Transverse-drive bogie with built-in axle box

A horizontal drive, built-in technology, applied in the bogie, the transmission device driven by the electric motor, the axle box installation, etc., can solve the problem that it is impossible to install the large-radius axle disc brake device, it is difficult to achieve the level of light weight, and the weight of the bogie Increase and other problems, to achieve the effect of improving the utilization rate of adhesion, improving the safety of rolling, and reducing the torsional rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

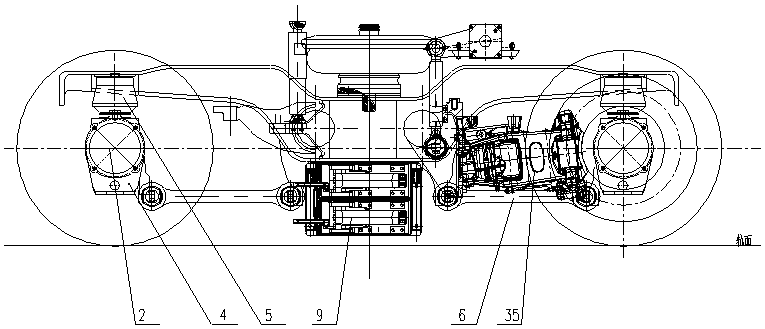

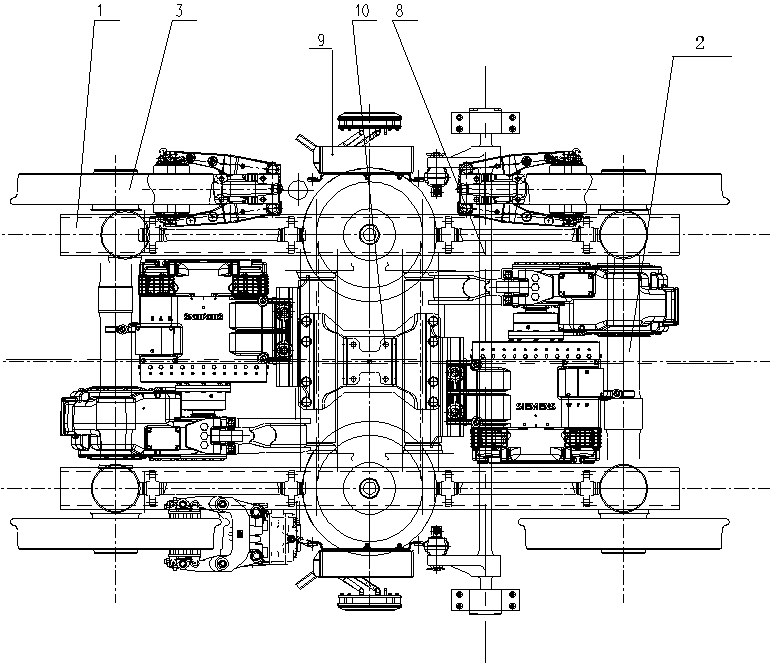

[0035] Such as figure 1 , figure 2 As shown, the axlebox built-in bogie of the present invention includes two axles 2 and a frame 1, wheels 3 are respectively installed at the two ends of the two axles 2, axleboxes 4 are respectively arranged on the axles 2 inside the two wheels 3, and axleboxes 4 of the frame 1 are arranged respectively. The two ends are respectively installed on the axle 2 through the primary suspension device 5 and the axle box 4, so that the frame 1 and the axle box 4 are arranged inside the two pairs of wheels 1, thereby reducing the overall lateral size of the bogie, and then can adapt to extreme The small lower limit of the vehicle also reduces the torsional stiffness of the bogie and improves the ability to pass through curves.

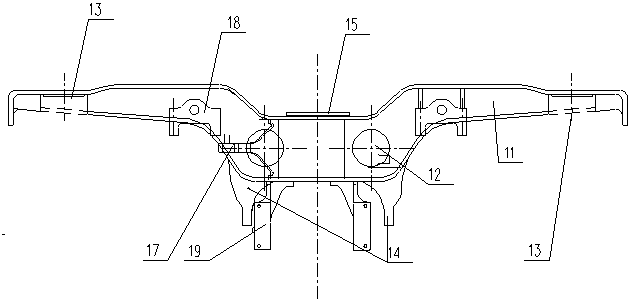

[0036] Such as image 3 , Figure 4 As shown, the frame 1 is formed by orthogonally connecting two side beams 11 and two cross beams 12 . The two side beams 11 are provided with 4 primary spring seats 13, 4 rotating arm p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com