Patents

Literature

30results about How to "Control oil content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing fruit and vegetable crisps by combination of vacuum low-temperature frying and vacuum microwave drying

The invention relates to a process for producing fruit and vegetable crisps by combination of vacuum low-temperature frying and vacuum microwave drying. The method mainly comprises the following steps of performing selecting, finishing, cleaning, blanching for enzyme deactivation or pretreatment such as precooking, cooling, steeping and quick-freezing on fruit and vegetable raw materials, and concretely comprises the steps: firstly processing the raw materials into a semi-product with a water content of 50%-35% and an oil content of 3%-10% through a vacuum low-temperature frying process, and then drying and dewatering the semi-product through a vacuum microwave drying process, wherein the water content of a finished product is controlled to be below 5%, the oil content is controlled to be below 10%, and the expansion ratio is 1.5-2.0. According to the process, the nutrients and shape of the product are ensured to the greatest extent, the dehydration time can be obviously shortened, the energy consumption is lowered, the cost is reduced, and meanwhile, the oil content of the product can be effectively controlled, so that the process is particularly suitable for application to processing of the fruit and vegetable crisps.

Owner:NANJING INST FOR THE COMPREHENSIVE UTILIZATION OF WILD PLANTS CHINA COOP

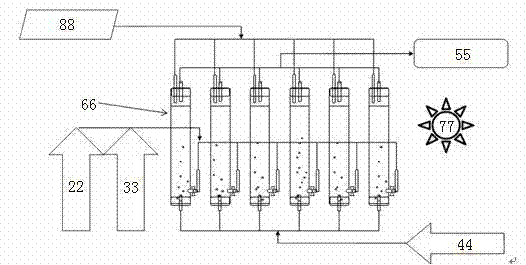

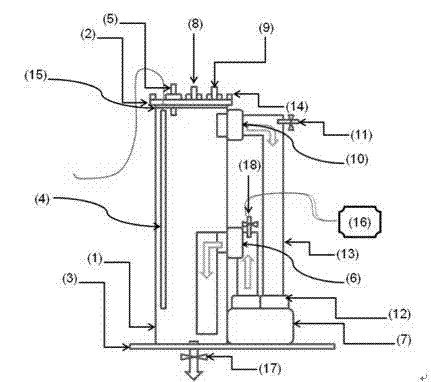

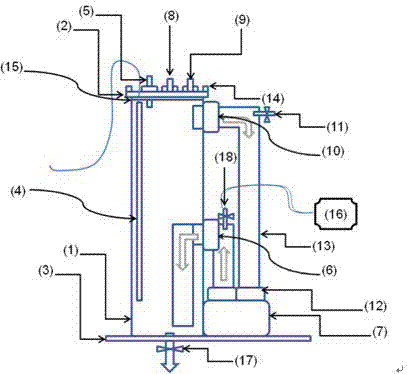

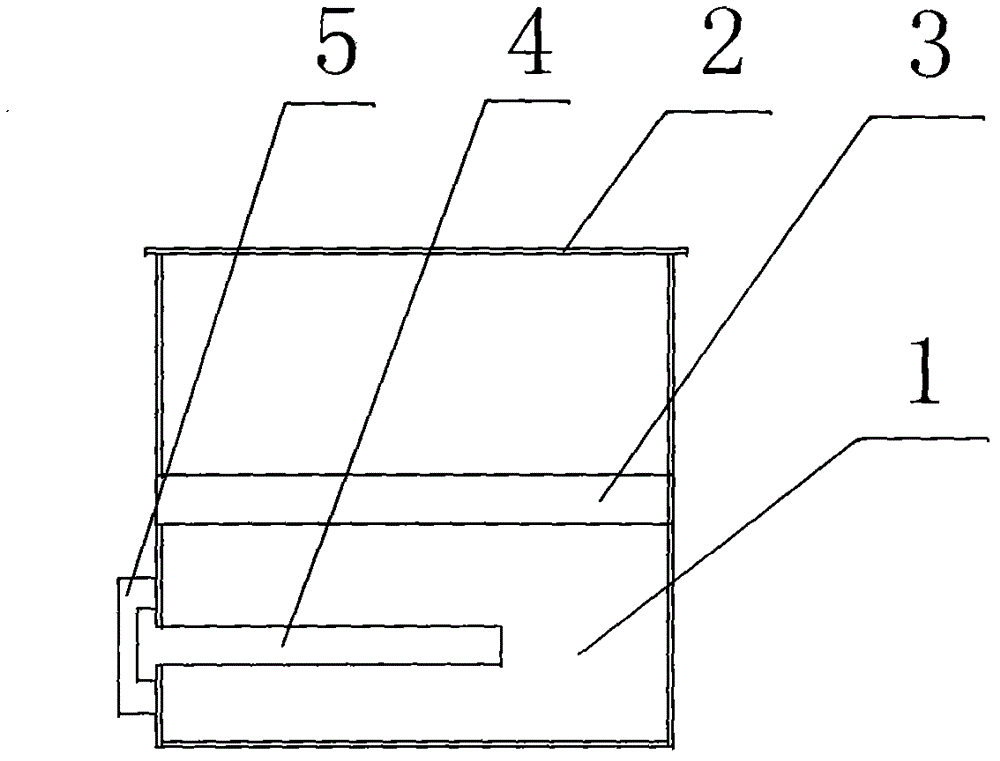

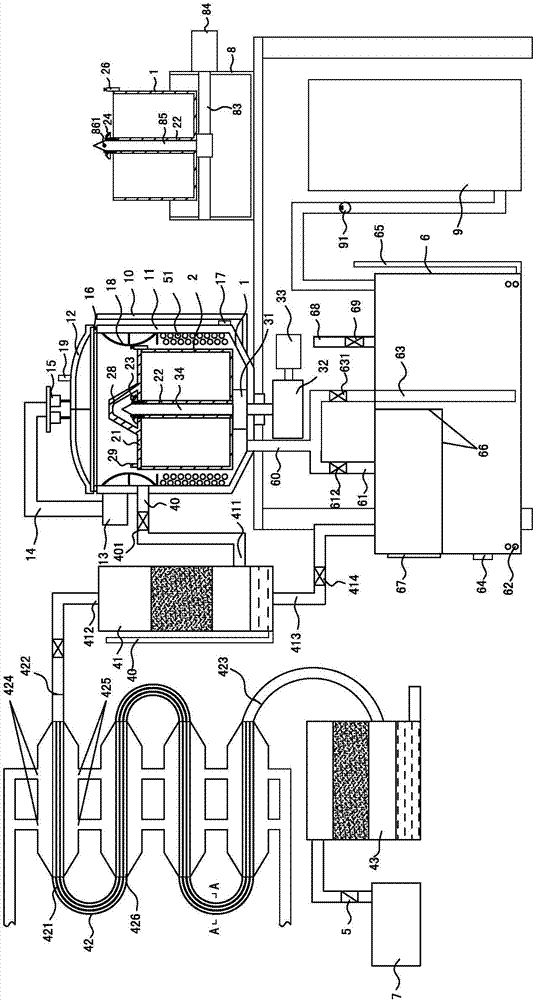

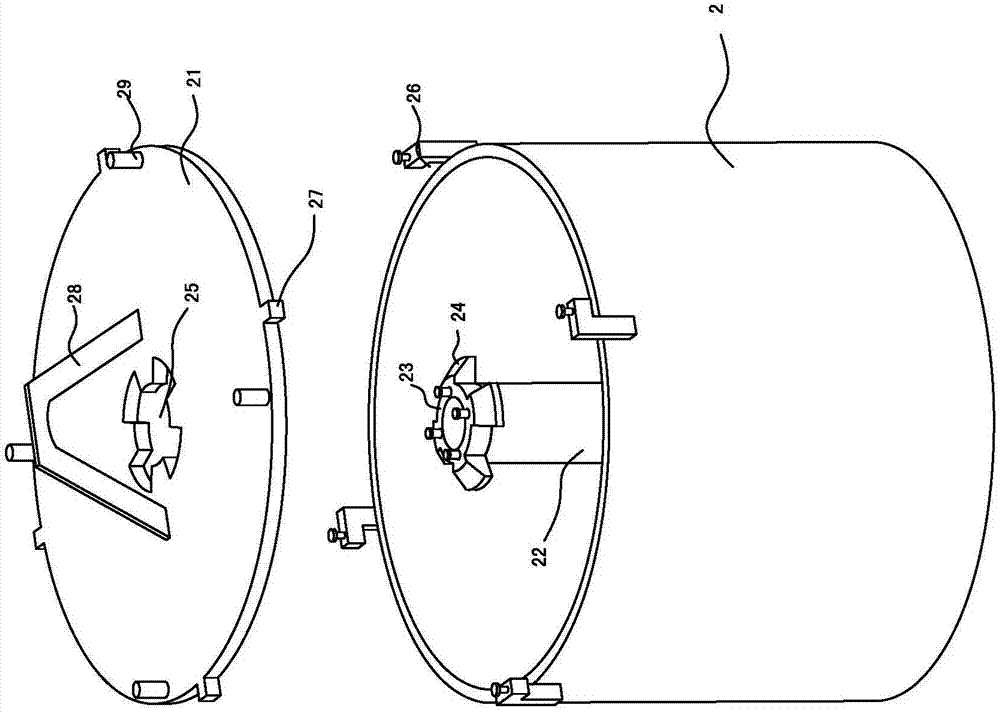

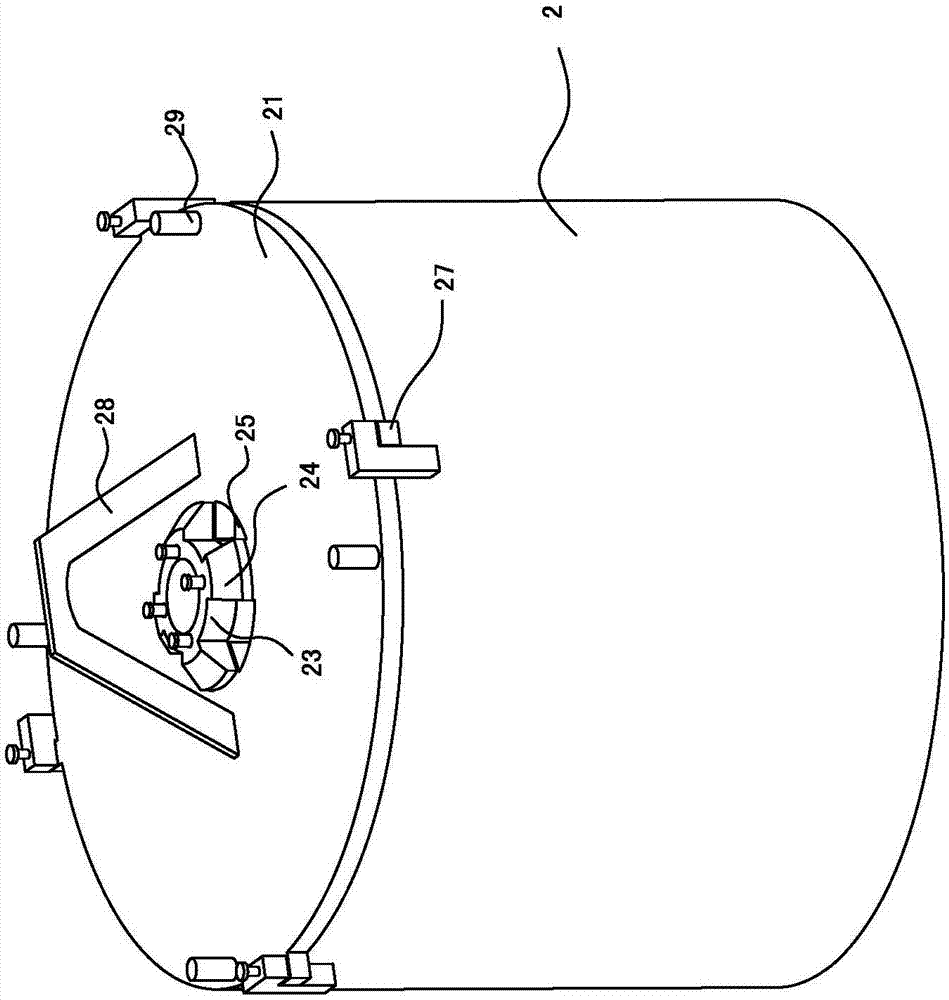

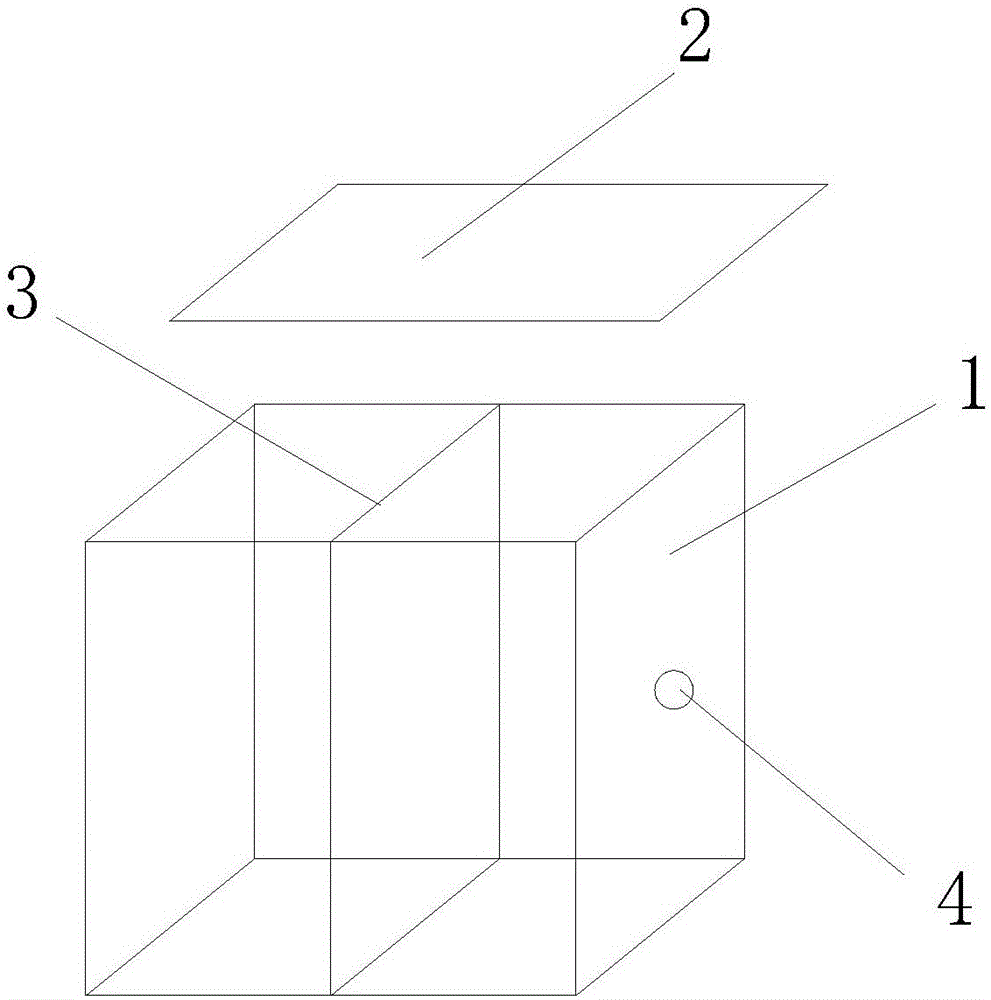

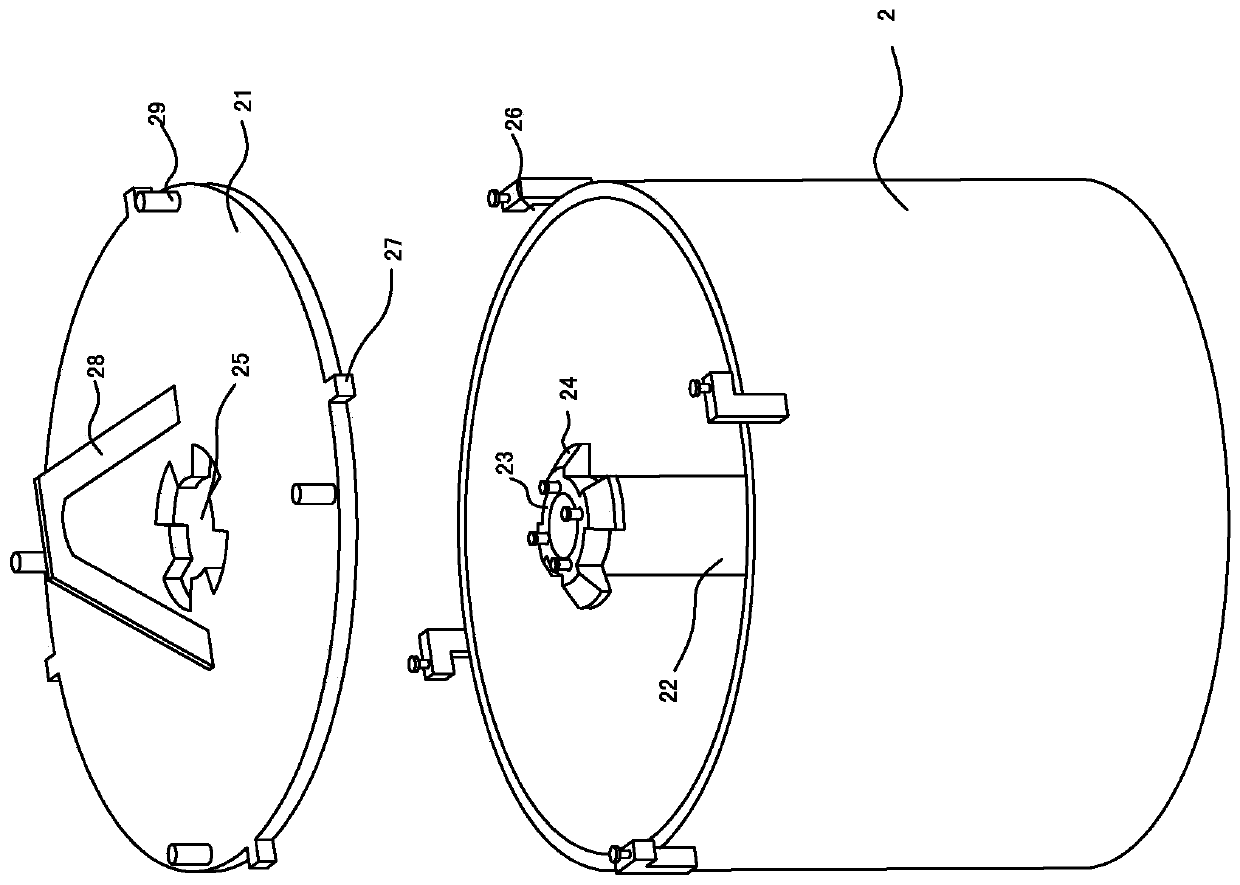

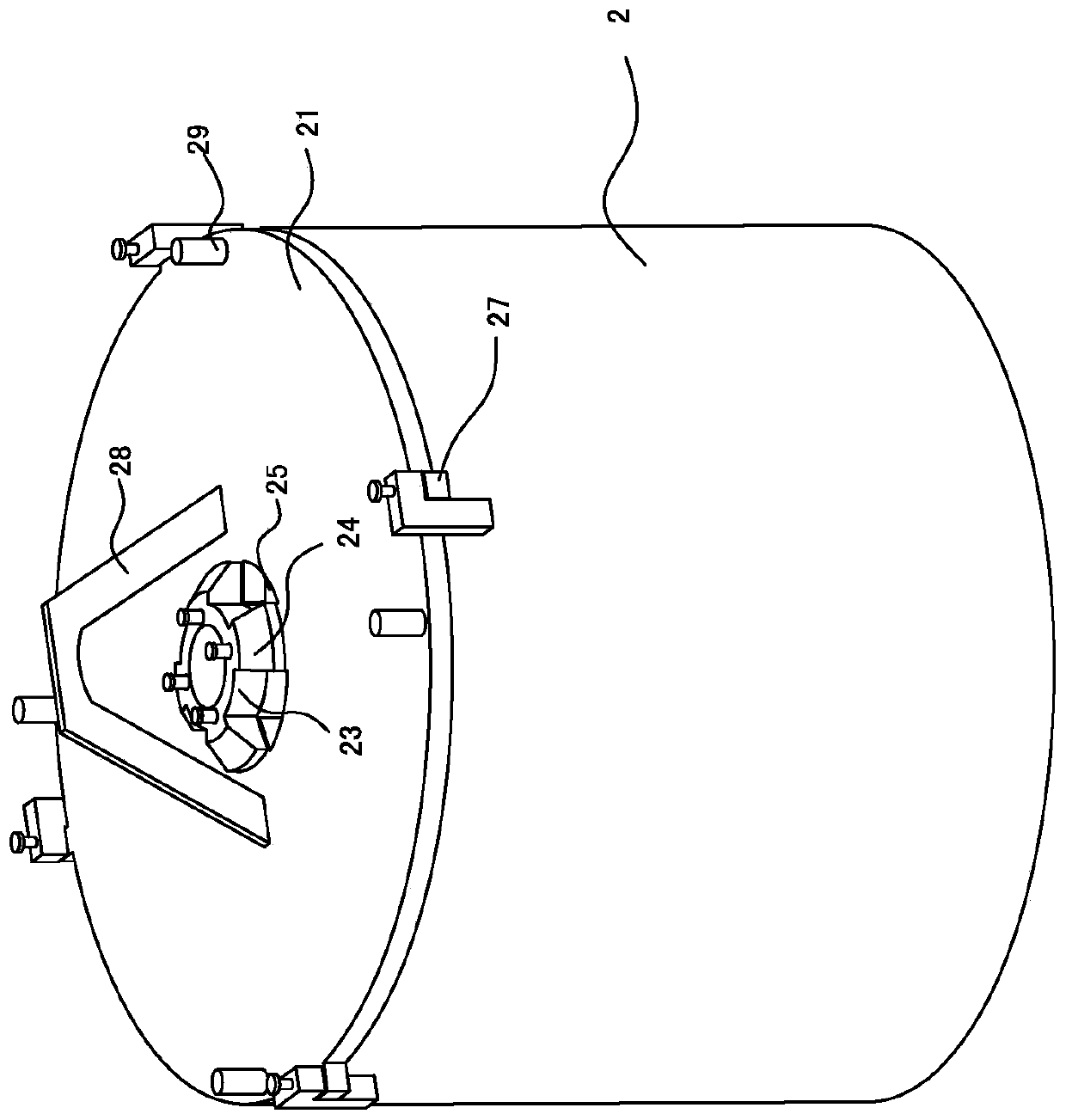

Full-plastic airtight modularized airlift light biological reactor

InactiveCN102533522AEasy to cleanEasy to replaceBioreactor/fermenter combinationsBiological substance pretreatmentsAdhesivePhotobioreactor

The invention relates to a full-plastic airtight modularized airlift light biological reactor in the biological field, which is characterized in that a full-plastic transparent barrel part (1) uses adhesives, a full-plastic transparent base (3) is fixed to form a container, and a drain hole is arranged on the full-plastic transparent base (3) and connected with a full-plastic water valve to form a collection water outlet (17). A full-plastic transparent top cover (2) is firmly connected with the full-plastic transparent barrel part (1) through a full-plastic closed bolt (14) and a full-plastic sealing part (15) so as to form a full-plastic airtight light