Watertight isolation structure used for pipeline to penetrating through watertight bulkheads

A technology of watertight bulkheads and isolation structures, applied in floating buildings and other directions, can solve the problems of reduced stability of damaged cabins, failure to guarantee watertightness requirements, failure to meet code requirements, etc., to reduce engineering investment and simplify the design of pipeline layout , the effect of shortening the construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

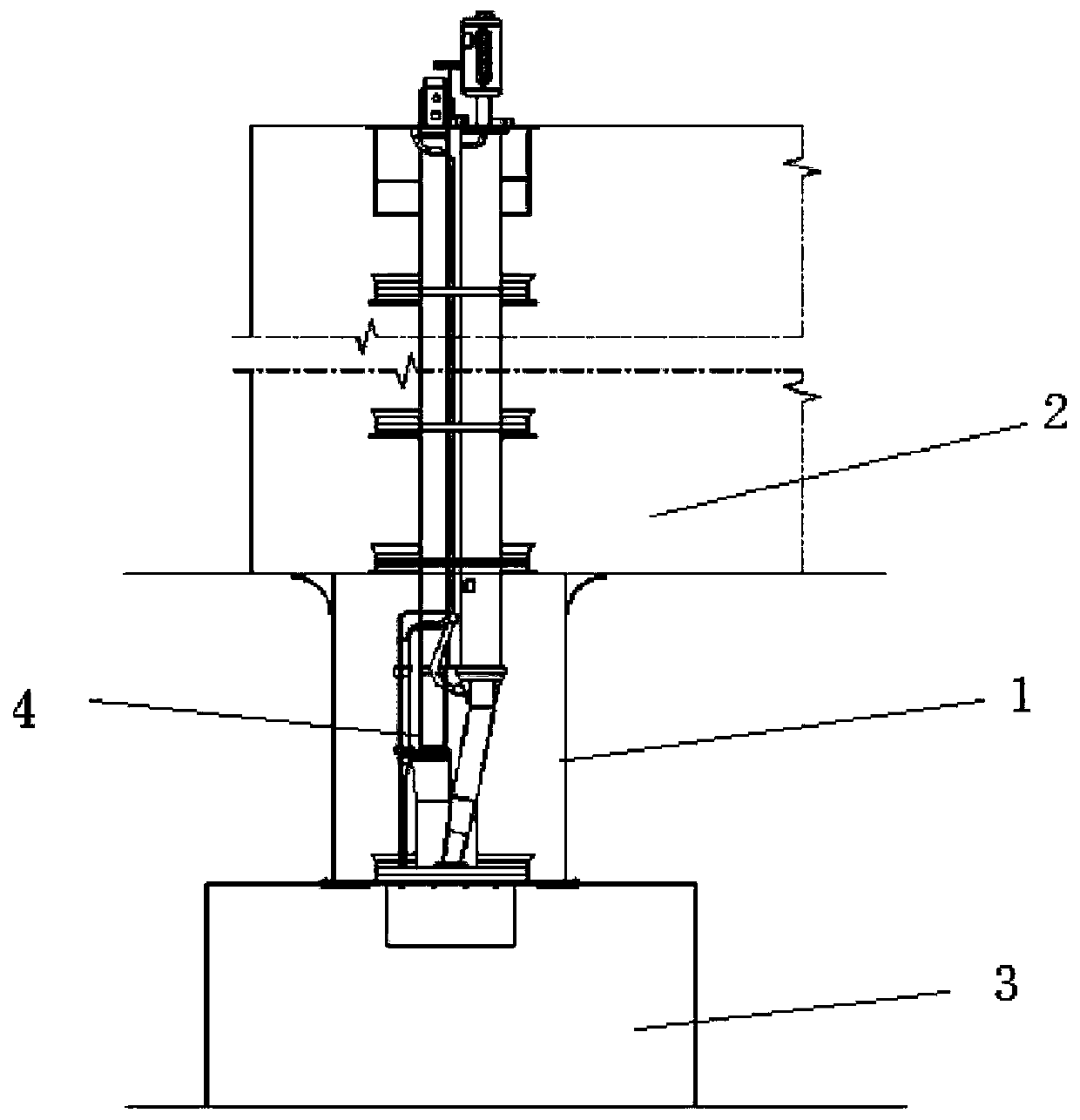

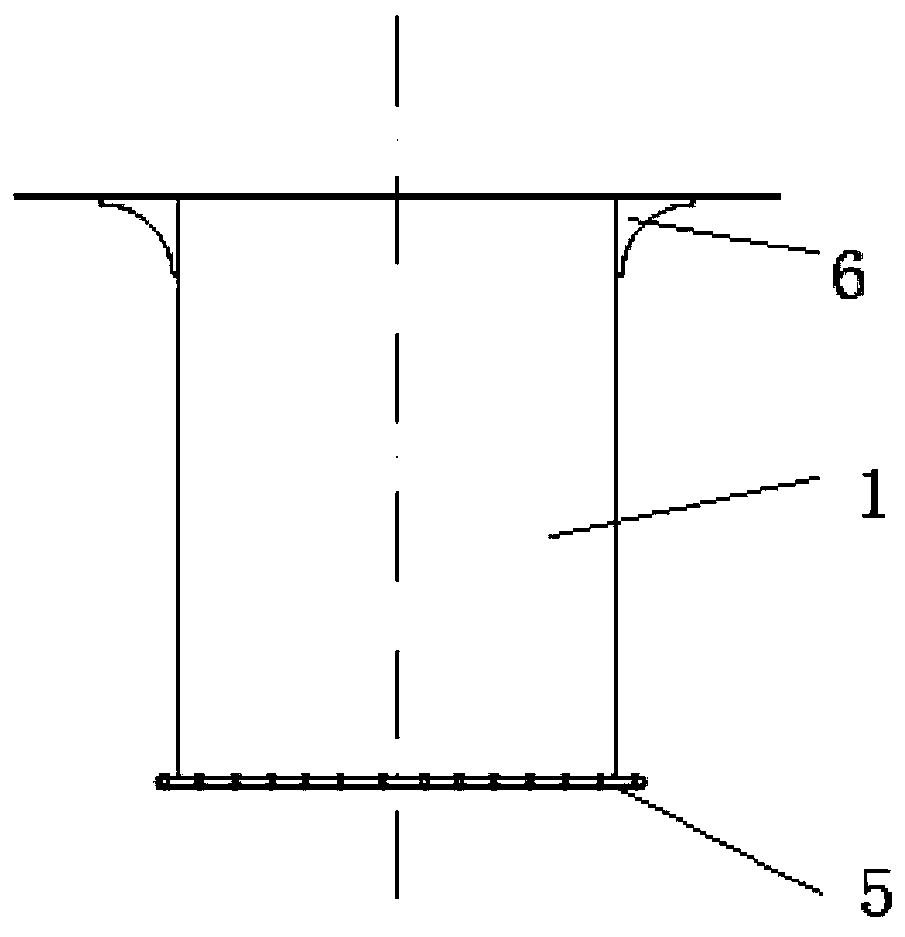

