Longitudinal-drive bogie with built-in axle boxes

A built-in, bogie technology, which is applied to bogies, transmission devices driven by electric motors, axle box installation, etc., can solve the problem that it is impossible to install large-radius axle-disc braking devices, it is difficult to achieve light weight, and the weight of bogies Increase and other issues to achieve the effect of improving power and traction performance, simplifying maintenance items and difficulty, and reducing unsprung mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

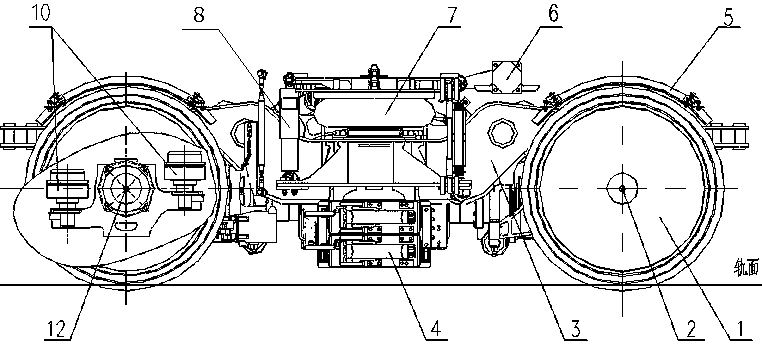

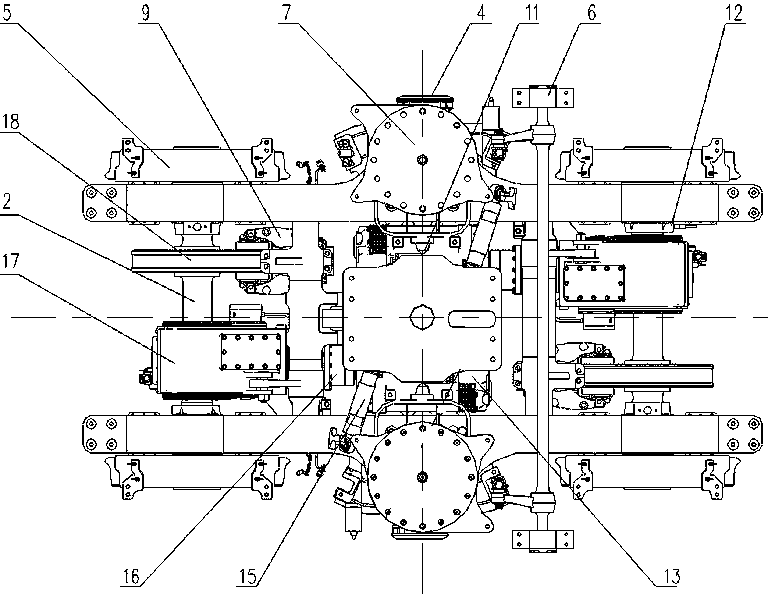

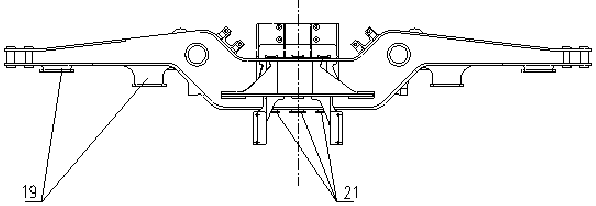

[0024] Such as figure 1 - Figure 5 As shown, an embodiment of the longitudinally driven axle box built-in bogie of the present invention includes a frame 3 installed on two axles 2, wheels 1 are respectively installed on the axles 2 outside the frame 3, and axles are installed on the inner sides of the wheels 1 at both ends of the axle 2. box 12, so that the frame 3 and the axle box 12 are arranged inside the wheel 1.

[0025] The frame 3 is formed by connecting two side beams 20 and the first and second beams 23 and 26 . The two frame side beams 20 are provided with a gear box hanging seat 24 and a motor hanging seat 21, the first beam 23 is provided with a traction seat 22, and the first and second beams 23, 26 are respectively provided with gear box anti-falling Seat 27, brake caliper mount 25. Two frame side beams 20 between the first and second crossbeams 23, 26 are respectively equipped with a traction motor 13 through the motor suspension seat 21, and the output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com