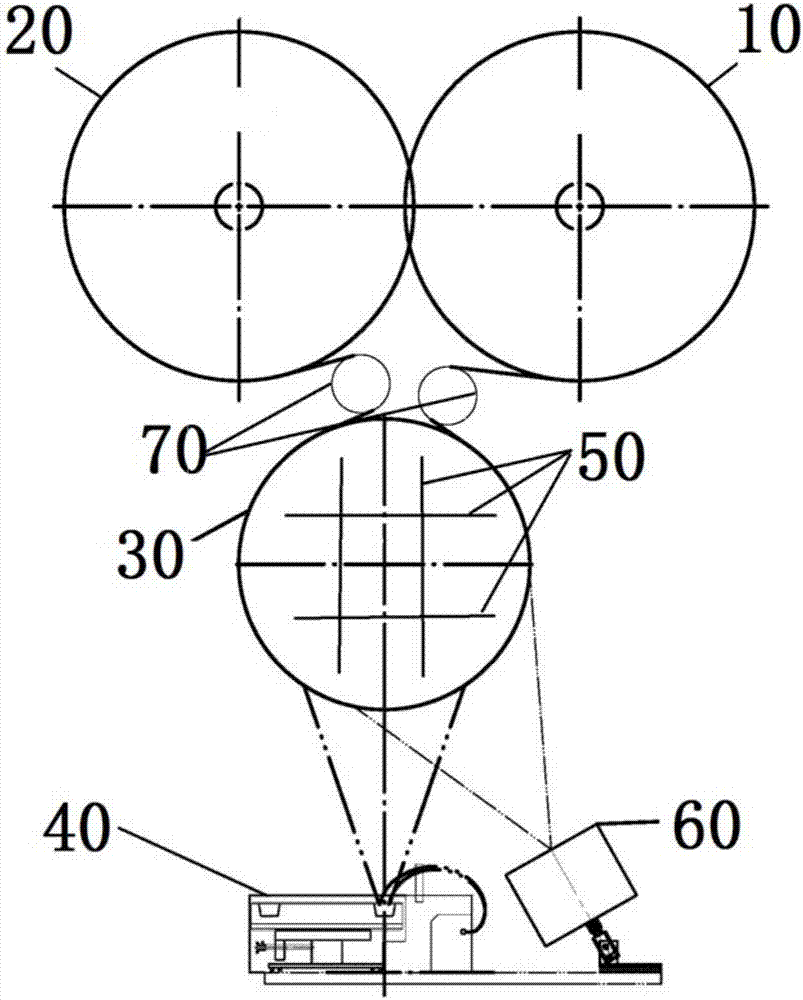

High-barrier nano inorganic nonmetal thin film, preparation method thereof and vacuum coiling coating equipment

A nano-inorganic and coating equipment technology, applied in vacuum evaporation coating, metal material coating process, sputtering coating, etc., can solve the problems of sensitive stretching deformation, uneven film, poor barrier performance, etc., and achieve excellent barrier Performance, increase economic efficiency, increase production rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

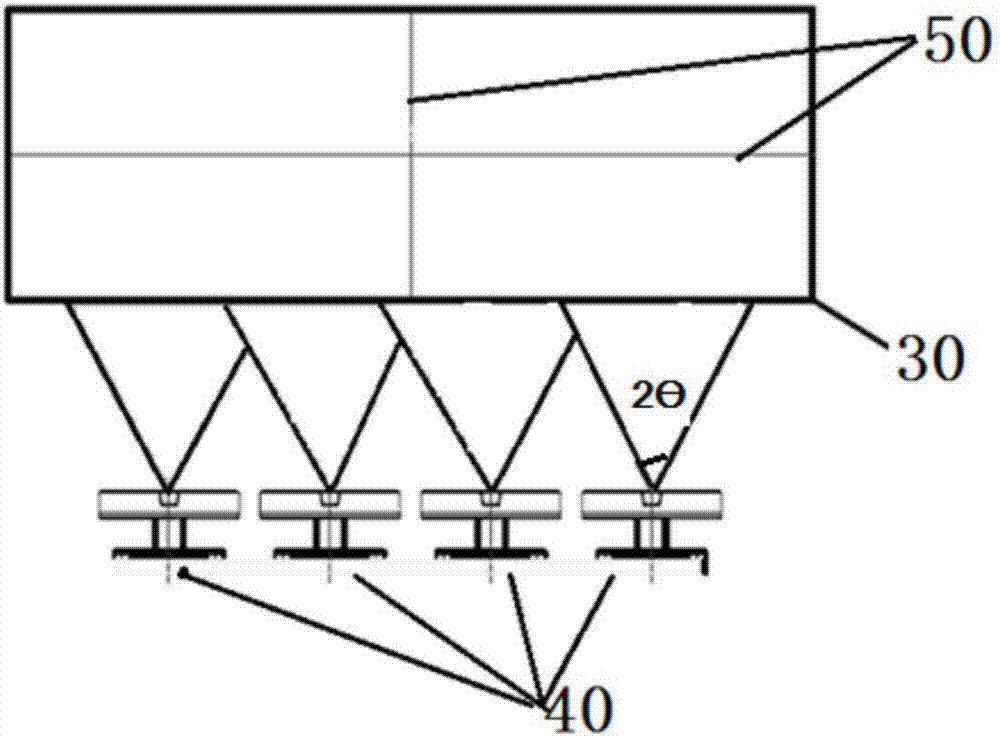

[0041] The aluminum oxide evaporation particles were evenly added to the annular crucible of the electron gun, and the distance between adjacent electron guns during evaporation was adjusted to be 350 mm. Place the 12μm thick PET roll on the unwinding shaft of the unwinding device, and complete the film-threading preparation according to the winding film path. Close the coating vacuum chamber and prepare to evacuate.

