Waterborne aluminum paste for decorative waterborne metallic shining coating and soaking production process thereof

A metal glitter coating and production process technology, applied in the direction of pigment slurry, etc., can solve the problems of product quality, inability to industrialize, uneven dispersion, etc., to reduce product quality problems, improve production pass rate, and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

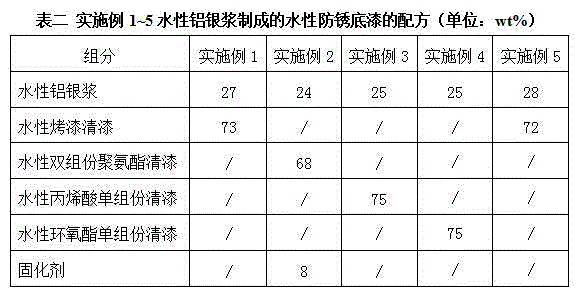

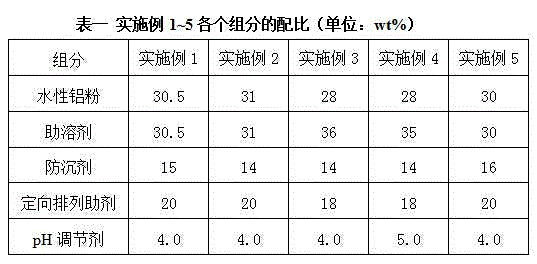

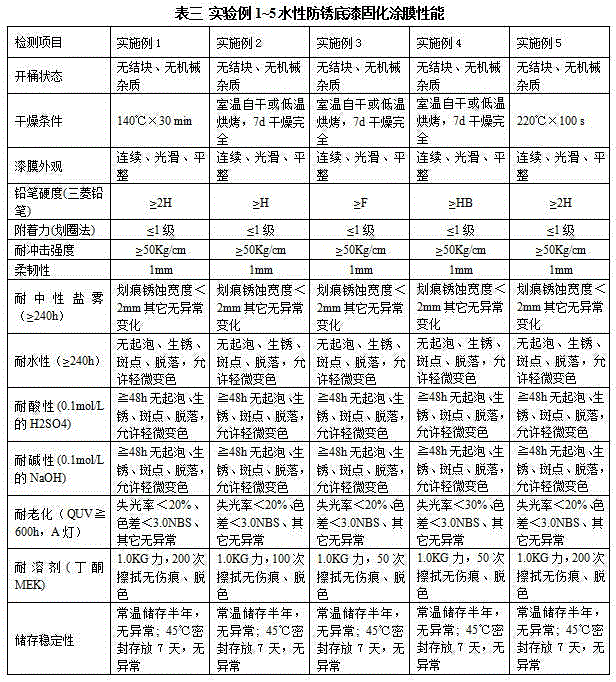

Examples

Embodiment 1

[0025] (1) Production preparation: check whether the production equipment is operating normally; ensure that the production equipment is clean; accurately measure and record the proportion and dosage of various raw materials in the production formula according to the formula sheet, and select measuring instruments with appropriate measuring ranges.

[0026] (2) Soaking and dispersing of water-based aluminum powder: first add the co-solvent ethylene glycol monobutyl ether, anti-sedimentation agent AQH-800 and alignment aid 3050 in the production formula into the mixing tank, move to the high-speed mixer, and press The high-speed mixer is operated according to the operation rules. The stirring speed is controlled at 1500r / min. After the dispersion is uniform, the stirring speed is reduced to 300r / min. After 30 minutes, use AMP-95 to adjust the pH value of the aluminum-silver paste to pH=7.0. After stirring evenly, let it stand for 1 hour, so that the water-based aluminum powder W...

Embodiment 2

[0030] (1) Production preparation: check whether the production equipment is operating normally; ensure that the production equipment is clean; accurately measure and record the proportion and dosage of various raw materials in the production formula according to the formula sheet, and select measuring instruments with appropriate measuring ranges.

[0031] (2) Soaking and dispersing of water-based aluminum powder: First, add the co-solvent propylene glycol, anti-sedimentation agent BYK-420 and alignment aid BYK-8421 into the mixing tank, move to the high-speed mixer, and operate according to the high-speed mixer According to the standard operation, the stirring speed is controlled at 2500r / min. After the dispersion is uniform, the stirring speed is reduced to 1000r / min. Under the stirring condition, add Zhongsu nano water-based aluminum powder 9918, disperse for 30min, and adjust the pH value of the aluminum silver paste to pH=8.0, after stirring evenly, let it stand for 2 hou...

Embodiment 3

[0035] (1) Production preparation: check whether the production equipment is operating normally; ensure that the production equipment is clean; accurately measure and record the proportion and dosage of various raw materials in the production formula according to the formula sheet, and select measuring instruments with appropriate measuring ranges.

[0036] (2) Soaking and dispersing of water-based aluminum powder: first add the co-solvent diethylene glycol butyl ether, anti-sedimentation agent BYK-420 and alignment aid LH-H018 in the production formula into the mixing tank, and move it to the high-speed mixer. And operate according to the operating procedures of the high-speed mixer, the stirring speed is controlled at 2000r / min, after the dispersion is uniform, the stirring speed is reduced to 800r / min, and Jinyangyang aluminum powder SX515 is added under the stirring condition, and the pH value of the aluminum silver paste is adjusted to pH=7.5, after stirring evenly, let it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com