biological reaction tank body. The full-plastic airtight modularized airlift light biological reactor solves problems that complex coastal environment of our country, large changes of sea water temperature and large storm waves bring difficulty to microalgae outdoor breeding, light cannot penetrate through water when a planar culture pond is deep by adopting the planar culture pond mode, microalgae at the bottom of the planar culture pond cannot absorb enough light and breeding output efficiency caused by insufficient circularly stirring is reduced .

Owner:镇江绿能创意设计有限公司

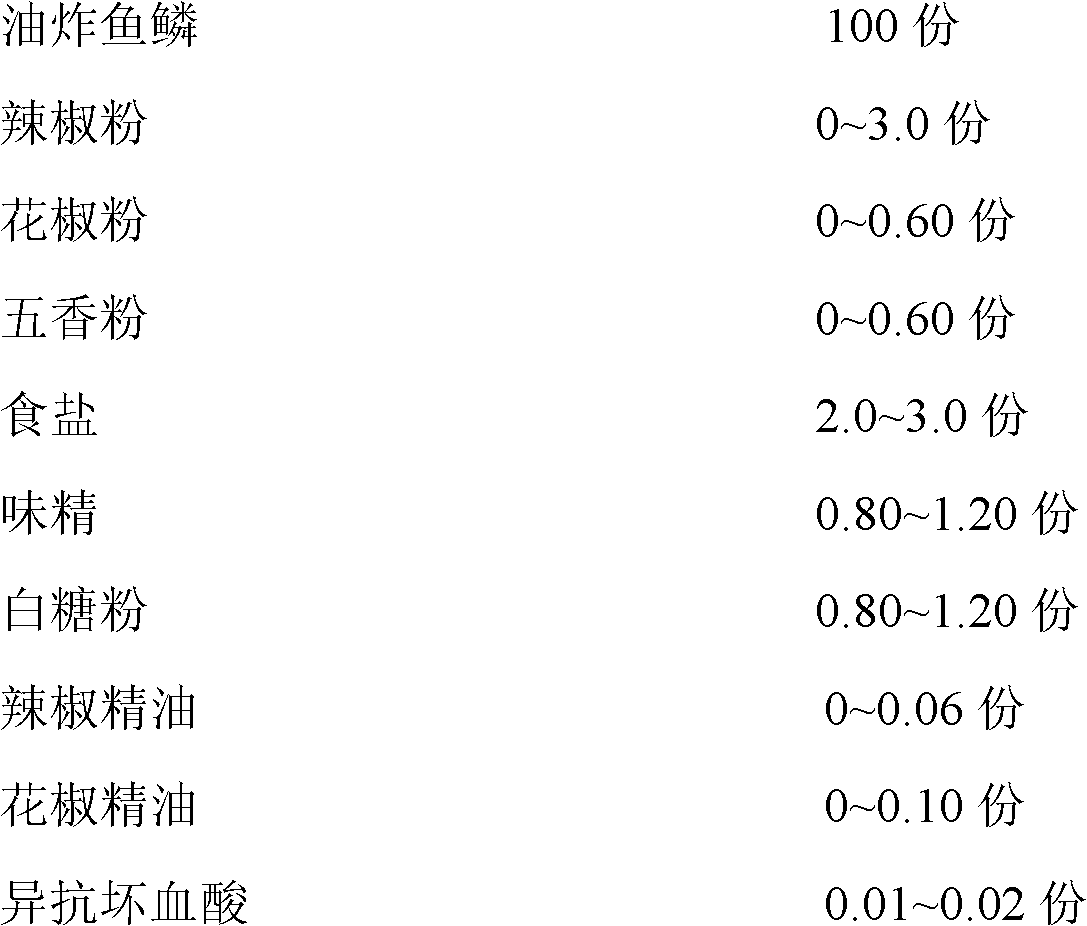

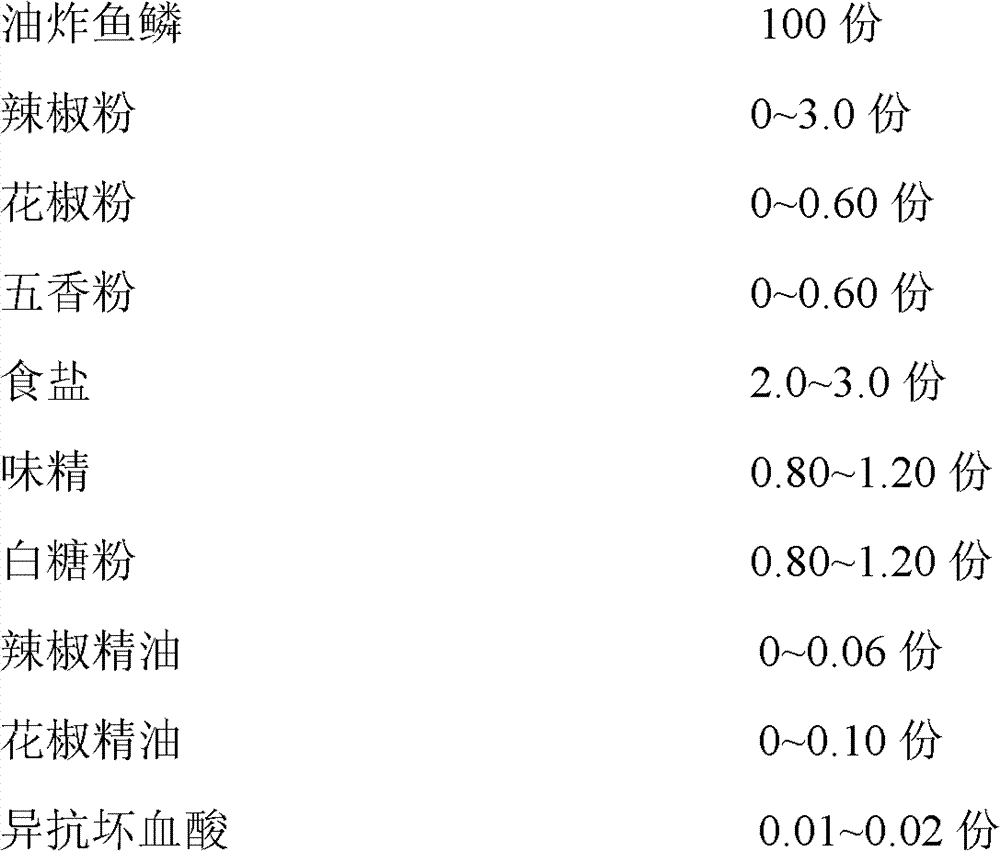

Fish scale leisure food and production process thereof

The invention discloses a fish scale leisure food and a production process thereof. The food is characterized in that: the food treats fresh or frozen stored fish scale as a raw material; the production process comprises operations of unfreezing, cleaning, pickling, cleaning, softening, frying, oil control, seasoning, bagging and the like; wherein a technology of low temperature pickling which isadopted allows pickling materials to uniformly penetrate; the technology of high temperature softening which is adopted allows partial scale collagen chains to fracture; and the technology of high and constant temperature frying which is adopted allows fish scale to rapidly puff. The leisure fish scale food produced through the process has a peculiar fish scale flavor, tastes crisp and delicious,and mellow, and can be transported, stored and sold at normal temperature.

Owner:SICHUAN UNIV

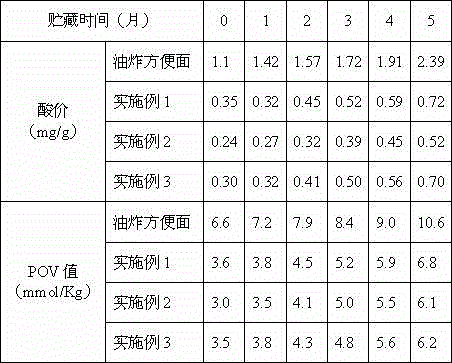

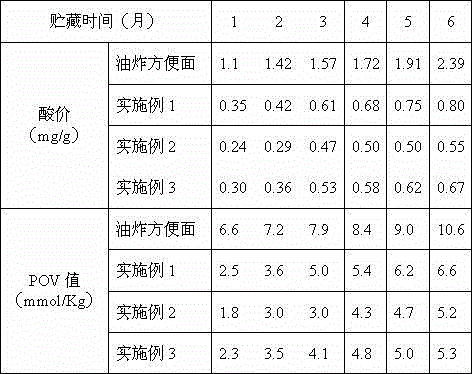

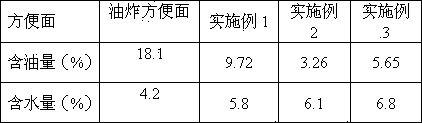

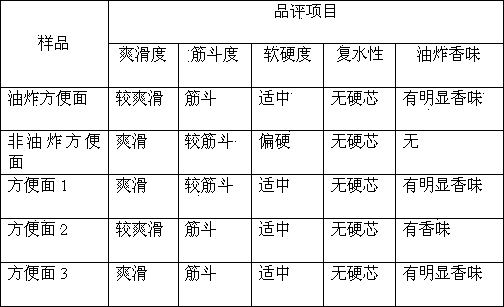

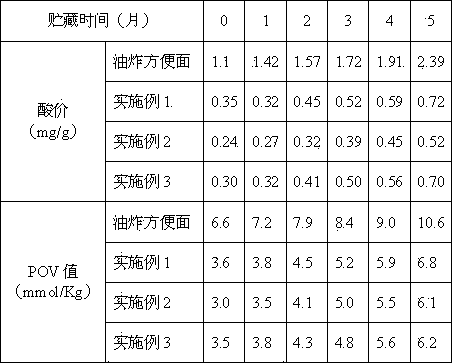

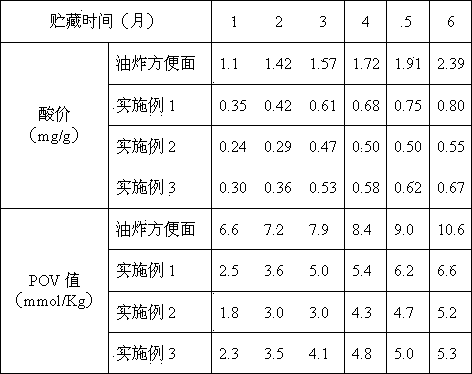

Healthy instant noodles with low oil content and preparation method thereof

InactiveCN103141766AAdd Noodle FlavorHigh nutritional valueFood preparationOil contentInstant noodle

The invention relates to healthy instant noodles with low oil content and a preparation method thereof. The preparation method comprises the steps of kneading a dough prepared from wheat flour, starch, water chestnut flour, raw peanut pulp, a mixed thickener, salt and an edible emulsifier, boiling, rolling, shredding, cooking, then enabling the noodles to pass through an oil sink at a temperature of 30-60 DEG C, draining oil and then carrying out far infrared drying and shaping on the noodle lump and obtaining an instant noodle lump after cooling. The preparation method has the advantages that the instant noodles have high nutritive value; the oil content of the pastry is controlled; and the reconstitution property, taste and flavor of the fried instant noodles are maintained.

