Amorphous strip bilateral winding device and method

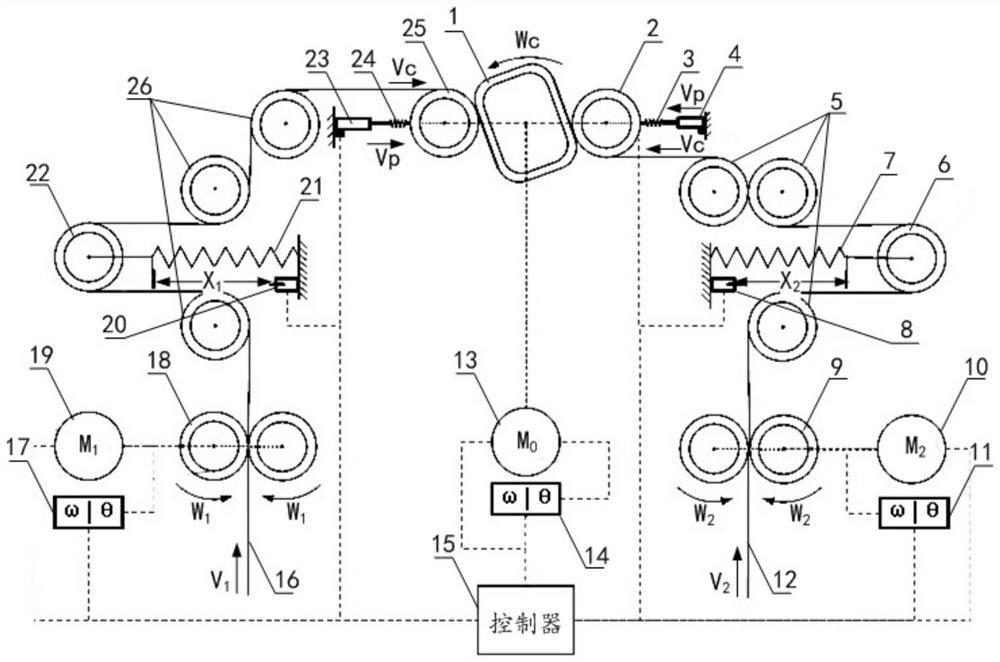

A technology of amorphous strip and winding device, which is applied in the direction of winding strip, transportation and packaging, thin material processing, etc., can solve the problems of inconsistent tension of amorphous strip, affecting product quality, outer layer fracture, etc., to achieve The effect of avoiding wrinkles and breakage, ensuring winding quality, and overcoming deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0065] see Figure 4 , Figure 4 The flow chart of the first embodiment of the double-sided winding method for amorphous strip based on the double-sided winding device for amorphous strip of the present invention is shown, which includes:

[0066] S101, acquiring in real time the elastic parameter information and preset tension information of the buffer component in the strip tension buffer mechanism, and adjusting the initial length of the buffer component according to the elastic parameter information and the preset tension information;

[0067] The elastic parameter information and preset tension information can be directly input to the controller by the user.

[0068] S102 , obtain the angular velocity information of the winding end of the strip winding mechanism during the winding process and the shape parameter information of the iron core in the strip winding mechanism in real time, and calculate the strip winding according to the angular velocity information and the s...

no. 2 example

[0089] see Figure 5 , Figure 5 Shown is the flow chart of the second embodiment of the double-sided winding method for amorphous strip based on the double-sided winding device for amorphous strip of the present invention, which includes:

[0090] S201 , acquiring the elastic parameter information and preset tension information of the buffer assembly in the strip tension buffer mechanism in real time, and adjusting the initial length of the buffer assembly according to the elastic parameter information and the preset tension information;

[0091] S202, obtain the angular velocity information of the winding end of the strip winding mechanism during the winding process and the shape parameter information of the iron core in the strip winding mechanism in real time, and calculate the strip winding according to the angular velocity information and the shape parameter information of the winding end The winding line speed function of the mechanism.

[0092] Wherein, the winding l...

no. 3 example

[0128] see Image 6 , Image 6 Shown is the flow chart of the third embodiment of the double-sided winding method for amorphous strip based on the double-sided winding device for amorphous strip of the present invention, which includes:

[0129] S301, obtaining the winding thickness of the strip in the strip winding mechanism in real time;

[0130] S302, comparing the winding thickness with a preset thickness set.

[0131] The preset thickness set includes at least one preset thickness, wherein each preset thickness corresponds to a longitudinal position of the iron core;

[0132] S303 , when the winding thickness is equal to the preset thickness, drive the iron core longitudinal moving mechanism to push the iron core to move to a corresponding iron core longitudinal position, so as to adjust the position of the iron core winding plane in the strip winding mechanism.

