High-speed and precise packaging machine

A sorting machine, precise technology, applied in the direction of packaging, transportation and packaging, packaged item types, etc., can solve the problem that it is difficult to balance the efficiency and accuracy of weighing at the same time, the production efficiency is not high, and it is difficult to accurately control material delivery Quantity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

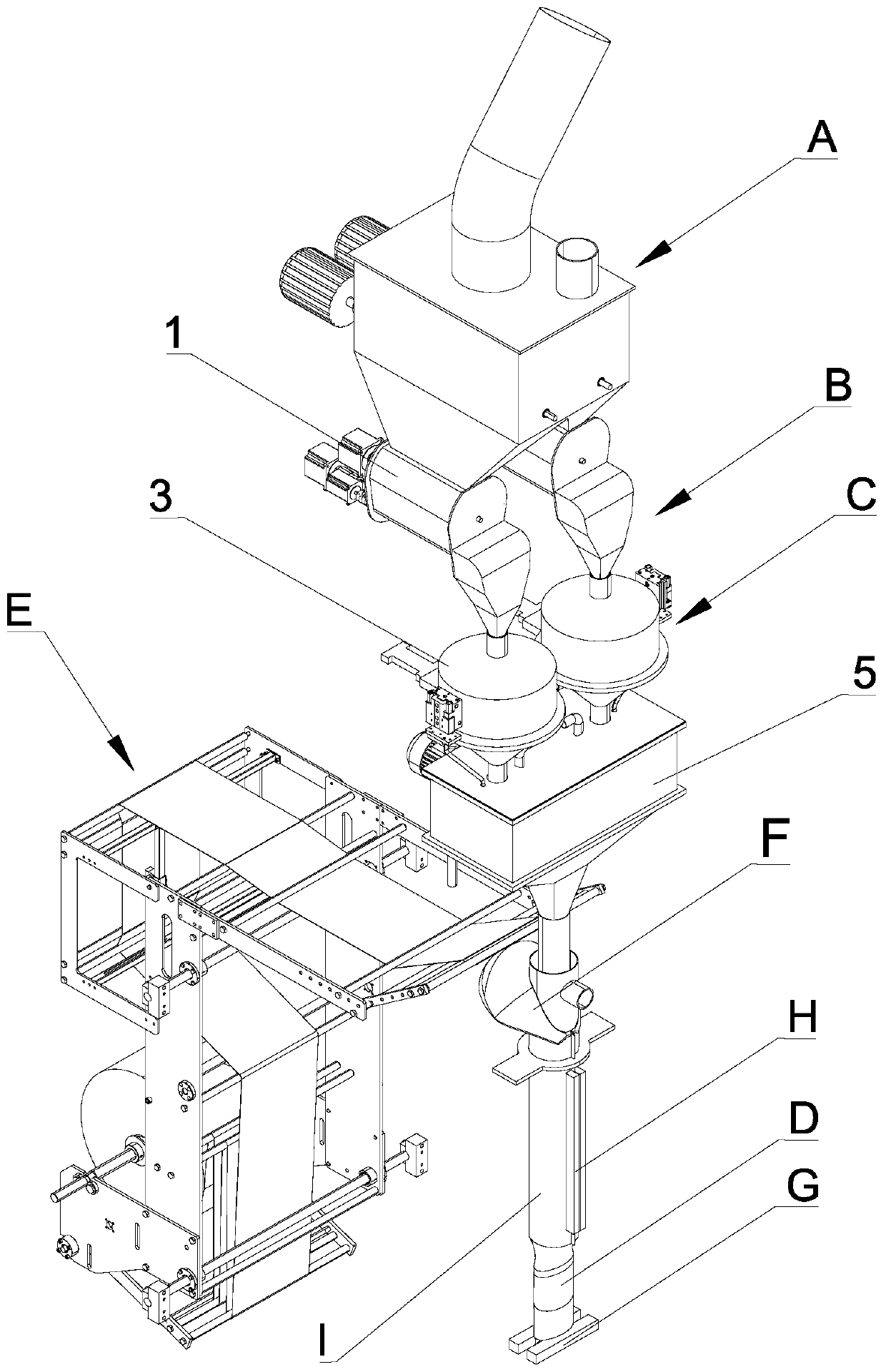

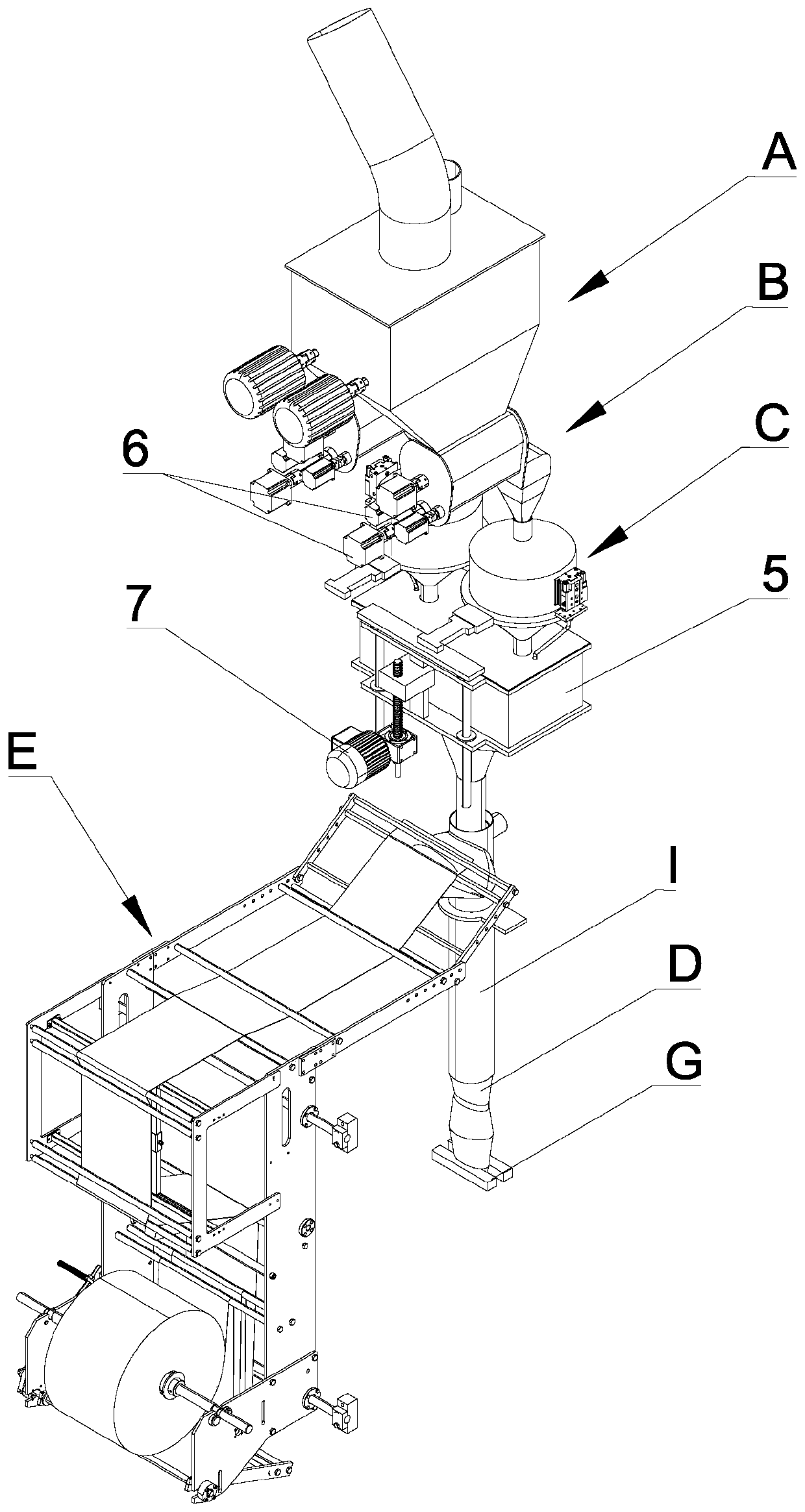

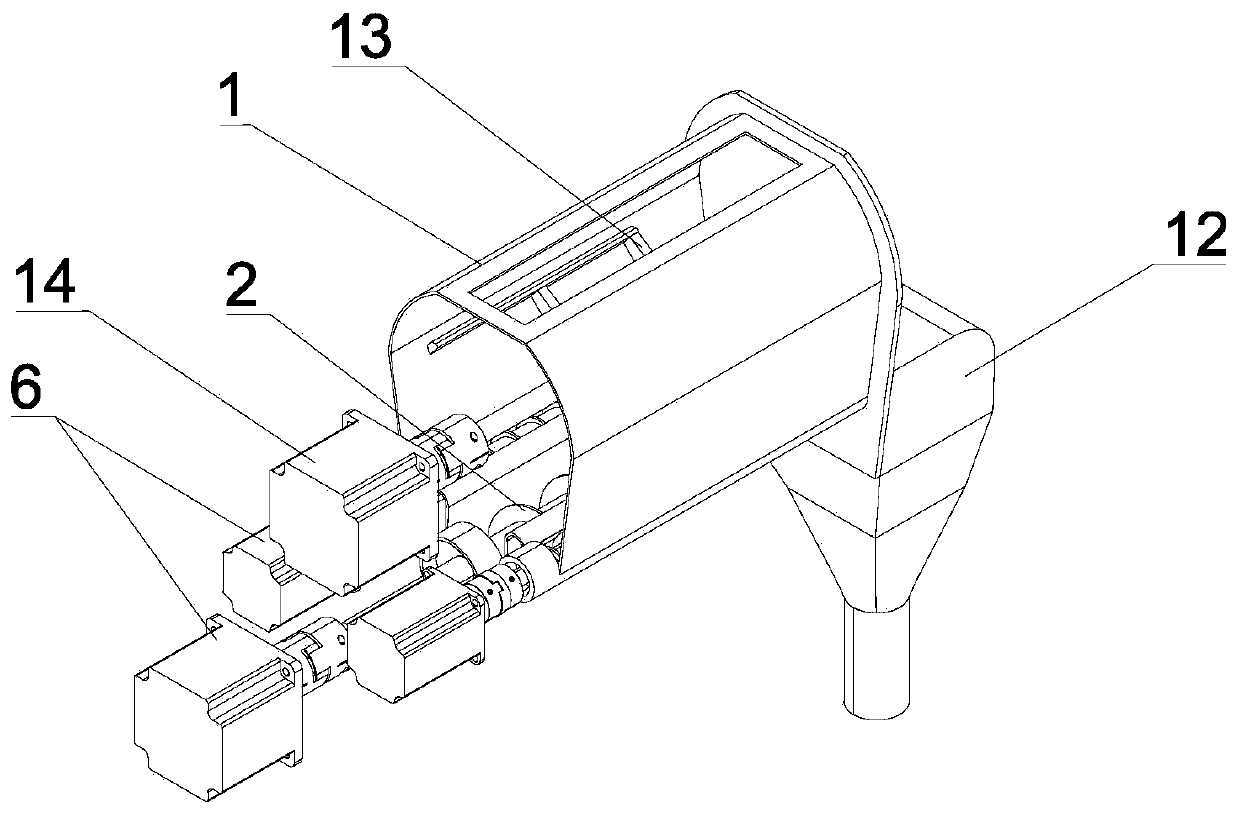

[0063] see Figure 1-6 , the high-speed precision packing machine in this embodiment includes a weighing unit for weighing materials and a charging unit for bagging the weighed materials; wherein, there are two weighing units, There is a feeding mechanism A above it; each weighing unit includes a primary metering feeding mechanism B and a weighing mechanism C, and the feeding mechanism B includes a charging hopper 1 for charging and a size that is arranged at the bottom