Secondary dosing and mixing system applied to processing rice noodles

A mixing system and secondary batching technology, applied in the field of secondary batching mixing system, can solve the problems of large manual operation error, difficulty in reclaiming materials from the bonding warehouse wall, inaccurate weighing, etc., so as to reduce the difference between batches, The effect of reducing manual weighing and improving overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further explained and illustrated through specific embodiments below in conjunction with the accompanying drawings.

[0018] Each control system in the hybrid system in this embodiment is automatically controlled by existing means.

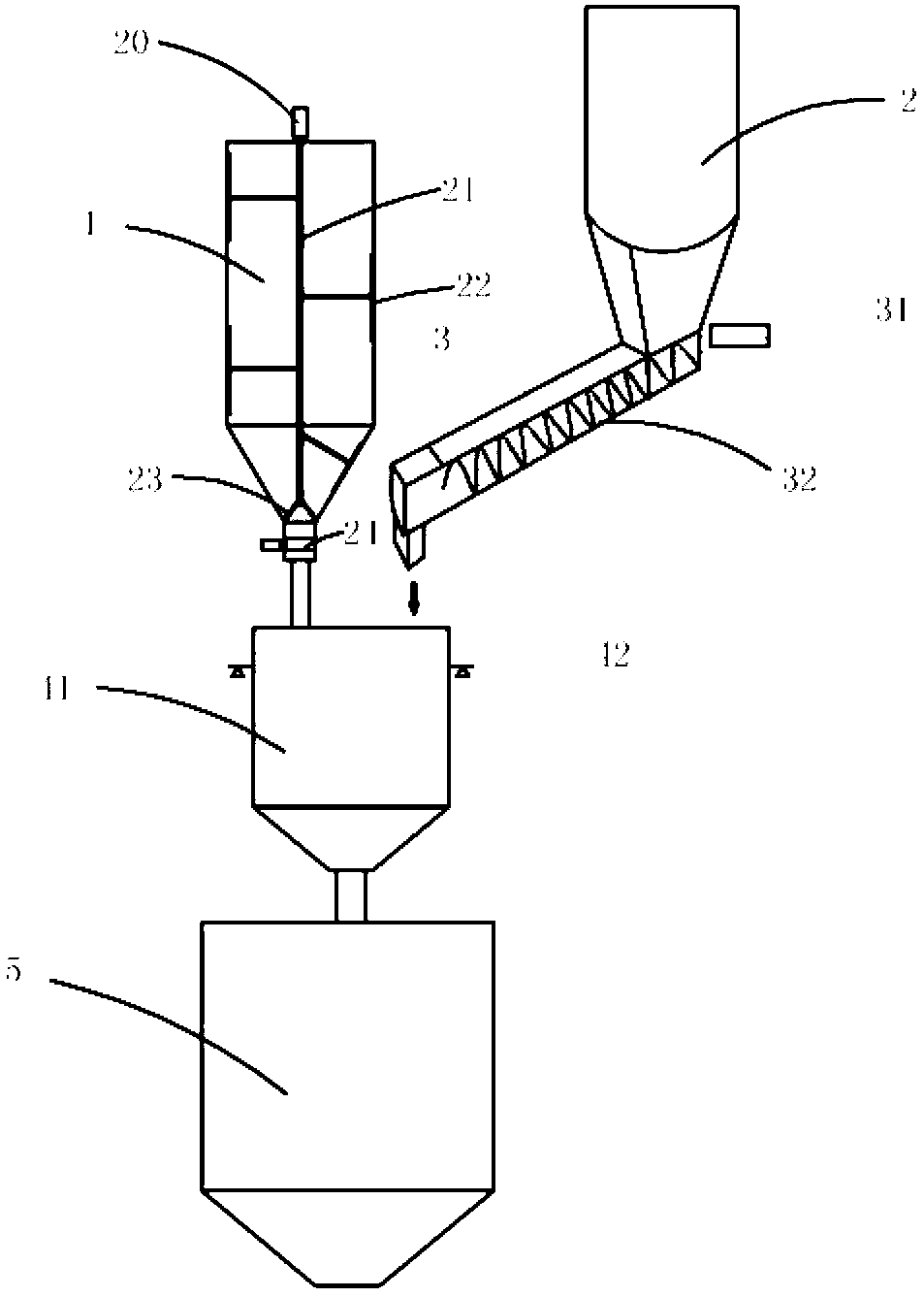

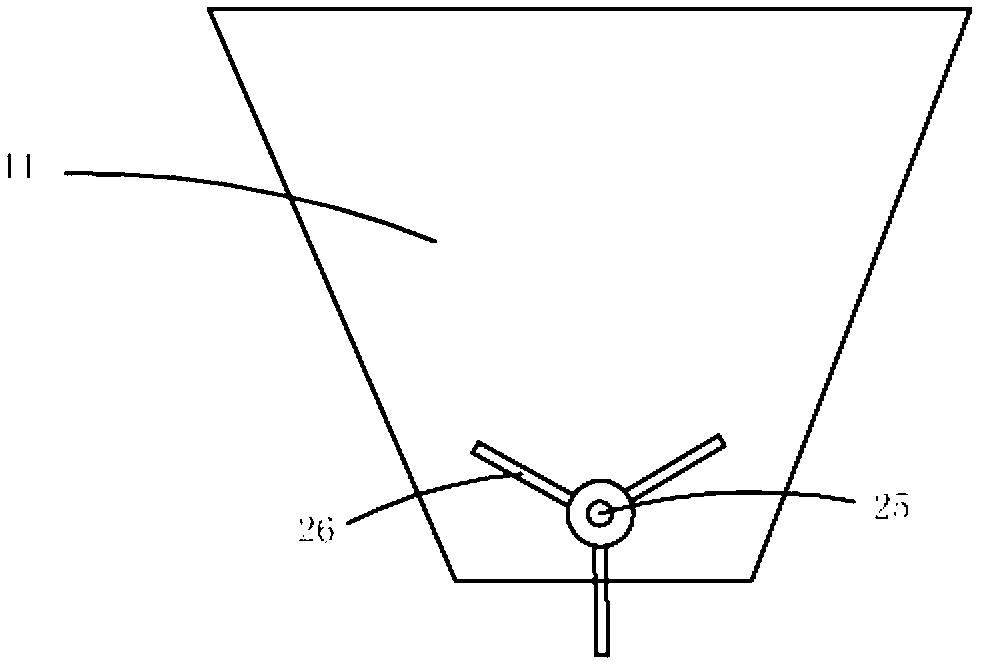

[0019] Secondary ingredient mixing system includes automatic control system, such as figure 1 As shown, the main body of the secondary batching mixing system includes a rice noodle temporary storage bin 1, a batching bin 2, a screw conveyor 3, an automatic weighing device 4 and a mixer 5. The outlet of the rice noodle temporary storage bin is connected with the material inlet of the automatic weighing device; the outlet of the batching bin is connected with the material inlet of the automatic weighing device through a horizontally arranged screw conveyor 3, and the screw conveyor 3 passes through the variable speed motor. 31 drives its internal screw pushing mechanism 32 to rotate; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com