A fully automatic low temperature vacuum frying device

A technology of low-temperature vacuum frying and vacuum frying tanks, which is applied in oil/fat baking, loading/unloading of ovens, food ovens, etc. General manual operation and other problems to achieve the effect of preventing offset, reducing manual operation and increasing sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be further described in conjunction with the accompanying drawings and specific embodiments.

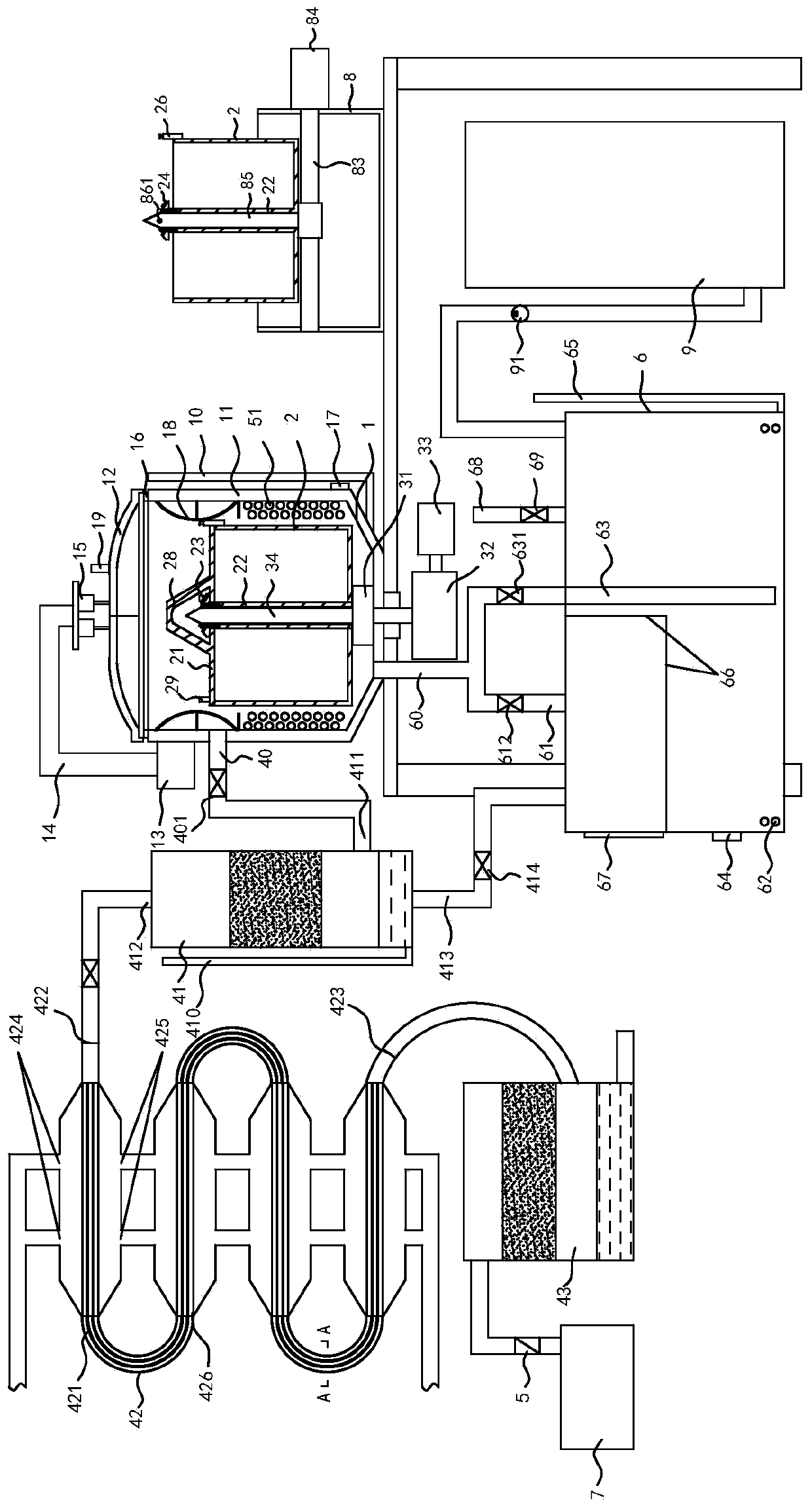