Owner:福家欢食品股份有限公司

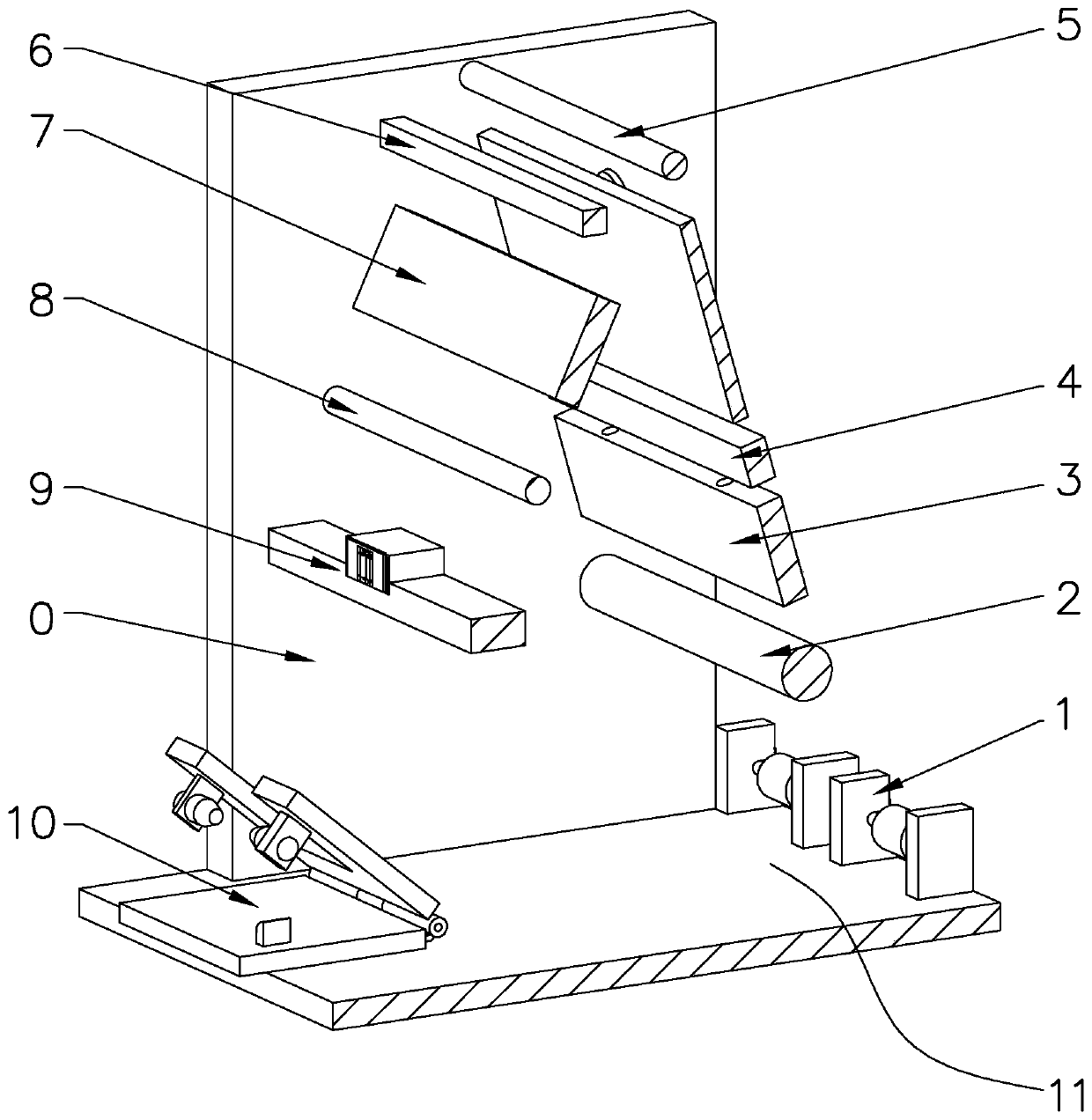

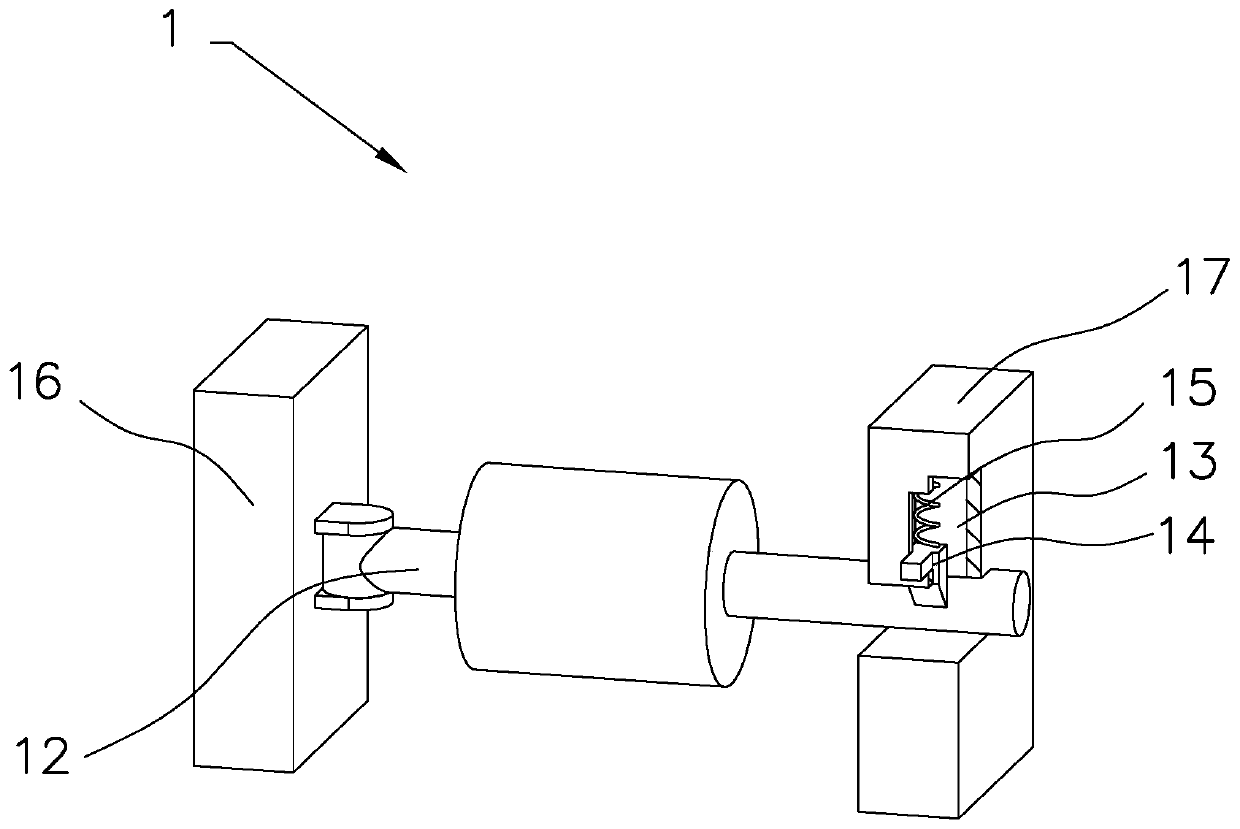

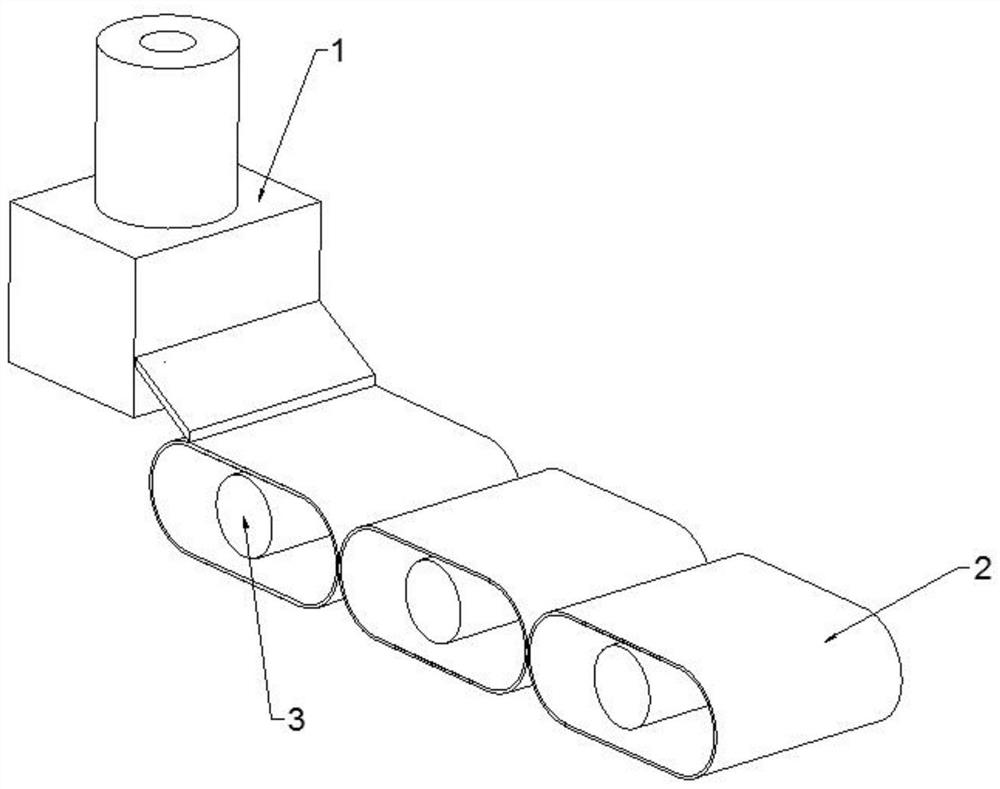

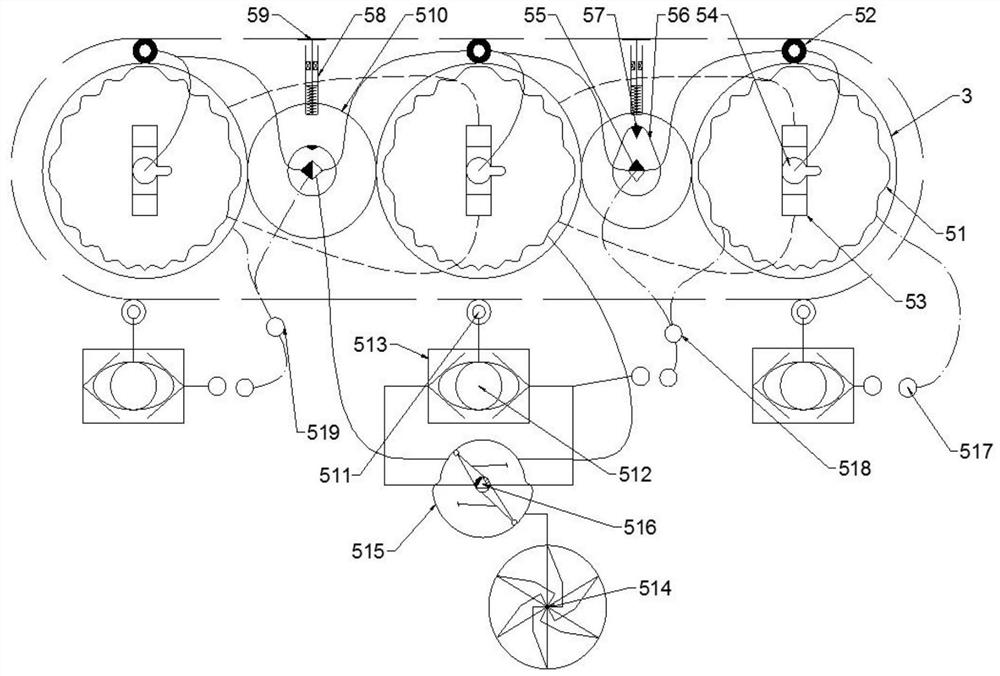

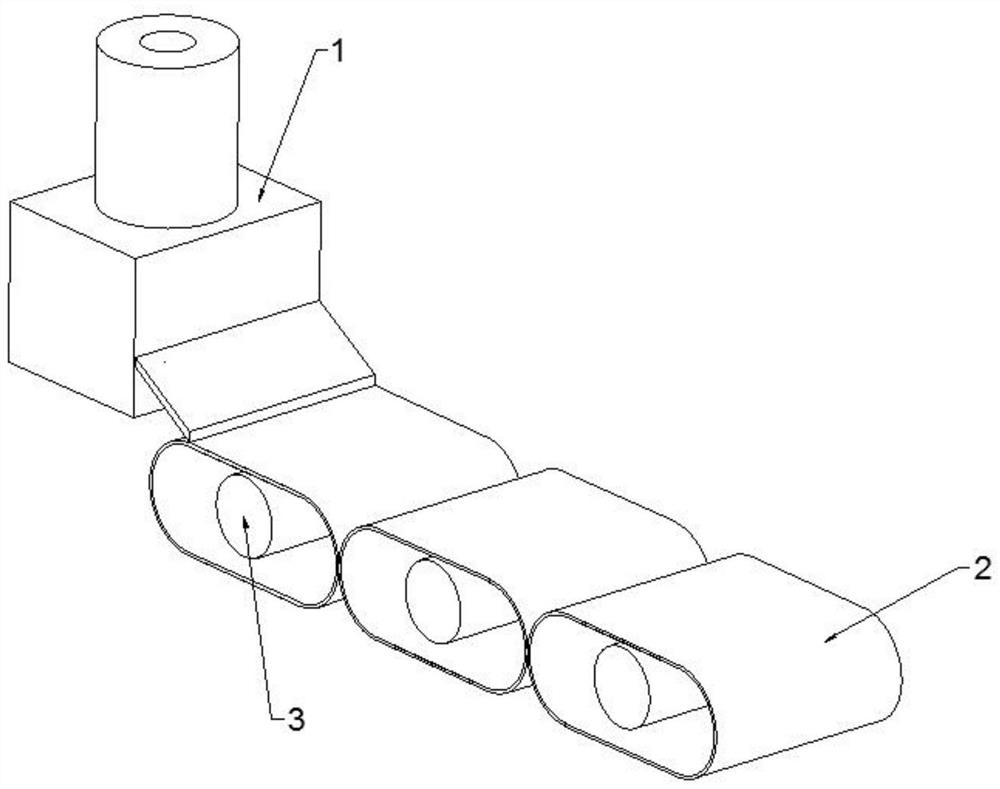

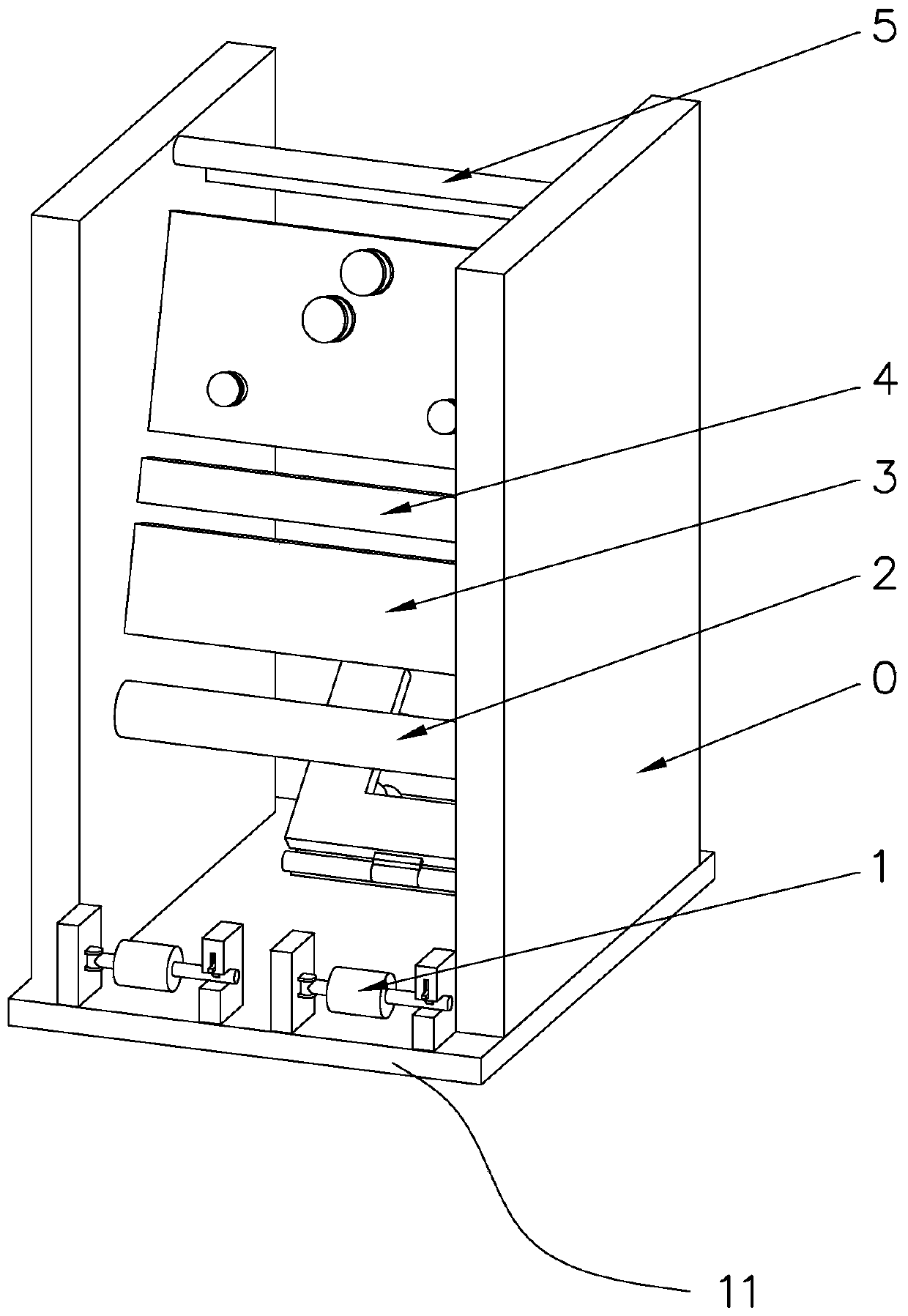

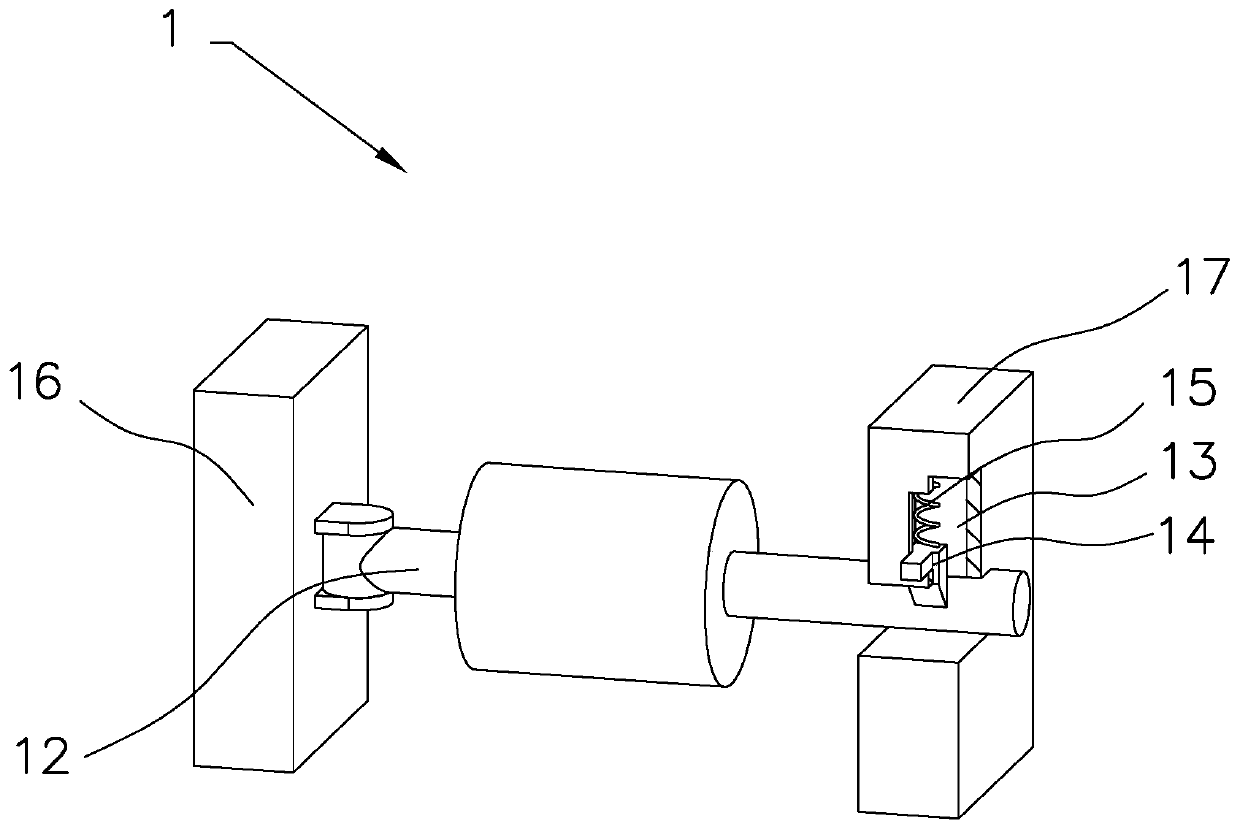

Draw texturing system of DTY high stretch yarn for knitted socks

The invention relates to a draw texturing system of a DTY high stretch yarn for knitted socks, and relates to the technical field of textile production. The draw texturing system comprises a base frame, and further comprises yarn inlet mechanisms, a first roller, a first hot box, a false twister, a second roller, a network nozzle, a second hot box, a third roller, an oiling mechanism and a windingmechanism, wherein the yarn inlet mechanisms, the first roller, the first hot box, the false twister, the second roller, the network nozzle, the second hot box, the third roller, the oiling mechanismand the winding mechanism are sequentially arranged on the base frame in the stretch yarn moving direction. The oiling mechanism comprises an oil box fixedly arranged on the base frame and an oil cover rotationally arranged on the base frame, the oil cover is located on the upper side of the oil box, the oil box is filled with an oiling agent, the oil cover is rotationally provided with an oilingwheel, and the lower end of the outer ring surface of the oiling wheel stretches into the oiling agent. The oil cover is provided with an oil control assembly used for squeezing the end face of the high stretch yarn to control the oiling quantity of the high stretch yarn, and the oil control assembly is located on the side, away from the third roller, of the oiling wheel. The draw texturing system has the advantages that the oil containing rate of the DTY high stretch yarn is controlled, so that the quality of the DTY high stretch yarn is improved.

Owner:浙江正堂实业股份有限公司

Low-oil-temperature instant noodles subjected to far infrared drying and preparation method thereof

The invention relates to low-oil-temperature instant noodles subjected to far infrared drying and a preparation method thereof. The preparation method comprises the steps of kneading a dough prepared from wheat flour, starch, water chestnut flour, raw peanut pulp, a mixed thickener, salt and an edible emulsifier, boiling, rolling, shredding, cooking, cutting off, uniformly spraying low-temperature frying oil on the upper and lower sides of the noodles, carrying out secondary far infrared drying and shaping and obtaining an instant noodle lump after cooling. The preparation method has the advantages that the instant noodles have high nutritive value; the oil content of the pastry is controlled; and the reconstitution property, taste and flavor of the fried instant noodles are maintained.

Owner:福家欢食品股份有限公司

Method for oiling ramie yarn of ramie rope embedded in steel wire rope on line

InactiveCN102720081ASimple and efficient operationReduce labor intensityRope making machinesYarnEngineering

The invention discloses a method for oiling a ramie yarn of a ramie rope embedded in a steel wire rope on line, relates to the field of steel wire rope auxiliary material processing, and solves the problems that the conventional method for immersing oil for a ramie rope core of the steel wire rope is complicated, coated oil is not uniform and the like. The method for oiling the ramie yarn of the ramie rope embedded in the steel wire rope on line comprises procedures of dividing and distributing; heating ramie core grease; stranding; and standing. By the method, a procedure of cooking oil by using a ramie rope oil immersing device is eliminated, labor is saved, cost is reduced and the operation is convenient; and moreover, the ramie yarn is oiled on line, and the quality of the ramie rope embedded in the steel wire rope is fundamentally ensured.