[0042] When the vacuum degree in the coating vacuum chamber reaches 5.0×10 -3 When the Pa background is vacuum, input oxygen through the oxygen input port on the upper end of the electron gun crucible, and adjust the coating working pressure to 5.0×10 -2 Pa. Turn on the e-type electron gun to work, the electron beam current is 550mA, the voltage is -8.0kV, and the aluminum oxide evaporation particles are evaporated at a high temperature of about 2100°C. Turn on the winding transmission system, set the winding speed of the winding transmission system to 100m / m...

Embodiment 2

[0045] The silicon oxide evaporation particles were evenly added to the annular crucible of the electron gun, and the spacing between adjacent e-type electron guns was adjusted to be misplaced during evaporation, and the distance between adjacent electron guns was 350 mm. Place the 12μm thick PET roll on the unwinding shaft of the unwinding device, and complete the film-threading preparation according to the winding film path. Close the vacuum chamber and prepare for vacuuming.

[0046] Vacuum up to 5.0×10 -3 When the Pa background is vacuum, input oxygen through the oxygen input port on the upper end of the electron gun crucible, and adjust the coating working pressure to 5.0×10 -2 Pa. Turn on the e-type electron gun to work, the electron beam current is 500mA, the voltage is -7.8kV, and the silicon oxide evaporation particles are evaporated at a high temperature of 1600°C. Turn on the winding transmission system, set the winding speed of the winding transmission system to...

Embodiment 3

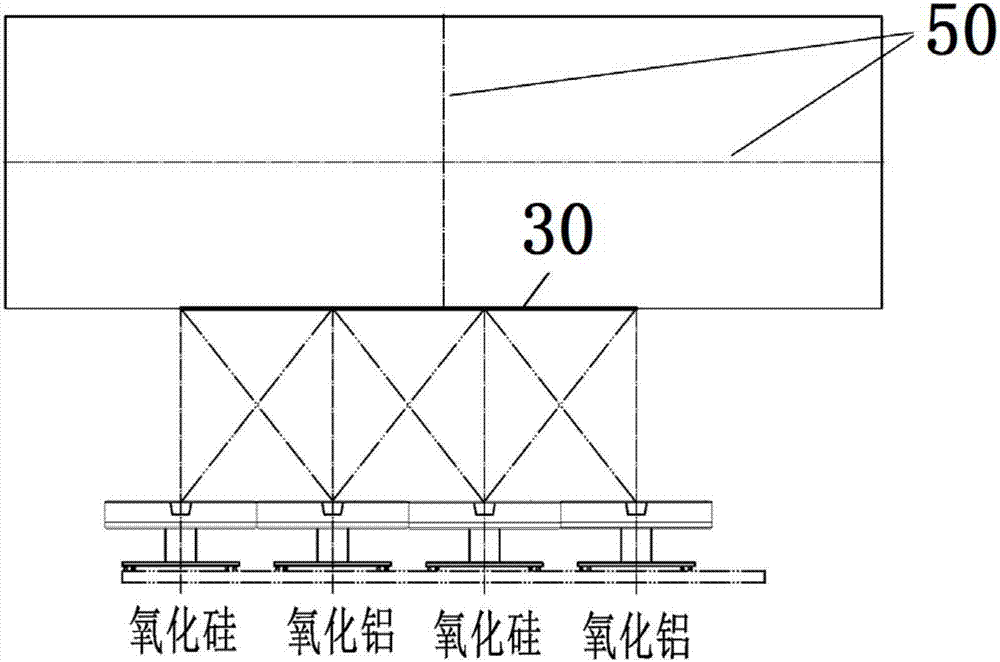

[0049] Such as image 3 As shown, the electron gun crucible groups to be evaporated silicon oxide and aluminum oxide particles were placed in a row, and the distance between adjacent electron guns during evaporation was adjusted to be 350 mm. Place the 12μm thick PET roll on the unwinding place, and follow the winding film path to complete the film-threading preparation. Close the vacuum chamber and prepare for vacuuming.

[0050] When the vacuum degree in the coating vacuum chamber reaches 5.0×10 -3 When the Pa background is vacuum, input oxygen through the oxygen input port on the upper end of the electron gun crucible, and adjust the coating working pressure to 5.0×10 -2 Pa. Turn on the e-type electron gun to work, the electron beam current of the e-type electron gun for evaporating alumina is 550mA, and the voltage is -8.0kV, the electron beam current of the e-type electron gun for evaporating silicon oxide is 500mA, and the voltage is -7.8kV. The silicon oxide vapor-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com