Barrier composite for plastic components

A technology of plastic parts and composites, applied in the direction of battery pack parts, applications, electrical components, etc., to reduce production costs and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

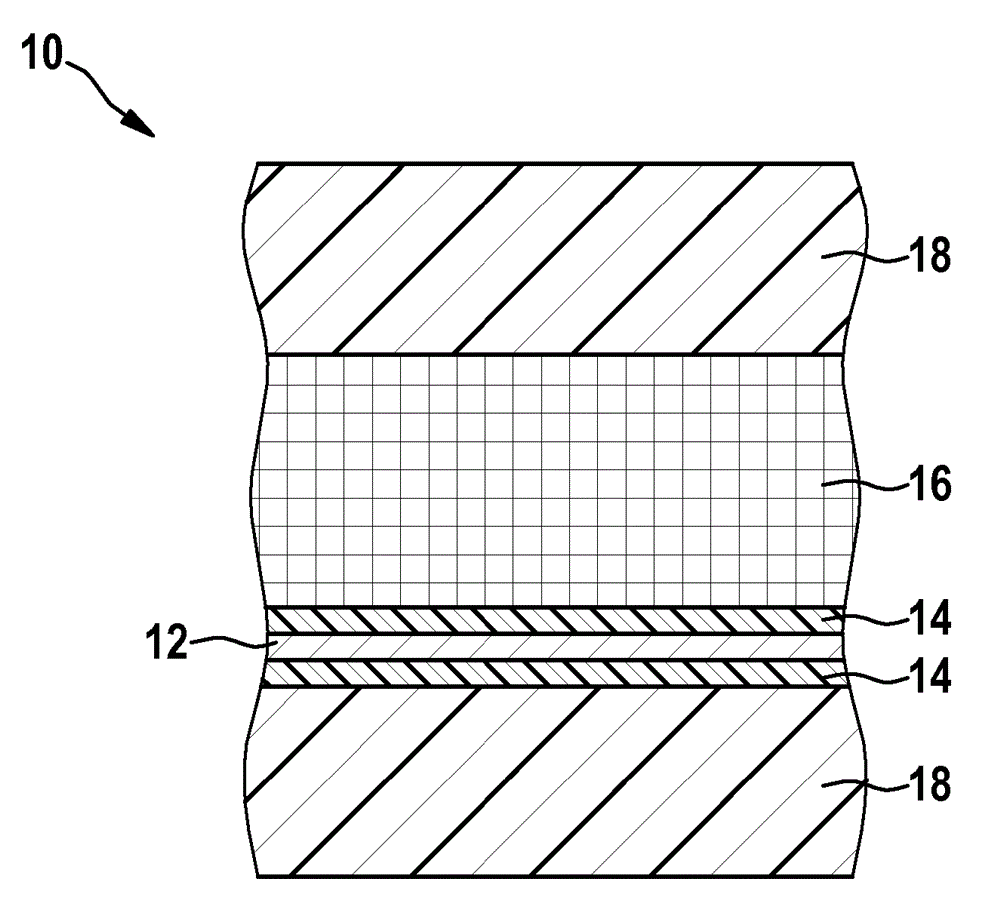

[0045] figure 1 A cross-section of the layered structure of the barrier composite 10 is schematically shown. The barrier composite 10 comprises a metal foil 12 , in particular an aluminum foil, with a thickness of, for example, 15 μm. The metal foil 12 functions as a barrier foil of the barrier composite 10 . Metal foil 12 has a coating 14 of thermoplastic, in particular polypropylene or polyamide 6 or polyamide 66, each having a thickness of, for example, 15 μm on both sides. The coated metal foil 12 forms a composite on one side with a fiber composite layer 16 comprising a thermoplastic matrix. The fiber composite layer 16 can be an impregnated and reinforced textile semi-finished product, a so-called organic board, having a thermoplastic as matrix material. The fabric semi-finished product may have a thickness of 1 mm. In particular, the organic sheet can have a glass fiber fabric with polypropylene or polyamide 6 or polyamide 66 as a matrix. The fiber composite layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com