Optimal adhesion control method based on optimal creep speed searching and tracking

A technology of creep speed and adhesion control, which is applied in the field of optimal adhesion control based on optimal creep speed search and tracking, can solve problems such as wheel idling/sliding, decrease of adhesion coefficient between wheel and rail, and derailment, so as to ensure driving safety , Improve the effect of adhesion utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

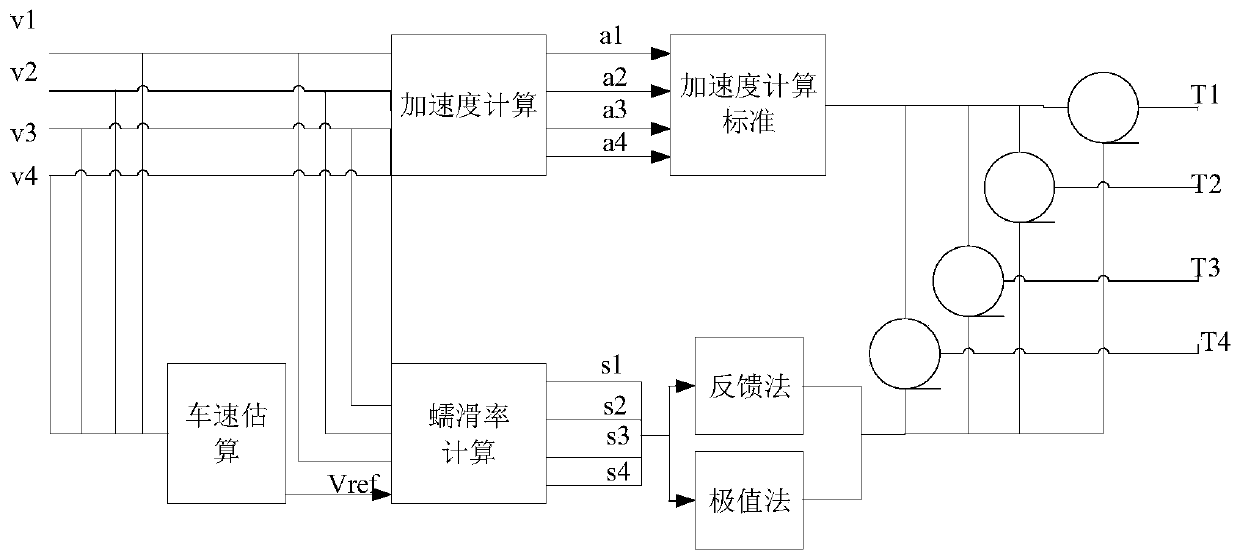

[0044] The present invention proposes an optimal sticking control based on optimal creep velocity search and tracking. The schematic diagram of the control system is as follows Figure 4 As shown, it mainly includes three modules: full-dimensional state observer, reference creep velocity search module and MPC adhesion controller.

[0045] 1. Design of full-dimensional state observer

[0046] Since the adhesion coefficient of the locomotive cannot be directly measured and obtained, the adhesion coefficient of the locomotive is obtained by using a full-dimensional state observer in the adhesion control system. The full-dimensional state observer is designed according to the dynamic model of the locomotive, and the load torque of the motor and the adhesion coefficient of the locomotive are estimated according to the traction torque of the motor and the speed of the wheel set.

[0047] The simplified dynamic model of the locomotive is as Figure 5 shown.

[0048] For the whole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com