Fuel cell graphitc composite flow field plate and its manufacturing method

A fuel cell and composite flow technology, applied in fuel cells, fuel cell parts, battery electrodes, etc., can solve the problem of high contact resistance between flow field plate and diffusion layer, high resistance of graphite/polymer flow field plate, high contact resistance, etc. problem, to achieve the effect of low cost, good gas barrier performance and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

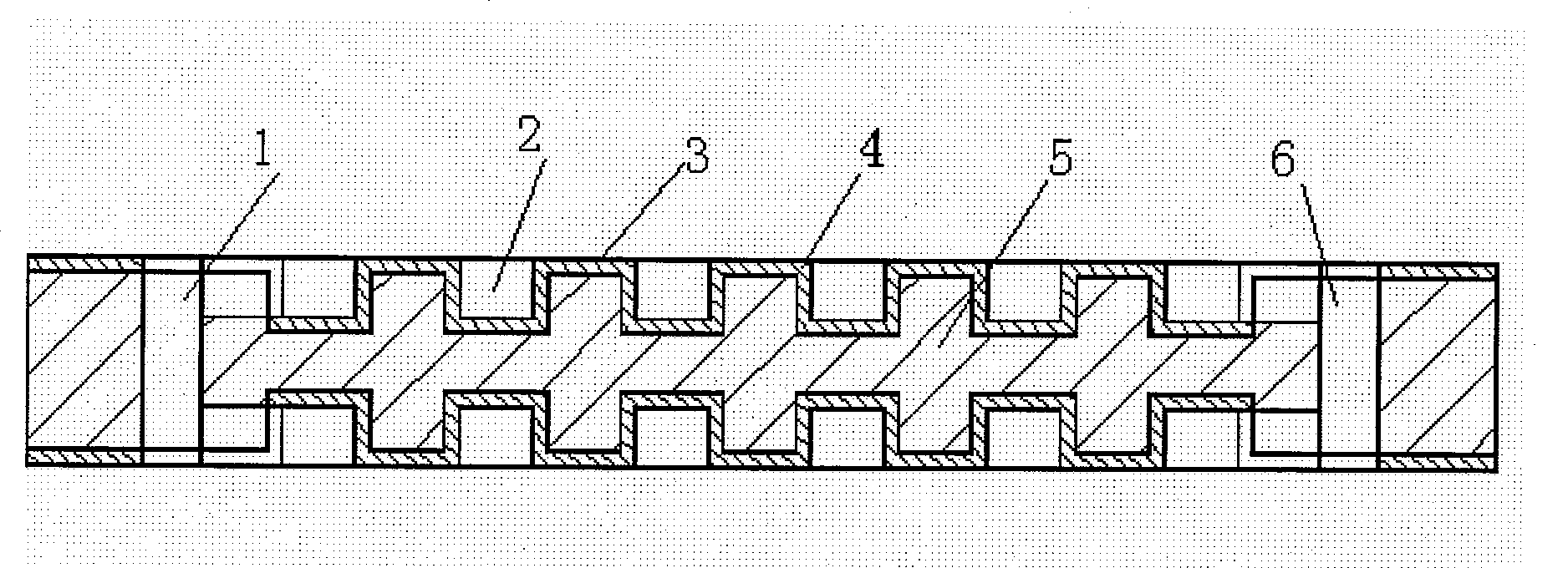

Embodiment 1

[0013] 0.14g of phenolic resin containing 0.014g of curing agent hexamethylenetetramine and 1.66g of natural flake graphite are put into a high-speed universal pulverizer and mixed evenly. Put the uniformly mixed powder into a flat mold and heat it to 90°C, pressurize it to 50MPa, hold it for 2 minutes, then cool it to 40°C and demould it to obtain a 2.1mm thick graphite composite flow field plate middle layer prefabricated plate . Add a piece of flexible graphite paper with a thickness of 0.22mm equal to the surface area of the prefabricated plate on both sides of the prefabricated plate in the middle layer, put them together in a mold with runners and heat to 150°C for 2 minutes at a constant temperature of 110MPa The thickness of the graphite composite flow field plate obtained by pressing down and forming is 2.48mm. The two surfaces of the graphite composite flow field plate are respectively composed of 10 ridges and 10 grooves, the width of the ridge is 1 mm, the groove wid...

Embodiment 2

[0015] 0.6 g of phenolic resin containing 0.06 g of six grade A tetramine as curing agent and 2.2 g of natural flake graphite are put into a high-speed universal pulverizer and mixed evenly. Put the uniformly mixed powder into a flat mold and heat it to 90°C, pressurize it to 50MPa, hold it for 2 minutes, then cool it to 40°C and demould it to obtain a 2.4mm thick graphite composite flow field plate middle layer prefabricated plate . Put a layer of expanded graphite particles with a mass of 0.05g on the bottom layer of the mold with a runner, then put the prefabricated plate on the expanded graphite particles, and then place a layer of expanded graphite particles with a mass of 0.05g on the prefabricated plate . The mold was heated to 150°C, held at a constant temperature for 2 minutes, and pressed at 70 MPa to obtain a graphite composite flow field plate with a thickness of 2.1 mm. The two surfaces of the graphite composite flow field plate are respectively composed of 10 ridges ...

Embodiment 3

[0017] Put 0.28g of polypropylene and 2.52g of natural flake graphite into a high-speed universal pulverizer and mix evenly. Put the mixed powder into a flat mold and heat it to 175℃, pressurize it to 50MPa, keep it for 3 minutes, and then cool to Demoulded at 60°C to obtain a prefabricated plate of the middle layer of the graphite composite flow field plate with a thickness of 2.2 mm. Add a piece of flexible graphite paper with a thickness of 0.3mm equal to the surface area of the prefabricated plate on both sides of the prefabricated plate in the middle layer, put it into a mold with runners and heat it to 210°C, at a constant temperature for 5 minutes, and press at 100MPa to obtain graphite The thickness of the composite flow field plate is 2.6mm. The two surfaces of the graphite composite flow field plate are respectively composed of 10 ridges and 10 grooves, the width of the ridge is 1 mm, the groove width is 1 mm, and the groove depth is 0.8 mm. The test results of the per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com