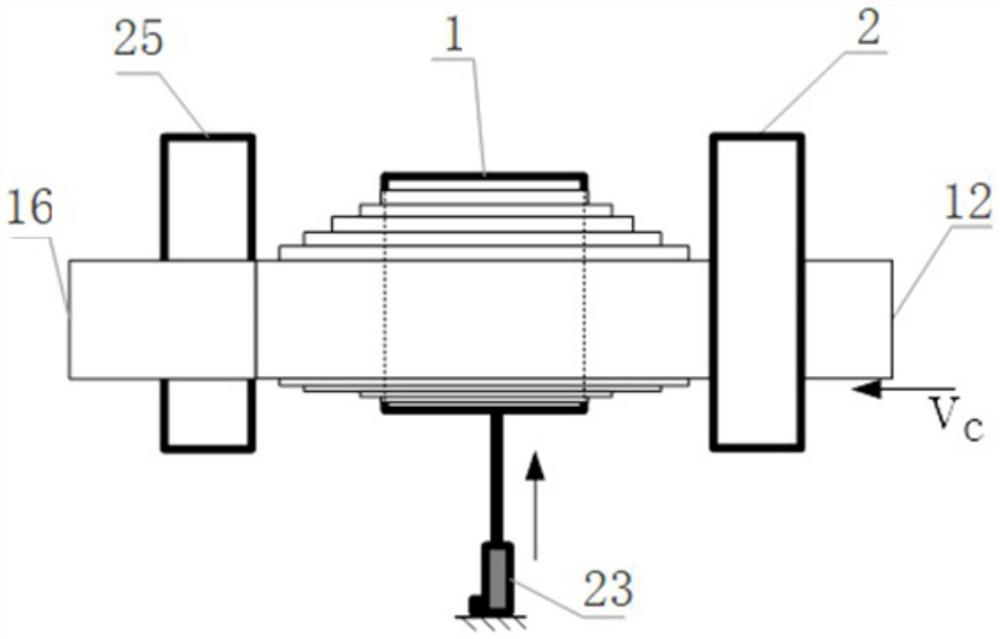

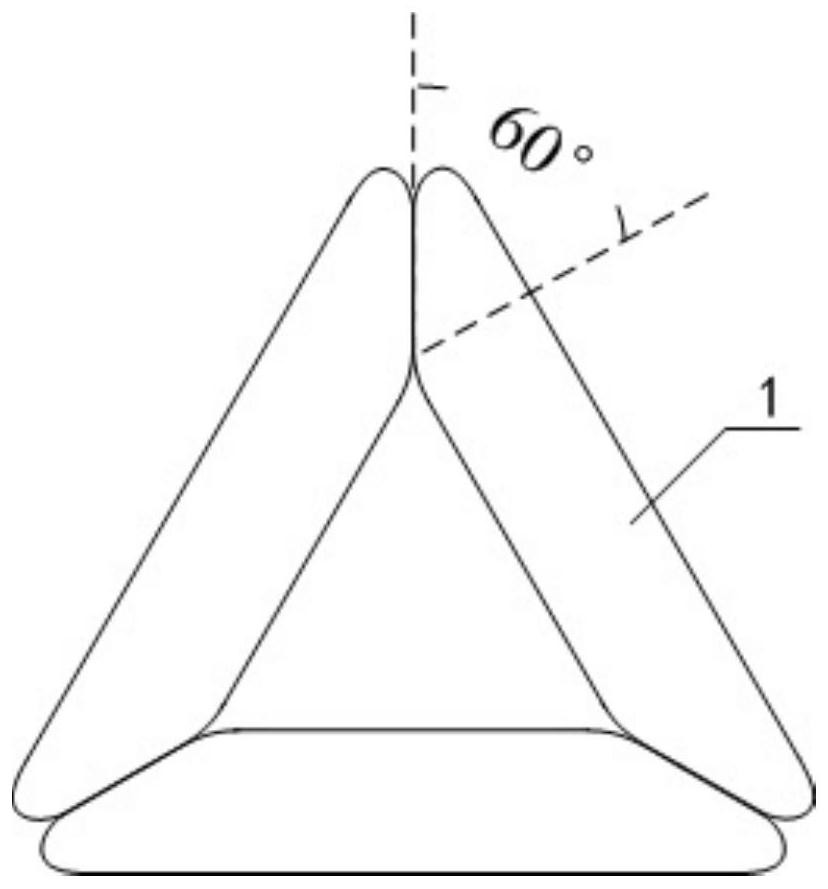

[0133] like image 3 As shown, the three-dimensional transformer core is composed of three frame-shaped i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com