Foodstuff butter atomization technique and multifunctional butter atomization still

A new technology, atomized oil technology, applied in the direction of oil/fat baking, pancake baking, etc., can solve the problems of oil pollution source, influence of nutritional components, uncontrollable food oil content, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

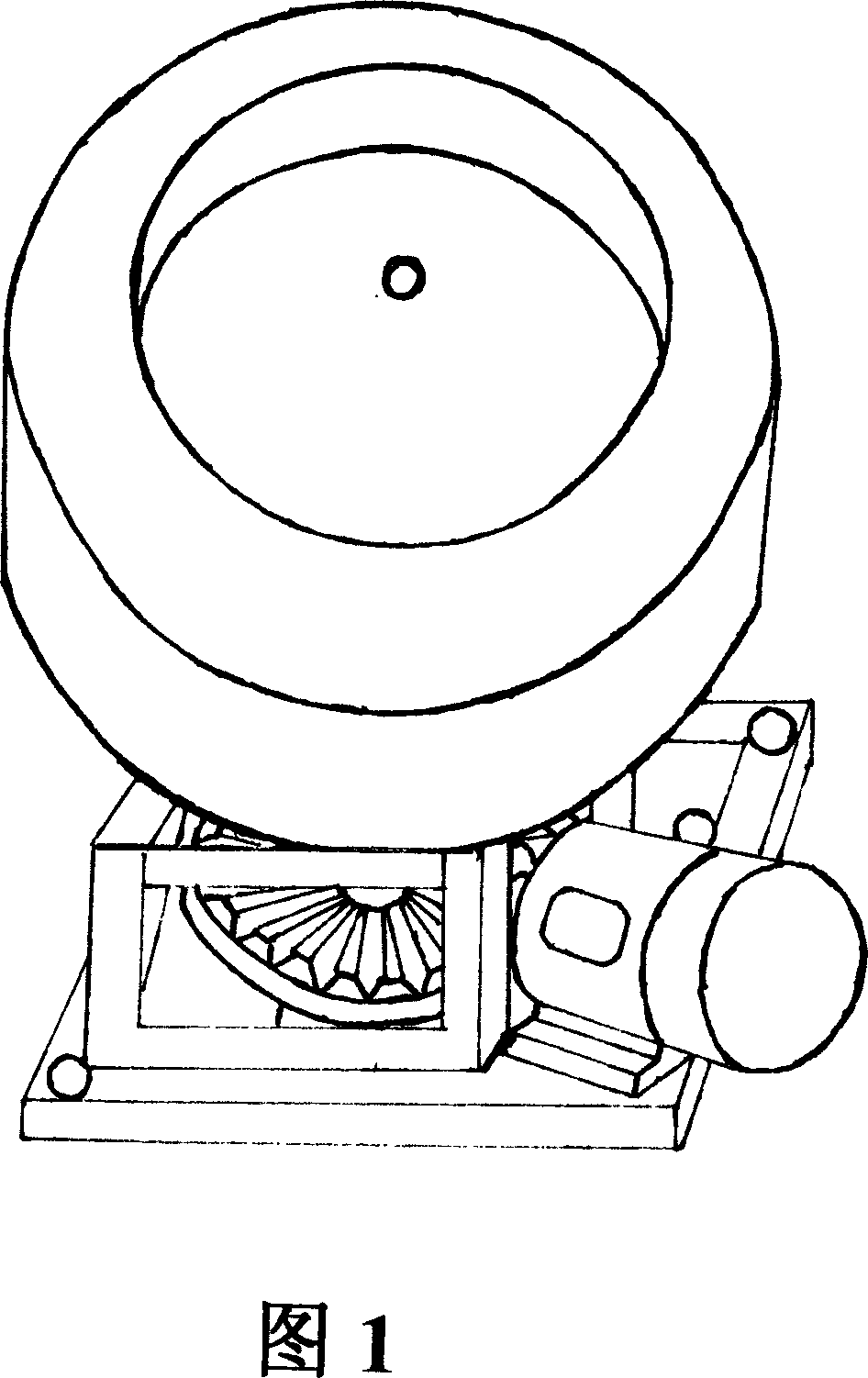

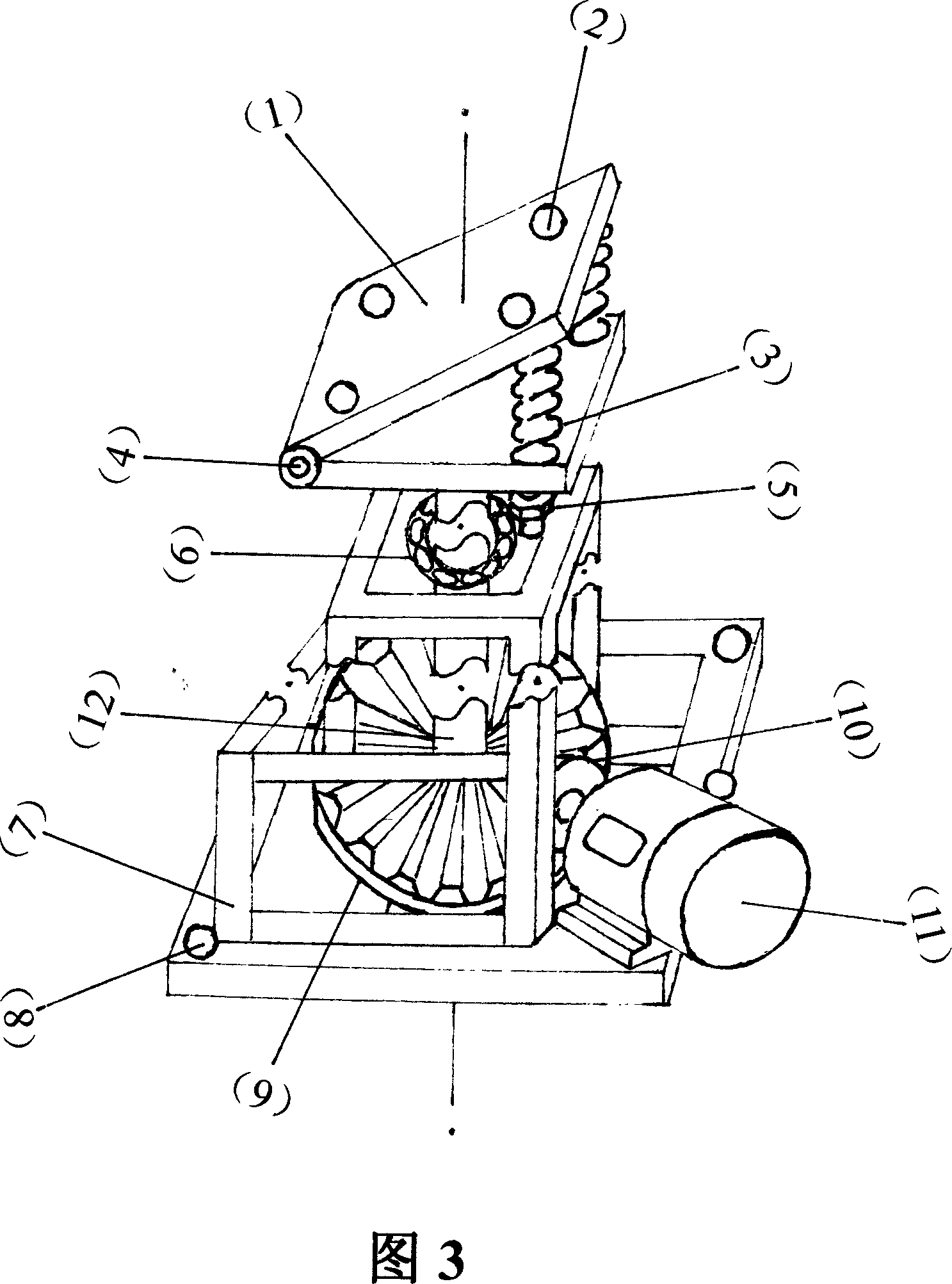

[0037] Atomize ghee with 25kg round billet in a multi-functional hot and warm rotary pot. The specific steps are:

[0038] 1. Calculate the weight of the oil for injection. According to the national standard, the oil content is ≤24%. ℃~150℃.

[0039] 2. Pour the dried round billet into the multi-functional hot and warm rotary pot from the feed port of the special transparent heat-resistant pot cover, and close the feed port door.