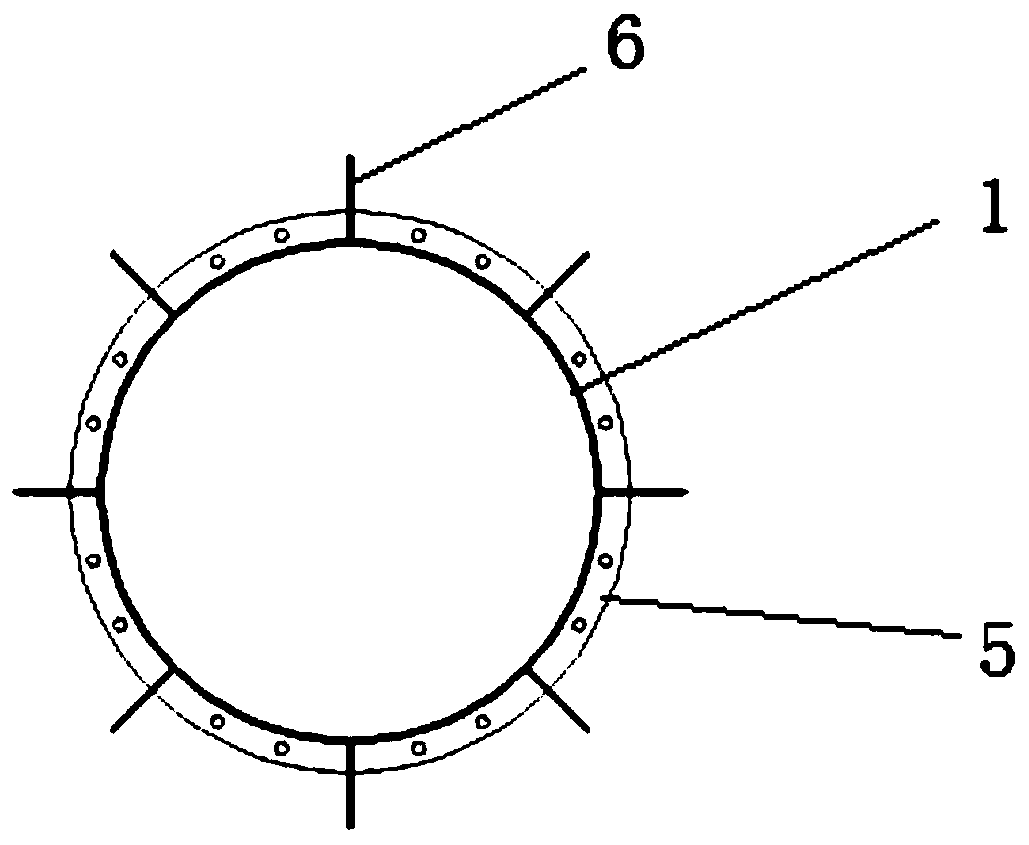

[0022] Such as figure 1 As shown, a watertight isolation structure for pipelines passing through a watertight bulkhead provided in this embodiment includes: a watertight isolation compartment body 1 with no upper and lower covers and a hollow interior, and the watertight isolation compartment body 1 is sleeved in the first watertight compartment. The exterior of the pipeline 4 between the cabin 2 and the second watertight cabin 3; the two ends of the watertight cofferdam body 1 are connected watertightly to the watertight bulkheads of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com