Bearing and bearing outer ring

A bearing outer ring and axis technology, applied in the field of electromechanical equipment, can solve problems such as high sealing quality requirements, large bearing friction, and lubricant leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It can be seen from the background technology that it is difficult for the bearing to facilitate the discharge of impurities and reduce the sealing requirements on the basis of ensuring the lubrication effect of the bearing.

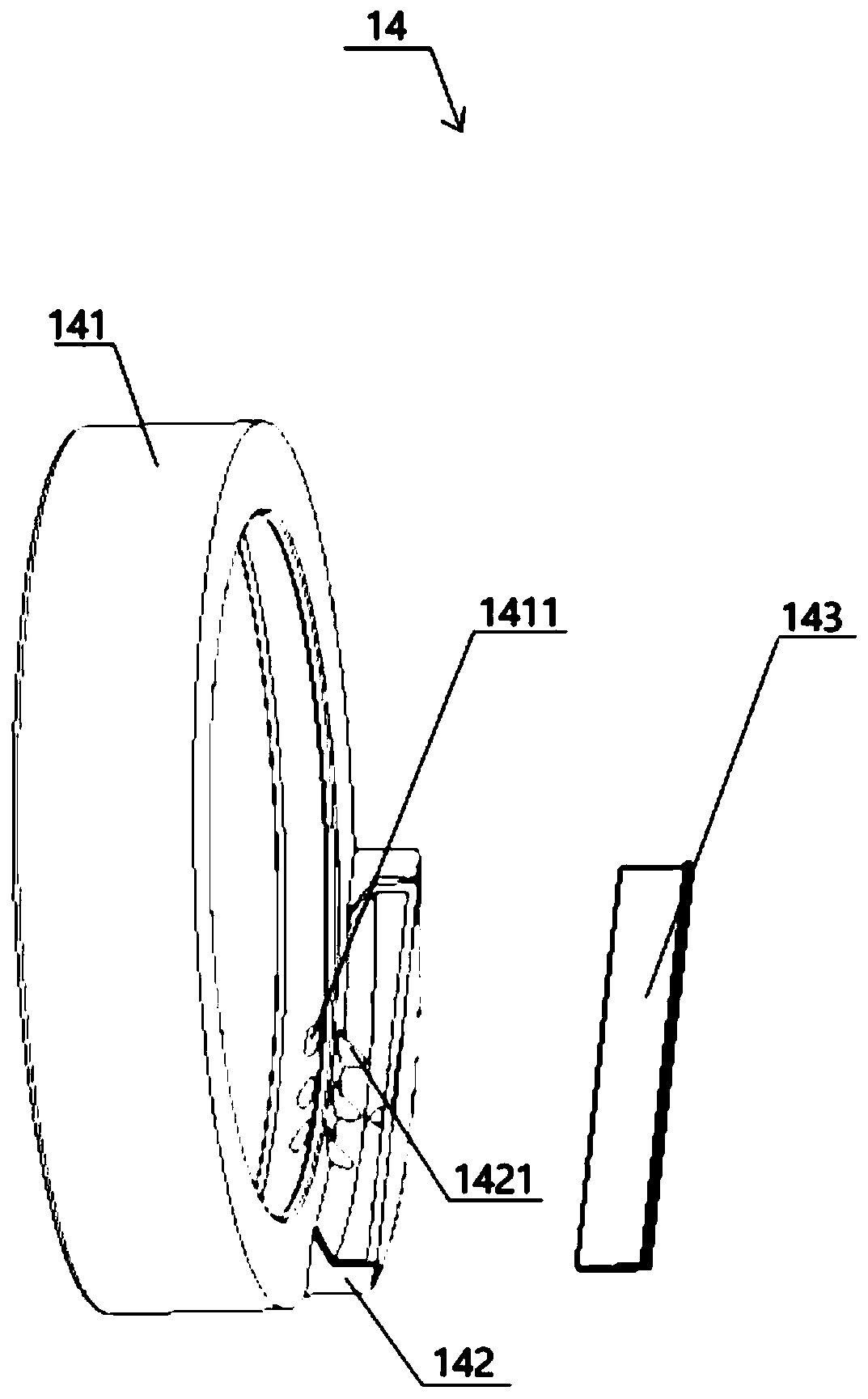

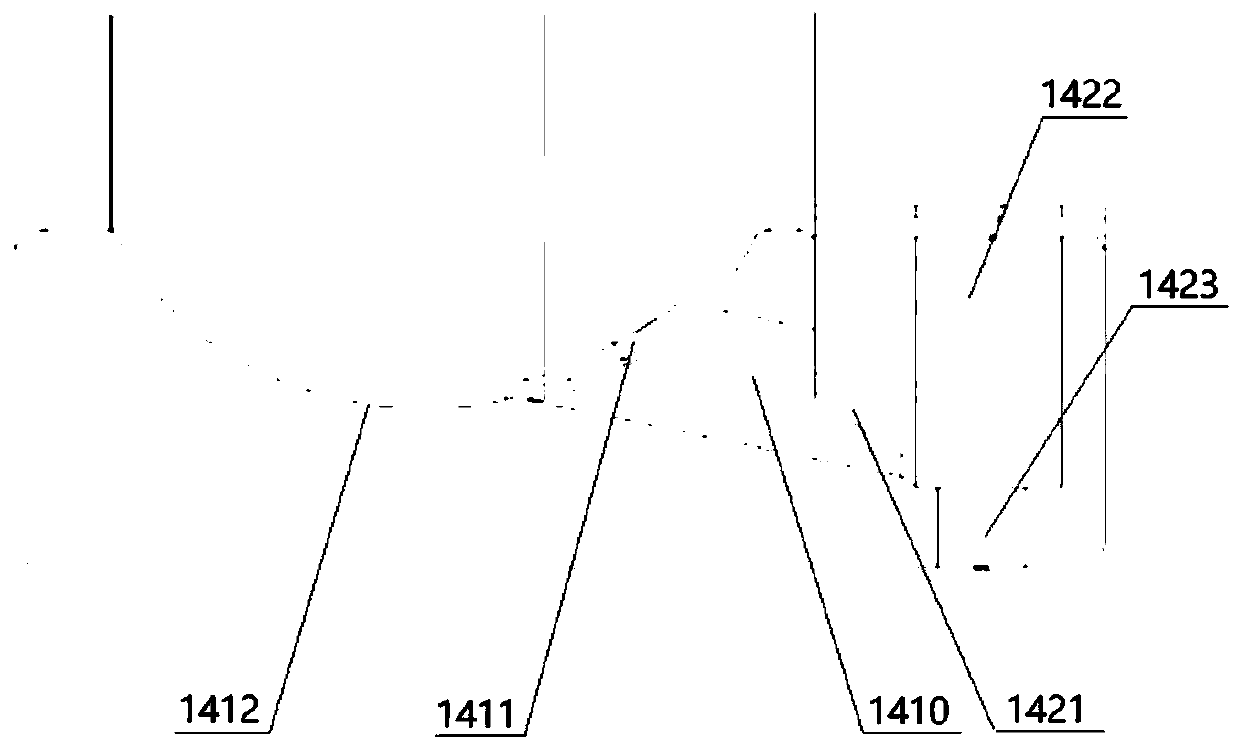

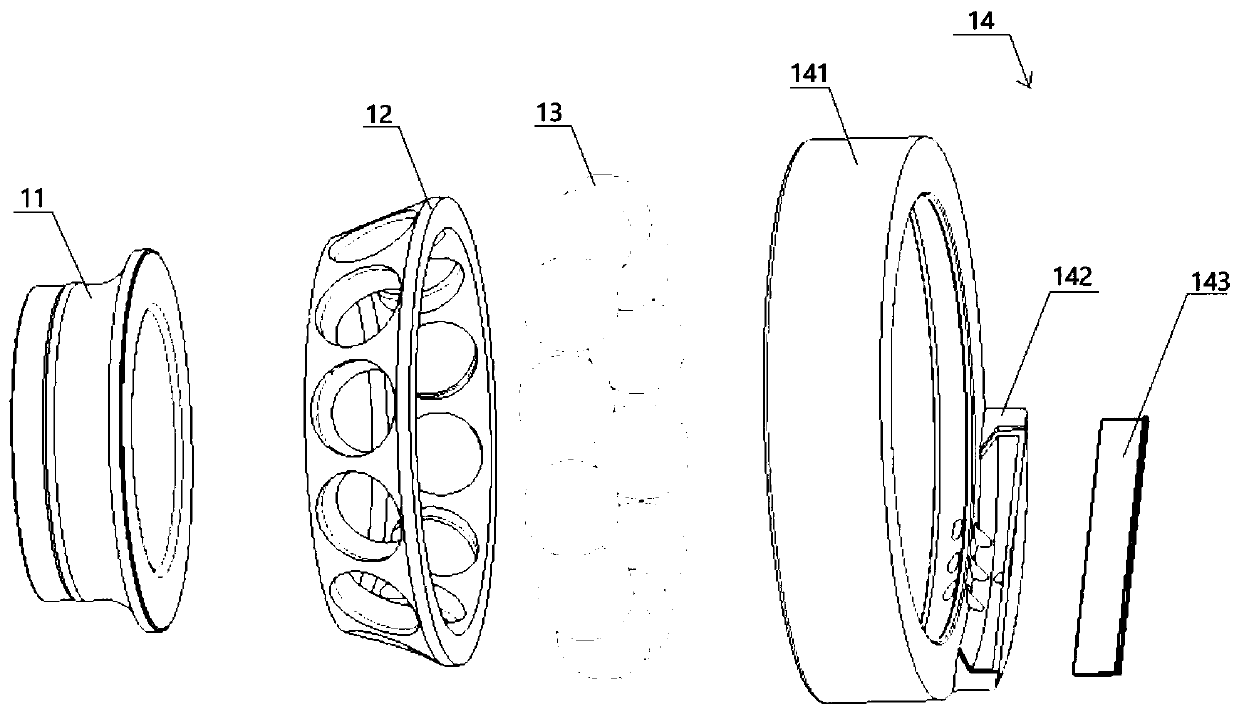

[0030] In order to solve the foregoing problems, an embodiment of the present invention provides a bearing and a bearing outer ring. The bearing outer ring includes a bearing outer ring body, and the raceway part of the bearing outer ring body is provided with lubricating oil holes; the lubricating oil containing part, Fixed on the end surface of the bearing outer ring body, the lubricating oil containing part includes an inner surface and an outer surface arranged along the radial direction of the bearing outer ring body, and the inner surface is aligned with the axis of the bearing outer ring body The distance is greater than or equal to the radius of the inner ring surface of the bearing outer ring body, and the axial distance between the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com