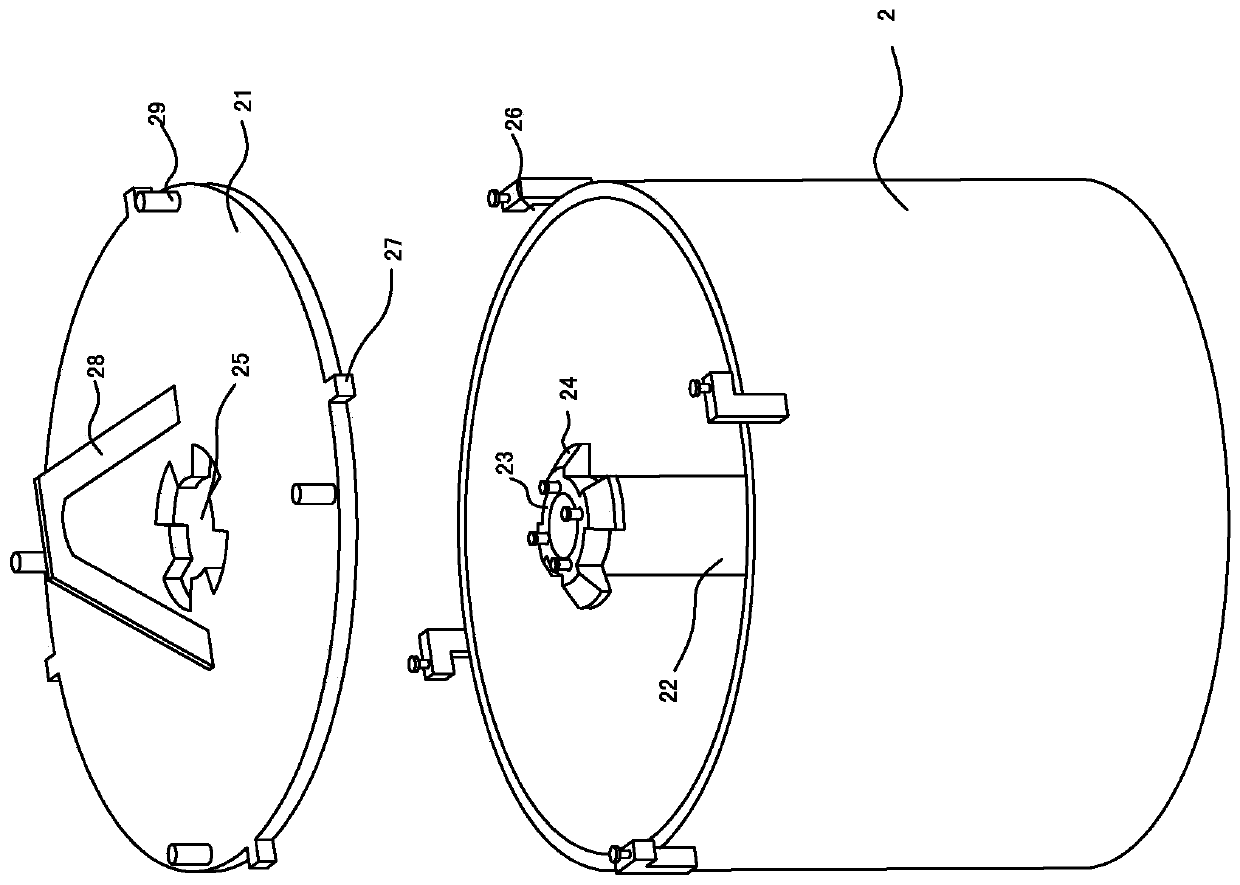

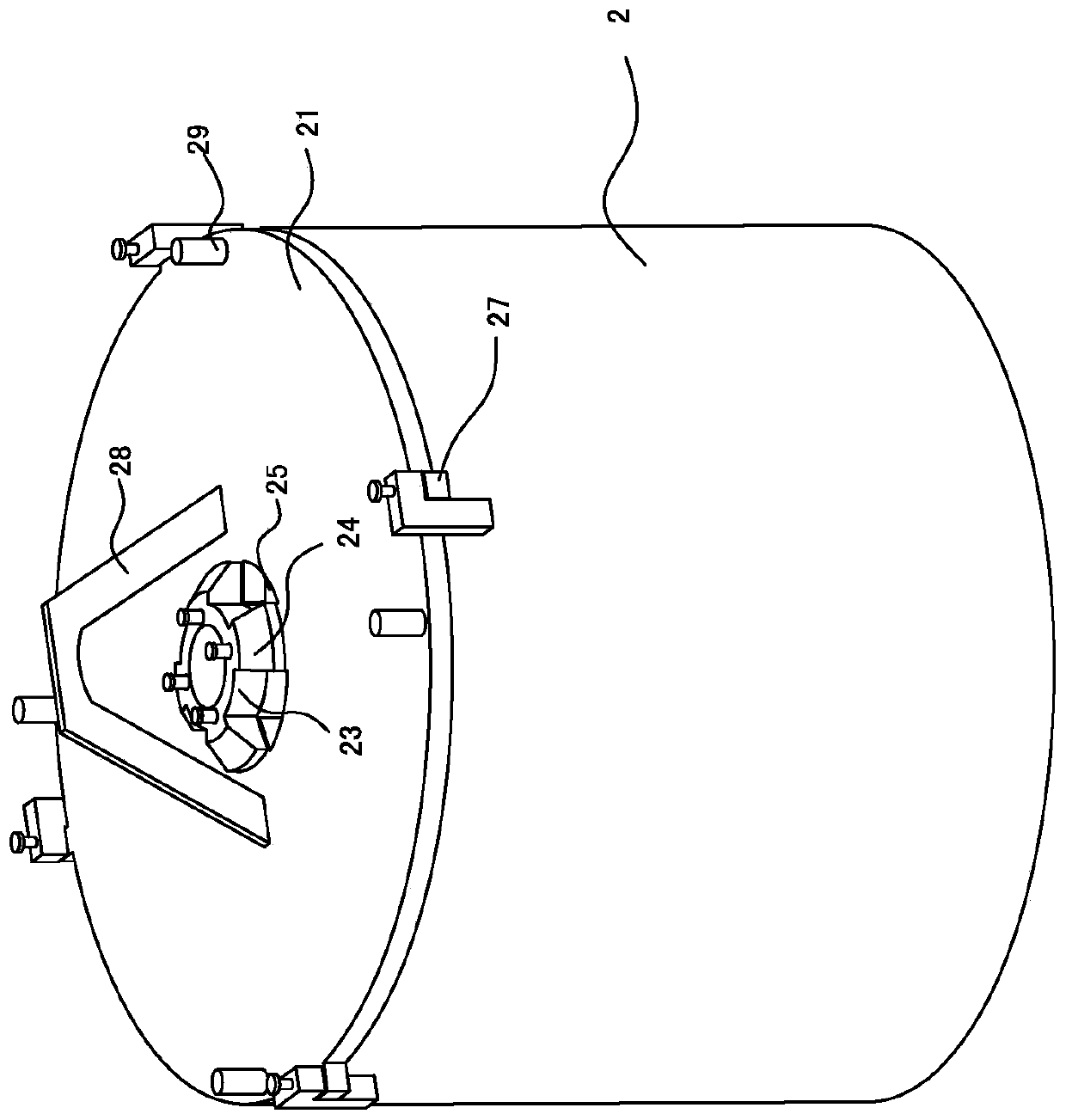

[0022] refer to Figure 1 to Figure 4 , the present embodiment provides a full-automatic low-temperature vacuum frying device, including a vacuum frying tank 1 arranged on a frame in turn, a discharge device 8 located on one side of the vacuum frying tank 1, a heating device, and a vacuum frying tank. The tank 1 is connected to a cooling device through a vacuum tube 40. The vacuum tube 40 is provided with a vacuum breaking valve 401. The vacuum frying tank 1 includes a tank body 11, a tank cover 12 arranged on the top of the tank body 11, and a tank cover 12. The vacuum sensor 19 used to detect the vacuum state inside the tank body 11 and the first liquid level gauge 10 arranged on one side of the tank body 11 and used to measure the oil level inside the tank body 11, the upper end of the tank body 11 is provided on the outside First motor 13, first motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com