Laminated packaging material, method for making said laminated material and package container made of said laminated material

A technology of packaging materials and core layers, applied in the field of manufacturing laminated packaging materials of the present invention, can solve the problems of not being able to easily bond extrusion adhesive layers, poor adhesion, high environmental damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0081] Comparison of Barrier Properties: Different Polyamide Oxygen Barriers

[0082] Measured against the complete packaging material structure, i.e. a co-extruded 5-layer structure (g / m 2 ):

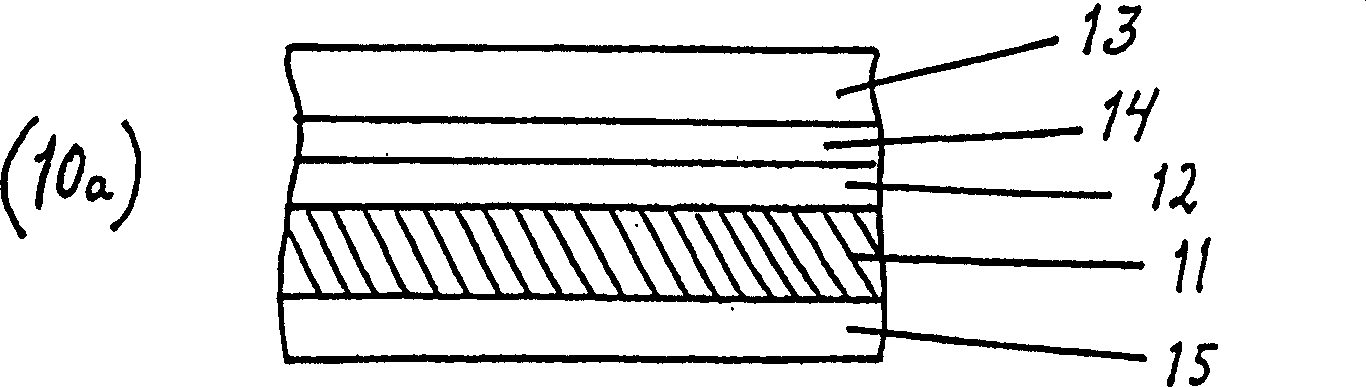

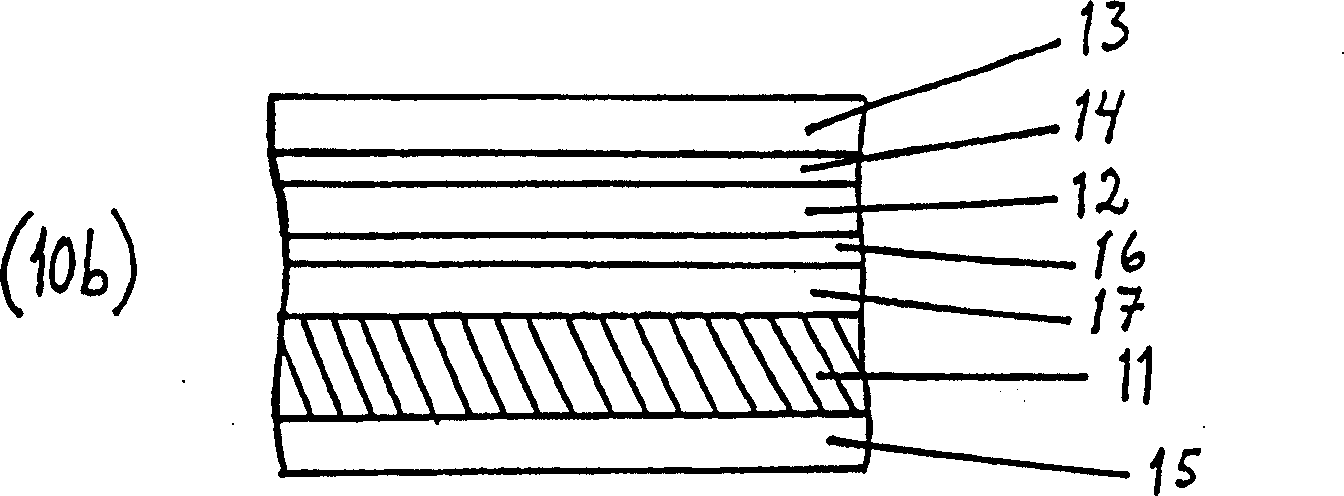

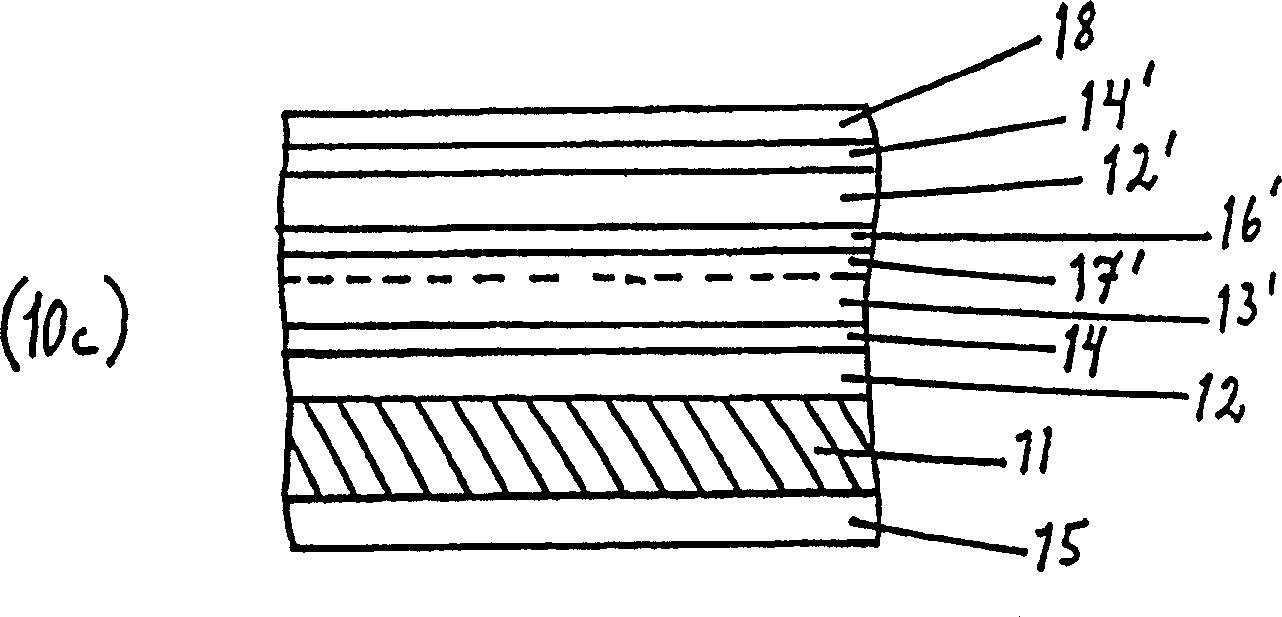

[0083] LDPE(13) / board / LDPE(10) / composite film adhesive layer(5) / PA(barrier layer)(6) / composite film adhesive layer(5) / LDPE(25)

[0084] Barrier coating weight: 6 and 10 g / m respectively 2

[0085] PA6: Standard PA-6 1024B grade in UBE industry

[0086] Selar PA3508: Amorphous polyamide

[0087] When used alone in the gas barrier layer, the oxygen permeability value of PA6 is about as high as Selar polyamide at 0% RH, but higher at higher relative humidity. As a separate gas barrier layer, Selar PA or PA6 is not economically important for ESL packaging.

[0088] Test method: "Mocon oxtran", 1000 flat sample method, test gas: 100% oxygen, T=23°C, t=24h, RH: 50%, 1atm, n (number of samples)=5

[0089] Table 1

[0090] Polyamide grades in barrier layers

Permeability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com