Non-fried instant noodles with low oil content and fried flavor and preparation method thereof

A technology for non-fried instant noodles and flavor, applied in the field of food processing, can solve the problems of lack of flavor of fried instant noodles, low oil content, and failure to meet the requirements of consumers, and achieves the effects of good toughness, good taste and increased flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: The dough is prepared by adding an appropriate amount of edible water, after ripening, calendering, shredding, wave making, steaming, cutting and folding, the cooked noodle pieces are obtained, and the noodle pieces are dried in stages at 100°C to 140°C with circulating hot air until After the water content of the noodle cake is less than or equal to 12% (weight), spray palm oil at 80°C to the noodle block to form a mist and spray evenly on the upper and lower sides of the instant noodle block at the same time, and the amount of oil sprayed is controlled at 13% of the weight of the dry noodle cake. Then microwave 5kW to dry for 20min, add seasoning pack after cooling;

Embodiment 2

[0040] Example 2: The dough is prepared by adding an appropriate amount of edible water. After ripening, calendering, shredding, wave making, steaming, cutting and folding, cooked noodle pieces are obtained, and the noodle pieces are dried in stages at 100°C to 140°C with circulating hot air until After the water content is less than or equal to 12% (weight), spray palm oil at 60°C on the noodles to form a mist and spray evenly on the upper and lower sides of the instant noodles at the same time, and the amount of oil sprayed is controlled at 5% of the weight of the dry noodles, and then microwave Dry at 10kW for 10min, add seasoning pack after cooling;

Embodiment 3

[0041] Example 3: The dough is prepared by adding an appropriate amount of edible water, after ripening, calendering, shredding, wave making, steaming, cutting and folding, the cooked noodle pieces are obtained, and the noodle pieces are dried in stages at 100°C to 140°C with circulating hot air until After the water content is less than or equal to 12% (weight), spray palm oil at 60°C on the noodles to form a mist and spray evenly on the upper and lower sides of the instant noodles at the same time, and the amount of oil sprayed is controlled at 8% of the weight of the dry noodles, and then microwave Dry at 10kW for 8 minutes, add seasoning packs after cooling.

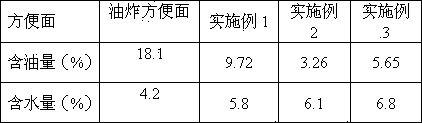

[0042] Table 1: Indicators of finished instant noodles

[0043]

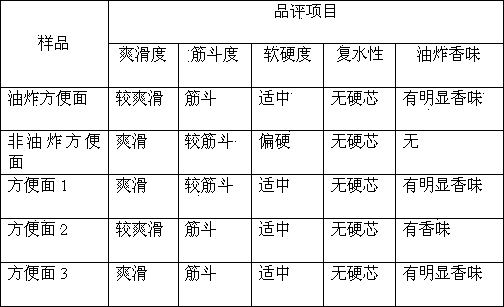

[0044] Table 2: Comparison of taste and flavor evaluation

[0045]

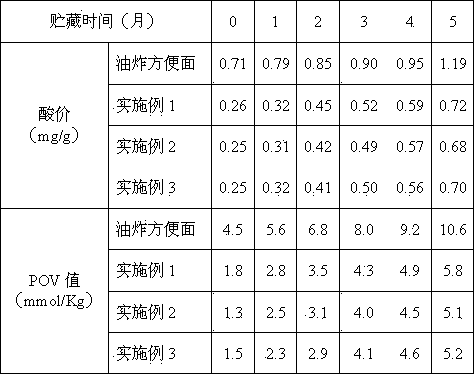

[0046] Preferred embodiment 3 of this method: spray the palm oil of 60 ℃, the amount of sprayed oil is controlled at 8% of dry noodle weight, and microwave 10kW is dried 8min a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com