High-gas-barrier high-temperature-cooking-resistant transparent resin as well as preparation method and application thereof

A technology of transparent resin and high temperature resistance, which is applied in the field of food plastic packaging. It can solve the problems of inability to apply food packaging, poor heat resistance and gas barrier performance of PETG materials, and achieve improved miscibility, lower melt viscosity, and lower molecular weight. The effect of interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

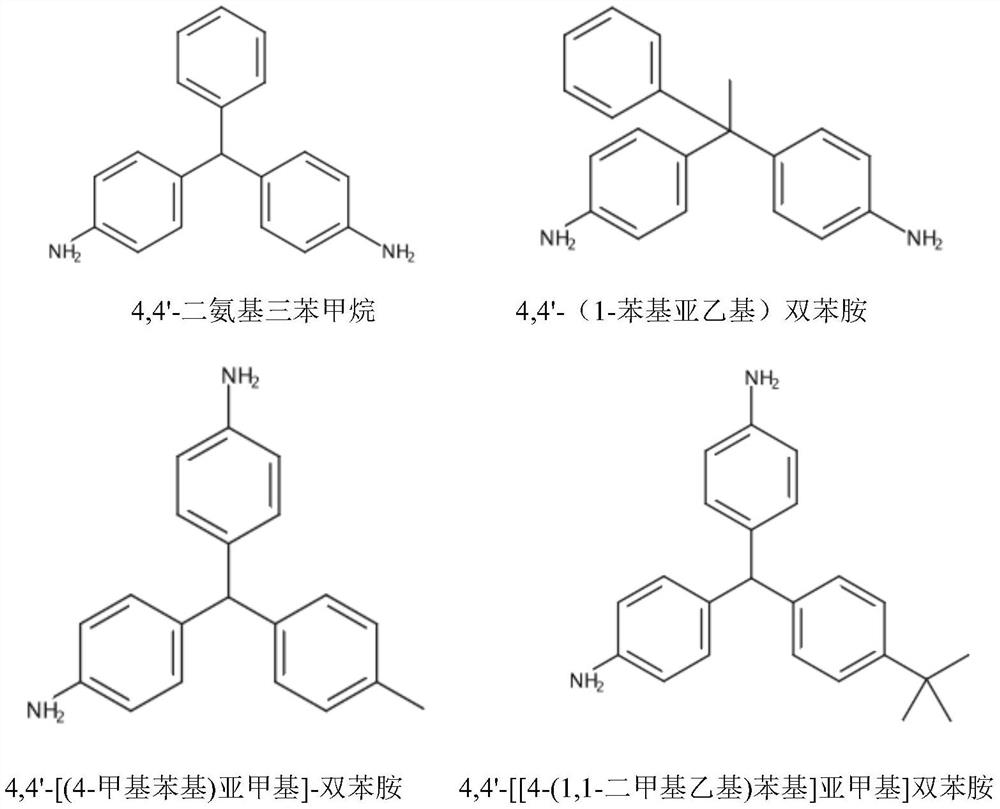

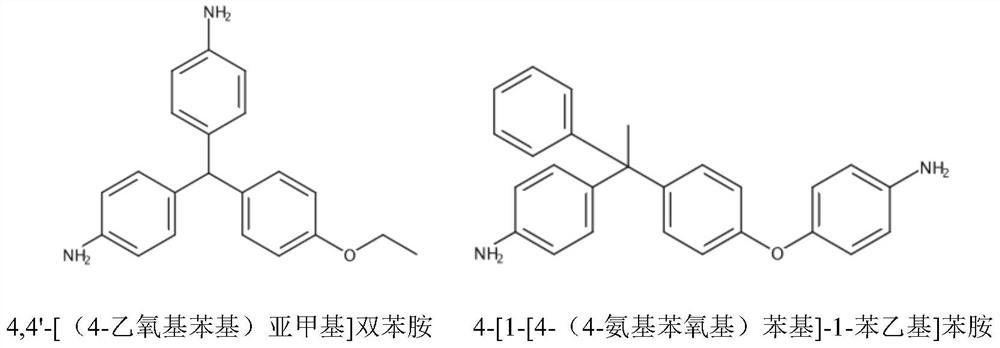

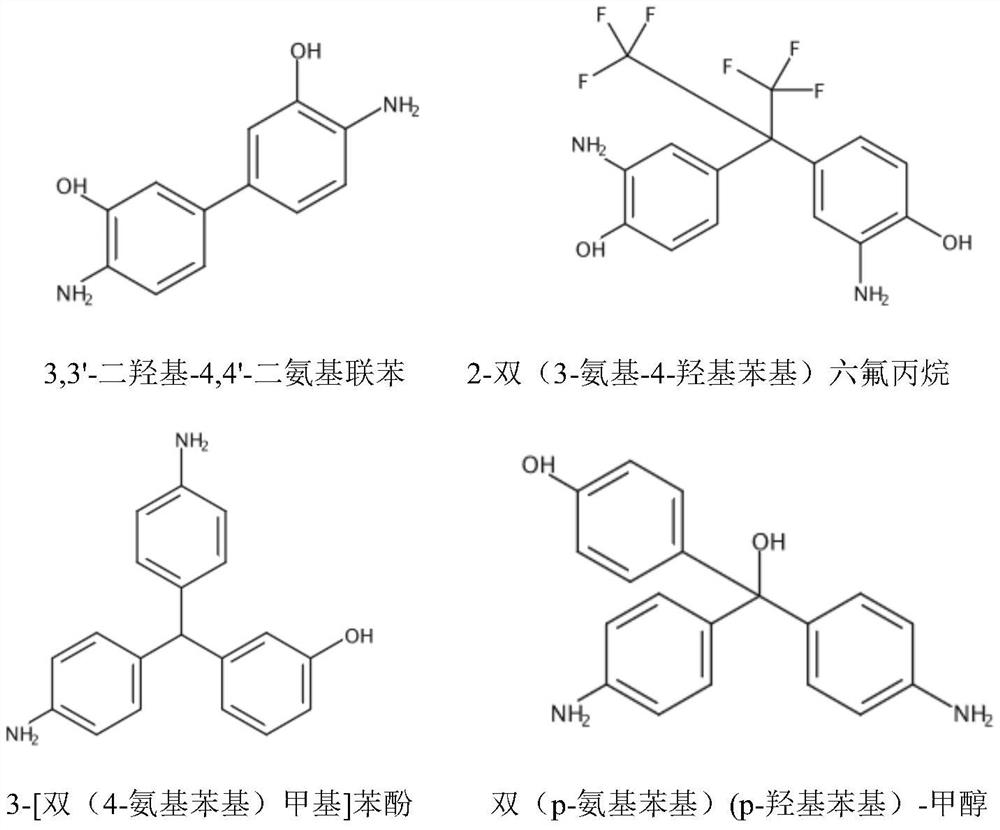

[0055] (1) Preparation of polyimide

[0056] S1. Introduce nitrogen into the reaction kettle, then according to the formula shown in Table 1, add solvent N,N-dimethylacetamide (700~1000mL), diamine compound and alicyclic carboxylic acid dianhydride successively at room temperature (20-30°C) to react for 8-10 hours; then add end-capping agent monocarboxylic acid anhydride to continue reaction for 3-6 hours;

[0057] S2. Continue to add the dehydration cyclization catalyst to carry out the dehydration cyclization reaction (also known as imidization reaction) for 16-24 hours, and then obtain polyimide (PEI) after filtering, washing and drying.

[0058] Table 1 Different polyimide formulations and dosage (g)

[0059]

[0060]

[0061] (2) Preparation of high-temperature cooking-resistant transparent resin with high gas barrier

Embodiment 1~9

[0063] The embodiments of the present application provide a series of high-temperature-resistant retort transparent resins with high gas barrier properties, which are prepared according to the following steps:

[0064] According to the formula in Table 2, put PETG, polyimide and end-capped polyurethane prepolymer into a high-speed mixer and mix until uniform, and then pass through a twin-screw extruder at a temperature of 200-260 ° C and a speed of 100 It is obtained by melt extrusion and granulation under the condition of ~150rpm.

[0065] Table 2 High temperature resistant cooking transparent resin formulation and dosage (parts by weight) of high gas barrier

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com