Aqueous film-forming foam fire extinguishing agent and preparation method thereof

A foam fire extinguishing agent and aqueous film-forming technology, which can be used in fire prevention equipment, chemical instruments and methods, mixers, etc., can solve the problems of poor degradation performance of fluorocarbon surfactants, failure to achieve mixing effects, and large environmental pollution. Achieve the effect of speeding up the turning and stirring speed, improving the quality and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

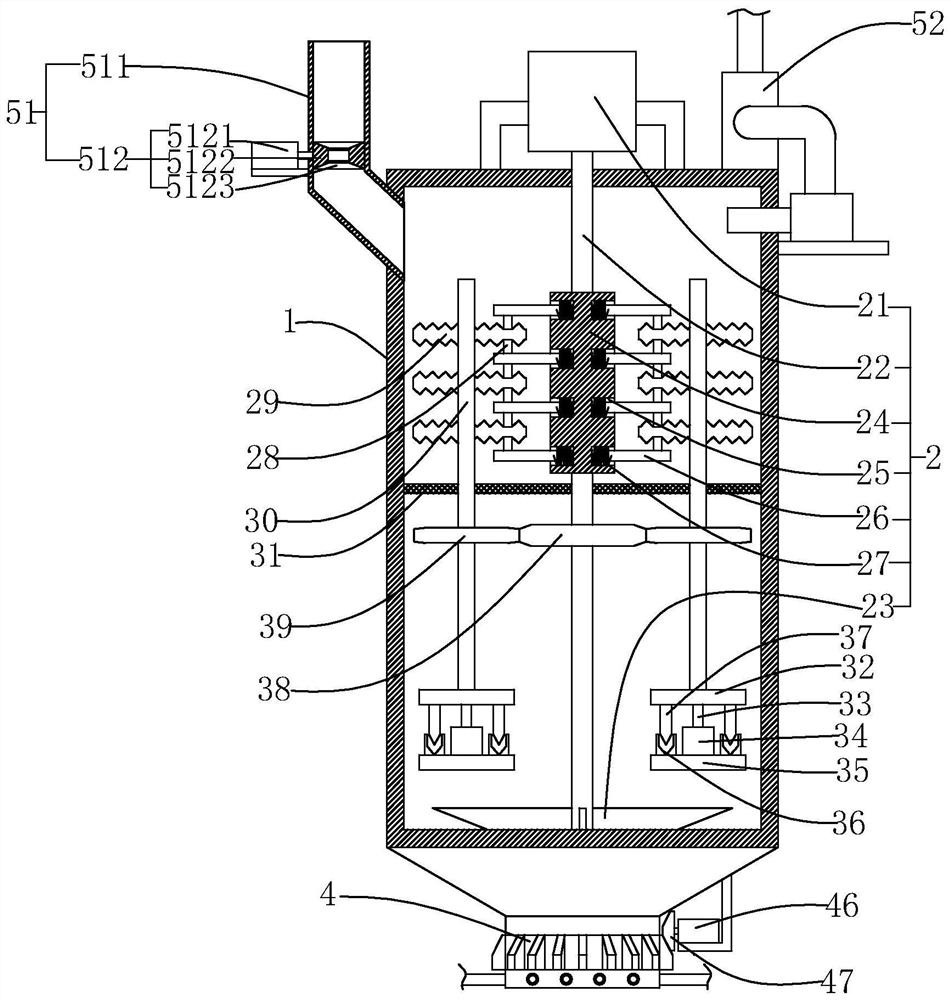

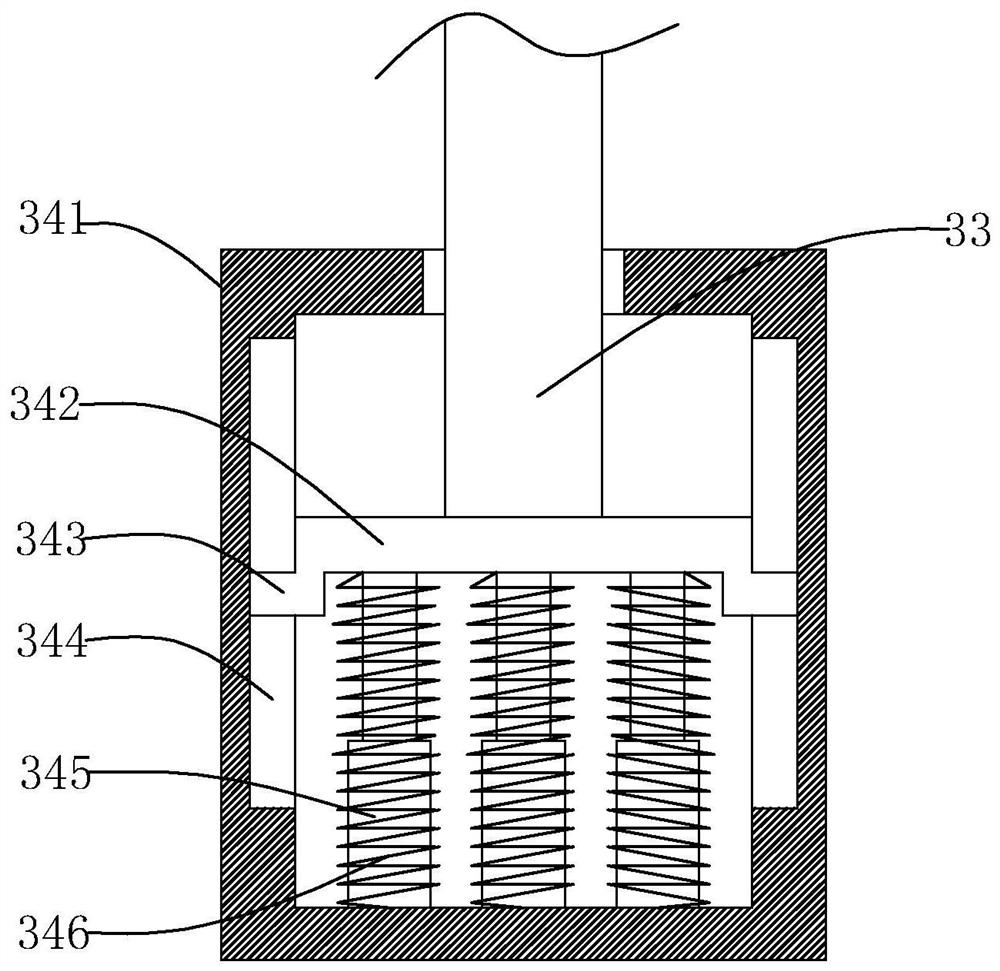

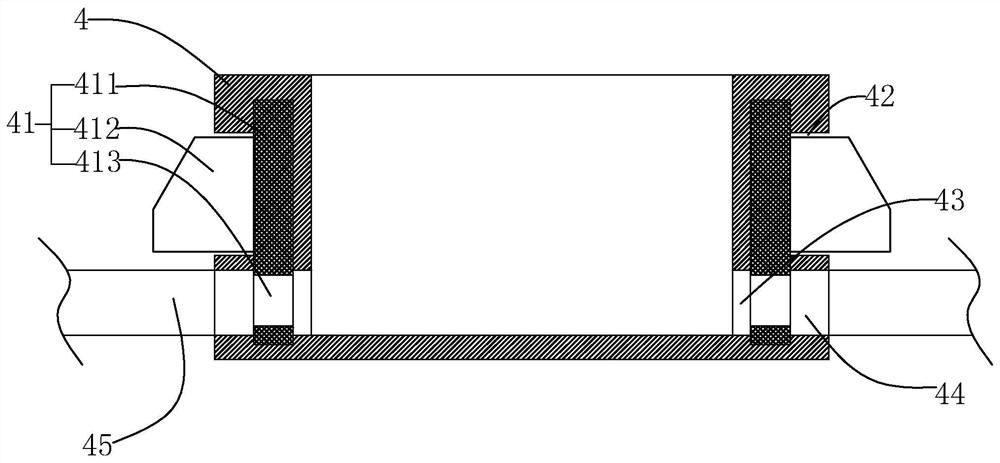

Image

Examples

Embodiment 1

[0035] A kind of aqueous film-forming foam fire extinguishing agent, its composition comprises the combined hydrocarbon surfactant 8% of weight percentage, the hydrocarbon surfactant 12% that does not contain perfluorooctane sulfonyl compound, blowing agent 15%, protective colloid 0.5%, urea 25.5%, foam stabilizer 5%, antifreeze 5%, solubilizer 4%, flame retardant 3%, water 30%.

[0036] The preparation method of aqueous film-forming foam fire extinguishing agent of the present invention is characterized in that, comprises the steps:

[0037] S1. Pre-adding water: add half of the mass fraction of water to the reactor;

[0038] S2. Adding material 1: Weigh and add foaming agent, combined hydrocarbon surfactant, protective colloid and hydrocarbon surfactant not containing perfluorooctanesulfonyl compound to the reaction kettle, and carry out stir;

[0039] S3. Adding material 2: After all the components in step S2 are dissolved, weigh and add urea, foam stabilizer and antifree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com