Owner:ANHUI HUAI MINING STEEL ROPE

Non-fried instant noodles with low oil content and fried flavor and preparation method thereof

The invention relates to non-fried instant noodles with low oil content and fried flavor and a preparation method thereof. The preparation method comprises the steps of kneading a dough prepared from wheat flour, starch, water chestnut flour, raw peanut pulp, a mixed thickener, salt and an edible emulsifier, carrying out the conventional procedures such as boiling, rolling, shredding, cooking, cutting off and folding, subjecting the obtained cooked noodle lump to circulating hot air drying at 100-140 DEG C until the water content is not more than 12%, then uniformly spraying mist-like edible oil on the cooked noodle lump, then carrying out microwave drying and shaping, adding seasoning packets after cooling and packaging the finished product. The preparation method has the advantages that the instant noodles have high nutritive value; the oil content of the pastry is controlled; and the reconstitution property, taste and flavor of the fried instant noodles are maintained.

Owner:福家欢食品股份有限公司

Staged oil-frying and steaming technology of Cantonese braised pork

The invention discloses a staged oil-frying and steaming technology of Cantonese braised pork. The staged oil-frying and steaming technology of the Cantonese braised pork comprises the following steps: removing hair, carrying out dicing, preparing pre-cooking soup, carrying out curing, injecting salt by puncturing, carrying out mixed oil-frying by using water and oil, carrying out mixed re-frying by using water and oil, carrying out steaming, and so on. The staged oil-frying and steaming technology of the Cantonese braised pork integrates cooking methods of traditional Chinese dishes and processing technologies of western meat products; during the oil-frying stage, the oil-frying is successively carried out at different temperature by adopting a water-oil mixed method, so that production of harmful materials can be effectively controlled during the oil-frying process so as to preserve good senses and flavors of the meat products to the maximum extent; moreover, vegetable fat, namely corn oil, is used as the oil for oil-frying in the staged oil-frying and steaming technology of the Cantonese braised pork, so that the oil-fried meat products are healthier, and better in edible properties.

Owner:GUANGXI UNIV

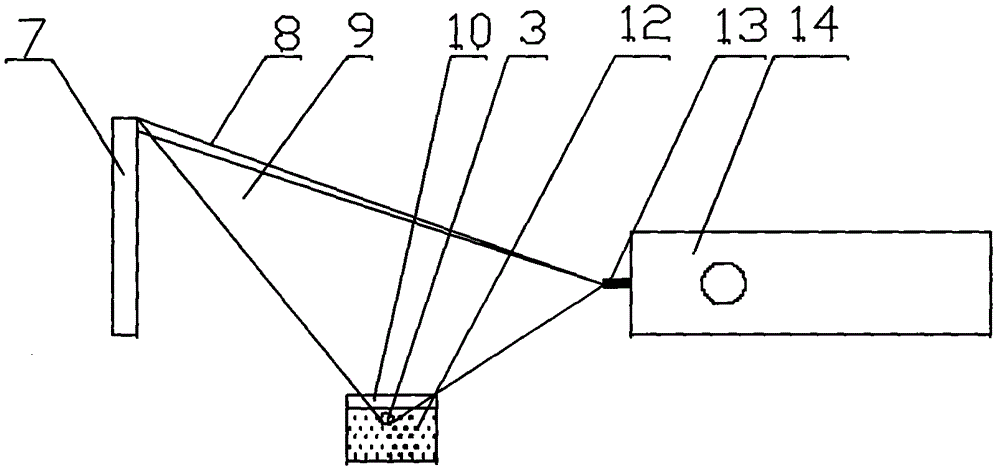

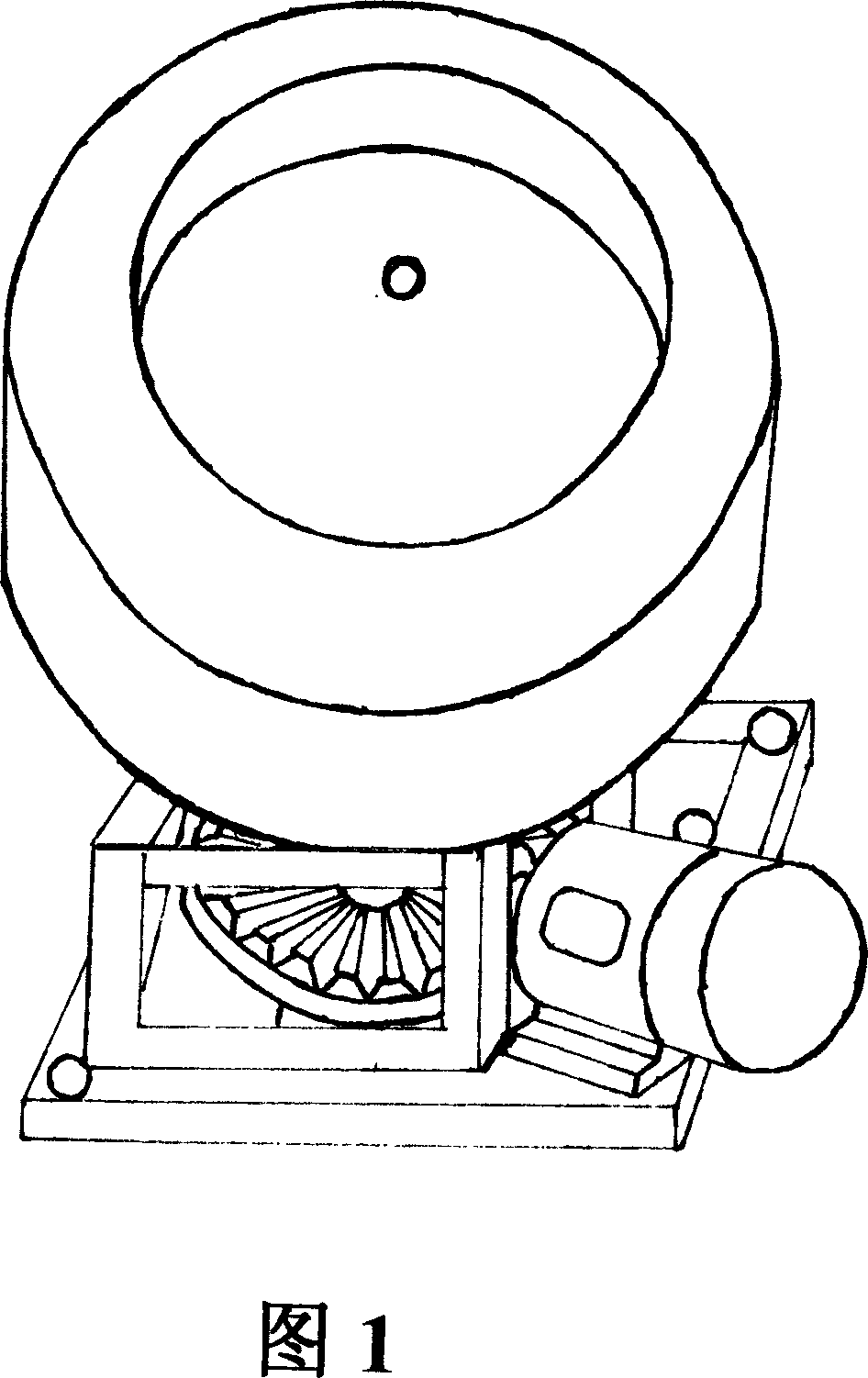

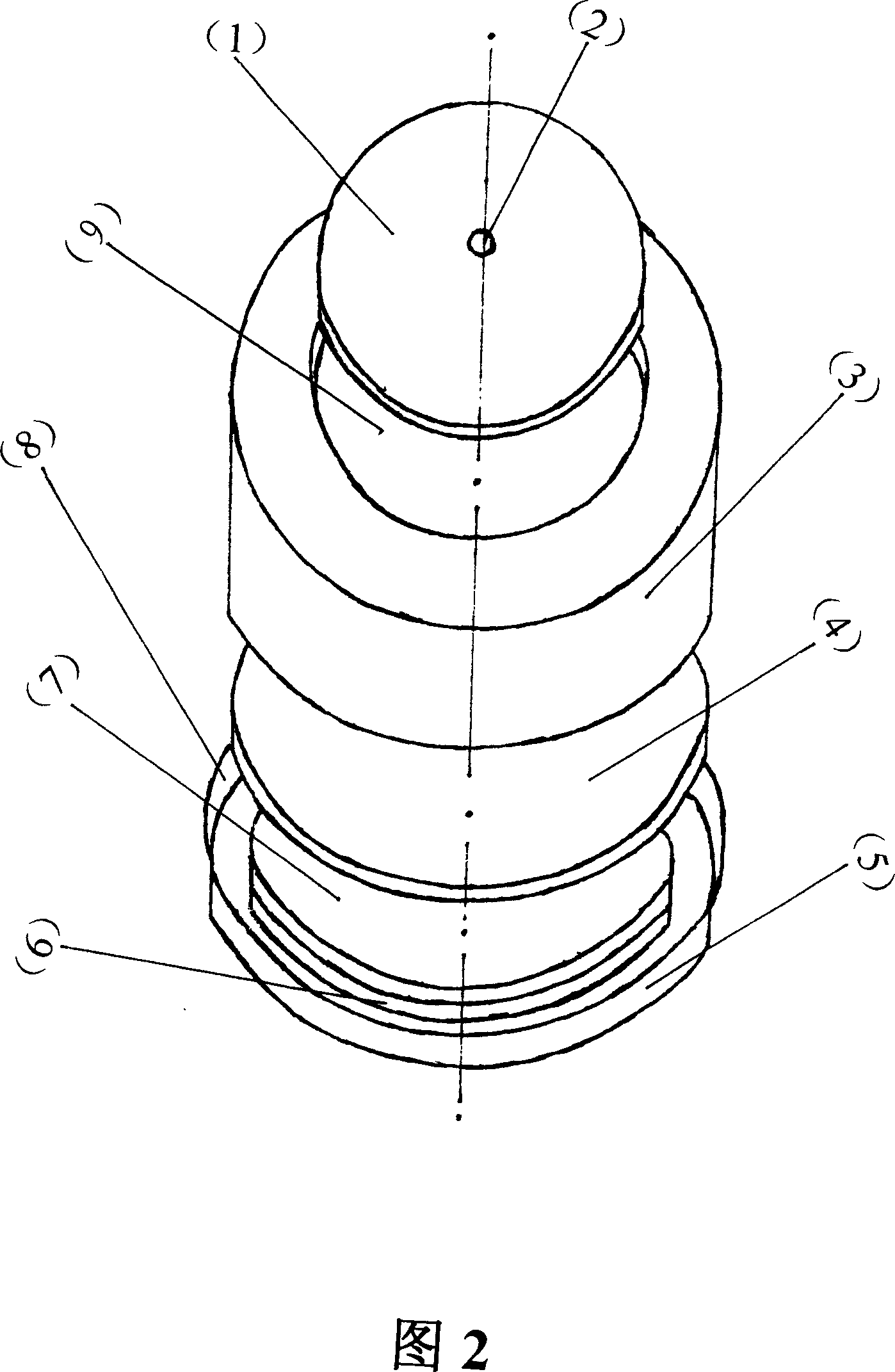

Foodstuff butter atomization technique and multifunctional butter atomization still

InactiveCN1989817AControl oil contentSolving the Ghee ProblemOil/fat bakingPancakes bakingDecompositionEngineering

The invention discloses a food atomised butter new technology and a new food mechanical multifunctional heat rotary pot.It changes the traditional operational method which is left by the thousands of years of history and fry food in the liquid oil in big lard pot into atomised butter food method, the food is under comprehensive roles of hot temperature, oil mist, micro-pressure, jet and rotary rolling in sealed container, the fry seems like steamed or roasted so makes the puff-pastry achieve the purpose of loose foam and delicious, especially crisp; it applies to sugar, meat, grain, vegetables and nuts roots;The food atomised butter new technology is proceeded in multifunctional heat rotary pot, round roll block is butter atomized in multifunctional heat rotary pot, it control the oleaginousness, glaze degree and so on of butter food effectively, the fried butter is heated one time and used only one time, it removes the oil pollution leaded by fried butter mixed many times, heated many times in high temperatures and oxidation decomposition thoroughly, and overcomes that the nutrient content of fried foods itself is damaged and lost.

