Low-temperature vacuum frying equipment and processing method that are easy to control temperature

A technology of low-temperature vacuum frying and temperature control, which is applied in the air treatment device of the oven, oil/fat roasting, food oven, etc. It can solve the problems of complex frying oil recovery, oil temperature instability, and fruit and vegetable adhesion, etc., to achieve Excellent appearance, control oil content, prevent sticking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

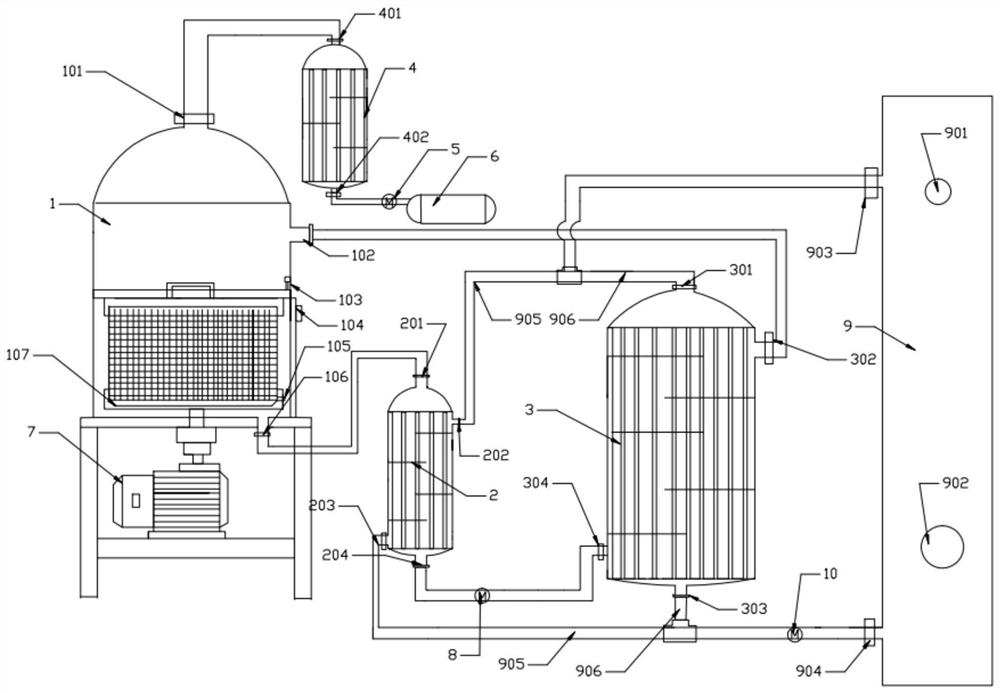

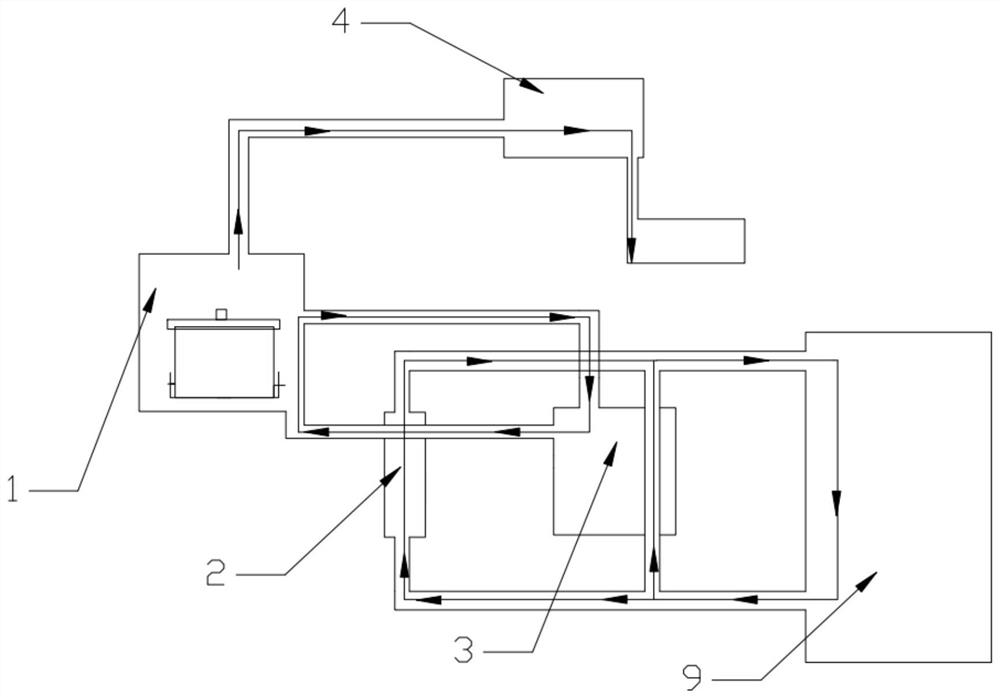

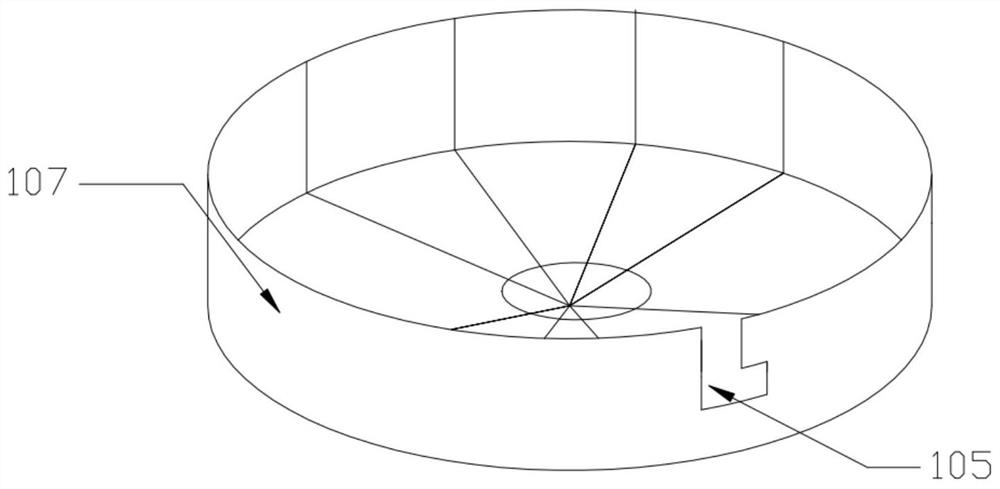

[0031] Such as Figure 1 to Figure 4 As shown, a low-temperature vacuum frying equipment that is easy to temperature control is characterized in that: it includes a frying chamber 1, a heat transfer oil tank 9, an oil storage tank 3, a heating oil tank 2 and a condensing device 4 for vacuuming. The upper side wall of the frying chamber 1 is provided with an oil overflow port 102, the bottom is provided with a first oil inlet 106, and the bottom of the frying chamber is provided with a tray 107, and the oil inlet is sequentially connected with the heating oil tank 2, the oil storage tank 3, the overflow The oil port 102 communicates; the frying chamber forms a closed loop with the heating oil tank and the oil storage tank in turn; the height of the oil overflow port 102 is higher than the height of the material cage, and the fruit and vegetable slices are comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com