High-performance steel wire rope with sisal hemp core

A technology of sisal core and steel wire rope, applied in the field of steel wire rope, can solve the problems of unfavorable service life of steel wire rope, unable to protect the sisal core, difficult to obtain guarantee, etc., and achieve the effect of slowing down the loss of oil, preventing corrosion, and being difficult to deform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

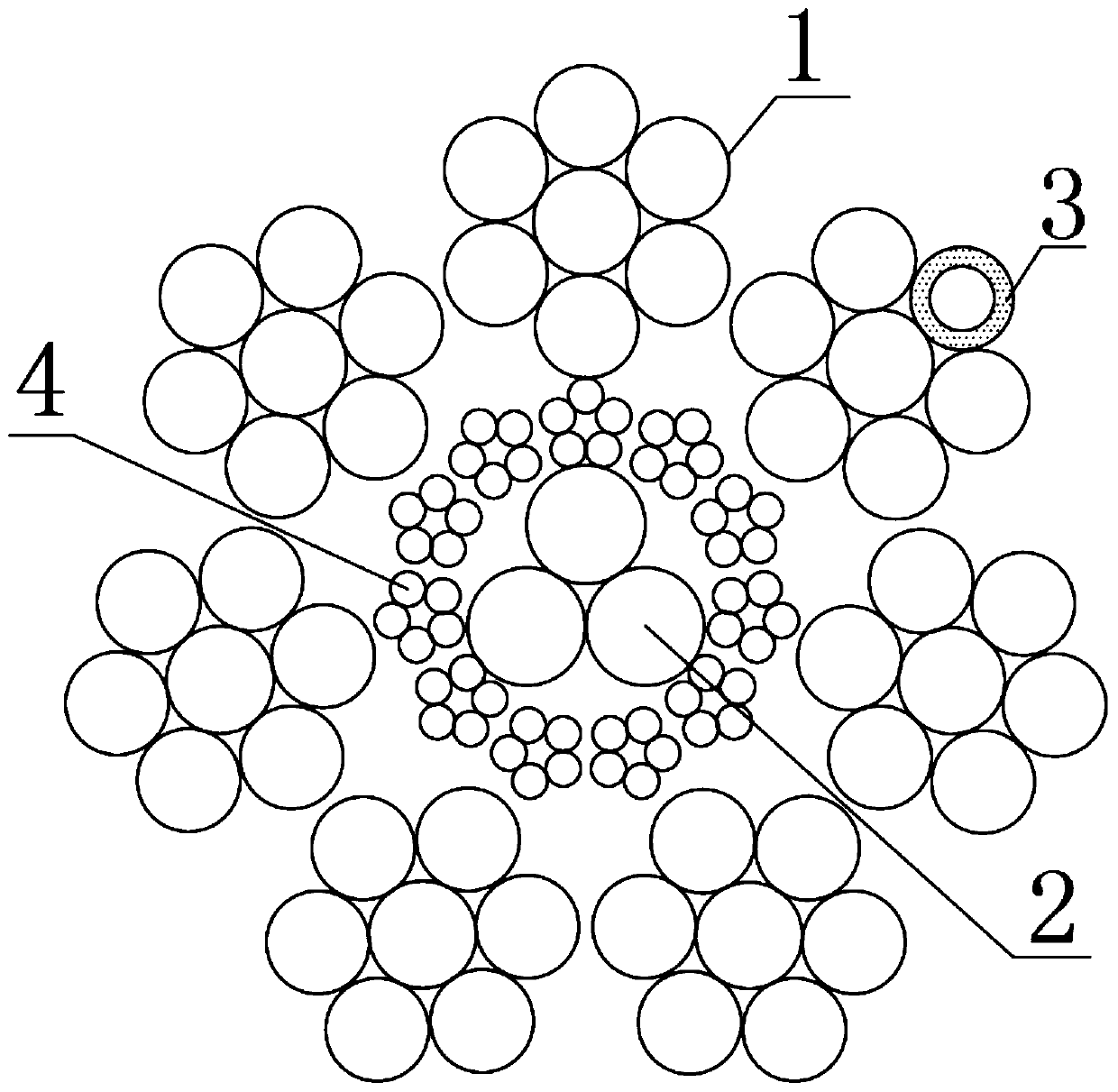

[0028] A high-performance sisal core steel wire rope, comprising a steel wire layer and a sisal core, the outer wall of the steel wire layer is provided with a zinc layer, the steel wire layer includes seven groups of galvanized steel ropes, and the galvanized steel rope consists of a Composed of main steel wire and six auxiliary steel wires, the six auxiliary steel wires are twisted on the outer wall of the main steel wire, the side wall of the auxiliary steel wire conflicts with the outer wall of the composite layer, and the side wall of the sisal core is twisted with composite layer, the steel wire layer is wrapped and twisted on the outer wall of the composite layer, and the sisal core is composed of three sisal rope strands;