Owner:王训勇

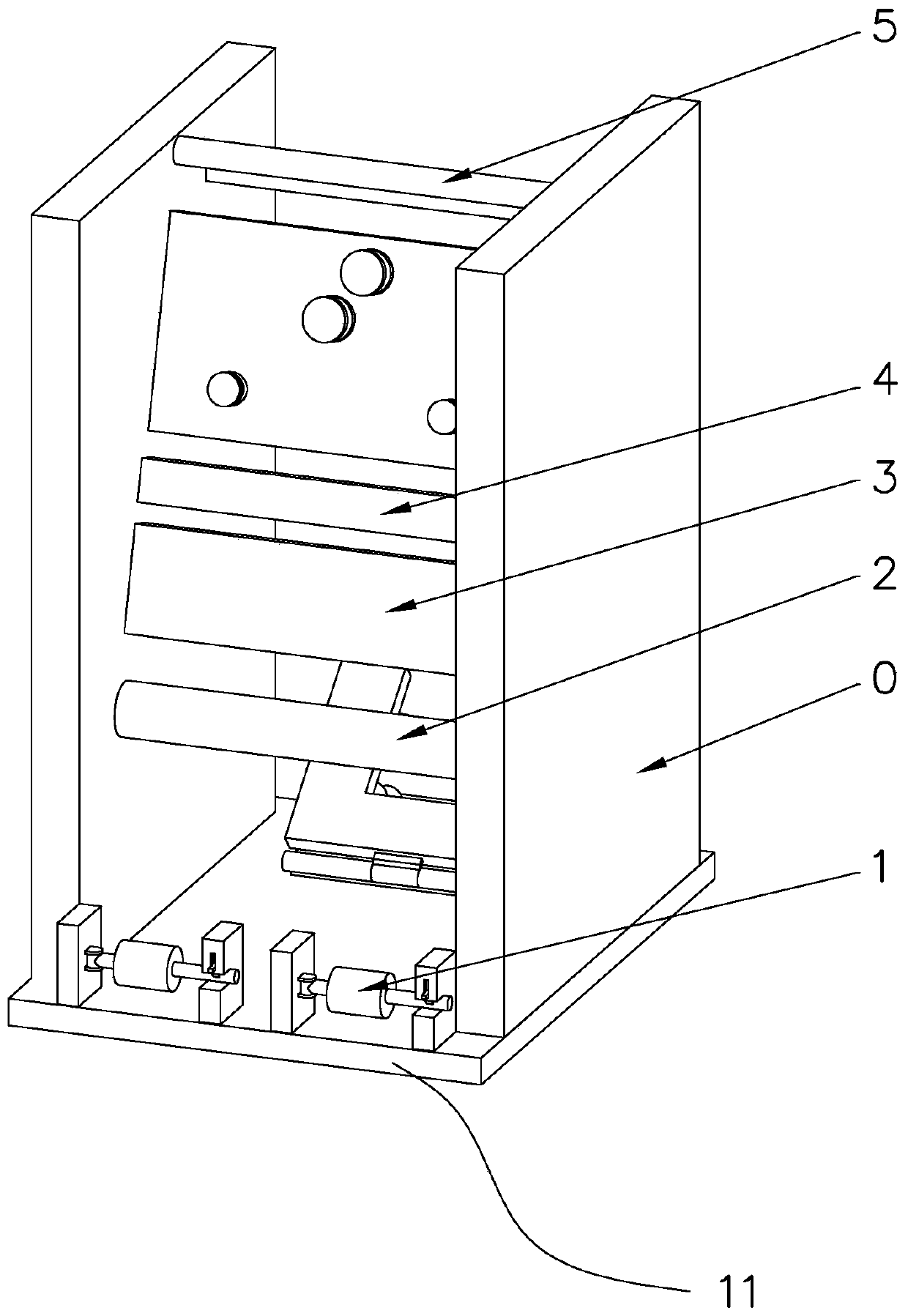

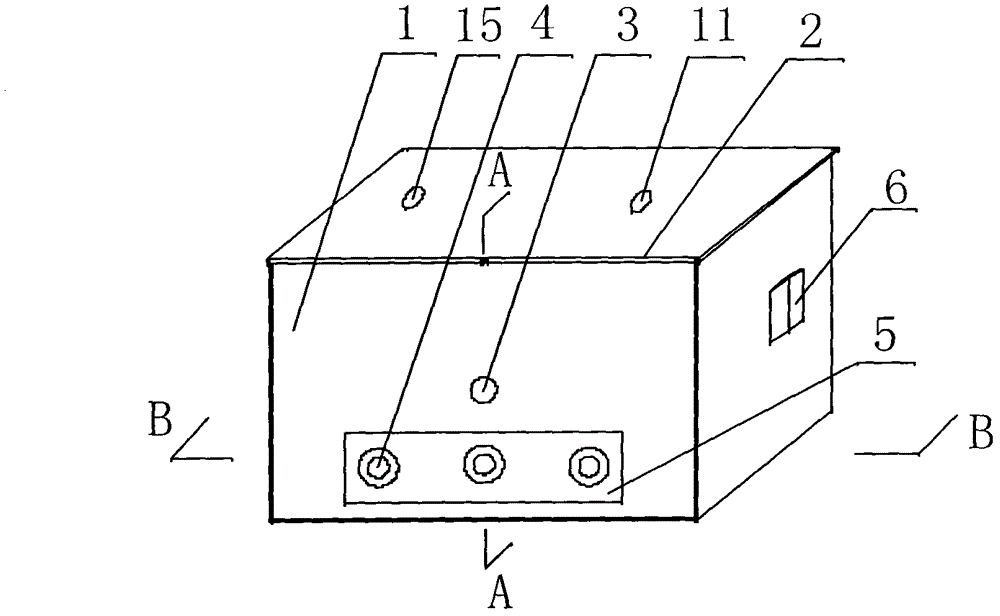

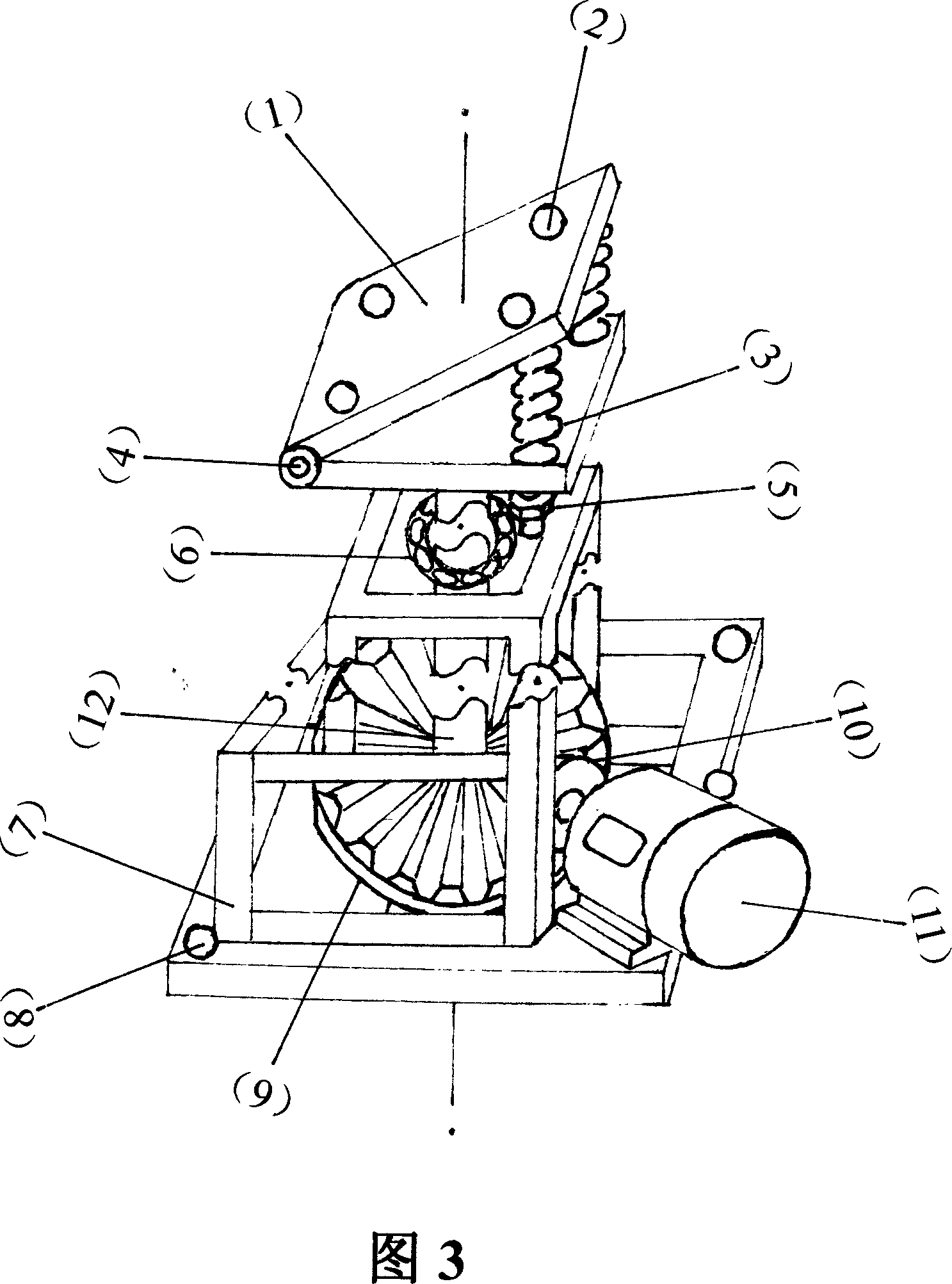

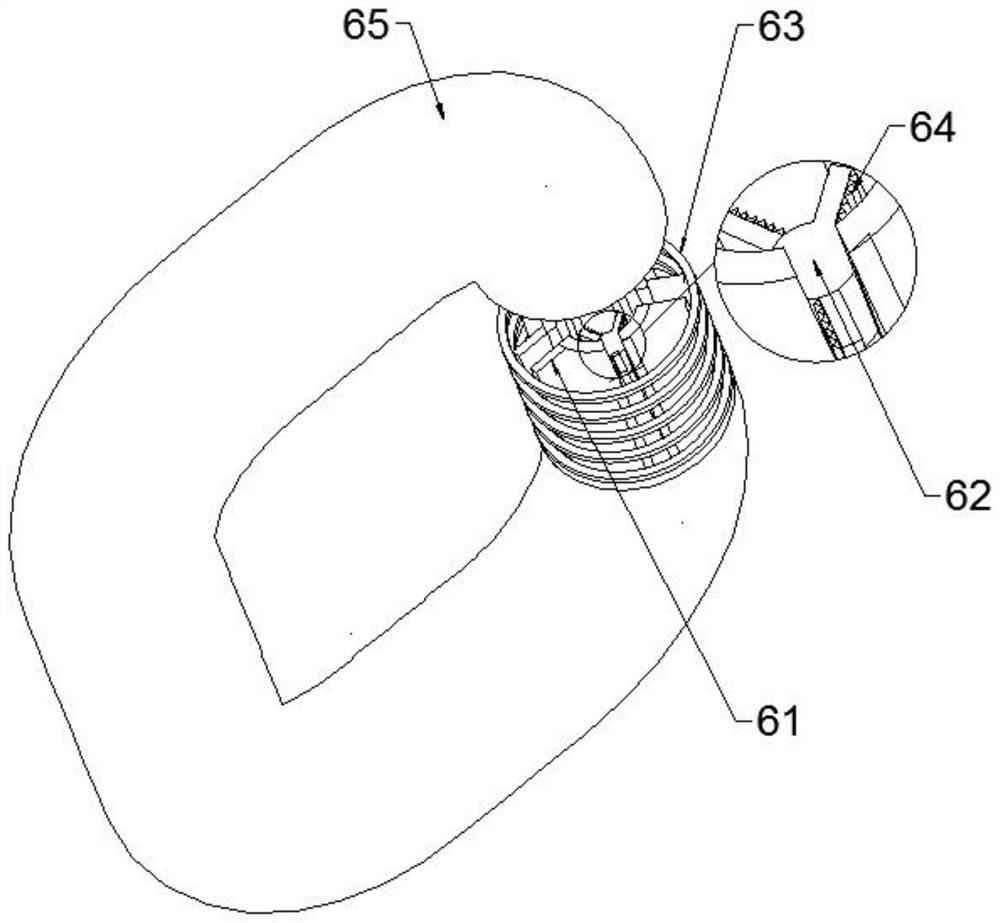

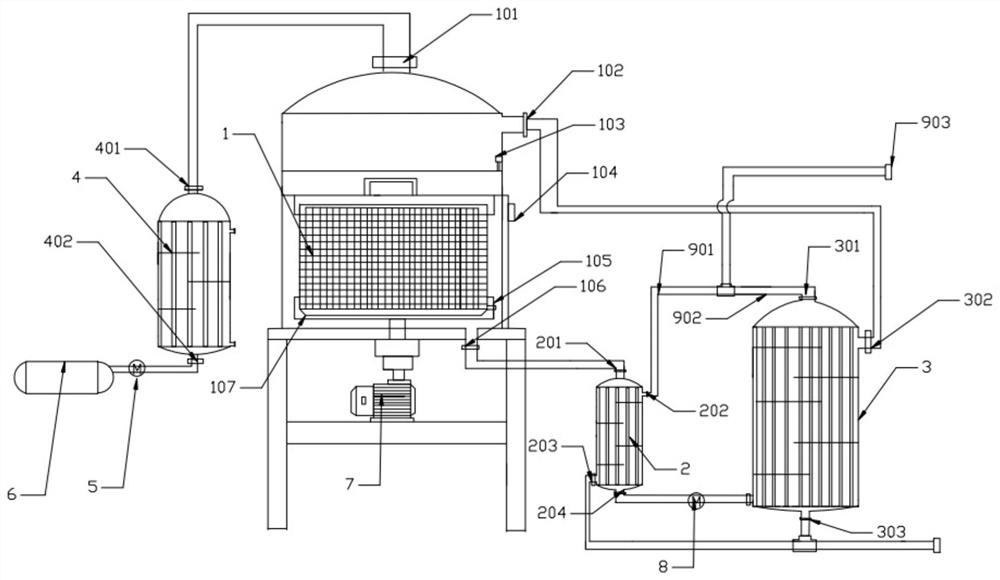

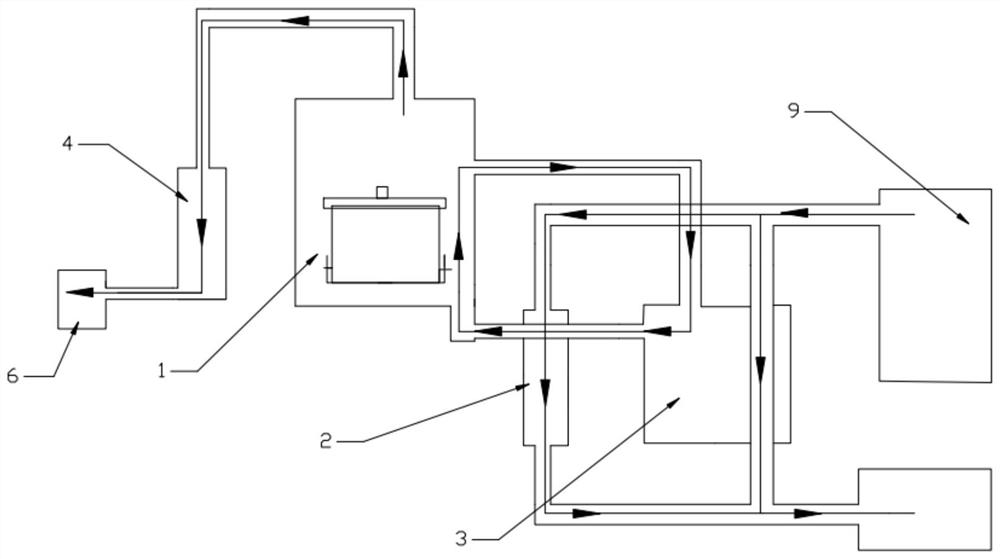

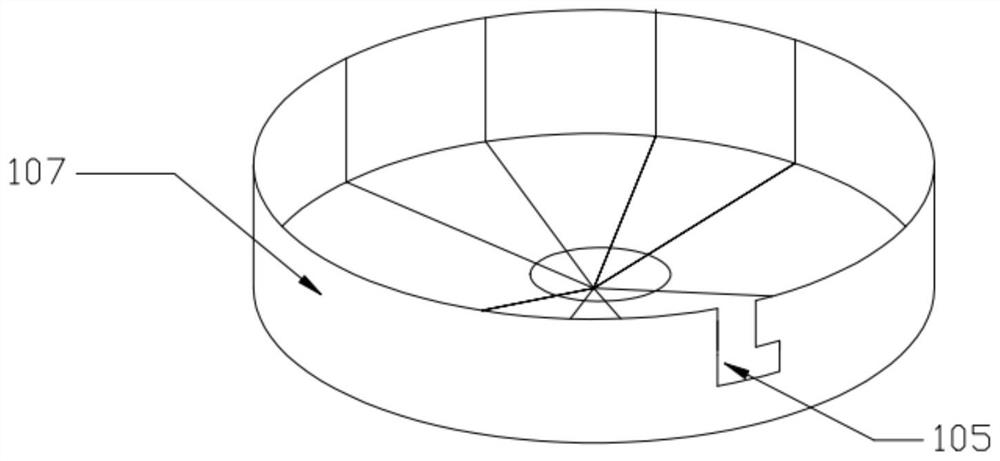

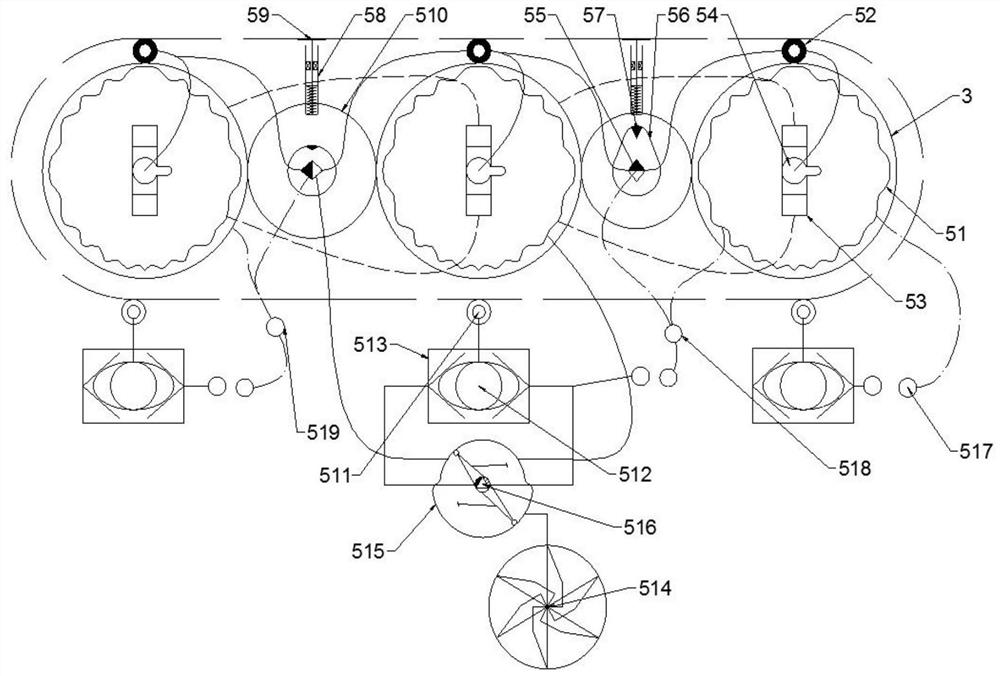

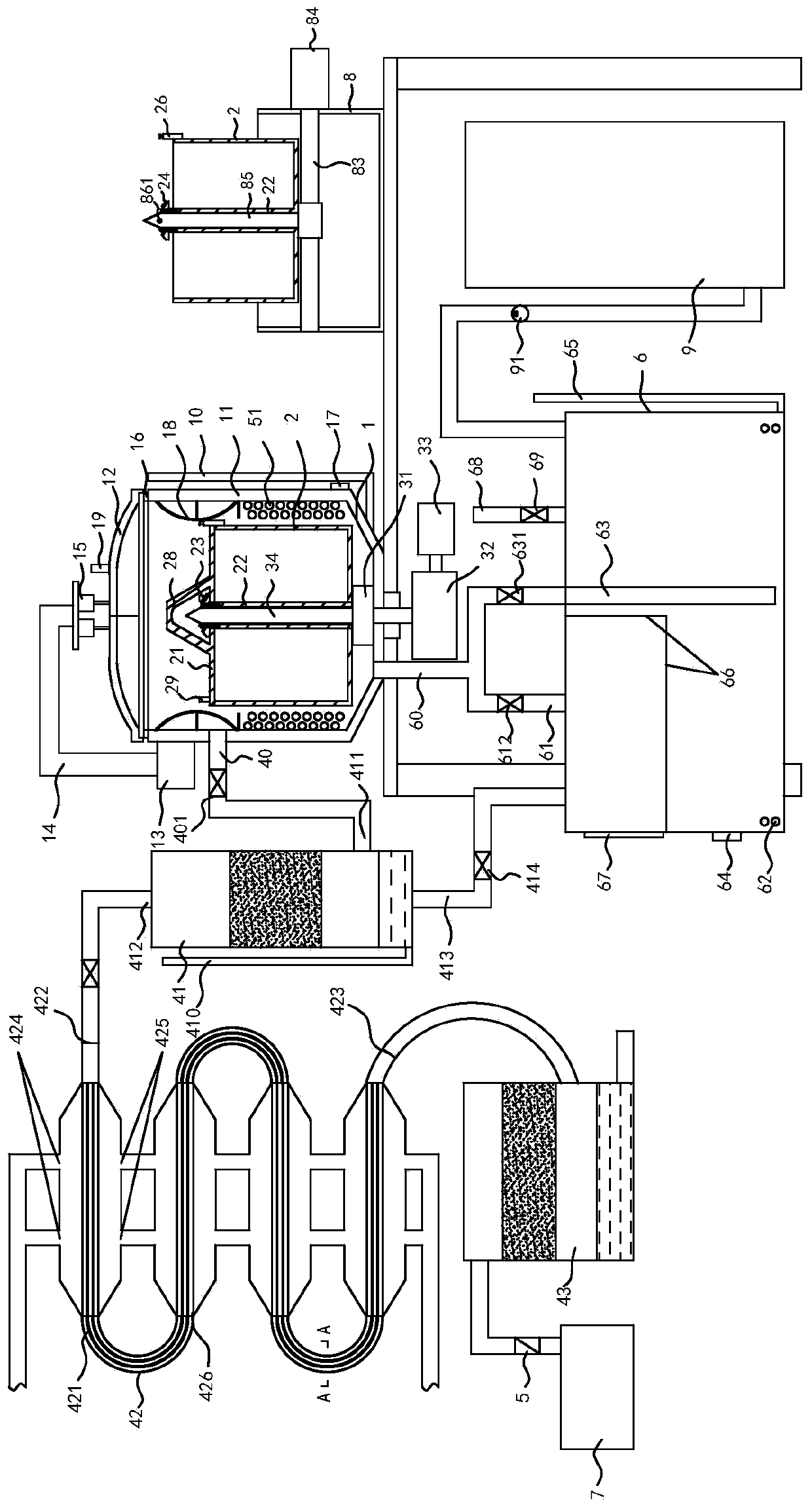

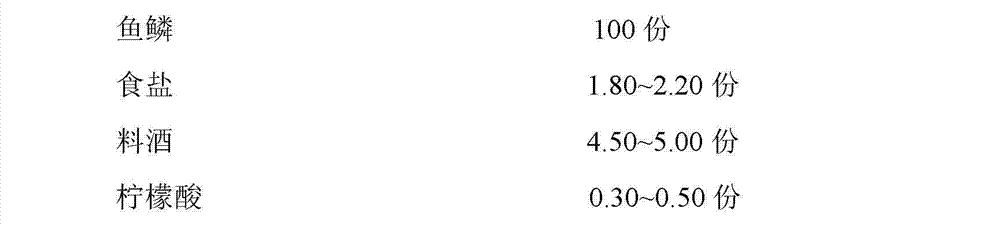

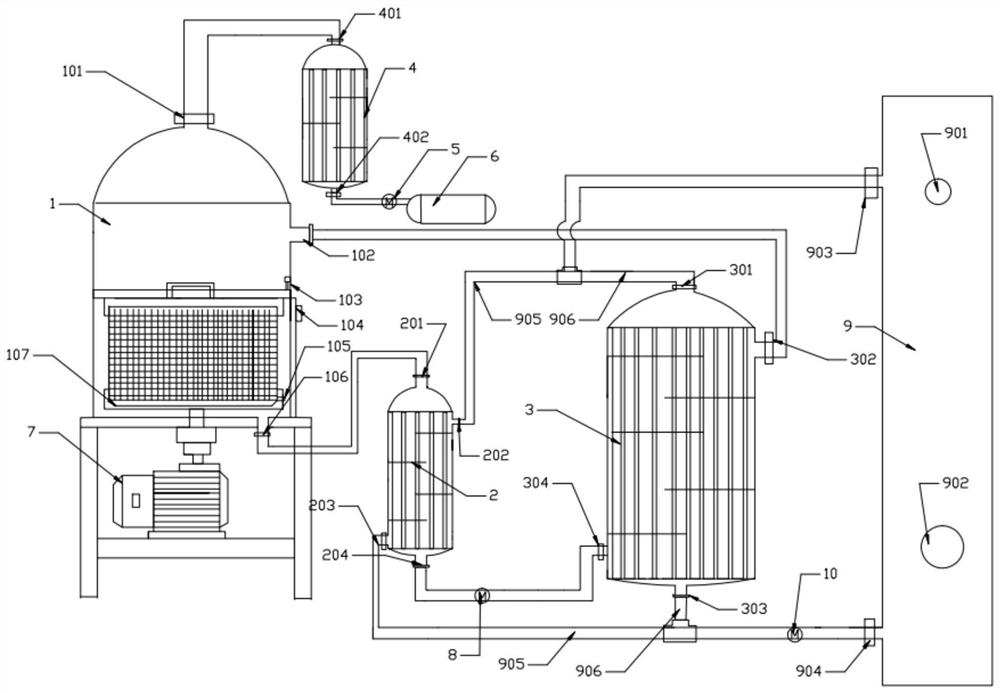

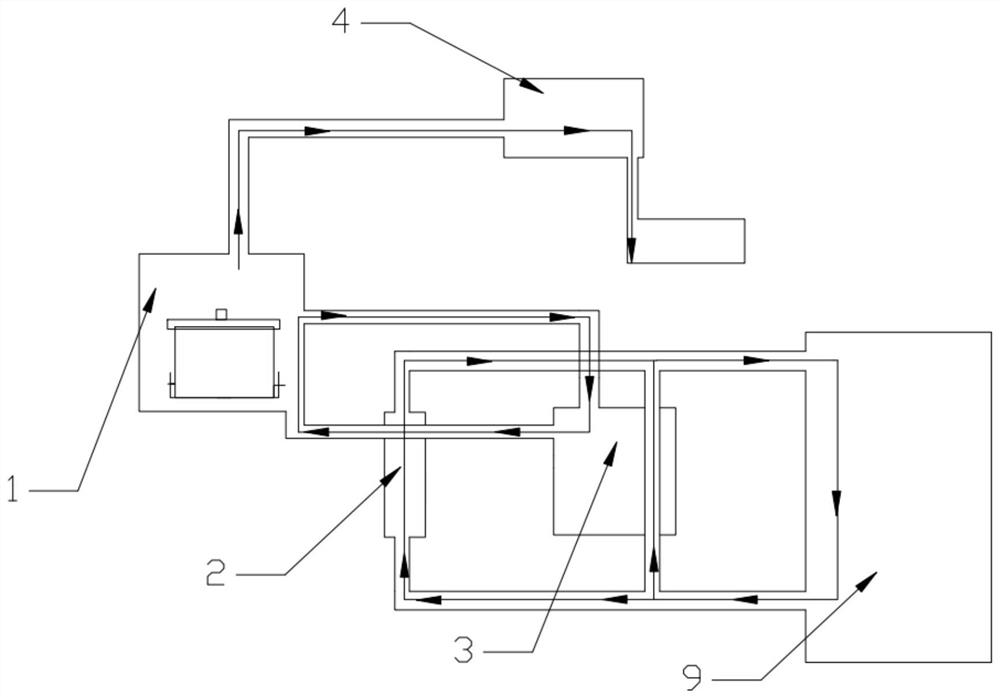

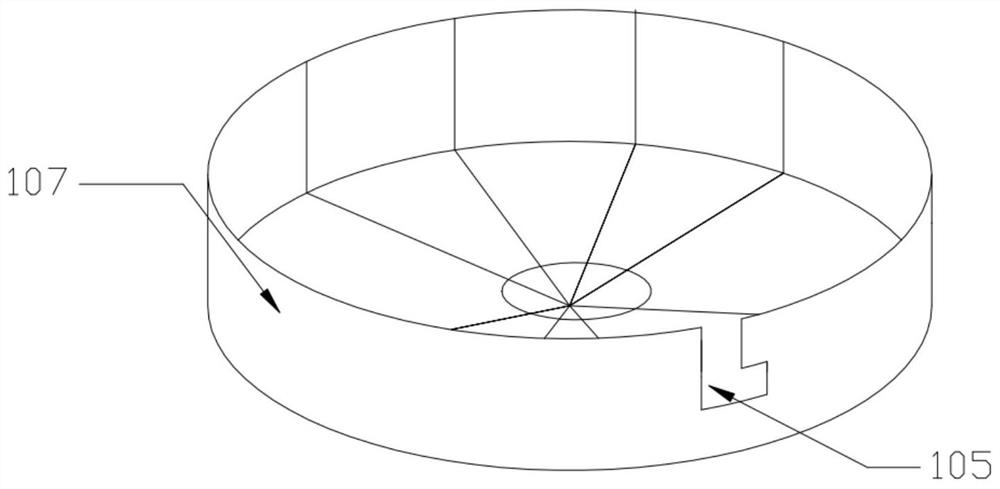

Full automatic low-temperature vacuum frying device

ActiveCN106857733AAvoid pollutionControl oil contentOil/fat bakingCharging/discharging ovensBlock matchVacuum drying

The invention relates to the technical field of food processing, in particular to a full automatic low-temperature vacuum frying device. The device comprises a vacuum frying tank, a discharging device, a heating device and a cooling device which are arranged on a rack in sequence, the discharging device is arranged at one side of the vacuum frying tank, the cooling device is communicated with the vacuum drying tank through a vacuum tube, the vacuum frying tank comprises a tank body and a tank lid arranged on the upper portion of the tank body, a rotating disc is arranged in the center of the bottom inside the tank body, the rotating dick is driven by a rotating motor to rotate, a guiding shaft is arranged on the rotating disc, a material frame is arranged on the rotating disc and provided with a shaft sleeve allowing the material frame to be inserted into the guiding shaft, a material frame lid is arranged on the material frame, a mounting block is arranged at the upper end of the shaft sleeve of the material frame, protruding blocks are arranged on the mounting block, the material frame lid is provided with a through hole matched with the mounting block, the material frame lid is located below the mounting block when covering the material frame, clamping grooves are upwards formed in the outer side around the upper end of the material frame, and the material frame lid is provide with clamping blocks matched with the clamping grooves.

