A dynamic weighing filtering method and system thereof

A technology of dynamic weighing and low-pass filter, which is applied in the field of weighing filtering, can solve the problems that the filter cannot meet the actual needs and reduce the performance of the filter, and achieve smooth filtering, reduce vibration noise and weighing error, and accuracy and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

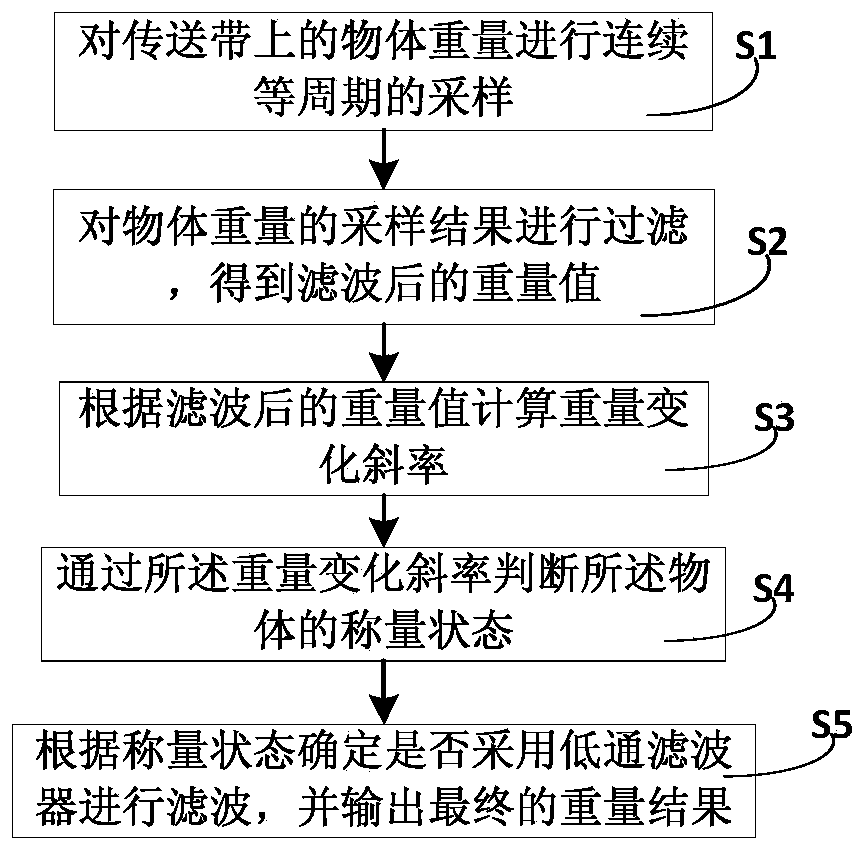

[0034] Such as figure 1 As shown, this example provides a dynamic weighing filtering method, including the following steps:

[0035] Step S1, performing continuous equal-period sampling on the weight of objects on the conveyor belt;

[0036] Step S2, filtering the sampling result of the weight of the object to obtain a filtered weight value;

[0037] Step S3, calculating the weight change slope according to the filtered weight value;

[0038] Step S4, judging the weighing state of the object according to the weight change slope;

[0039] Step S5, determine whether to use a low-pass filter for filtering according to the weighing state, and output the final weight result.

[0040]In step S1 described in this example, during the continuous equal-period sampling process of the weight of the object, the sampling cycle time is T s ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com