Automatic cotton core weighing device

An automatic weighing device and cotton core technology, applied in textiles and papermaking, fiber processing, fiber feeding, etc., can solve the problems of not meeting production needs, affecting measurement accuracy, affecting weighing errors, etc., to save labor costs , Reduce weighing errors, and achieve accurate weighing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings.

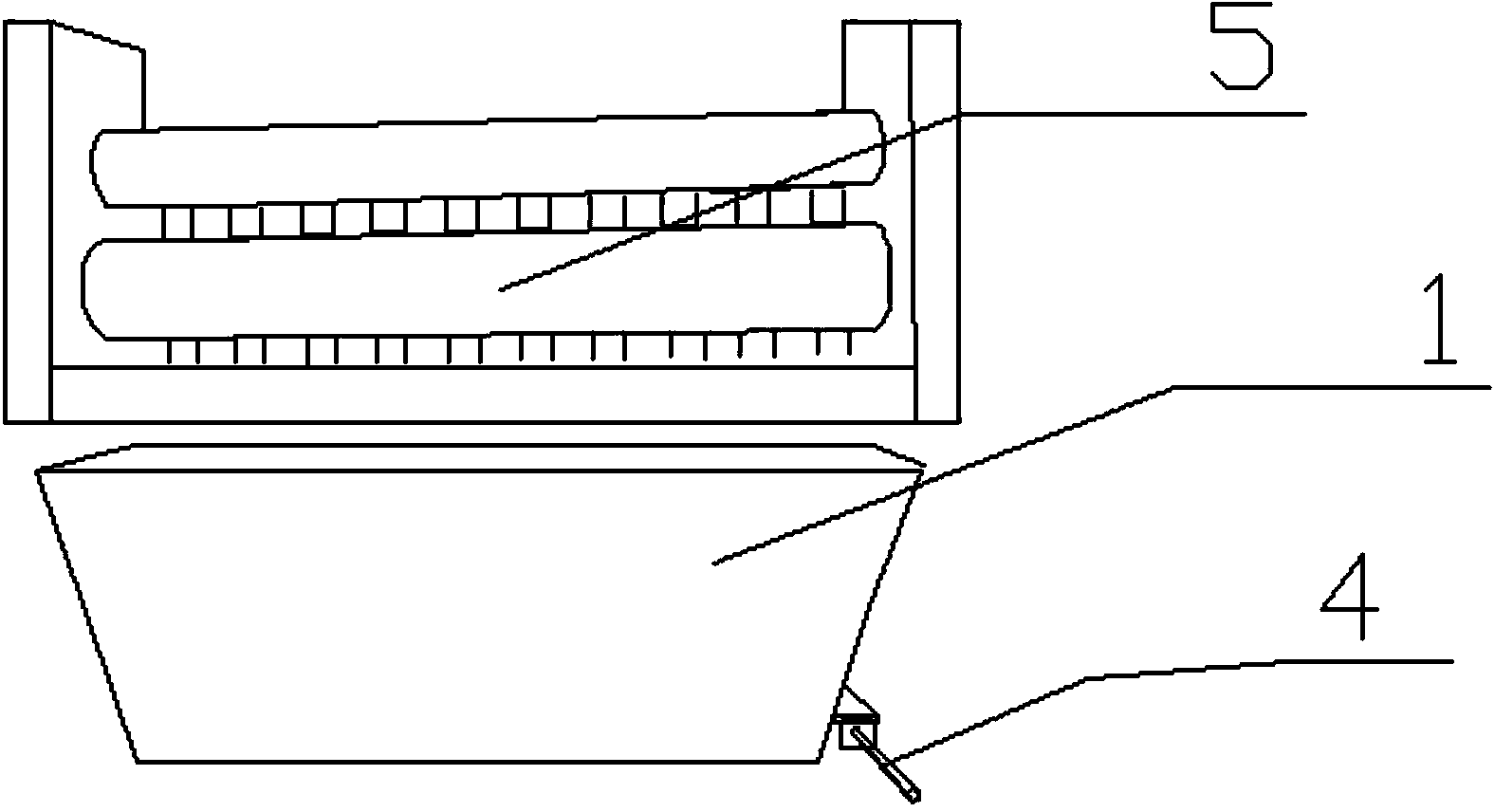