Owner:吕丙生

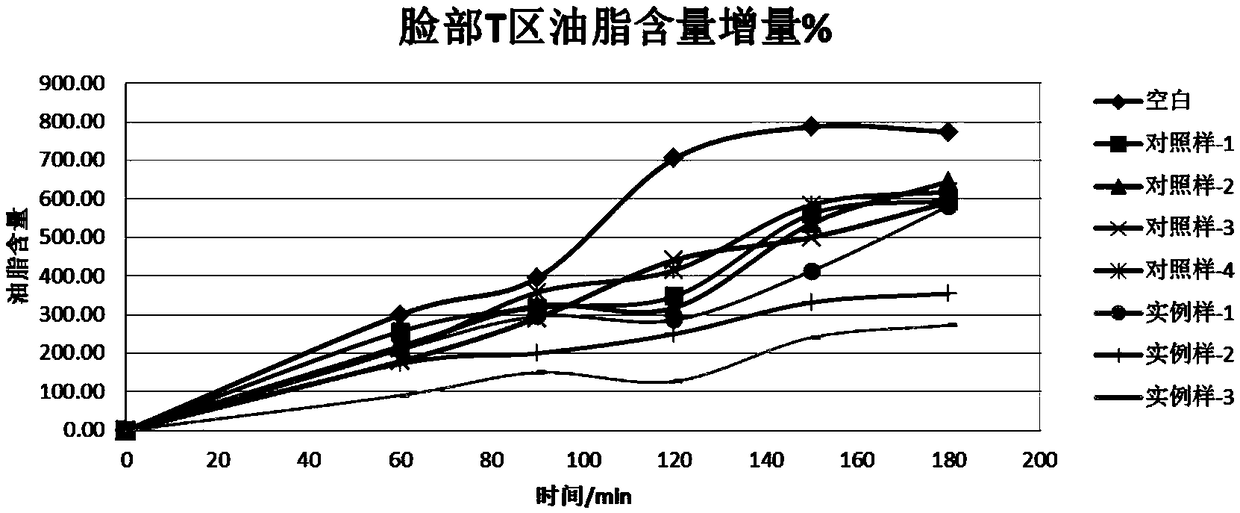

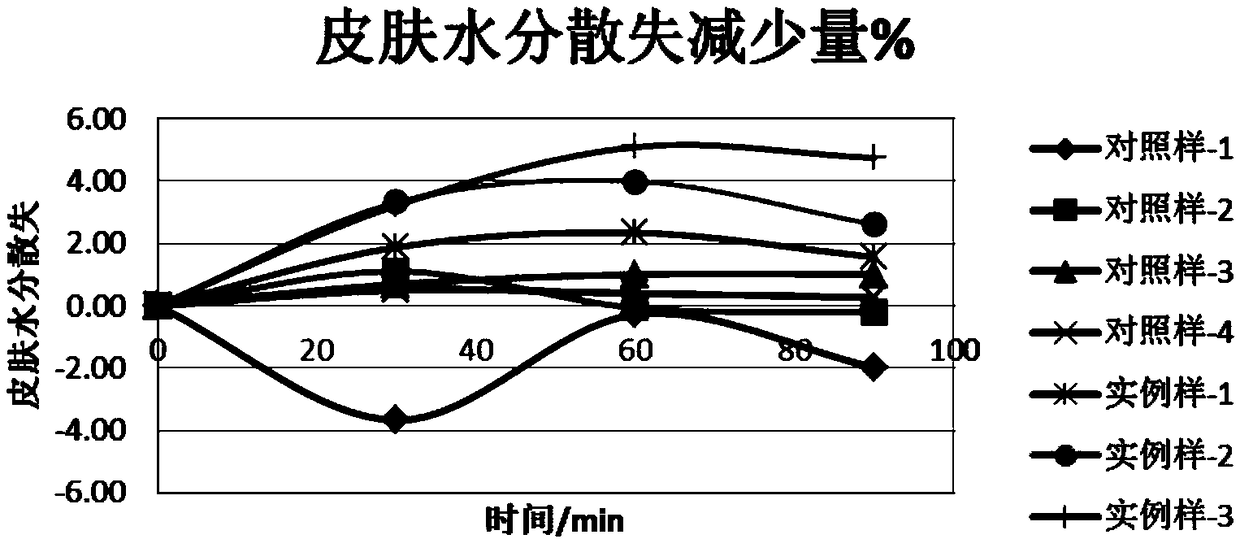

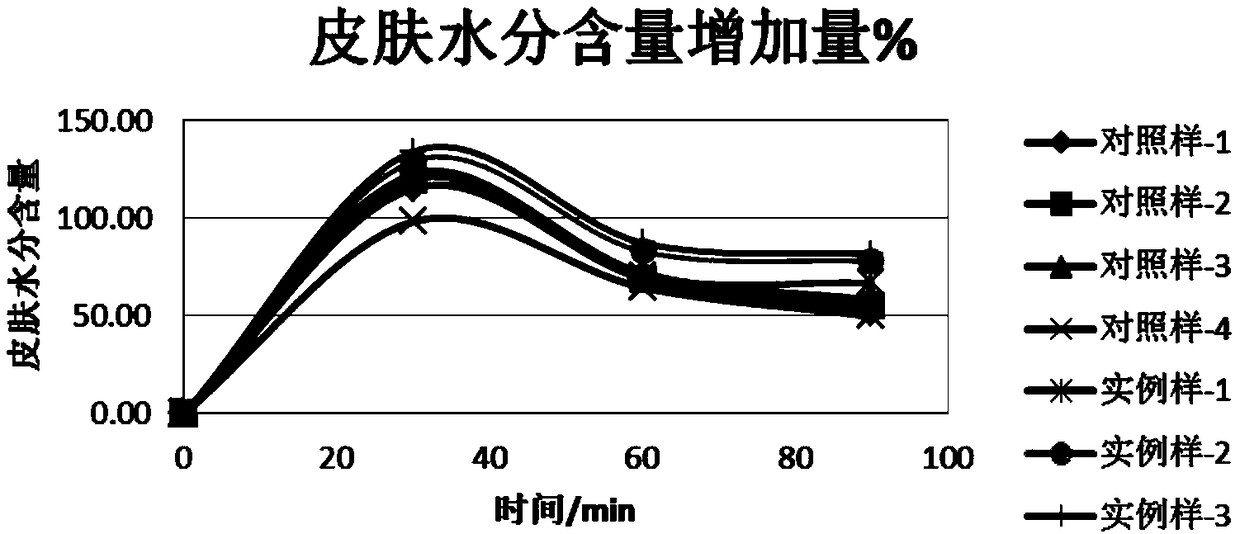

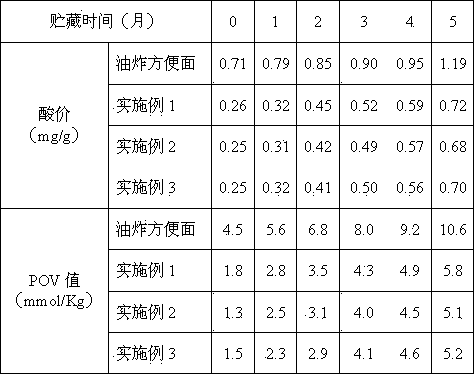

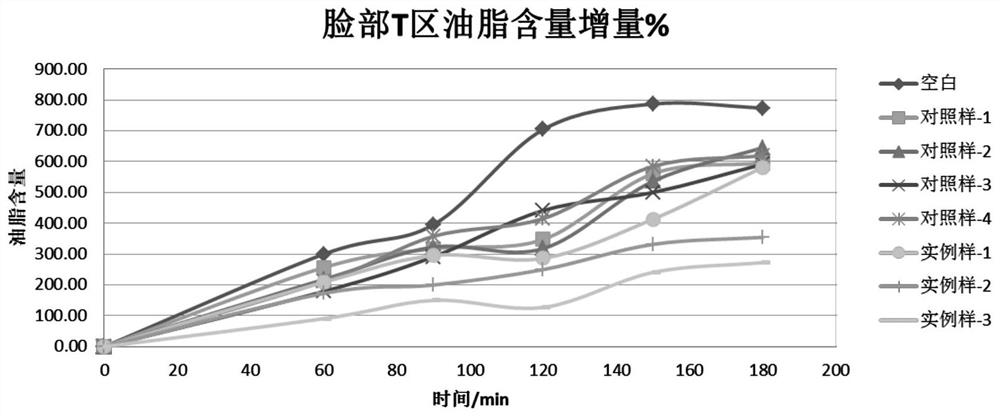

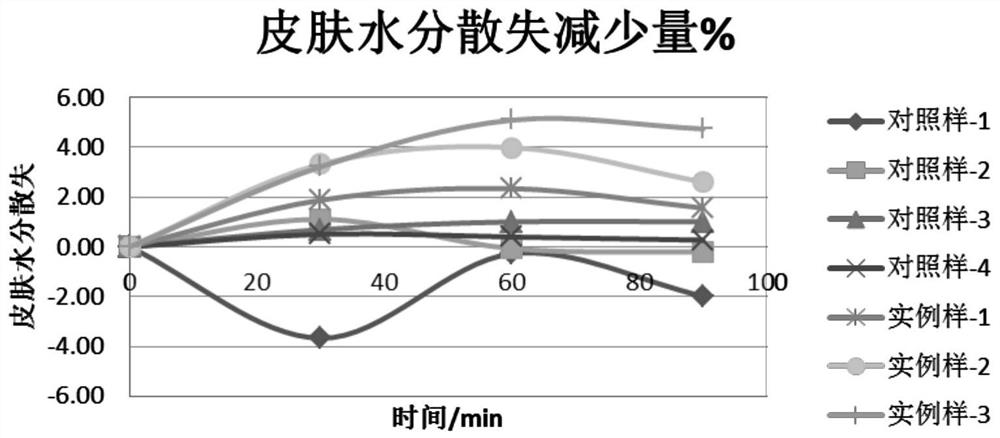

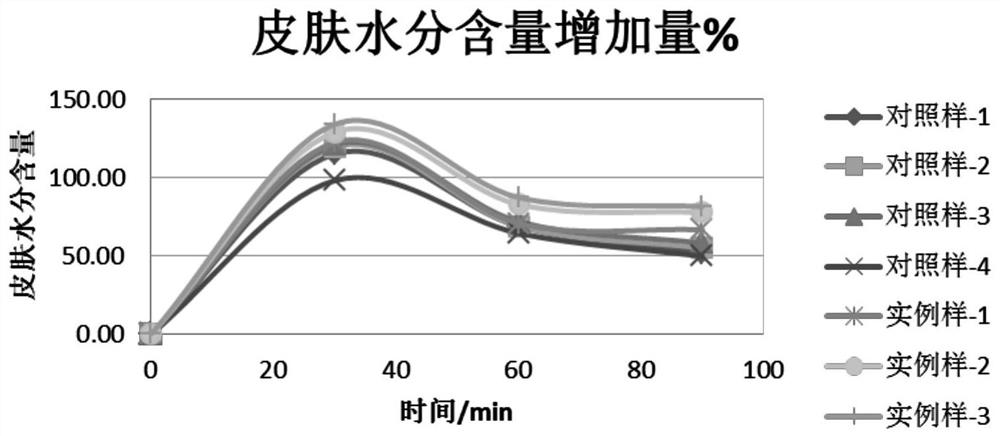

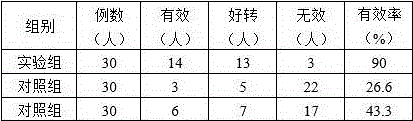

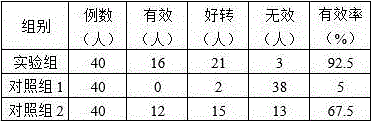

Composition and cosmetics for oil control and refining

ActiveCN108815008AGood effectControl oil contentCosmetic preparationsToilet preparationsOil and greaseMedicine

The invention relates to the technical field of cosmetics, in particular to a composition and cosmetics for oil control and refining. The composition is prepared from grapefruit extractives, ocean yogon factors and glycylglycine compounds, and the formed composition can have the effect of better controlling the skin oil content, improving the skin water content, restraining skin water dispersion,and refining pores. According to the composition, all the components are integral, the synergetic cooperation effect can be generated through cooperation, and under the proper ratio, the effect of thecomposition can be the best.

Owner:HUNAN YUJIA COSMETICS MFG CO LTD

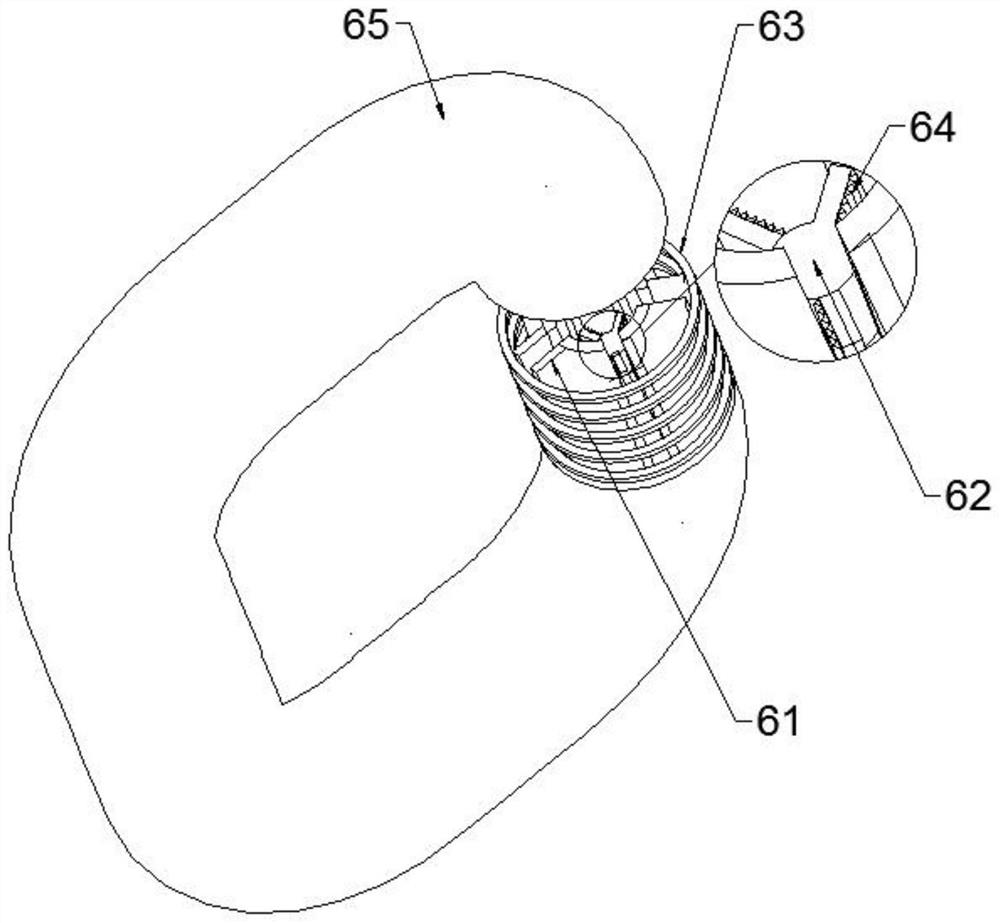

Fish scale and avocado compound food and making method and packing box thereof

The invention provides fish scale and avocado compound food which comprises, by weight, 15-25 parts of fish scale, 3-5 parts of avocado and fish bone soup. The fish scale and avocado compound food has the advantages that the fish scale is high in freezing yield and calcium content, nutritional ingredients cannot be damaged, the fish scale is simple in process, convenient to extract and low in cost, and the fish scale is utilized fully; high-temperature softening operation is adopted to break colloidal macromolecular fish scale collagen chains, part of colloidal macromolecular fish scale collagen is decomposed into low-molecular protein peptide which is easy for human bodies to absorb nutrition, and product quality is improved; constant-high-temperature deep frying is adopted, so that the fish scale can quickly bubble and expand and is crispy and tasty, and product flavor and nutrition are maintained; centrifugal oil control technology is adopted, so that product oil content can be controlled effectively, and product shelf life is prolonged.

Owner:温州市锦达味业食品有限公司

A double-cylinder-cover cooking and processing process of guava-flavor fried braised pork

InactiveCN105520067AAdd flavorQuality improvementFood ingredient as mouthfeel improving agentEngineeringFood flavor

A double-cylinder-cover cooking and processing process of guava-flavor fried braised pork is disclosed. The process includes steps of removing hairs, cutting into pieces, preparing pre-cook soup, cooking, piercing to inject salt, performing water-oil-mixed type frying, performing secondary water-oil-mixed type frying, cooking, and the like. The process combines traditional Chinese dish cooking methods and a western type meat product processing technique. In a frying step, the process adopts water-oil-mixed type frying and frying is performed at difference temperatures in sequence, thus effectively controlling generation of harmful compounds in the frying step and greatly maintaining good sense and flavor of meat products. Corn coil that is vegetable type oil is adopted as oil for frying in the process so that the fried meat products are healthier and higher in edibility.

Owner:GUANGXI UNIV

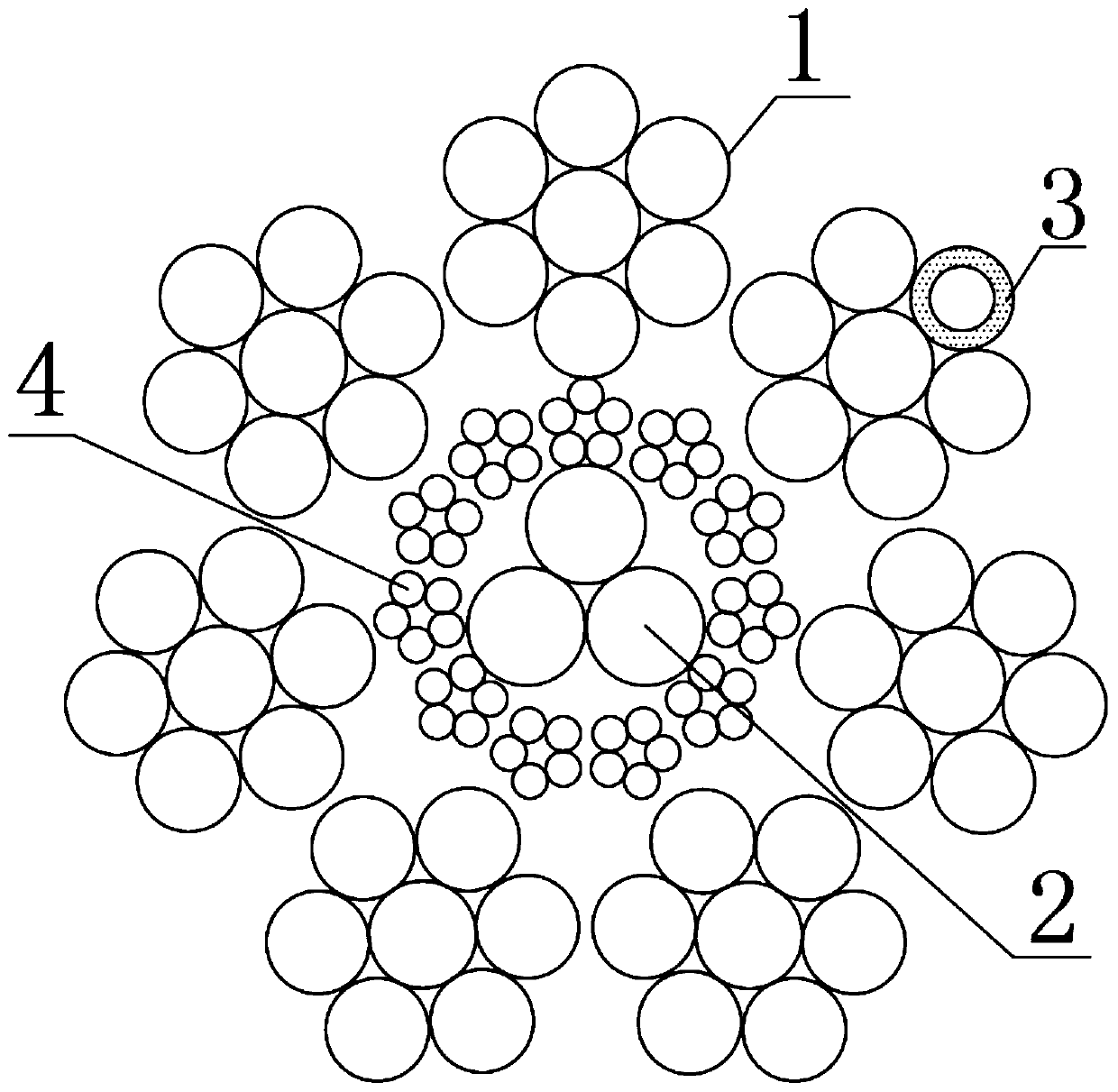

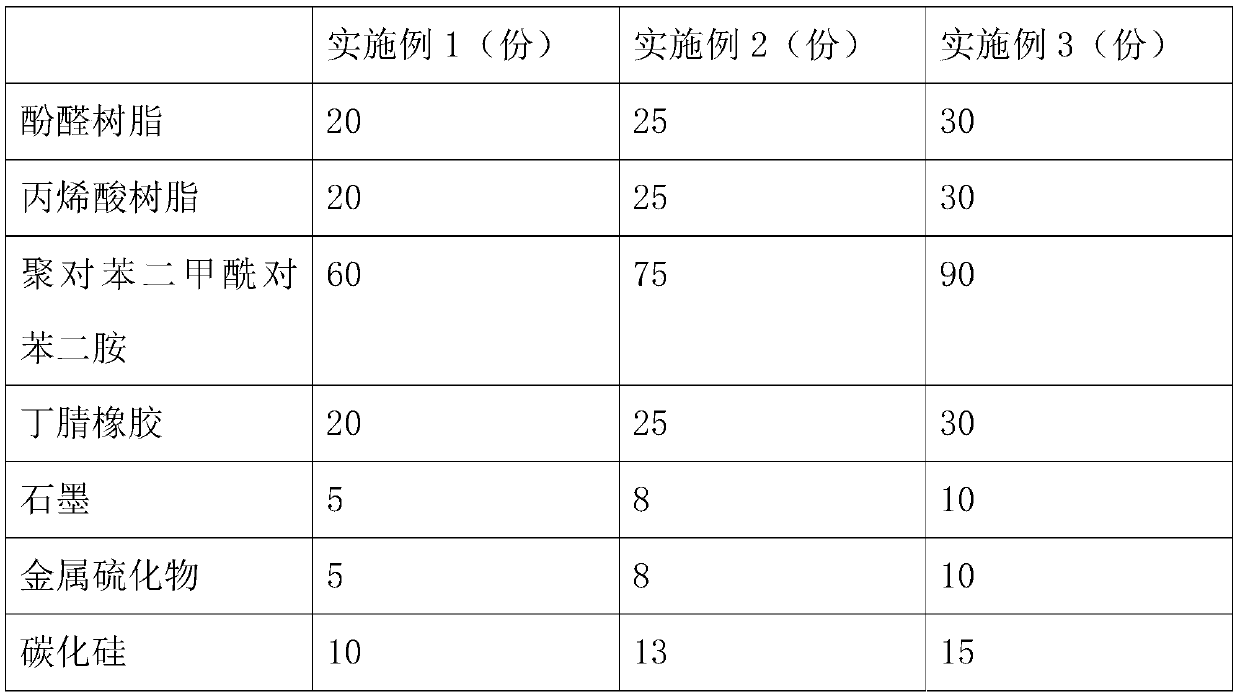

High-performance steel wire rope with sisal hemp core

InactiveCN110846915AAvoid deformationImprove toughnessConjugated synthetic polymer artificial filamentsCoatingsCarbide siliconNitrile rubber

