Fish bone leisure food and production method thereof

A technology for snack food and fish bone, which is applied in the field of food processing, can solve the problems of fish bone food raw materials not being effectively used, the taste is not crispy enough, and the process is complicated, and achieves the effects of low cost, improved product quality, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

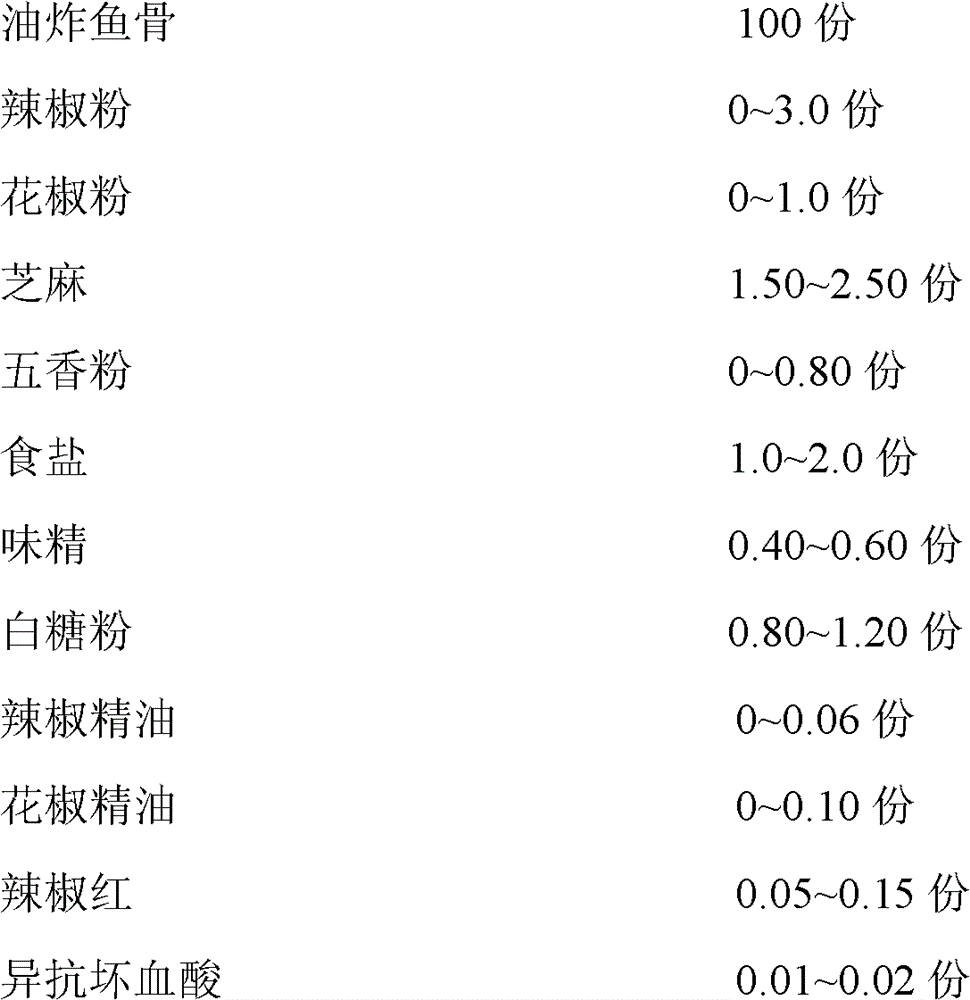

Method used

Image

Examples

Embodiment 1

[0042] When using frozen tilapia fish bone raw materials, the raw materials should be thawed in a thawing room at a temperature of 15°C for 12 hours until the raw material temperature is -2°C; remove fish heads, fish tails, internal organs, and select fish fins, fish scales, fish meat, etc. Debris; cut off the long side thorns on both sides of the spine, leaving about 2cm each; rinse in the cleaning tank, cut into 6cm lengths, and wash away the congestion, aponeurosis, dirt, etc. on the fish bones; after cleaning the above Transfer the raw materials into the stainless steel marinating tank in the marinating room, and then add the marinating raw materials: 100 parts of fish bones, 1.80 parts of salt, 4.50 parts of cooking wine, 0.80 parts of citric acid, cover with plastic wrap and marinate for 12 hours. 0°C, turning once every 2 hours during the marinating period; soften the marinated fish bones within 1 hour, and use a high-pressure steam sterilizer for softening treatment; sp...

Embodiment 2

[0044]When using frozen grass carp bone raw materials, the raw materials need to be thawed in a thawing room at a temperature of 16°C for 11 hours until the raw material temperature is -1°C; remove fish heads, fish tails, internal organs, and select fish fins, fish scales, fish meat and other miscellaneous cut off the overly long side thorns on both sides of the spine, leaving about 2cm each; rinse in the cleaning tank, cut into 5.50cm in length, and wash away the congestion, aponeurosis, dirt, etc. on the fish bones; after cleaning the above Transfer the raw materials into the stainless steel marinating tank in the marinating room, and then add the marinating raw materials: 100 parts of fish bones, 2.0 parts of salt, 4.70 parts of cooking wine, 1.0 parts of citric acid, cover with plastic wrap and marinate for 13 hours. 1 ℃, turning once every 2 hours during the marinating period; soften the marinated fish bones within 1 hour, and use a high-pressure steam sterilizer for softe...

Embodiment 3

[0046] When using frozen carp bone raw materials, the raw materials need to be thawed in a thawing room at a temperature of 18°C for 10 hours until the raw material temperature is 0°C; remove fish heads, fish tails, internal organs, and select fish fins, fish scales, fish meat and other sundries ; Cut off the too long side thorns on both sides of the spine, leaving about 2cm each; rinse in the cleaning tank, cut into 5cm lengths, and wash away the congestion, aponeurosis, dirt, etc. on the fish bones; wash the above raw materials Transfer to the stainless steel marinating tank in the marinating room, and then add marinating raw materials: 100 parts of cleaned fish bones, 2.0 parts of salt, 5.0 parts of cooking wine, 1.0 parts of citric acid, cover with plastic wrap and marinate for 14 hours. The temperature is 2°C, and it is turned every 2 hours during the pickling period; the marinated fish bones are softened within 1 hour, and are softened in a high-pressure steam sterilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com