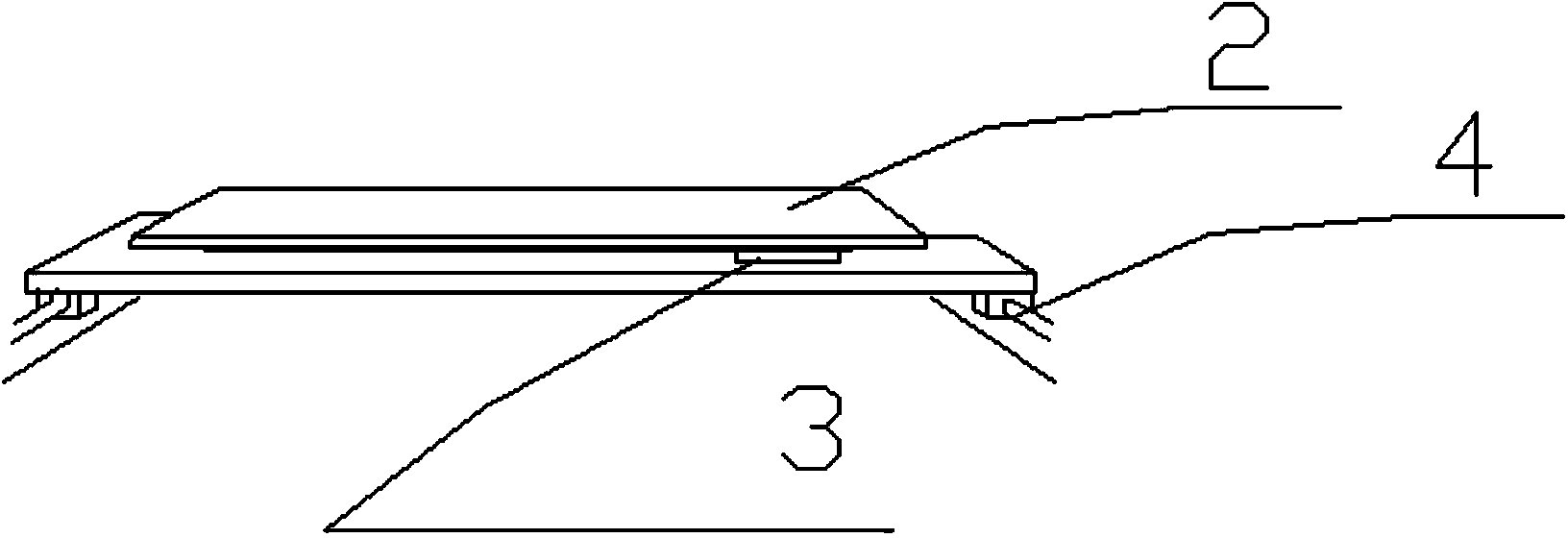

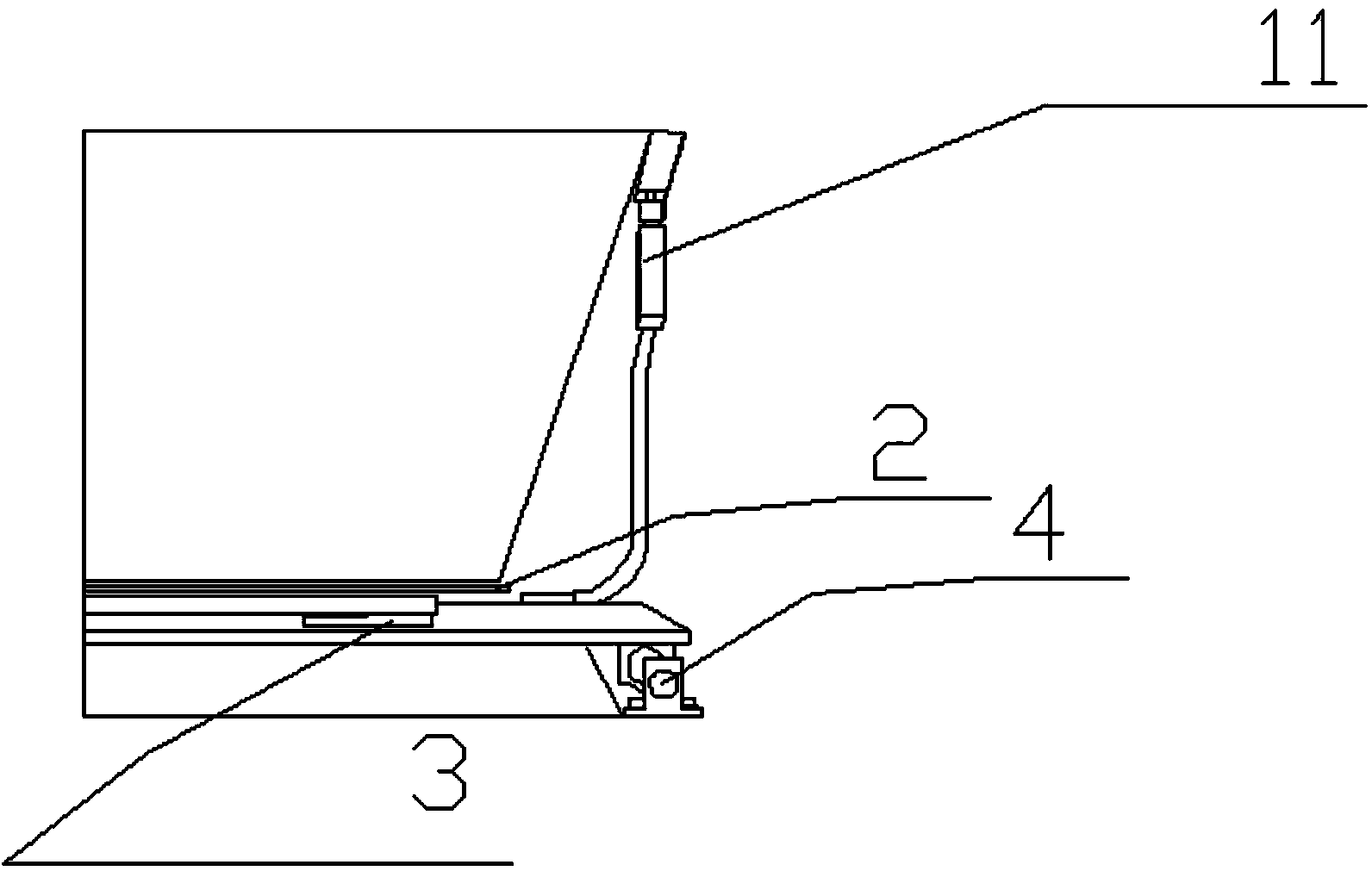

[0018] In this embodiment, taking the automatic pillow filling machine as an example, the cotton core automatic weighing device of the present invention is a part of the pillow automatic filling machine, as figure 1 As shown, it includes a cotton storage box 1 and a cotton feeding box. The cotton feeding box is provided with a cotton picking roller 5, and the cotton picking roller is provided with cotton picking teeth; the cotton storage box 1 is an inverted opening with an upper opening. trapezoidal, the described cotton feeding box is located directly above the cotton storage box and is aligned with its opening; the bottom of the cotton storage box 1 is provided with a movable box bottom, such as figure 2 As shown, the two sides of the bottom of the movable box are connected with guide rail devices 4, and the bottom of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com