The invention discloses a high-performance steel wire rope with a sisal hemp core. The high-performance steel wire rope with the sisal hemp core comprises a steel wire layer and the sisal hemp core,wherein a zinc layer is arranged on the outer wall of the steel wire layer; a composite layer is arranged on the side wall of the sisal hemp core in a twisting manner; the steel wire layer is arrangedon the outer wall of the composite layer in a twisting manner; and the sisal hemp core is formed by stranding three sisal hemp ropes. The formula of the composite layer comprises the following components by mass: 20-30 parts of phenolic resin, 20-30 parts of acrylic resin, 60-90 parts of poly (p-phenylene terephthalamide), 5-10 parts of graphite, 20-30 parts of nitrile rubber, 5-10 parts of metalsulfide and 10-15 parts of silicon carbide. The service life of the steel wire rope and the service life of the sisal hemp core can be prolonged, the sisal hemp core is protected, the corrosion resistance of the sisal hemp core is improved, and the strength of the steel wire rope is improved.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

Reverse store linkage conveyor

ActiveCN113060484APrevent slippingAvoid water seepageControl devices for conveyorsLoading/unloadingControl systemTransmission belt

The invention discloses a reverse store linkage conveyor. The conveyor comprises a discharging shell and is characterized in that a left conveyor belt, a middle conveyor belt and a right conveyor belt are arranged on one side of the discharging shell, power cylinders are arranged in the conveyor belts, a processing system is arranged at the inner side of the conveyor belts, a control system is arranged in the discharging shell, a sorting mechanism is arranged on the upper side of the discharging shell, the processing system comprises three transmission balls, a rotating arm is in pipeline connection with one side of the transmission ball on the right side, a control chamber is in bearing connection with the lower side of the rotating arm and divided into an upper cavity, a middle cavity and a lower cavity, the upper cavity of the control chamber is in pipeline connection with the middle power cylinder, friction films are arranged in the power cylinders, the lower cavity of the control chamber is in pipeline connection with the middle friction film, and one side of the right transmission ball is in pipeline connection with a rotating needle. The reverse store linkage conveyor has characteristics of low energy consumption and being capable of automatically solving related problems.

Owner:江苏锡安达防爆股份有限公司

Non-fried instant noodles with low oil content and fried flavor and preparation method thereof

Owner:福家欢食品股份有限公司

Composition and fine oil control cosmetics

ActiveCN108815008BGood effectControl oil contentCosmetic preparationsToilet preparationsGRAPEFRUIT EXTRACTEngineering

The invention relates to the technical field of cosmetics, in particular to a composition and cosmetics for oil control and refining. The composition is prepared from grapefruit extractives, ocean yogon factors and glycylglycine compounds, and the formed composition can have the effect of better controlling the skin oil content, improving the skin water content, restraining skin water dispersion,and refining pores. According to the composition, all the components are integral, the synergetic cooperation effect can be generated through cooperation, and under the proper ratio, the effect of thecomposition can be the best.

Owner:HUNAN YUJIA COSMETICS MFG CO LTD

A kind of low-temperature vacuum frying equipment and processing method

The invention relates to the field of food processing equipment, in particular to a low-temperature vacuum frying equipment and processing method, comprising: a frying chamber, a water vapor heat source, an oil storage tank, a heating oil tank and a vacuum condensing device, the bottom of the frying chamber A pallet is arranged at the center, and the pallet is connected with the motor at the bottom. The low-temperature vacuum frying machine provided by the present invention can solve the problems of unstable oil temperature, excessive oil temperature, fruit and vegetable sticking, and complicated frying oil recovery. High quality, suitable for industrial production.

Owner:青岛六一机械有限公司 +1

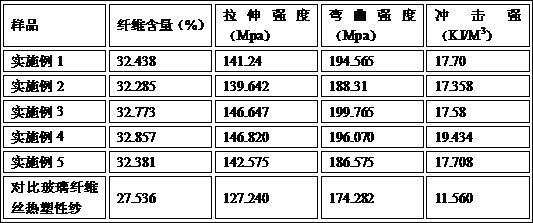

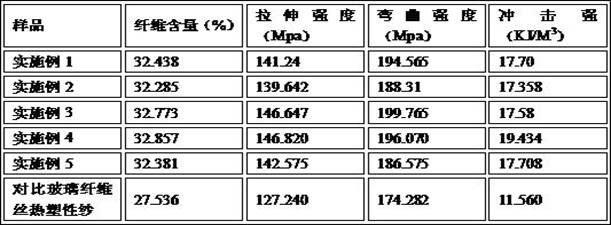

Method for producing thermoplastic chopped strands after modification of glass fiber filaments

ActiveCN113060946BImprove bindingExcellent performance such as bending resistance and impact resistanceGlass making apparatusThermoplasticGlass fiber

The invention relates to the technical field of production technology of thermoplastic chopped strands, in particular to a method for producing thermoplastic chopped strands after modification of glass fiber filaments. The process waste produced in the glass fiber production process of the present invention is short-cut by a Humen guillotine, granulated by a granulator, then sprayed with a self-developed infiltration agent, then dedusted by a dust removal device, and finally enters a vibration fluidization The bed is dried to produce thermoplastic-reinforced chopped strands. The sizing agent is composed of the following raw materials in weight percentage: coupling agent 0.3‑1%, film forming agent A1‑15%, film forming agent B1‑16%, lubricant 0.6‑2%, crosslinking agent 0.050.01‑0.3% , 0.05‑0.2% of antistatic agent and the balance of deionized water, and optimize the preparation method of wetting agent. The treatment process of the invention is simple and reasonable, and the final product is clean and of good quality.

Owner:山东墨匠新材料科技有限公司 +1

Healthy instant noodles with low oil content and preparation method thereof

The invention relates to healthy instant noodles with low oil content and a preparation method thereof. The preparation method comprises the steps of kneading a dough prepared from wheat flour, starch, water chestnut flour, raw peanut pulp, a mixed thickener, salt and an edible emulsifier, boiling, rolling, shredding, cooking, then enabling the noodles to pass through an oil sink at a temperature of 30-60 DEG C, draining oil and then carrying out far infrared drying and shaping on the noodle lump and obtaining an instant noodle lump after cooling. The preparation method has the advantages that the instant noodles have high nutritive value; the oil content of the pastry is controlled; and the reconstitution property, taste and flavor of the fried instant noodles are maintained.

Owner:福家欢食品股份有限公司

A reverse accumulation type linkage conveyor

ActiveCN113060484BReduce sizeControl oil contentControl devices for conveyorsLoading/unloadingControl systemTransmission belt

The invention discloses a reverse accumulation type linkage conveyor, which includes a discharge shell, and is characterized in that: one side of the discharge shell is provided with three sets of left, middle and right conveyor belts, and the inside of the conveyor belt is provided with a power cylinder , the inner side of the conveyor belt is provided with a processing system, the inside of the discharge shell is provided with a control system, the upper side of the discharge shell is provided with a selection mechanism, the processing system includes three transmission balls, the right side One side of the transmission ball is connected to a rotating arm, and the lower bearing of the rotating arm is connected to a control room. The control room is divided into three chambers: upper, middle and lower. On the power cylinder on the middle side, a friction film is arranged inside the power cylinder, the control room chamber pipeline on the lower side is connected to the friction film on the middle side, and the transmission ball on the right side is connected to a rotating needle by a pipeline. The invention has the characteristics of low energy consumption and the ability to deal with related problems independently.

Owner:江苏锡安达防爆股份有限公司

Impregnating compound for thermoplastic chopped yarn production, preparation method of impregnating compound and method for producing thermoplastic chopped yarn after modification of glass fiber filaments

ActiveCN113060946AImprove bindingExcellent performance such as bending resistance and impact resistanceGlass making apparatusYarnThermoplastic

The invention relates to the technical field of thermoplastic chopped yarn production processes, and in particular, relates to an impregnating compound for thermoplastic chopped yarn production, a preparation method of the impregnating compound and a method for producing the thermoplastic chopped yarn after modification of the glass fiber filaments. Process waste generated in the glass fiber production process is chopped by a tiger's guillotine, granulated by a granulator, sprayed with the independently developed impregnating compound, dedusted by a dedusting device, finally enters a vibrated fluidized bed and is dried to finally produce the reinforced thermoplastic chopped yarn. The impregnating compound is prepared from the following raw materials in percentage by weight: 0.3-1% of a coupling agent, 1-15% of a film-forming agent A, 1-16% of a film-forming agent B, 0.6-2% of a lubricating agent, 0.05-0.3% of a cross-linking agent, 0.05-0.2% of an antistatic agent and the balance being deionized water. The preparation method of the impregnating compound is optimized. The treatment process is simple and reasonable, and the final product is clean and good in quality.

Owner:山东墨匠新材料科技有限公司 +1

A fully automatic low temperature vacuum frying device

ActiveCN106857733BAvoid pollutionControl oil contentOil/fat bakingCharging/discharging ovensEngineeringBlock match

Owner:吕丙生

Fish scale leisure food and production process thereof

ActiveCN102228269BIncrease added valueRealize comprehensive utilizationFood preparationFlavorSoftening

The invention discloses a fish scale leisure food and a production process thereof. The food is characterized in that: the food treats fresh or frozen stored fish scale as a raw material; the production process comprises operations of unfreezing, cleaning, pickling, cleaning, softening, frying, oil control, seasoning, bagging and the like; wherein a technology of low temperature pickling which is adopted allows pickling materials to uniformly penetrate; the technology of high temperature softening which is adopted allows partial scale collagen chains to fracture; and the technology of high and constant temperature frying which is adopted allows fish scale to rapidly puff. The leisure fish scale food produced through the process has a peculiar fish scale flavor, tastes crisp and delicious, and mellow, and can be transported, stored and sold at normal temperature.

Owner:SICHUAN UNIV

A stretching system of dty high stretch yarn for hosiery

Owner:浙江正堂实业股份有限公司

Low-oil-temperature instant noodles subjected to far infrared drying and preparation method thereof

The invention relates to low-oil-temperature instant noodles subjected to far infrared drying and a preparation method thereof. The preparation method comprises the steps of kneading a dough prepared from wheat flour, starch, water chestnut flour, raw peanut pulp, a mixed thickener, salt and an edible emulsifier, boiling, rolling, shredding, cooking, cutting off, uniformly spraying low-temperature frying oil on the upper and lower sides of the noodles, carrying out secondary far infrared drying and shaping and obtaining an instant noodle lump after cooling. The preparation method has the advantages that the instant noodles have high nutritive value; the oil content of the pastry is controlled; and the reconstitution property, taste and flavor of the fried instant noodles are maintained.

Owner:福家欢食品股份有限公司

Preparation method of qi-tonifying blood-nourishing chicken wrapped in paper

InactiveCN106343387ASignificantly replenishes blood and QiOutstanding aromaNatural extract food ingredientsFood ingredient functionsFlavorMedicine

Disclosed are qi-tonifying blood-nourishing chicken wrapped in paper and a preparation method of the qi-tonifying blood-nourishing chicken wrapped in paper. The qi-tonifying blood-nourishing chicken wrapped in paper is characterized in that a marinade is composed of Radix Angelicae Sinensis, Radix Astragali, Fructus Psoraleae, Radix Morindae Officinalis, Semen Cuscutae, Cortex Cinnamomi, Fructus Amomi, Flos Caryophylli, Semen Myristicae, Radix Glycyrrhizae and Fructus Tsaoko. The qi-tonifying blood-nourishing chicken wrapped in paper retains original taste and flavor of chicken wrapped in paper and is capable of tonifying qi, nourishing blood, tonifying the spleen and the kidney and promoting the circulation of qi and appetite.

Owner:梧州市麦劲堡餐饮配送有限公司

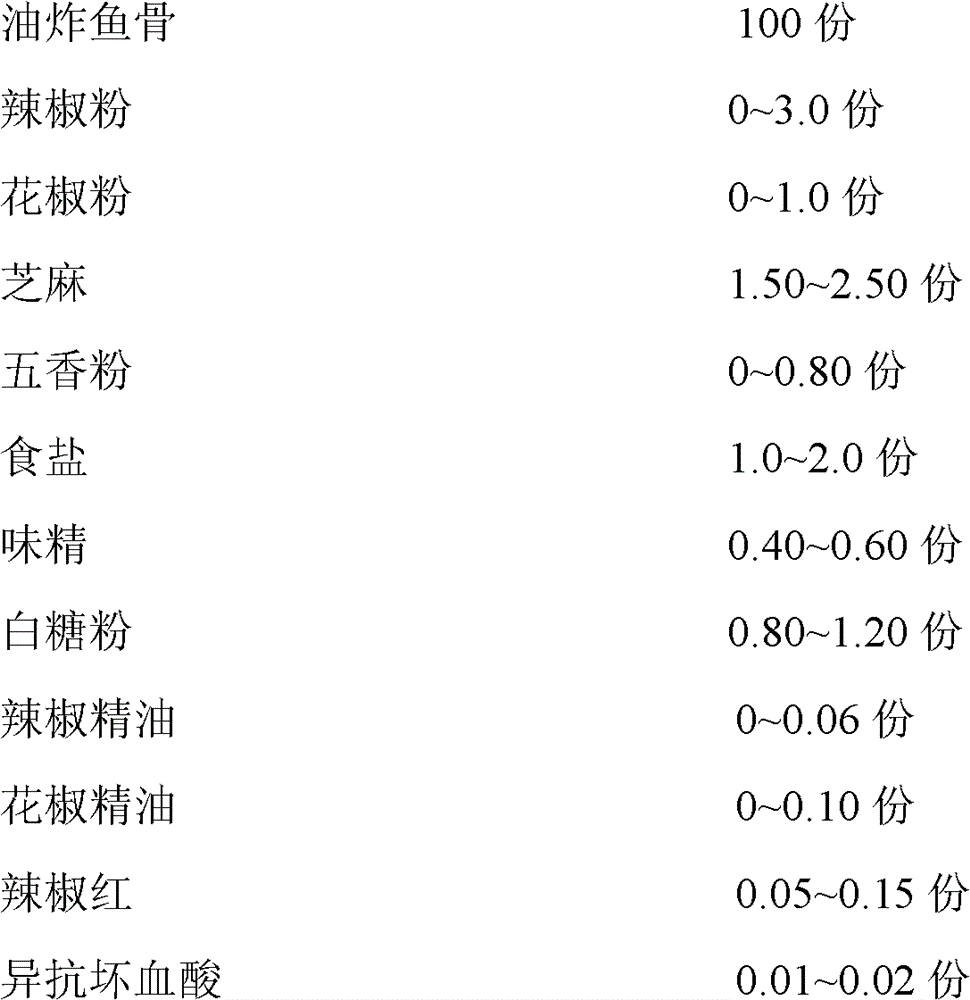

Fish bone leisure food and production method thereof

ActiveCN102283400BIncrease added valueRealize comprehensive utilizationFood preparationBiotechnologyEngineering

The invention discloses a fish bone leisure food and a production method thereof. The method is characterized in that: fresh or frozen fish bones are taken as raw materials, and the production method comprises the steps of unfreezing, cleaning, pickling, softening, deep-frying, removing oil, seasoning, bagging and the like, wherein pickling materials are uniformly permeated by a low-temperature pickling technology; the fish bones are softened through high-temperature steam treatment; the fish bones are quickly dehydrated to form the crispy quality by a high-temperature constant-temperature deep-frying technology; and the quality guarantee period of a product can be effectively prolonged by a centrifugal oil removal technology. The fish bone leisure food produced by the method has the flavor of the fish bones, is crispy and delicious, has mellow taste and can be transported, stored and sold at normal temperature.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com