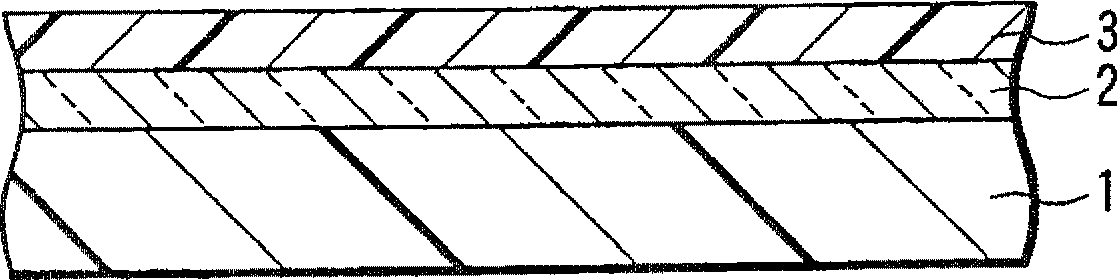

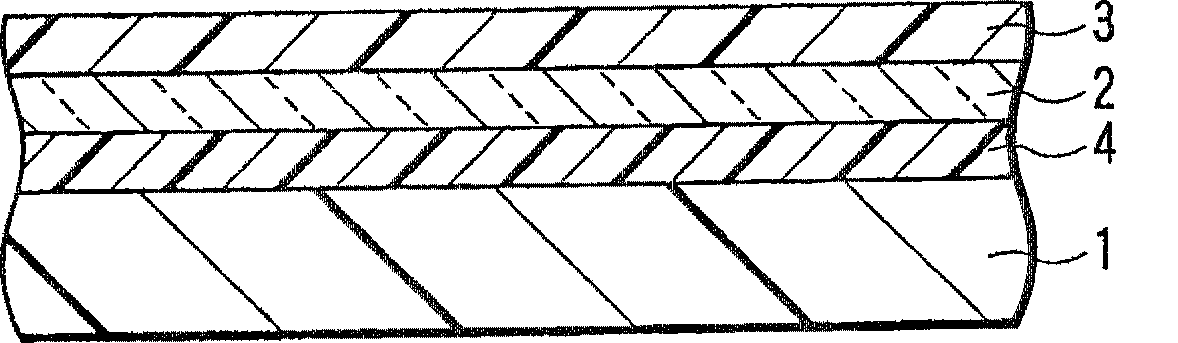

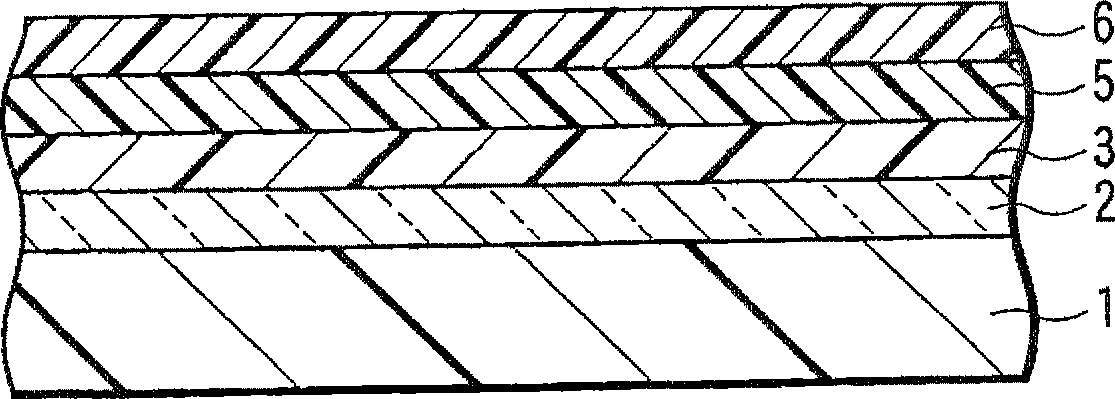

Gas barrier laminate film

A gas-barrier layer and film technology, used in coatings, layered products, etc., can solve the problems of reduced gas-barrier properties, inability to visually identify the contents of the package, and inability to use metal detectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0067] Using biaxially oriented PET (P60; Toray Co., Ltd.) with a thickness of 12 μm and a corona-treated surface as a substrate, aluminum was thermally deposited on the corona-treated surface by an electron beam heating system using an aluminum evaporation source. In this case, the evaporation of aluminum was adjusted while adding oxygen to obtain a predetermined film composition, thereby forming an aluminum oxide vapor-deposited layer with a thickness of 150 angstroms. The film composition of the aluminum oxide vapor deposition layer including aluminum and oxygen was measured using an X-ray photoelectron spectroscopic analyzer (ESCA) (JPS-90SXV; Nippon Denshi Co., Ltd.) and etched with argon gas according to the Depth Profiling method, consisting of This adjusted and obtained the film composition as follows.

Embodiment 1-5、8

[0068] Embodiment 1-5,8, comparative example; Al:O=1:1.8

Embodiment 6

[0069] Embodiment 6; Al:O=1:1.0

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com