of the charging hopper 1 Three different screw feeding rods 2, the feeding port of the charging hopper 1 is provided with a lower hopper 12 for conveying materials downward; the weighing mechanism C includes a weighing hopper 3 and a weighing hopper 3 for determining And the weighing module 4 of the weight of the material in the hopper, the weighing hopper 3 is arranged below the lower hopper 12; A bag support mechanism that supports the material bag D and opens its opening; an intermediate transition hopper 5...

Embodiment 2

[0083] Different from Embodiment 1, the high-speed precision subpackaging machine in this embodiment also includes a bagging drive mechanism for driving the material bag for vertical lifting movement, and the bagging drive mechanism includes a lifting drive motor and a lifting transmission assembly; The lifting transmission assembly includes a screw rod and a screw nut, the lifting drive motor is fixed on the frame of the equipment, and the screw nut is fixedly connected to the material bag through the lifting frame. In addition, the lifting transmission assembly may also be composed of a rack and pinion transmission assembly. Before bagging, the bagging drive mechanism first drives the material bag to be loaded up to the outlet of the intermediate transition hopper, minimizing the gap between the outlet of the intermediate transition hopper and the bottom of the material bag; during bagging During the process, as the material accumulates, the bagging drive mechanism slowly dr...

Embodiment 3

[0085] In this embodiment, the weighing hopper and the intermediate transition hopper are provided with a vibrating device to prevent material residue during discharge. The vibrating device can be composed of a vibrator or a vibrating hammer. The tapered part of the weighing hopper and the intermediate transition hopper is prone to residual materials. Vibration prevents the material from remaining on the inner wall of the weighing hopper and the intermediate transition hopper during unloading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com