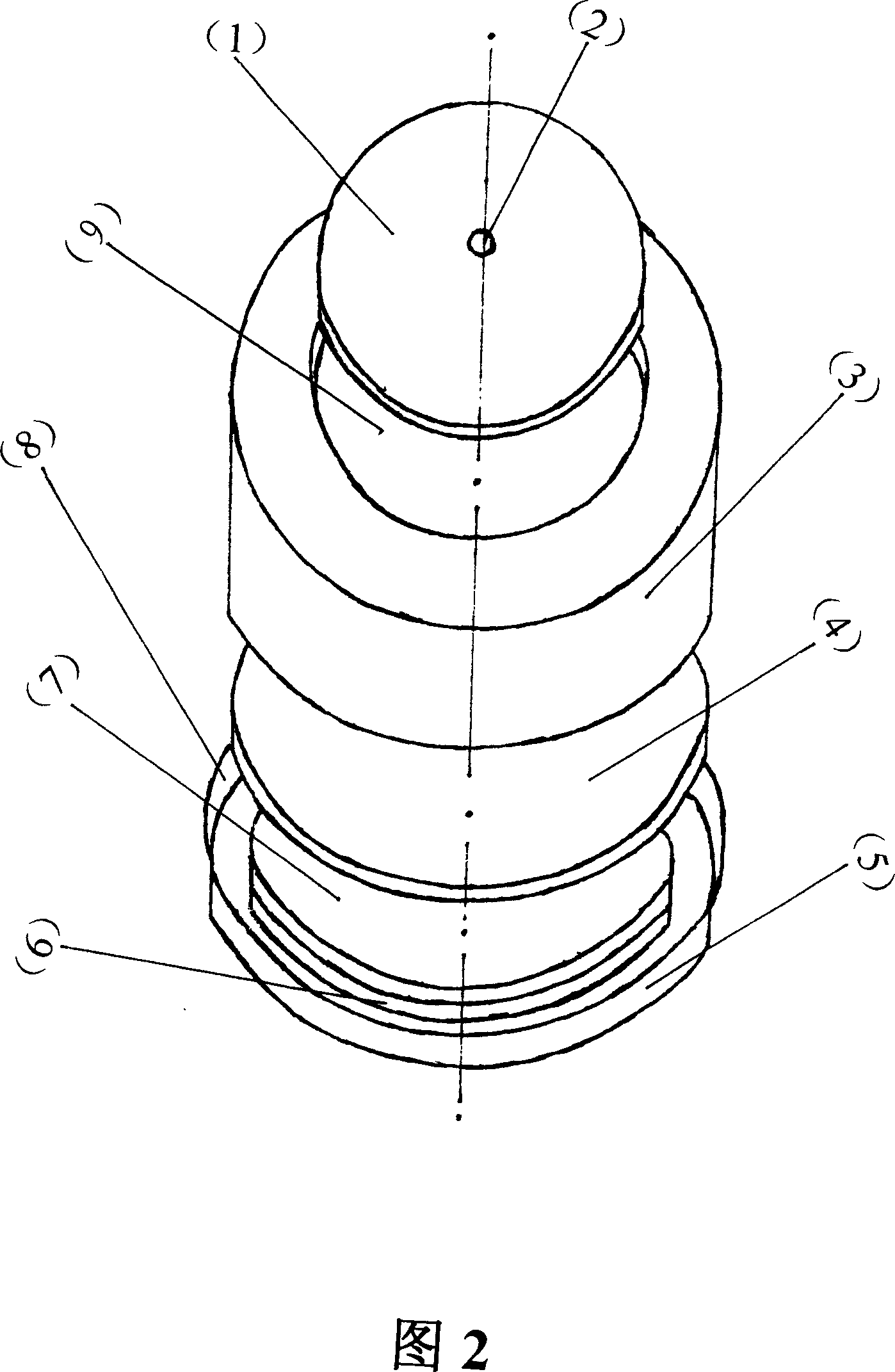

[0040] 3. Start the multi-functional hot-temperature rotary pot, and as it rotates, the round roll blank will automatically roll in the pot. When the temperature rises to 130°C, insert the oil-spraying nozzle into the center hole of the special transparent heat-resistant pot cover, and cover it well. Spray the oil heated to 130°C to 150°C directly onto the rolling round billet at the orifice for 5 to 7 minutes, adjust the haze of the oil spray, and use it up at one time.

[0041] 4. The temperature is controlled at about 145°C, and cannot exceed 150...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com