Automatic weighing and labeling device for steel wire roll

An automatic weighing and weighing device technology, applied in labeling machines, labels, packaging, etc., can solve the problems of low weighing efficiency, low production efficiency, time-consuming and laborious, and achieve high automatic weighing accuracy and improve production efficiency. , the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

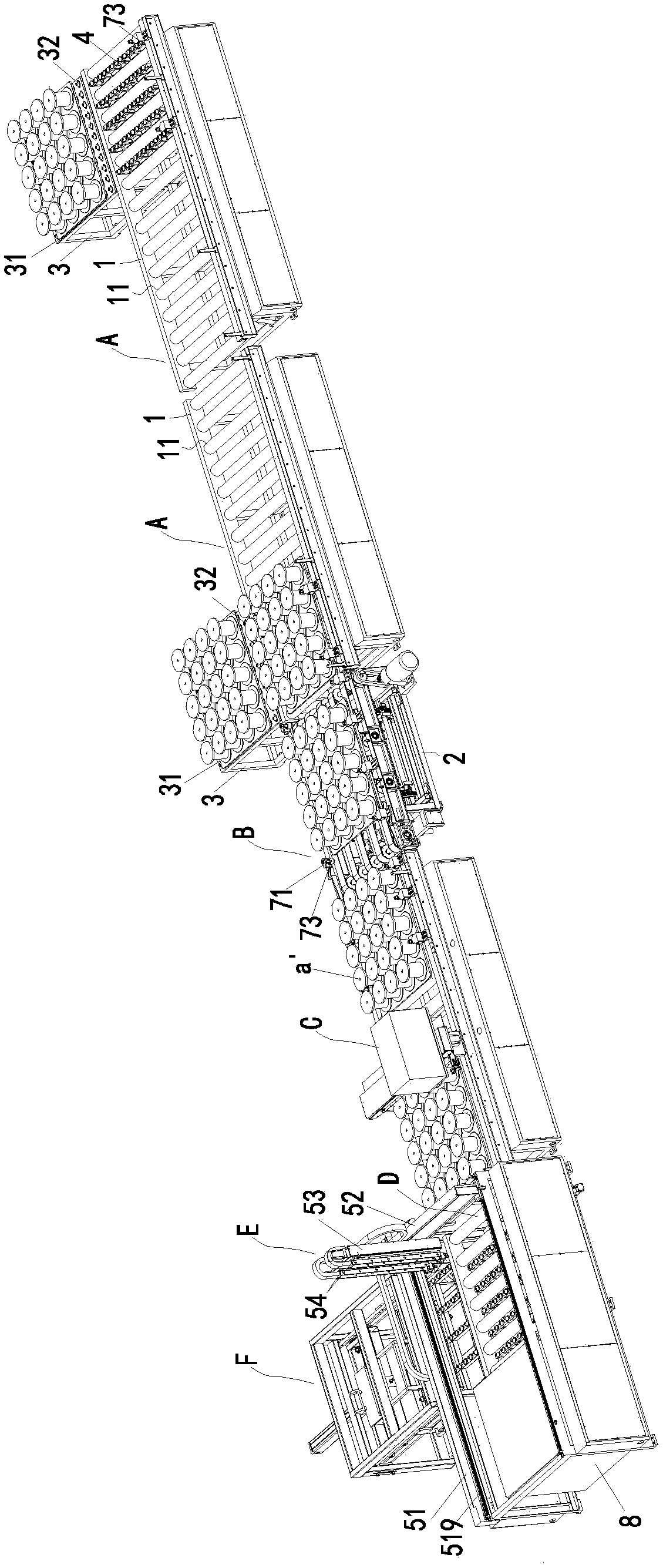

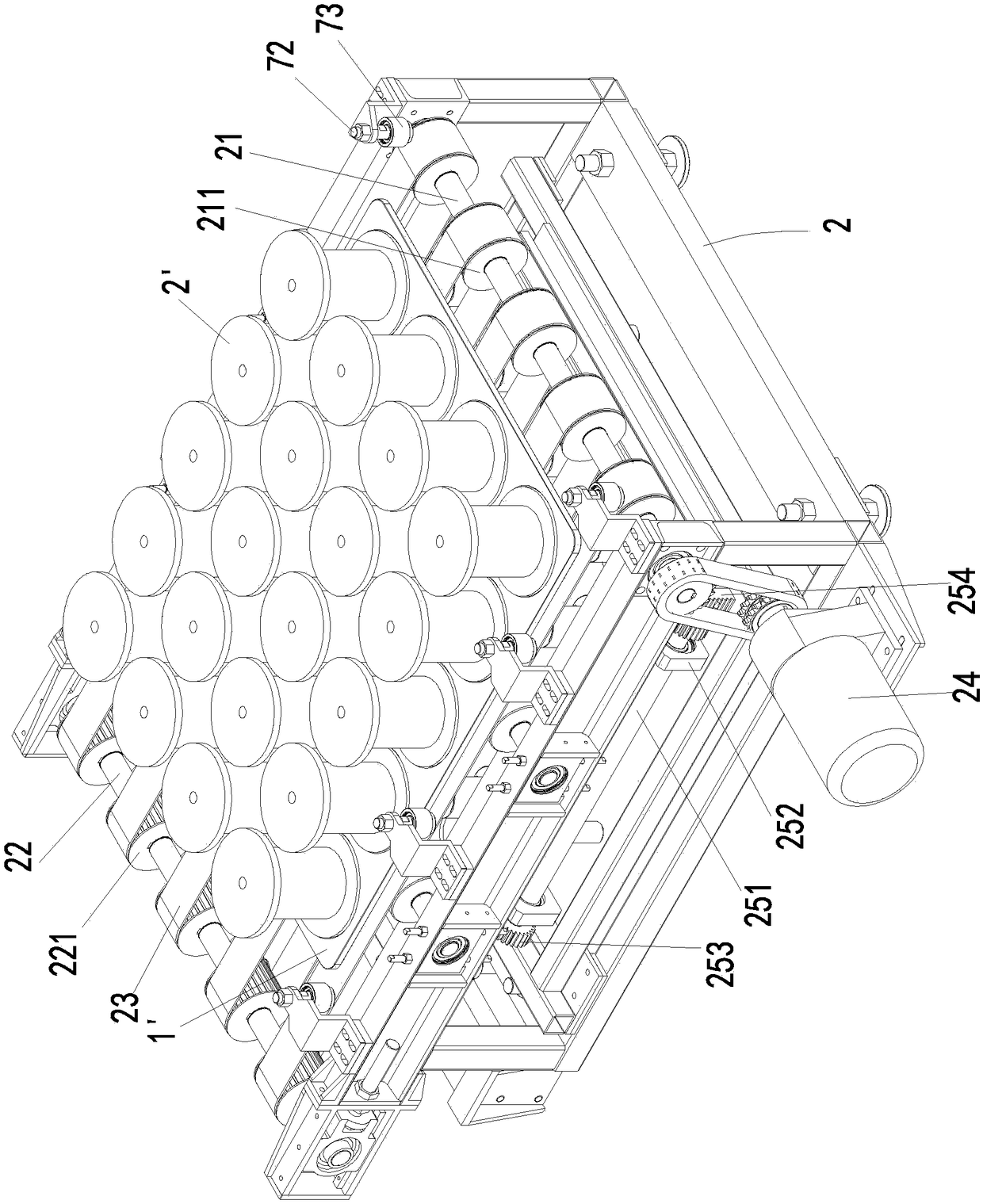

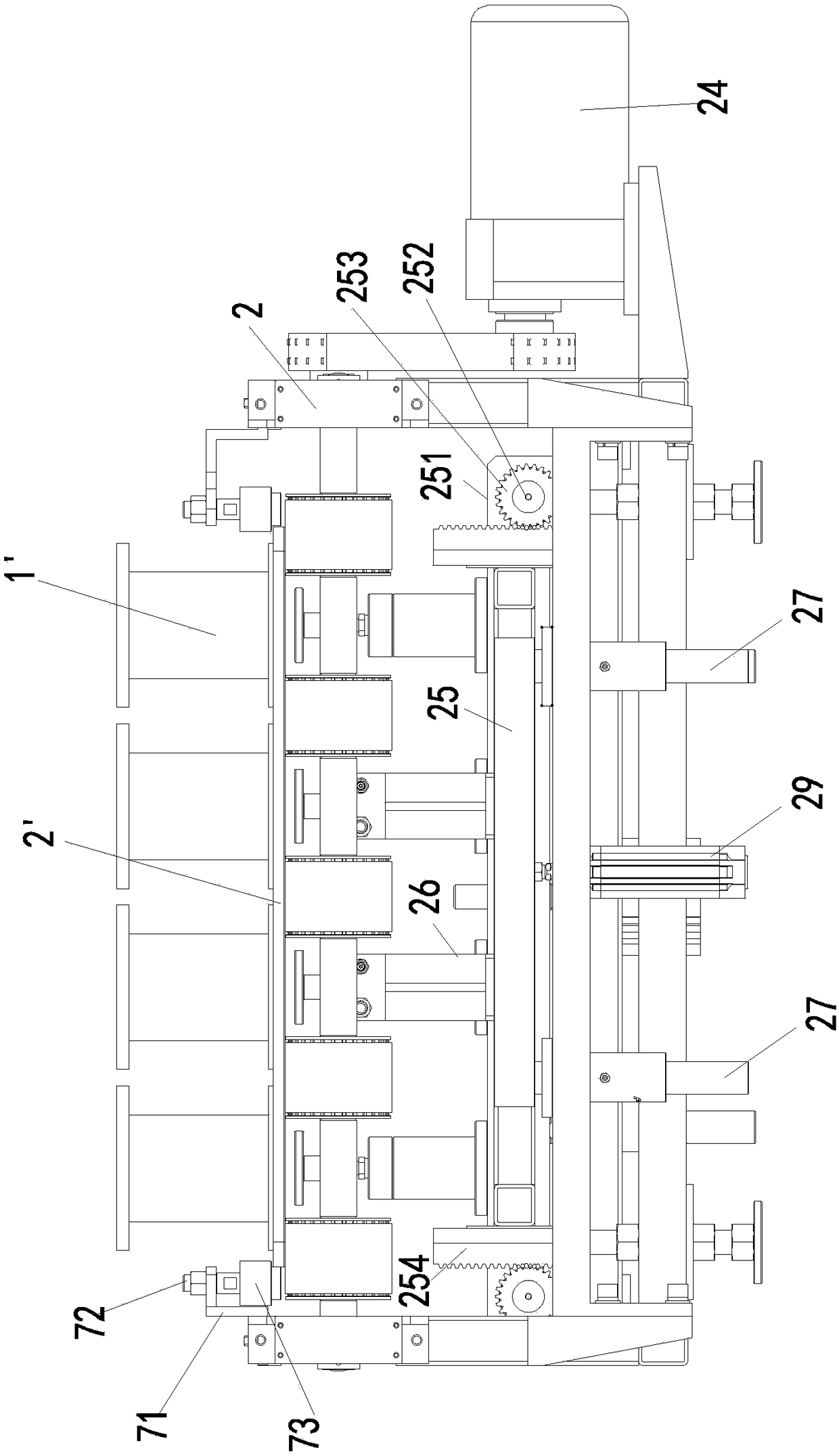

[0027] Such as Figure 1 to Figure 7 As shown, the embodiment of the present invention provides an automatic weighing and labeling device for steel wire coils, including a conveying device A arranged in accordance with the assembly line, a weighing device B for weighing the delivered products, and affixing the weighed products Labeling printer C for weight labeling, output device D for storing labeled products, product grabbing device E for grabbing and outputting products from the output device, and product removal of empty mold plates from the output device The mold plate is removed from the unit F. Labeling printer C is an outsourced product, purchased from Guangzhou Juhao Information Technology Co., Ltd., the model is: Bar code Printer IX300P, and the structure of this printer will not be described in detail in this invention.

[0028] The conveying device and the output device respectively include a conveying frame 1 and transmission shafts 11 arranged at intervals on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com