Method for producing thermoplastic chopped strands after modification of glass fiber filaments

A glass fiber yarn and thermoplastic technology, applied in the field of thermoplastic chopped strand production technology, can solve the problems of poor control of product performance indicators such as water and oil content, single production varieties, waste of water resources, etc., to achieve control of oil content and clean finished products , The effect of reducing the amount of hair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

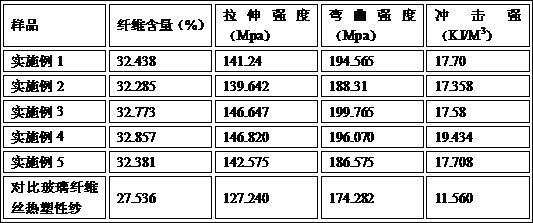

Examples

Embodiment 1

[0031] A method for producing thermoplastic chopped strands after modification of glass fiber filaments, comprising the steps of:

[0032] S1. The glass fiber filaments are chopped by a chopping system equipped with a guillotine, and the chopped length is 4mm to form short filaments;

[0033] S2. The chopped short filaments are transported to the granulator by the conveyor belt for granulation, and the sizing agent is atomized and sprayed through the high-pressure air gun in the granulator to form spare granules;

[0034] S3. The spare granules after spraying are transported to the vibrating fluidized bed by the conveyor belt for drying. The dust removal device is equipped above the vibrating fluidized bed. While drying, the dedusting device sucks the hairs mixed between the spare granules clean. That is, thermoplastic chopped strands modified by glass fiber filaments are obtained.

[0035] The chopping system includes a feeding platform, a guillotine blade and a blanking out...

Embodiment 2

[0044] A method for producing thermoplastic chopped strands after modification of glass fiber filaments, comprising the steps of:

[0045] S1. The glass fiber filaments are chopped by a chopping system equipped with a guillotine, and the chopped length is 4mm to form short filaments;

[0046] S2. The chopped short filaments are transported to the granulator by the conveyor belt for granulation, and the sizing agent is atomized and sprayed through the high-pressure air gun in the granulator to form spare granules;

[0047] S3. The spare granules after spraying are transported to the vibrating fluidized bed by the conveyor belt for drying. The dust removal device is equipped above the vibrating fluidized bed. While drying, the dedusting device sucks the hairs mixed between the spare granules clean. That is, thermoplastic chopped strands modified by glass fiber filaments are obtained.

[0048] The chopping system includes a feeding platform, a guillotine blade and a blanking out...

Embodiment 3

[0057] A method for producing thermoplastic chopped strands after modification of glass fiber filaments, comprising the steps of:

[0058] S1. The glass fiber filaments are chopped by a chopping system equipped with a guillotine, and the chopped length is 4mm to form short filaments;

[0059] S2. The chopped short filaments are transported to the granulator by the conveyor belt for granulation, and the sizing agent is atomized and sprayed through the high-pressure air gun in the granulator to form spare granules;

[0060] S3. The spare granules after spraying are transported to the vibrating fluidized bed by the conveyor belt for drying. The dust removal device is equipped above the vibrating fluidized bed. While drying, the dedusting device sucks the hairs mixed between the spare granules clean. That is, thermoplastic chopped strands modified by glass fiber filaments are obtained.

[0061] The chopping system includes a feeding platform, a guillotine blade and a blanking out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com