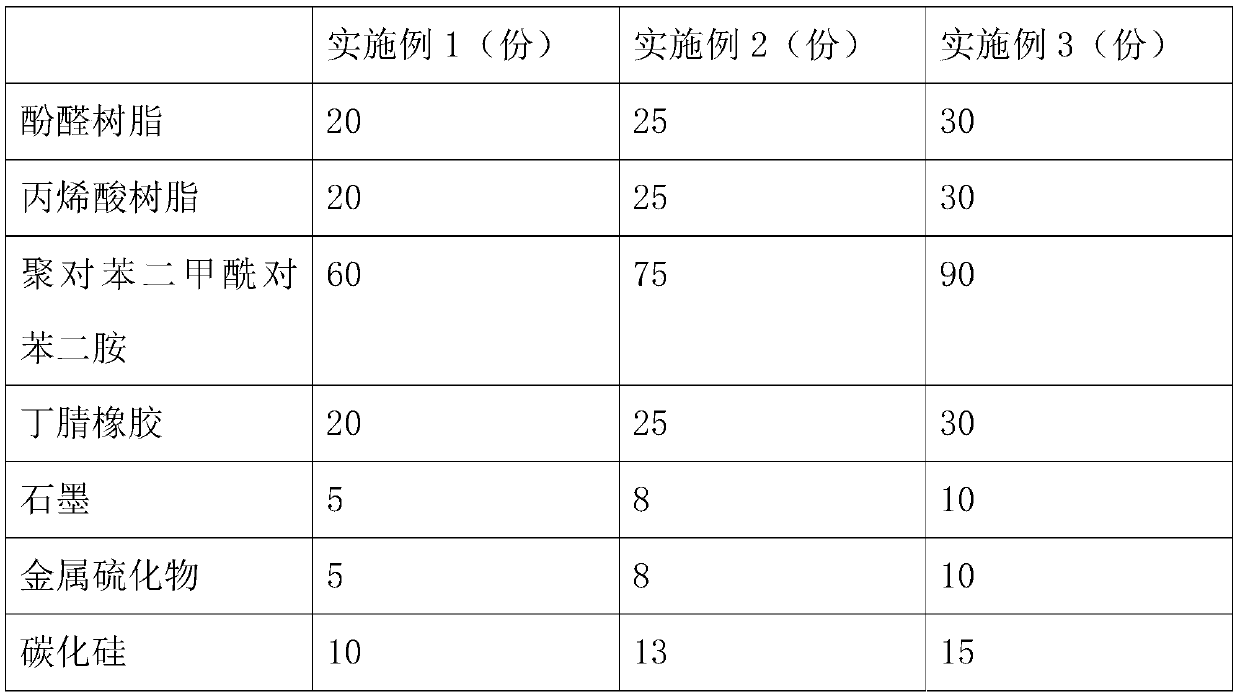

[0029] The formula of the composite layer calculated according to the mass proportion of the components is as follows: 20 parts of phenolic resin, 20 parts of acrylic resin, 60 parts of poly-p-phenylene terephthalamide, 5 parts of graphite, 20 parts ...

Embodiment 2

[0040] A high-performance sisal core steel wire rope, comprising a steel wire layer and a sisal core, the outer wall of the steel wire layer is provided with a zinc layer, the steel wire layer includes seven groups of galvanized steel ropes, and the galvanized steel rope consists of a Composed of main steel wire and six auxiliary steel wires, the six auxiliary steel wires are twisted on the outer wall of the main steel wire, the side wall of the auxiliary steel wire conflicts with the outer wall of the composite layer, and the side wall of the sisal core is twisted with composite layer, the steel wire layer is wrapped and twisted on the outer wall of the composite layer, and the sisal core is composed of three sisal rope strands;

[0041] The formula of the composite layer calculated according to the mass proportion of the components is as follows: 25 parts of phenolic resin, 25 parts of acrylic resin, 75 parts of poly-p-phenylene terephthalamide, 8 parts of graphite, 25 parts ...

Embodiment 3

[0052] A high-performance sisal core steel wire rope, comprising a steel wire layer and a sisal core, the outer wall of the steel wire layer is provided with a zinc layer, the steel wire layer includes seven groups of galvanized steel ropes, and the galvanized steel rope consists of a Composed of main steel wire and six auxiliary steel wires, the six auxiliary steel wires are twisted on the outer wall of the main steel wire, the side wall of the auxiliary steel wire conflicts with the outer wall of the composite layer, and the side wall of the sisal core is twisted with composite layer, the steel wire layer is wrapped and twisted on the outer wall of the composite layer, and the sisal core is composed of three sisal rope strands;

[0053] The formula of the composite layer calculated according to the mass proportion of the components is as follows: 30 parts of phenolic resin, 30 parts of the acrylic resin, 90 parts of poly-p-phenylene terephthalamide, 10 parts of graphite, 30 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com