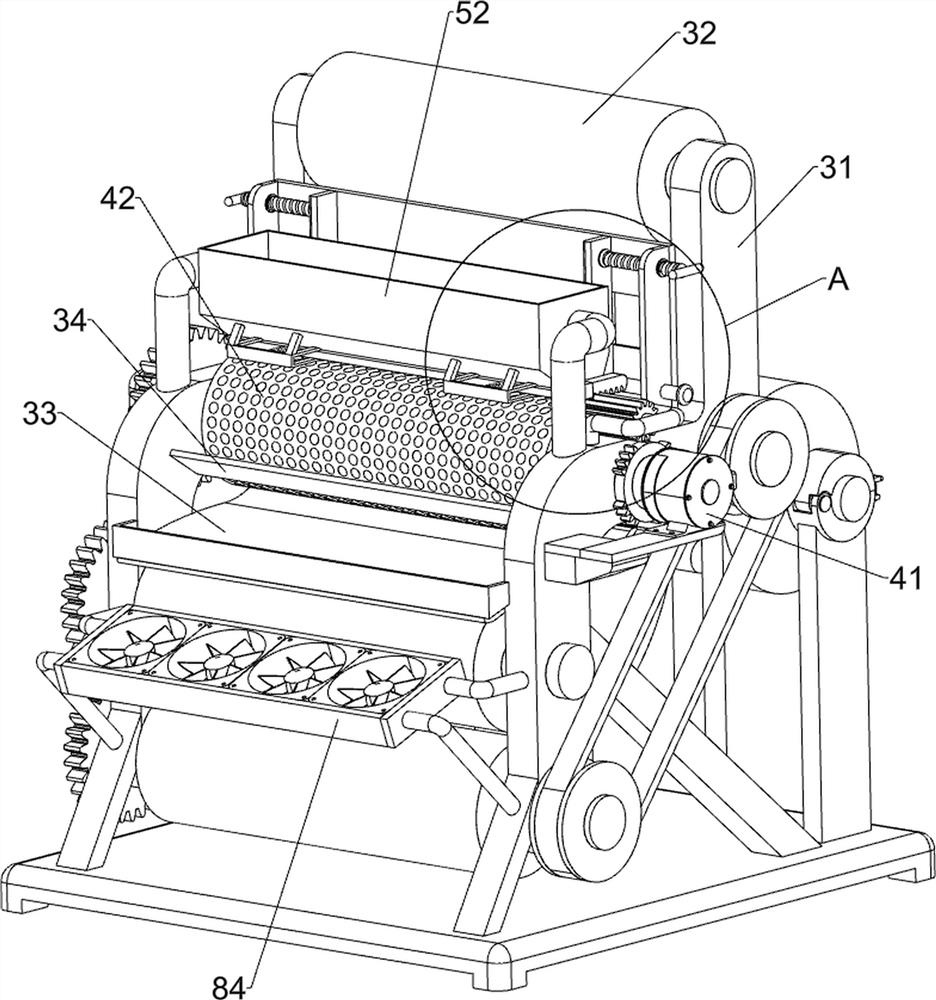

[0030] A fast powder-pointing equipment for interlining for garment production, such as figure 1 , figure 2 , image 3 and Figure 5 As shown, it includes a bottom plate 1, a bracket 2, an installation and placement component 3, a powder spot component 4, a material storage component 5 and an interval blanking component 6. The left and right sides of the rear side of the top of the bottom plate 1 are connected with brackets 2. An installation and placement assembly 3 is installed between the two, on which a powder spot assembly 4 and a material storage assembly 5 are respectively installed, and an interval blanking assembly 6 is installed on the right bracket 2 .

[0031] The installation and placement assembly 3 includes an installation frame 31, a rotating roller 32, a pallet frame 33, a scraper plate 34 and a guide plate 35. The installation frame 31 is connected to the bracket 2, the bottom of the installation frame 31 is connected to the top of the bottom plate 1, and ...

Embodiment 2

[0037] On the basis of Example 1, as figure 1 , Figure 4 and Figure 5 As shown, it also includes a guide assembly 7. The guide assembly 7 includes a third fixing frame 71, a slotted baffle frame 72, a sliding side plate 73, a screw rod 74, a fixing nut 75 and a guide rod 76. The upper part of the inner side of the mounting frame 31 A third fixing frame 71 is connected, and a slotted baffle frame 72 is connected between the two third fixing frames 71. The left and right sides of the slotted baffle frame 72 are slidably connected with sliding side plates 73. The left and right sides of the plate frame 72 are connected with fixed nuts 75, and the fixed nuts 75 are connected with screw rods 74 by means of screw connection. , the guide rod 76 is slidably connected with the slotted baffle frame 72 .

[0038] According to the size of the interlining cloth 10, the screw 74 can be rotated to make the sliding side plate 73 move inward and contact the side of the interlining cloth 1...

Embodiment 3

[0040] On the basis of Example 2, as Figure 1-4 As shown, it also includes a compaction cooling assembly 8. The compaction cooling assembly 8 includes a transmission belt group 81, a pressing roller 82, a second opposing gear group 83 and a fan cooling frame 84, and the mounting frame 31 is rotatably connected with a Two pressing rollers 82, a transmission belt group 81 is connected between the lower pressing roller 82 and the flat heating roller 43, a second opposing gear group 83 is connected between the two pressing rollers 82, and the front side of the mounting frame 31 is connected There are fan cooling racks 84 .

[0041] The lining cloth 10 after powder dot coating enters between the pressing rollers 82 through the guide plate 35, and the flat heating roller 43 rotates in the reverse direction through the transmission belt group 81 to make the lower side pressing roller 82 rotate in the reverse direction, through the second opposing gear group 83. The upper side press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com